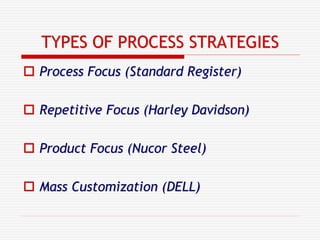

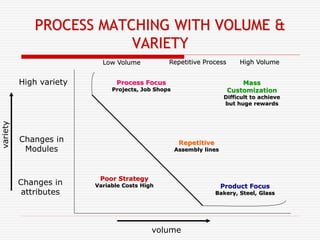

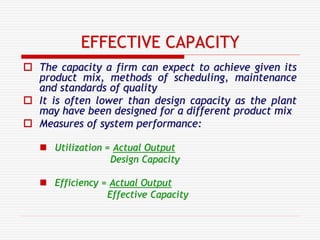

This document provides an overview of operations management concepts related to process and capacity design. It discusses different process strategies like process focus, repetitive focus, product focus, and mass customization. It also covers tools for process analysis, designing service processes, process reengineering, selecting equipment, designing capacity, and managing demand and capacity. The key topics covered are matching process strategies to volume and variety, analyzing and improving processes, and determining capacity requirements and managing demand versus capacity.