Embed presentation

Downloaded 128 times

![Compound Function Composition

(wt%)

Preparation

Technique

γ-Al2O3 Support 72.70 Powder phase

MoO3

Active Agent

15.00

Equilibrium

Deposition

CoO

Active Agent

4.00

Dry

Impregnation

K2O

Basic Promoter

0.08

Dry

Impregnation

CaO

Basic Promoter

0.02

Dry

Impregnation

[Ref] [Centeno et al, 2010] [Shaikh, 2013] [Kordulis et al, 2004]](https://image.slidesharecdn.com/catalysisofhydrotreatingprocess-2-150122091230-conversion-gate02/85/Catalysis-of-Hydrotreating-Process-6-320.jpg)

![Surface Area (m2/g) Catalyst Diameter (nm) Catalyst Life (yr)

Value 193 10 1.5

Method BET SEM -

[Ref] Mochida et al, 2004 Mochida et al, 2004 UOP , 2003

* Courtesy of Mochida et al, 2004](https://image.slidesharecdn.com/catalysisofhydrotreatingprocess-2-150122091230-conversion-gate02/85/Catalysis-of-Hydrotreating-Process-7-320.jpg)

![ Pilot Plant ,Ras Tanura refinery, funded by

Saudi Aramco,1990-1992 [A.Ali, KFUPM].

Pilot Plant, Riyadh Refinery, funded by Saudi

Armco, 1991-1992 [A.Ali, KFUPM].](https://image.slidesharecdn.com/catalysisofhydrotreatingprocess-2-150122091230-conversion-gate02/85/Catalysis-of-Hydrotreating-Process-9-320.jpg)

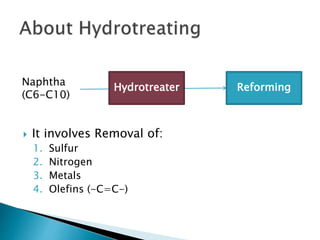

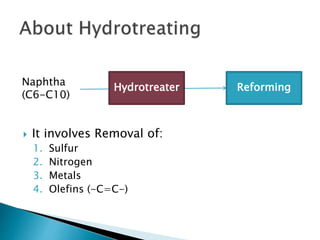

The document discusses naphtha hydrotreating, which involves removing sulfur, nitrogen, metals, and olefins from naphtha. It presents information on the process overview, reactor configuration, catalyst preparation and characterization. Details are provided on the catalyst composition and properties, as well as pilot plant trials conducted in Saudi Arabia in the 1990s. Challenges mentioned include providing optimal reaction conditions and adapting to variations in feedstock quality.

![Compound Function Composition

(wt%)

Preparation

Technique

γ-Al2O3 Support 72.70 Powder phase

MoO3

Active Agent

15.00

Equilibrium

Deposition

CoO

Active Agent

4.00

Dry

Impregnation

K2O

Basic Promoter

0.08

Dry

Impregnation

CaO

Basic Promoter

0.02

Dry

Impregnation

[Ref] [Centeno et al, 2010] [Shaikh, 2013] [Kordulis et al, 2004]](https://image.slidesharecdn.com/catalysisofhydrotreatingprocess-2-150122091230-conversion-gate02/85/Catalysis-of-Hydrotreating-Process-6-320.jpg)

![Surface Area (m2/g) Catalyst Diameter (nm) Catalyst Life (yr)

Value 193 10 1.5

Method BET SEM -

[Ref] Mochida et al, 2004 Mochida et al, 2004 UOP , 2003

* Courtesy of Mochida et al, 2004](https://image.slidesharecdn.com/catalysisofhydrotreatingprocess-2-150122091230-conversion-gate02/85/Catalysis-of-Hydrotreating-Process-7-320.jpg)

![ Pilot Plant ,Ras Tanura refinery, funded by

Saudi Aramco,1990-1992 [A.Ali, KFUPM].

Pilot Plant, Riyadh Refinery, funded by Saudi

Armco, 1991-1992 [A.Ali, KFUPM].](https://image.slidesharecdn.com/catalysisofhydrotreatingprocess-2-150122091230-conversion-gate02/85/Catalysis-of-Hydrotreating-Process-9-320.jpg)