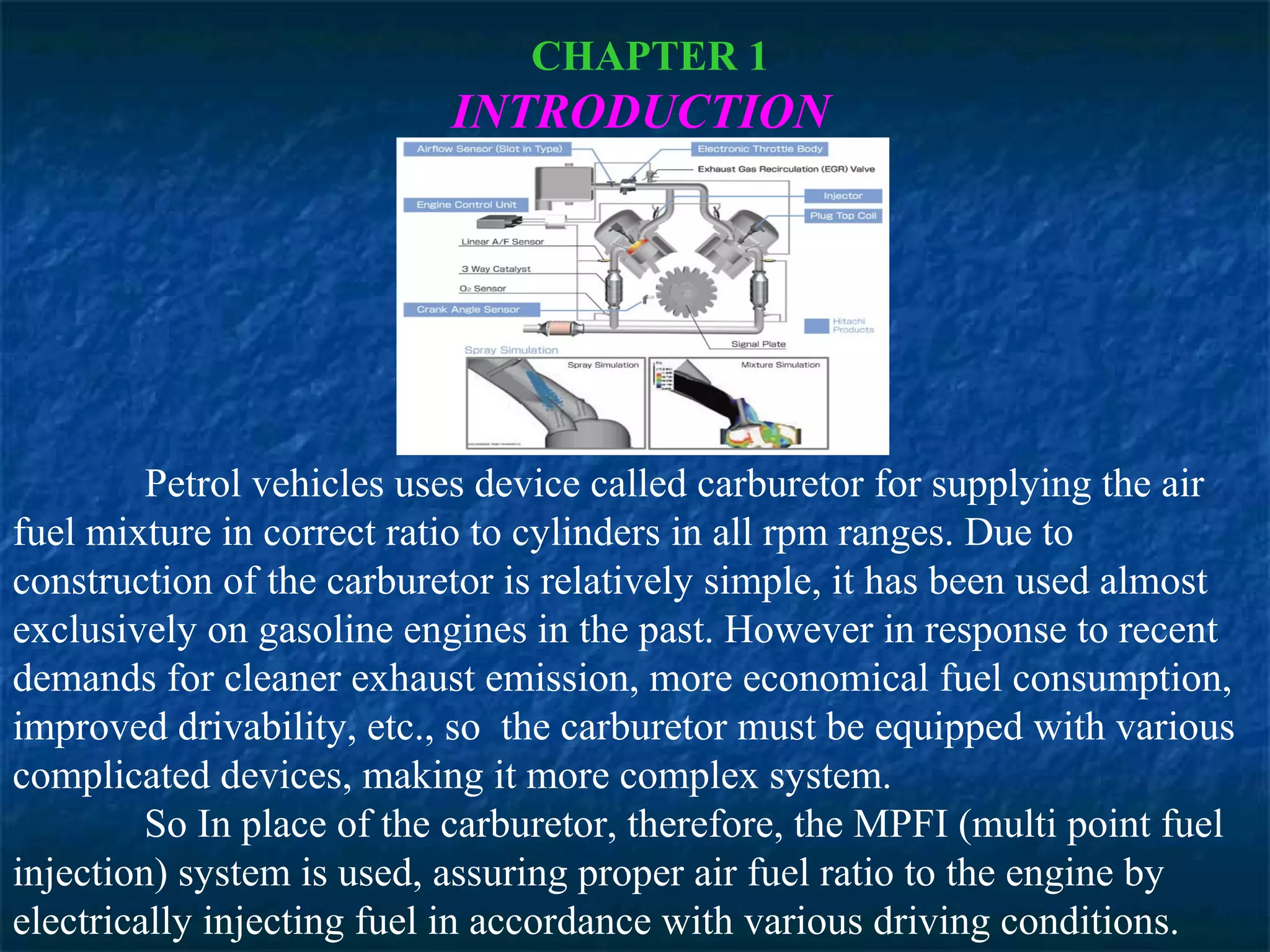

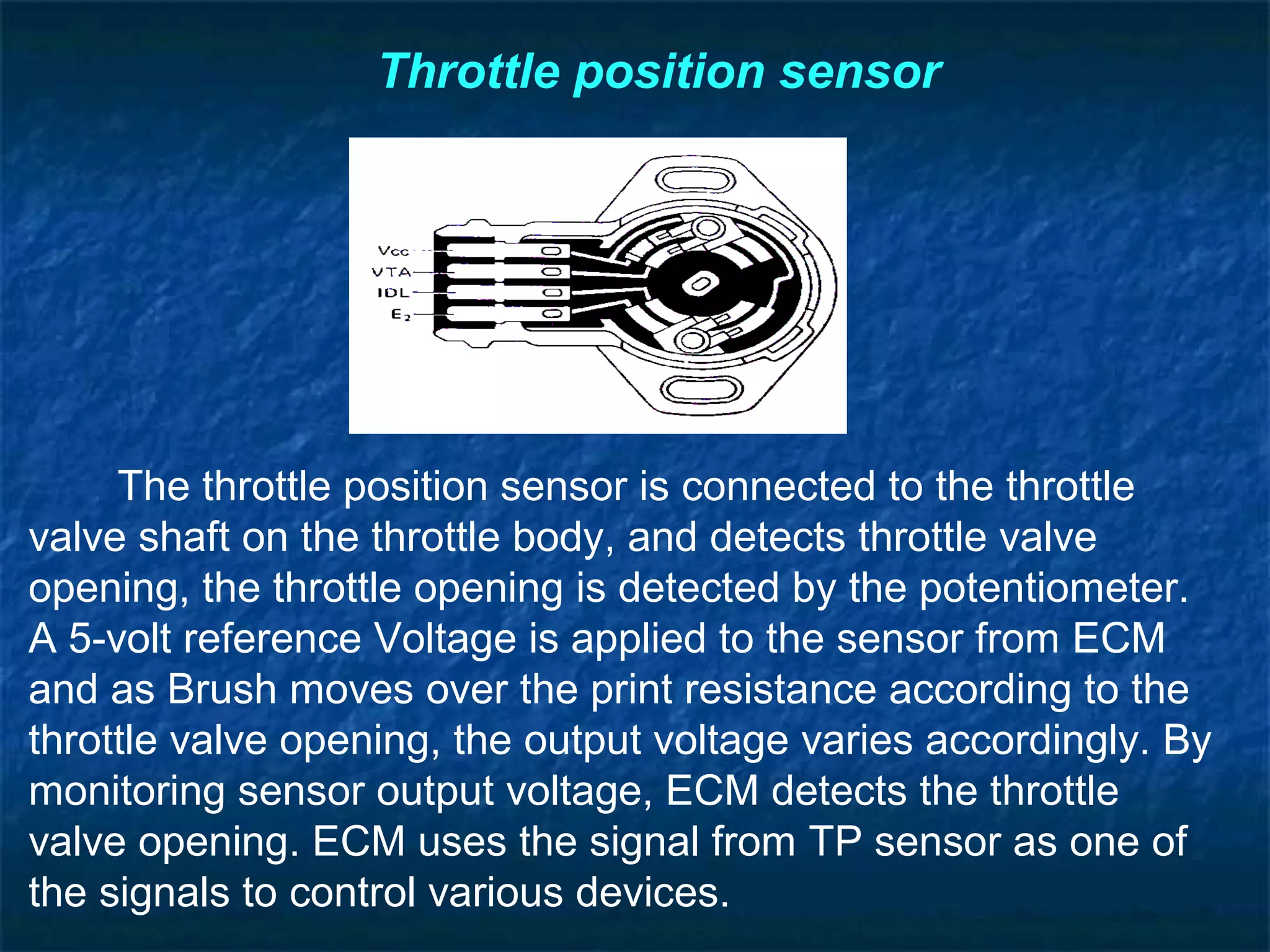

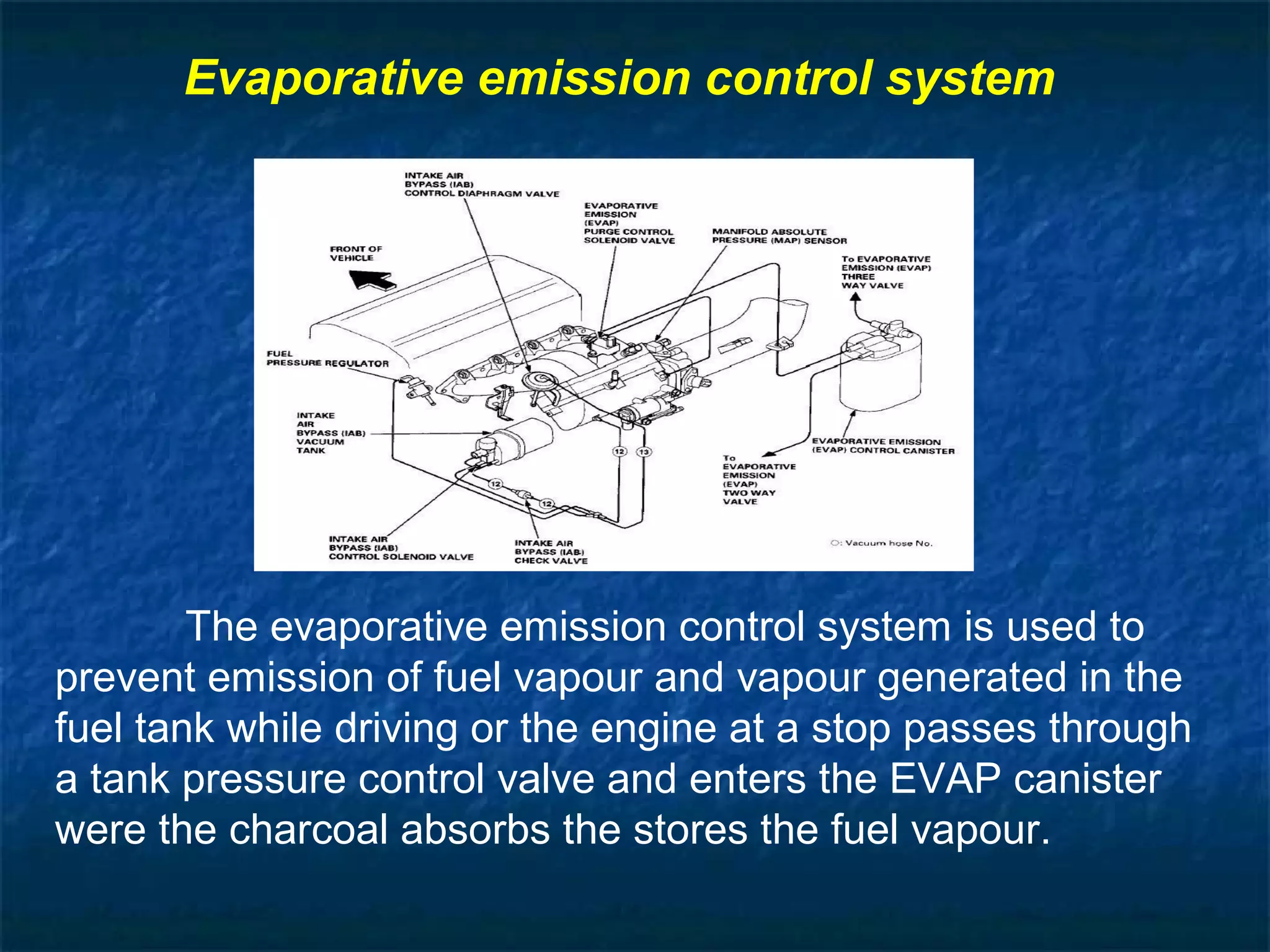

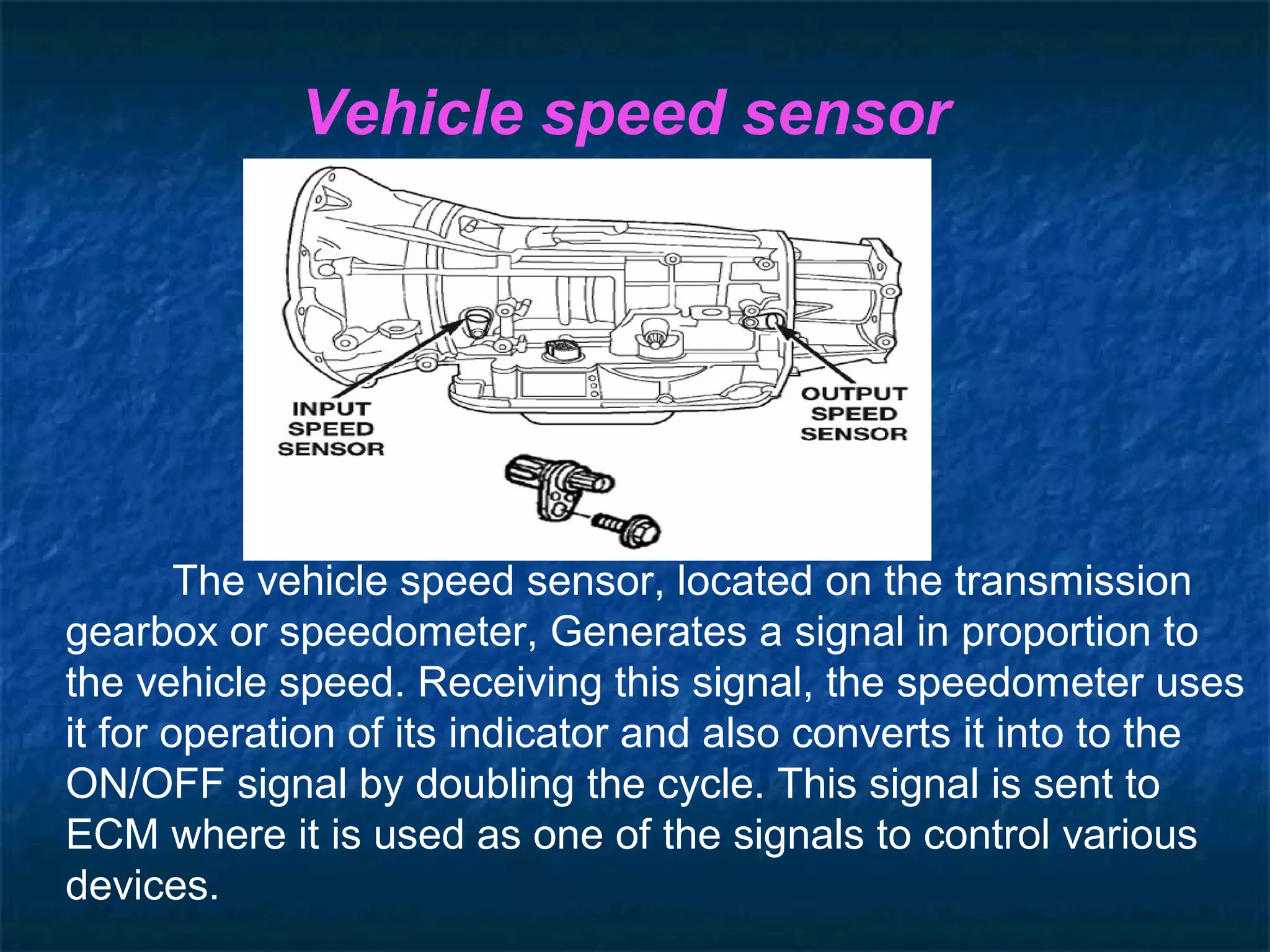

