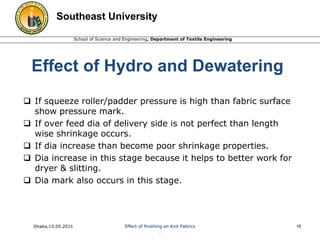

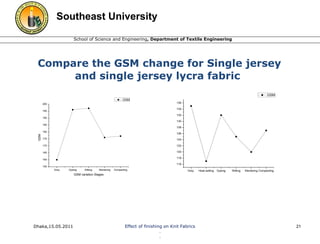

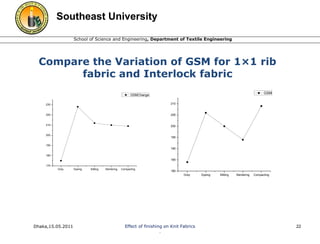

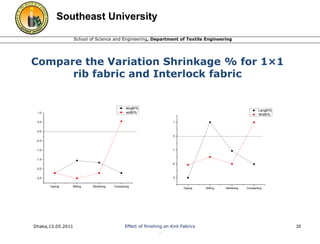

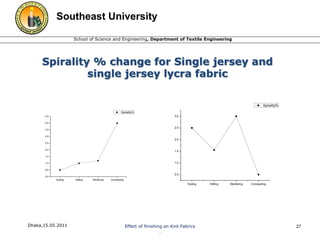

This document discusses the effect of finishing processes on knit fabrics. It describes how finishing improves physical properties like feel, strength and shrinkage. The techniques of finishing depend on factors like the fabric composition and its intended end use. Common finishing treatments aim to impart properties like softness, luster and dimensional stability. The document then examines specific finishing stages like hydroextraction, drying, slitting, stenting and compacting. Graphs show how properties like GSM and shrinkage are affected differently for various fabric types as they progress through finishing. The discussion analyzes the results and references additional sources for information on textile finishing.