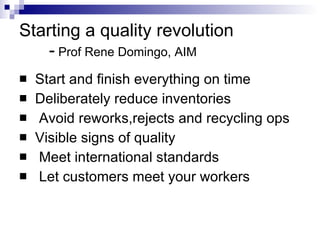

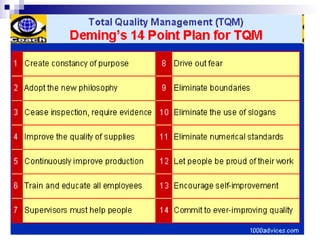

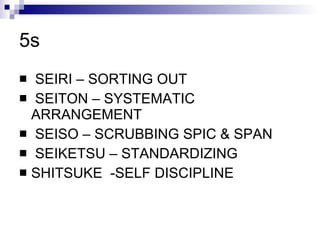

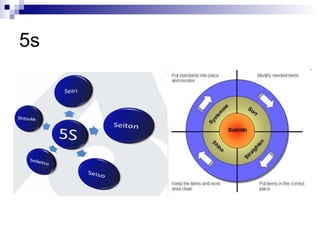

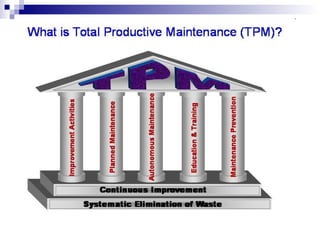

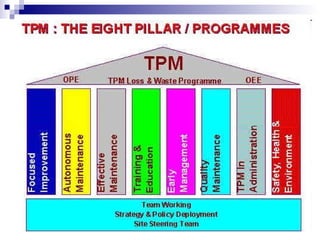

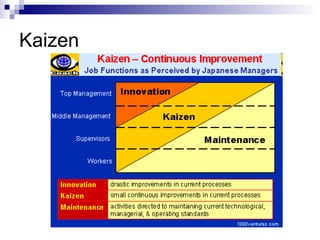

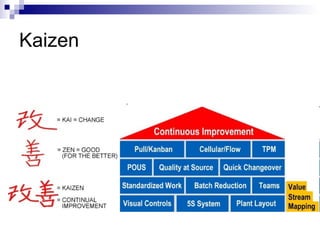

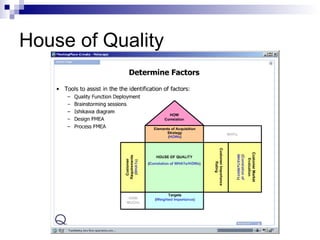

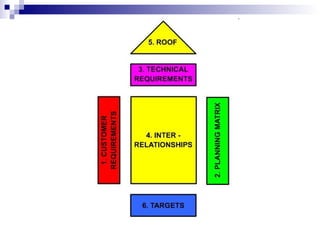

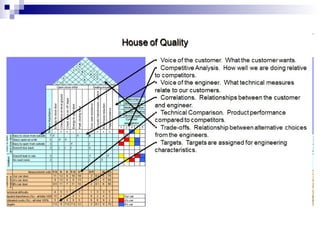

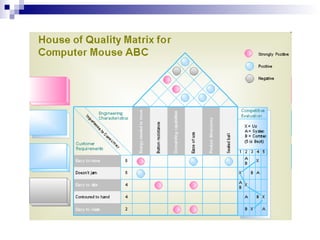

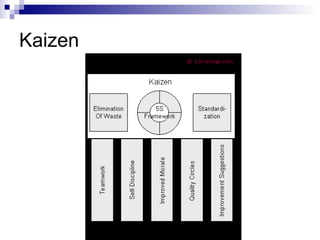

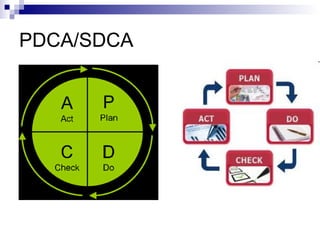

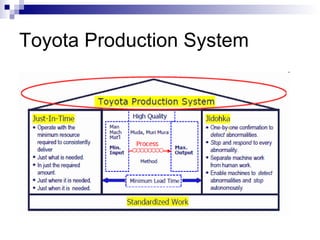

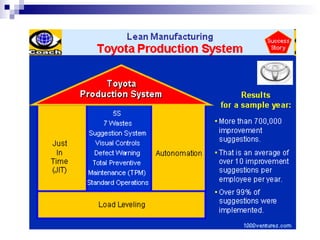

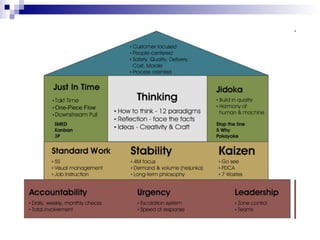

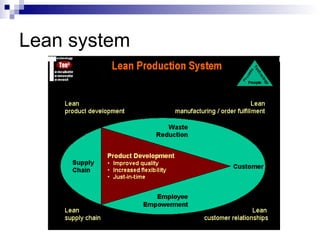

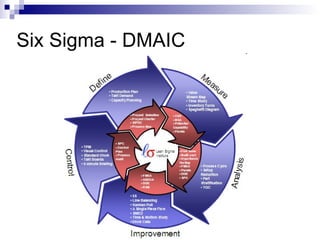

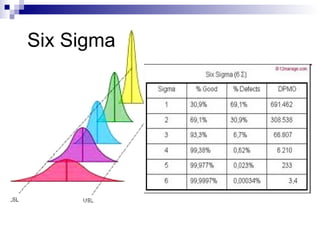

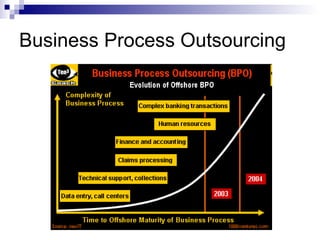

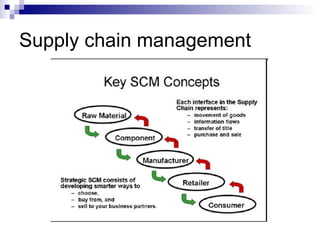

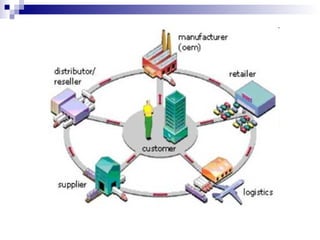

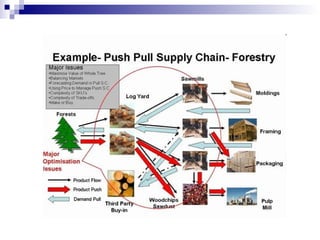

The document discusses business process innovation aimed at entrepreneurship students, emphasizing the importance of quality management and process improvement in delivering valuable outputs. It covers concepts such as total quality management, lean systems, and techniques for process optimization like six sigma and kaizen. Additionally, it highlights the significance of customer satisfaction, cost reduction, and efficient supply chain management in the growing business process outsourcing industry.

![Thank you! [email_address] Ateneo Graduate School of Business](https://image.slidesharecdn.com/businessprocessinnovation-110520195023-phpapp01/85/Business-process-innovation-for-entrepreneurs-69-320.jpg)