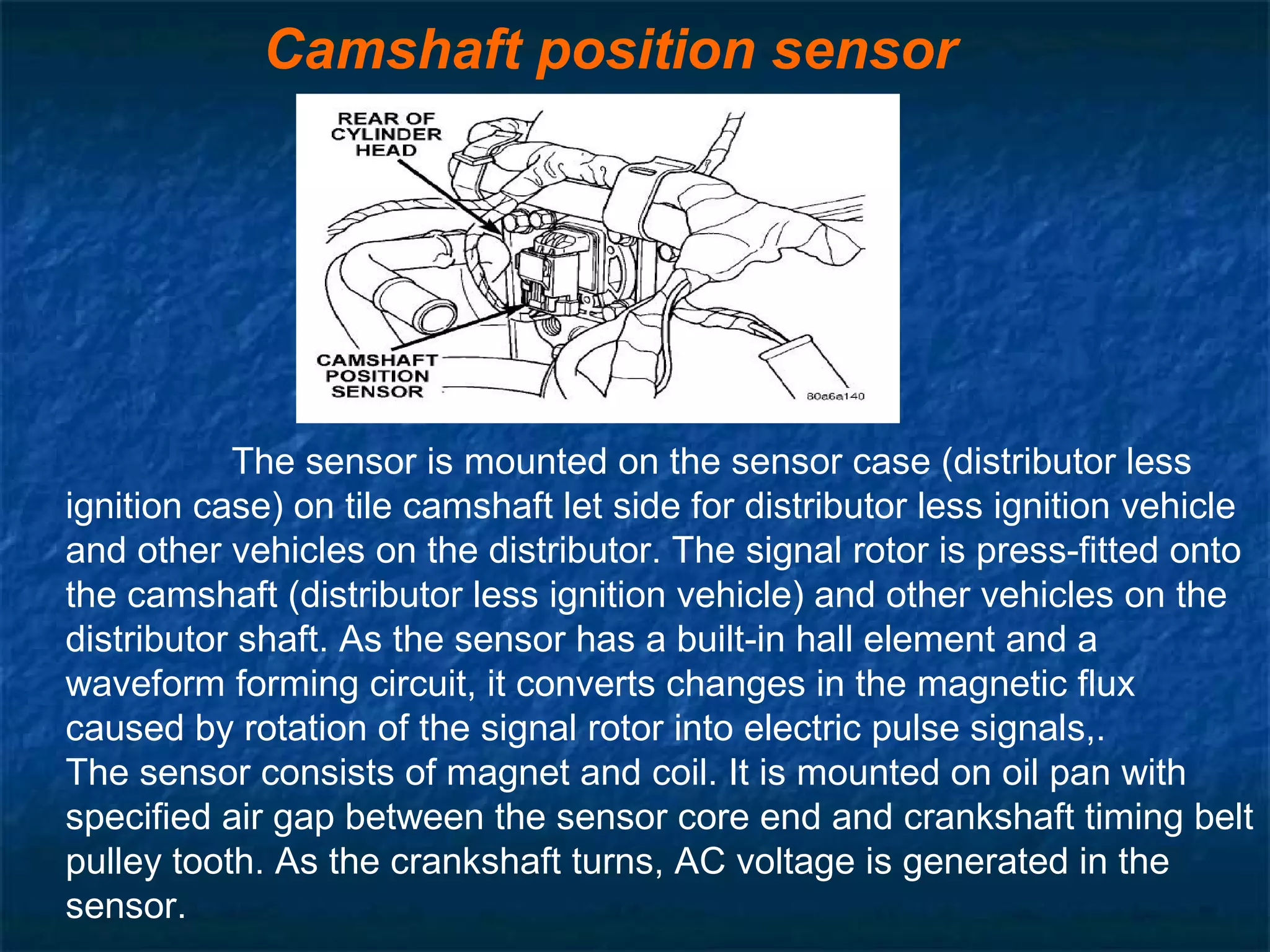

The document provides details about a seminar report on multi-point fuel injection systems. It discusses the main components of an MPFI system including the air intake system, fuel delivery system, and electronic control system. Sensors used in MPFI systems are described such as the manifold absolute pressure sensor, throttle position sensor, oxygen sensor, intake air temperature sensor, engine coolant temperature sensor, and vehicle speed sensor. Advantages of MPFI systems are more uniform air-fuel mixtures, improved fuel efficiency and emissions, and immediate acceleration response due to electronic control.