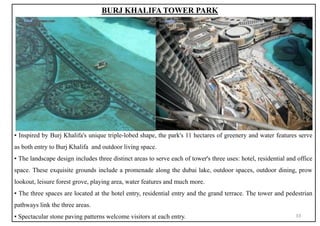

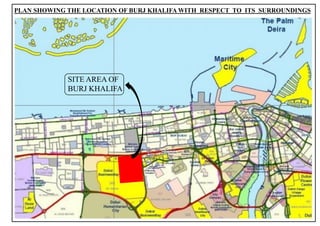

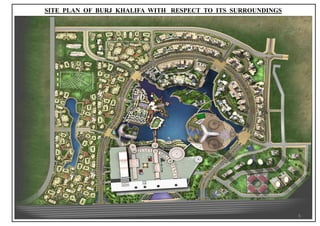

The document provides an overview of the Burj Khalifa, detailing its design, construction, and significance as the world's tallest building at 828 meters. It outlines the project's purpose, construction timeline, architectural features, and the mixed-use development surrounding it, which includes residential, commercial, and leisure spaces. The Burj Khalifa, completed in 2010, symbolizes modern engineering and aims to enhance Dubai's international status.

![PURPOSE

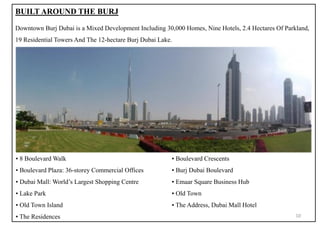

▪ Burj Dubai has been designed to be the centerpiece of a large-scale, mixed-use development that will include

30,000 homes, nine hotels such as the Burj Dubai Lake Hotel & Serviced Apartments, 0.03 km² (0.01 sq mi) of

parkland, at least 19 residential towers, the Dubai Mall, and the 0.12 km² (0.05 sq mi) man-made Burj Dubai lake.

▪ Burj Dubai cost US$ 800 million to build and the entire 2 km² (0.77 sq mi) development cost around US$ 20

billion.

▪ The silvery glass-sheathed concrete building gives the title of earth's tallest free-standing structure to the Middle

East — a title not held by the region since 1311 AD when Lincoln Cathedral in England surpassed the height of the

Great Pyramid of Giza, which had held the title for almost four millennia.

▪ The decision to build Burj Dubai is reportedly based on the government's decision to diversify from a trade-based

economy to one that is service- and tourism-oriented.

▪ According to officials, it is necessary for projects like Burj Dubai to be built in the city to garner more

international recognition, and hence investment. "He [Sheikh Mohammed Bin Rashid Al Maktoum] wanted to put

Dubai on the map with something really sensational," said Jacqui Josephson, a Tourism and VIP Delegations

Executive at Nakheel Properties.

“BURJ KHALIFA IS THE ARAB WORLD’S TRIBUTE TO THE ART AND SCIENCE OF MODERN

ENGINEERING AND DESIGN. BURJ KHALIFA SYMBOLIZES THE AESTHETIC UNISON OF MANY

CULTURES – FROM ARABIAAND THE REST OF THE WORLD.” - Mohamed Alabbar(Chairman, Emaar)4](https://image.slidesharecdn.com/finalpptonburjkhalifa-180202194513/85/Burj-Khalifa-4-320.jpg)

