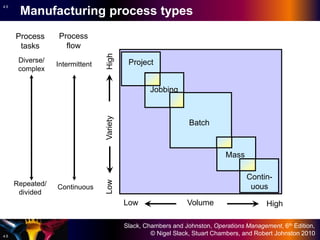

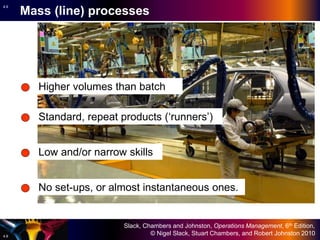

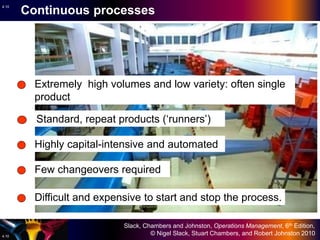

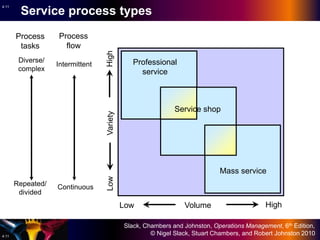

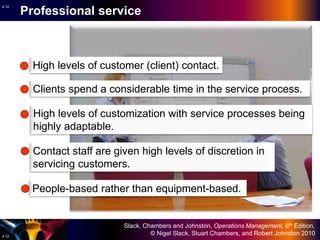

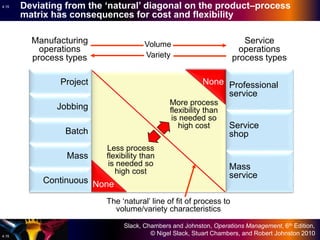

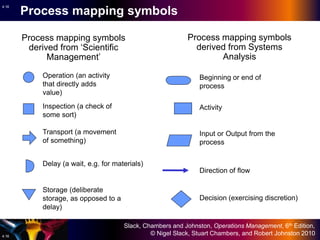

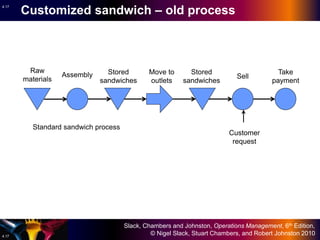

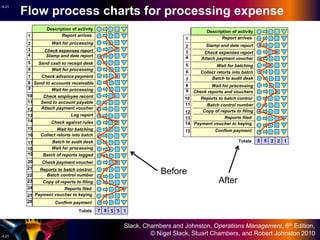

The document discusses process design as outlined in the 6th edition of 'Operations Management' by Slack, Chambers, and Johnston, emphasizing the interrelationship between product/service design and process design. It categorizes different process types based on volume and variety, including project, jobbing, batch, mass, and continuous processes, alongside service process types like professional service and mass service. The document also highlights key considerations in process mapping and the impact of deviation from the product-process matrix on cost and flexibility.