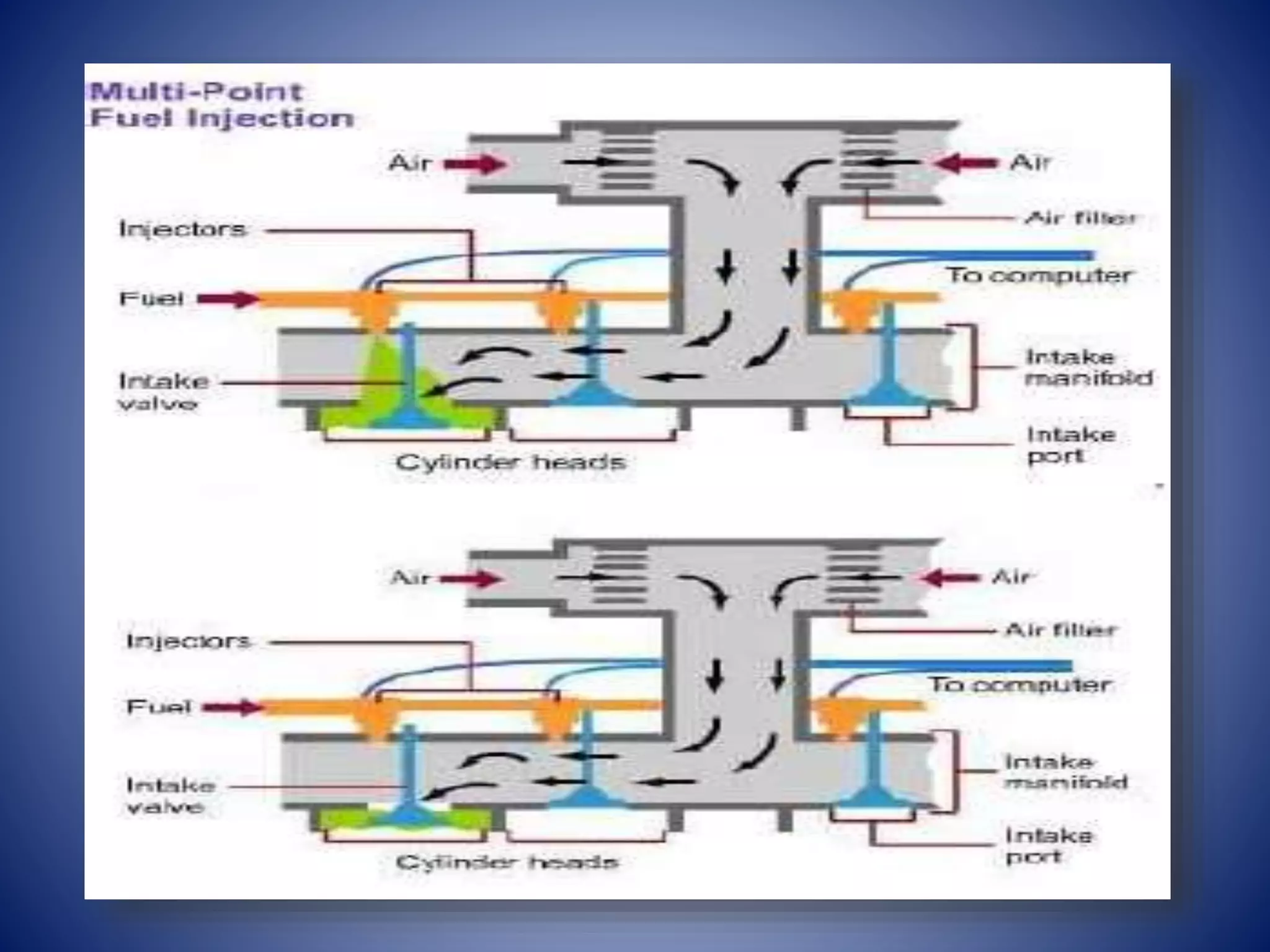

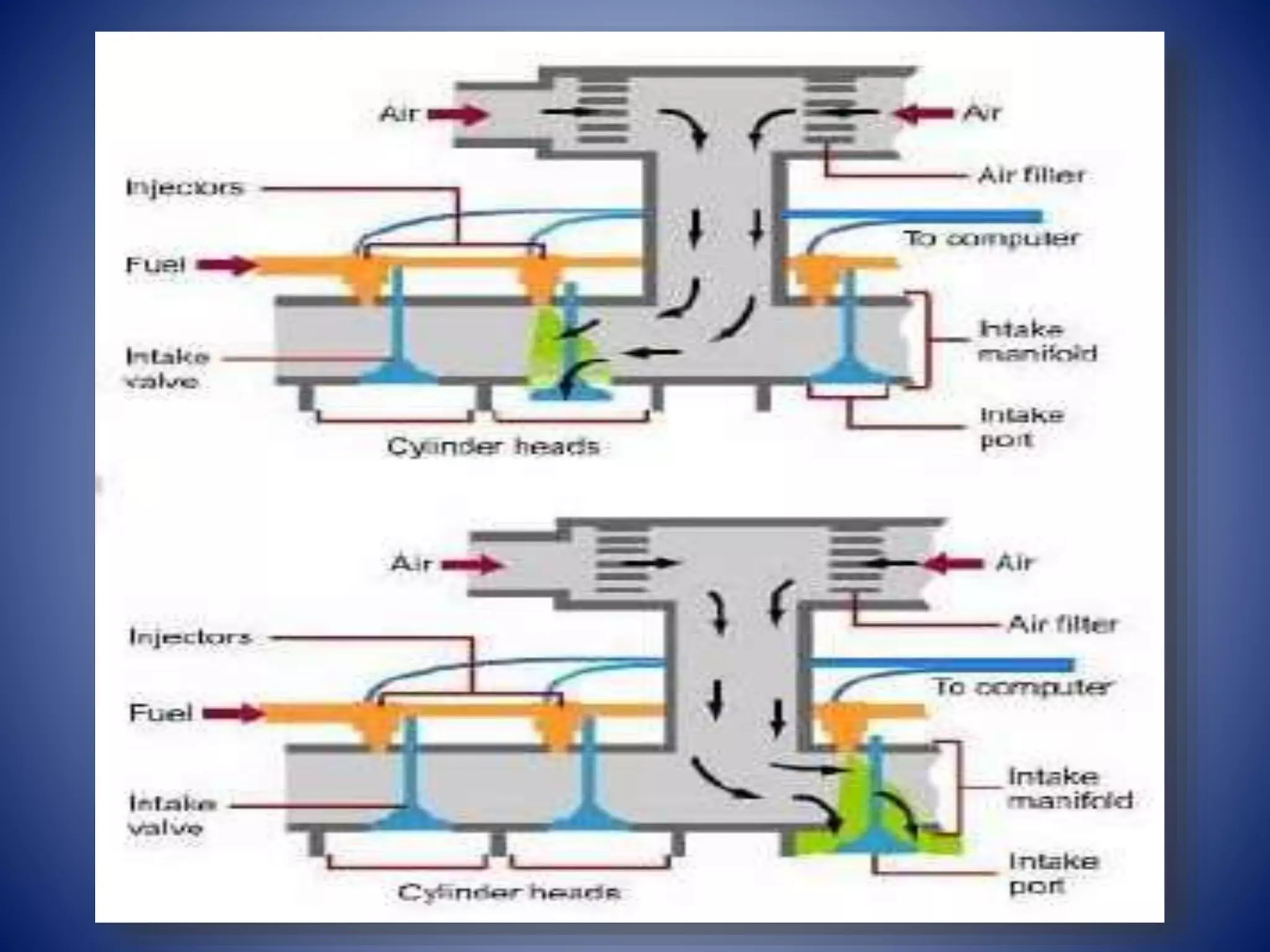

The document discusses multipoint fuel injection (MPFI) systems as an improvement over carburetors. MPFI systems inject fuel directly into engine cylinders and are controlled electronically by an engine control unit (ECU) to provide optimal air-fuel ratios under varying driving conditions. This leads to better engine performance, emissions control, fuel efficiency, and drivability compared to carburetors. The key components of an MPFI system are the air intake, fuel delivery, electronic control, and emission control systems.

![Type Of MPFI Systems

• The various types of MPFI systems are:

1.Simuntaneous: Together in all the

cylinders.

2. Sequential: Direct injection into the

individual cylinders against their power

strokes.

3.Group: In cylinder pairs [in V engines]](https://image.slidesharecdn.com/multipointfuelinjection-140922060007-phpapp01/75/Multi-point-fuel-injection-8-2048.jpg)