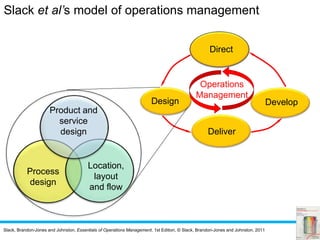

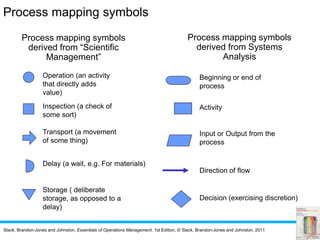

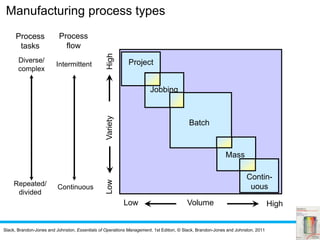

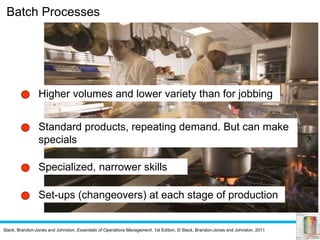

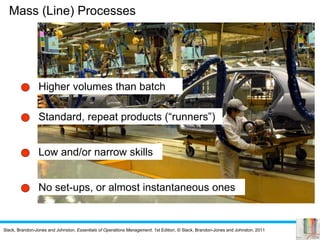

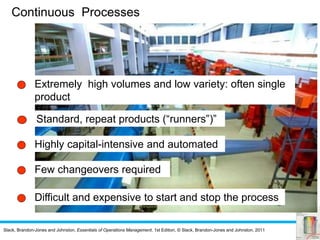

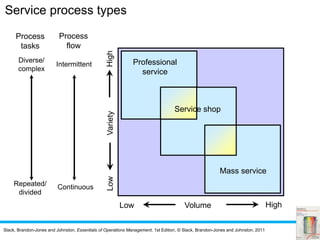

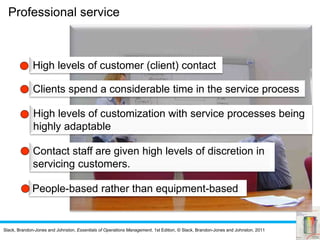

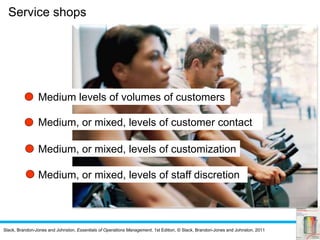

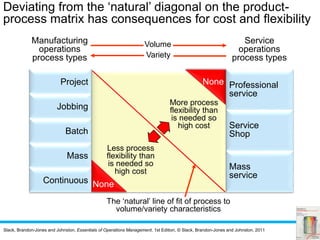

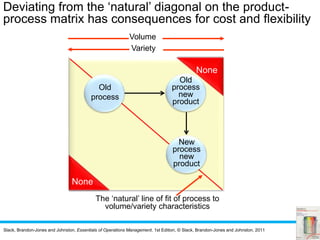

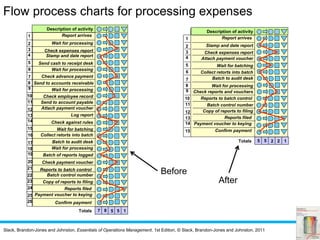

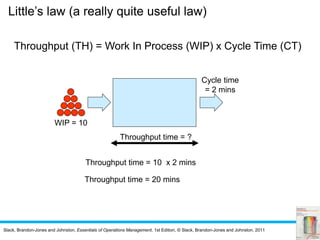

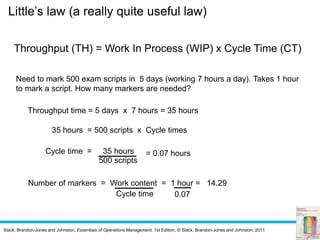

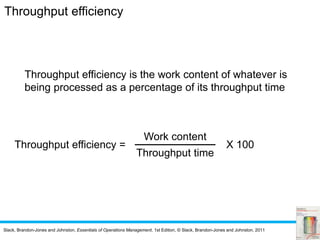

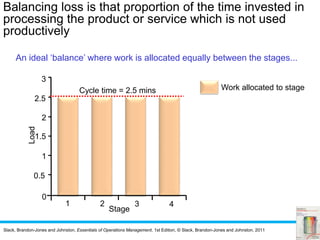

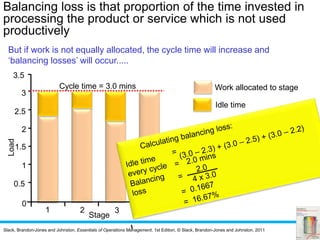

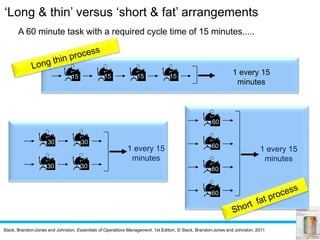

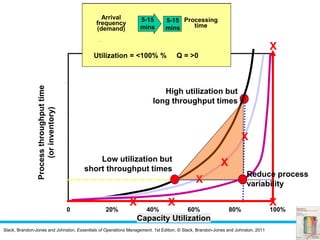

This document summarizes key concepts from Chapter 5 of Slack, Brandon-Jones and Johnston's book "Essentials of Operations Management". It discusses process design and the different types of processes that exist based on volume and variety, including manufacturing processes like project, jobbing, batch, mass production and continuous processes as well as service processes like professional services, service shops and mass services. It also covers topics like process mapping, the relationship between process design and product-process fit, Little's Law, throughput efficiency and balancing flow in processes.