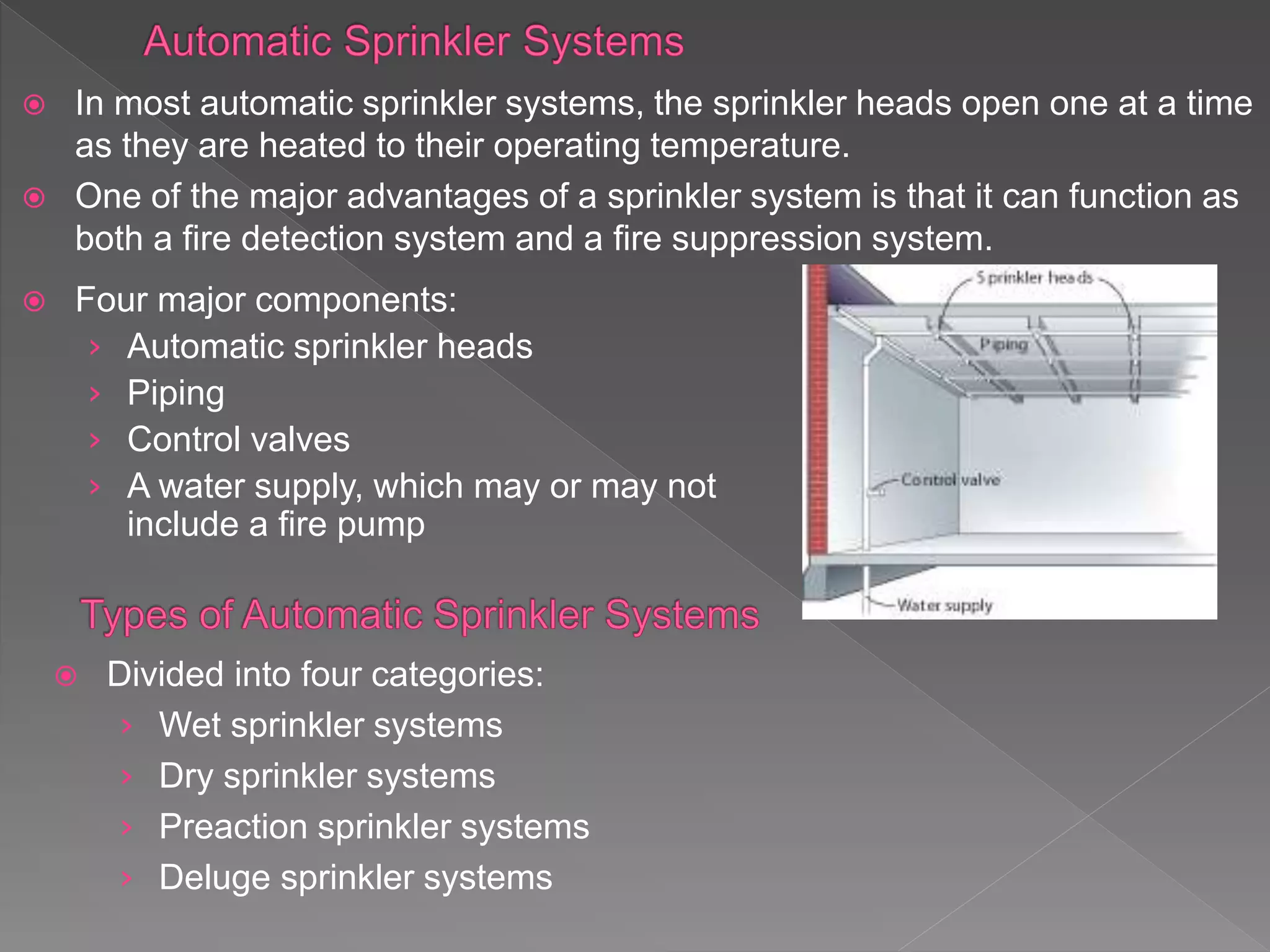

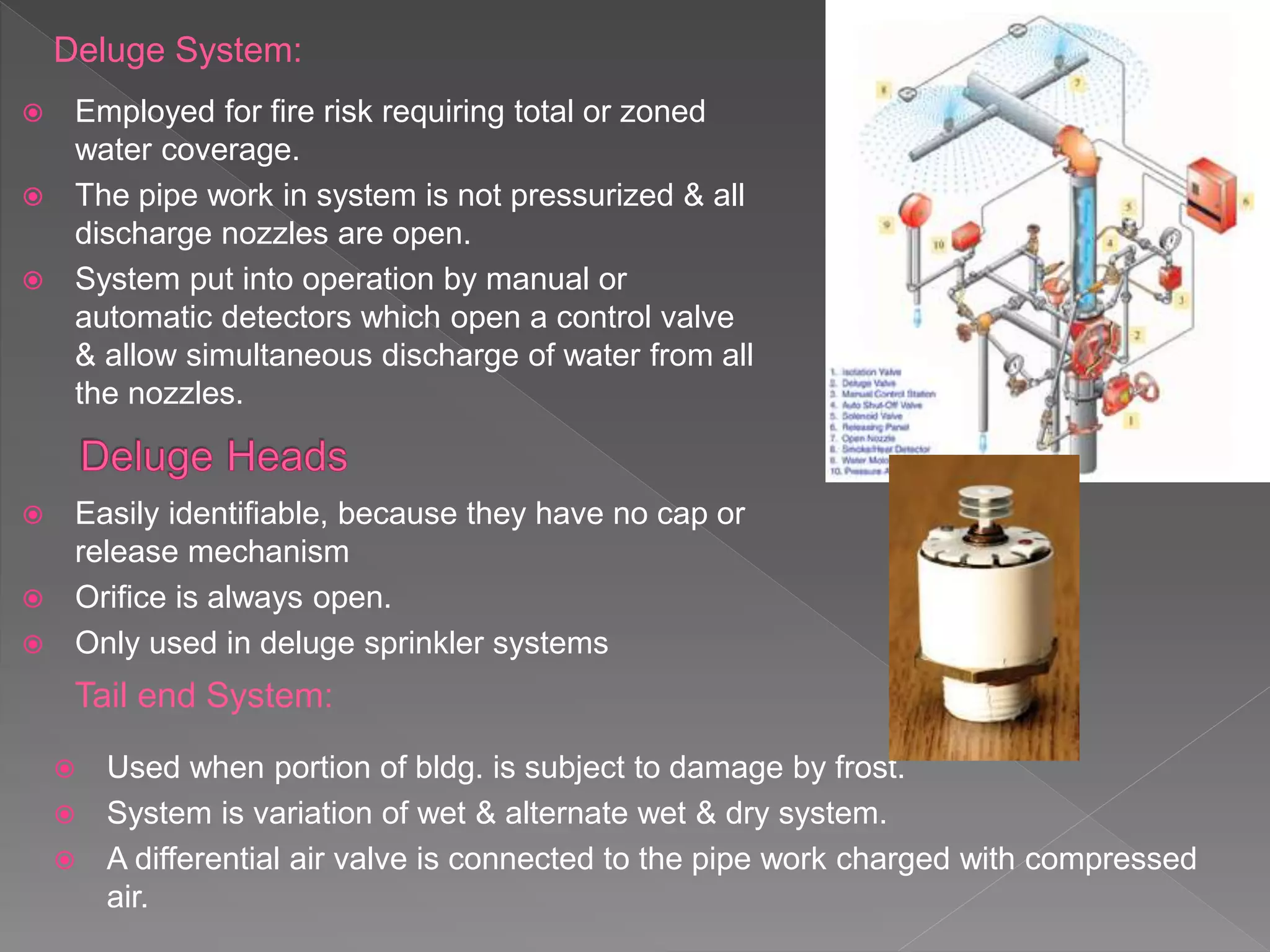

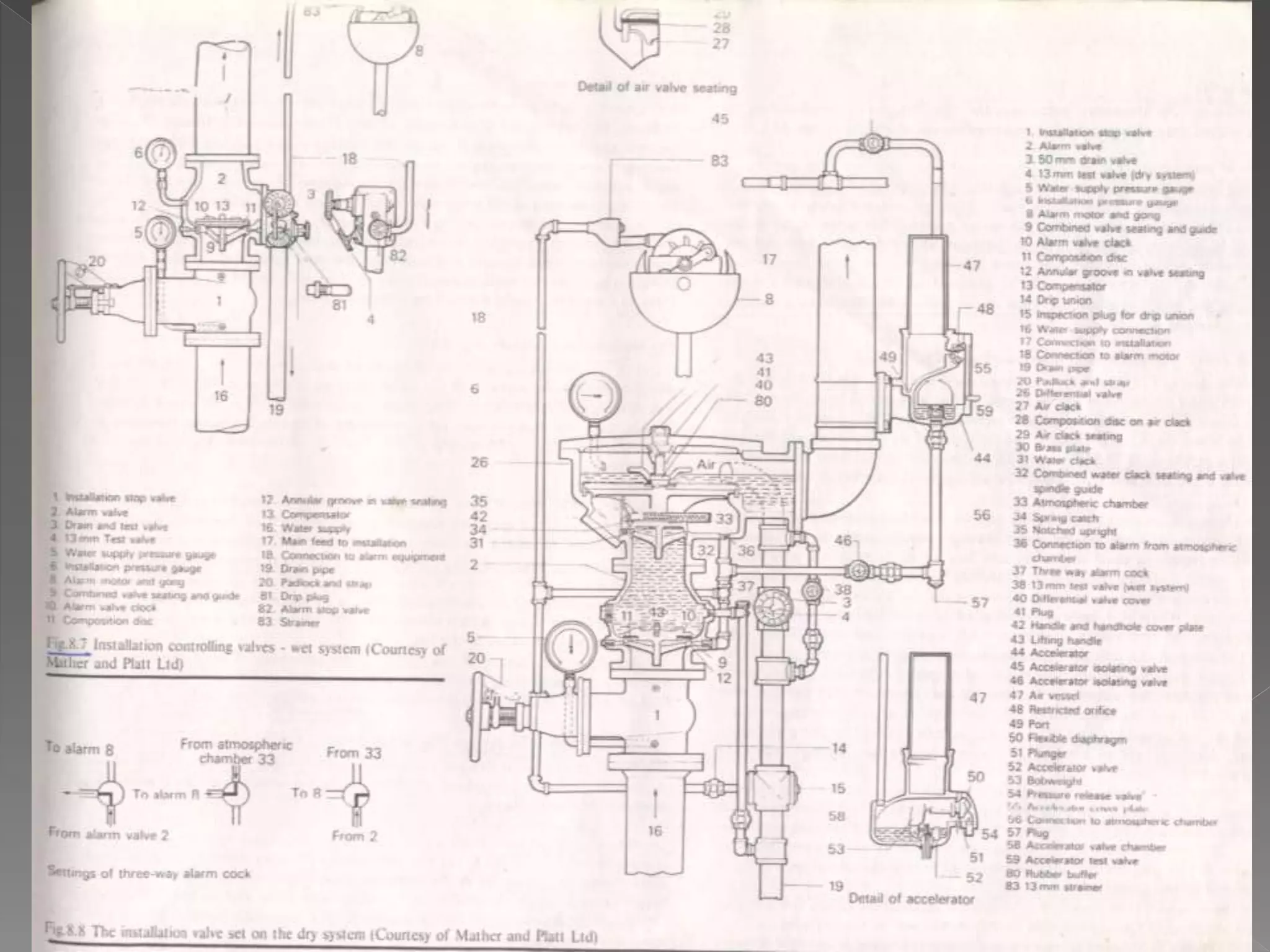

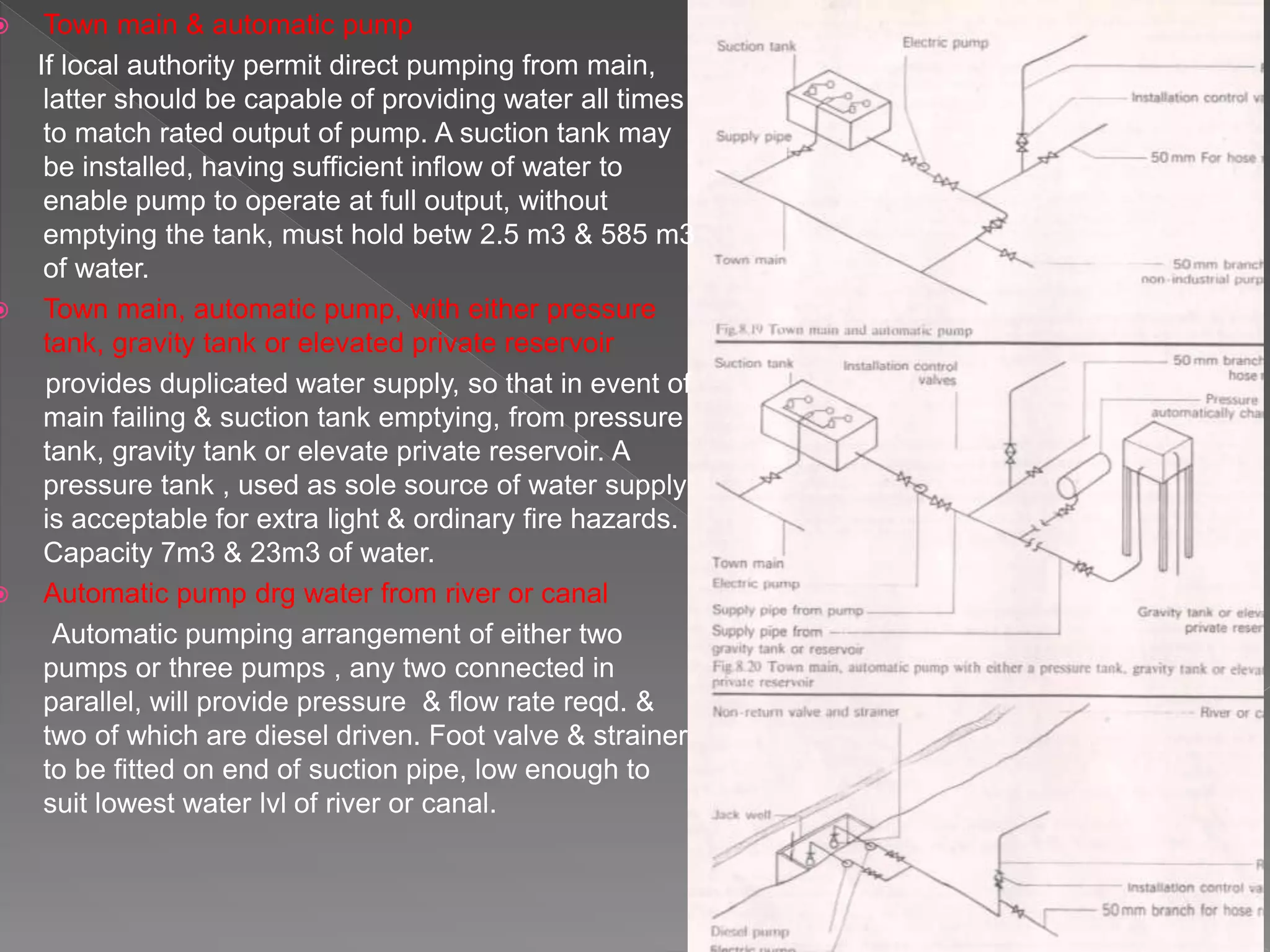

Sprinkler systems have four major components and can be divided into four categories: wet, dry, preaction, and deluge. Wet sprinkler systems have piping filled with water at all times so sprinkler heads activate immediately when heated. Dry systems are charged with compressed air and use a differential air valve to allow water in after a head activates. Preaction systems have air-pressurized piping and use detectors to signal a valve to release water. Sprinkler systems are classified based on the fire hazard of the occupancy being protected.