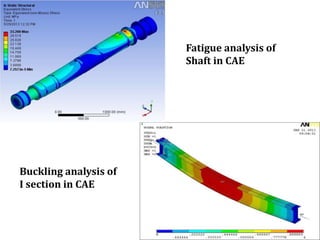

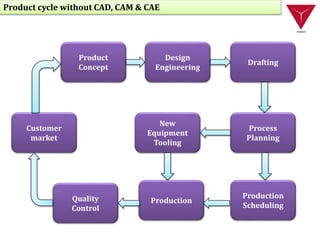

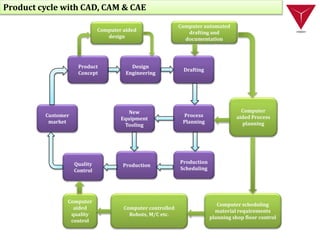

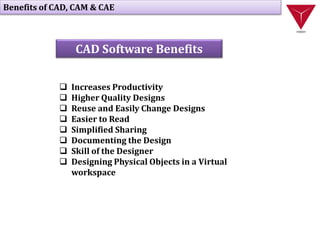

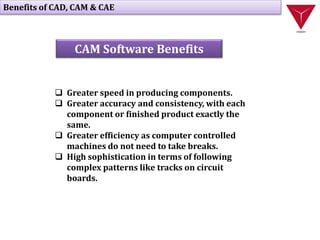

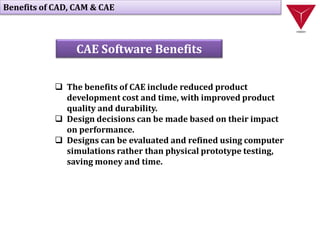

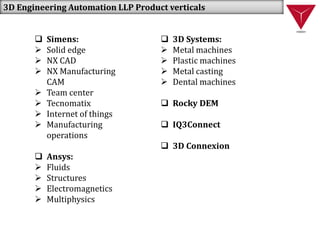

The document outlines the roles of CAD (Computer Aided Design), CAM (Computer Aided Manufacturing), and CAE (Computer Aided Engineering) in the product development cycle. It highlights the benefits of these technologies, including increased productivity, improved design quality, and enhanced simulation capabilities, while also introducing PLM (Product Lifecycle Management) software that supports the entire product development process. Additionally, it lists various software and tools related to 3D engineering automation, including those from Siemens, Ansys, and 3D Systems.