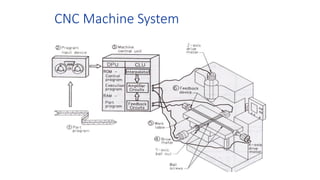

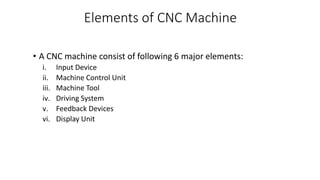

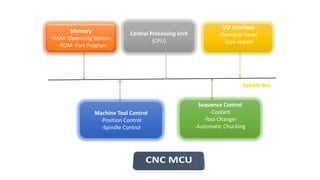

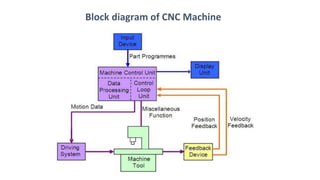

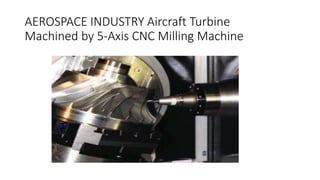

CNC machines are computer-controlled machine tools that can be programmed to automatically perform tasks like cutting, drilling, grinding, milling, turning, and others. Key elements of a CNC machine include inputs, machine control units, machine tools, drives, feedback devices, and displays. CNC machines are used across industries like aerospace, machinery, automotive, and more to manufacture complex parts for products with high accuracy. Some common applications of CNC machines include engine blocks, aircraft parts, electronic components, and molds.