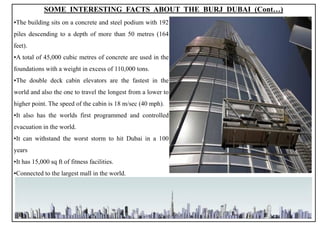

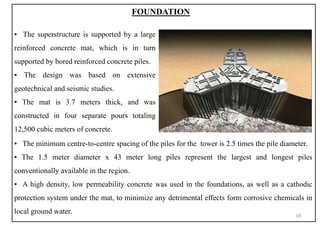

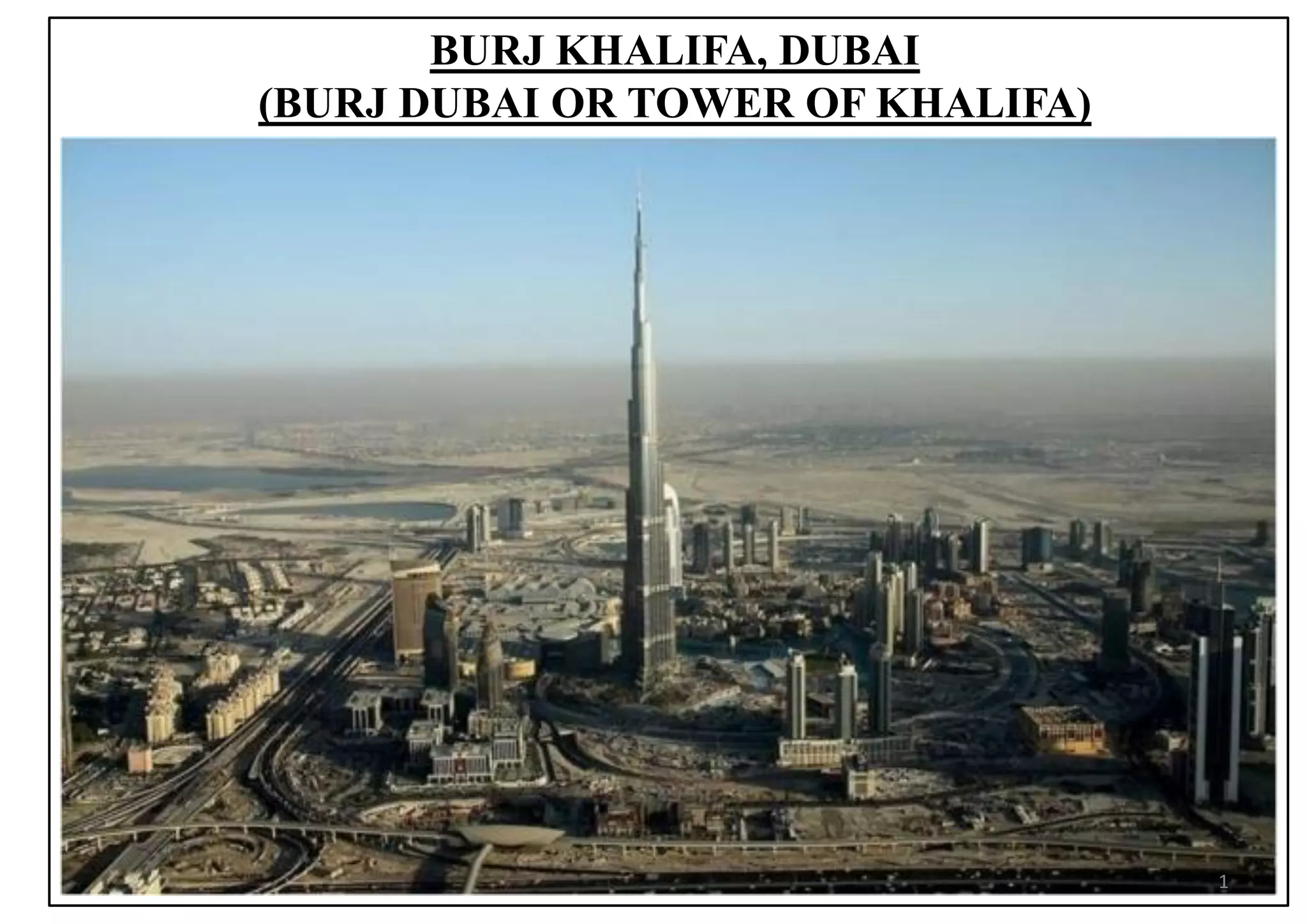

![STRUCTURE IN GENERAL

Construction Type: Skyscraper

Current Status: Existing [Completed]

Structural System: Buttressed Core

Structural Material: Concrete, Steel

Facade Material: Stainless Steel

Facade System: Curtain Wall

Architectural Style: Modernism

Floor Plan: 517,240m2

KEY DATA

Order Year: 2003

Construction Start: 2004

Project Type: Mall, Residential And Retail Facilities And World's Tallest Skyscraper

Location: Dubai, United Arab Emirates

Estimated Investment: Aed800m (Mall, Residential And Retail Facilities); Aed3.9bn

(Tower); Overall Development $8bn

Completion: 2008 (Mall); 2008 (Tower), Mall Opening On 31st August 2008, Tower

Officially Opened 4 January 2010

Retail Space: 9 Million Square Feet 7](https://image.slidesharecdn.com/finalpptonburjkhalifa-180202194513/85/Burj-Khalifa-7-320.jpg)