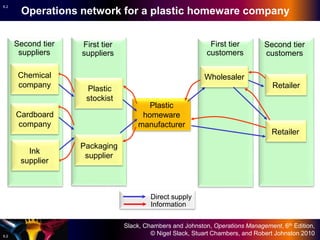

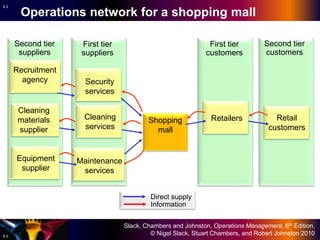

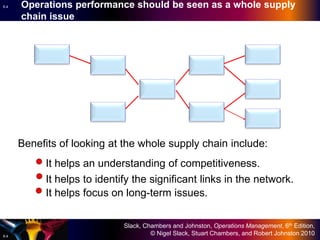

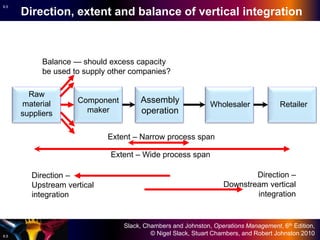

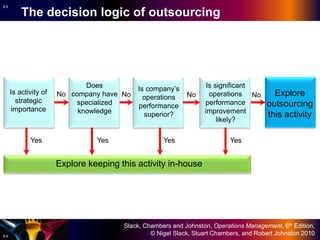

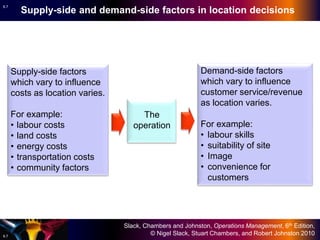

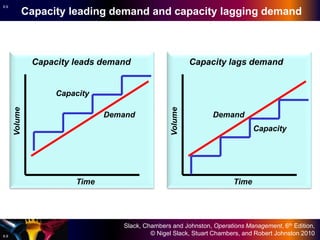

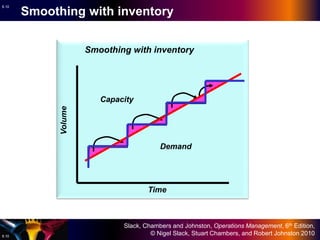

The document discusses supply network design and operations management, primarily focusing on vertical integration, outsourcing decisions, and factors influencing location choices. It outlines the importance of evaluating supply-side and demand-side factors in operational performance and strategic decision-making. Furthermore, it highlights the balance of capacity in relation to demand and the role of inventory in managing fluctuations.