Us20130091879 a1

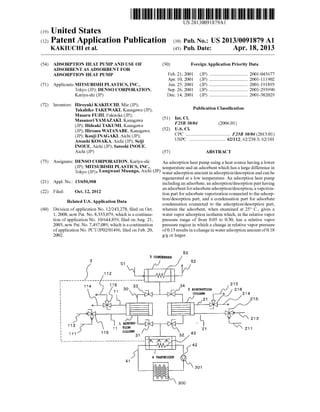

- 1. (19) United States US 20130091879A1 (12) Patent Application Publication (10) Pub. No.: US2013/0091879 A1 KAKUCHI et al. (43) Pub. Date: Apr. 18, 2013 (54) ADSORPTION HEAT PUMPAND USE OF ADSORBENT ASADSORBENT FOR ADSORPTION HEAT PUMP (71) Applicants:MITSUBISHI PLASTICS, INC., Tokyo (JP); DENSO CORPORATION, Kariya-shi (JP) (72) Inventors: Hiroyuki KAKIUCHI, Mie (JP): Takahiko TAKEWAKI, Kanagawa (JP); Masaru FUJII, Fukuoka (JP); Masanori YAMAZAKI, Kanagawa (JP); Hideaki TAKUMI, Kanagawa (JP); Hiromu WATANABE, Kanagawa (JP): Kouji INAGAKI, Aichi (JP); Atsushi KOSAKA, Aichi (JP); Seiji INOUE, Aichi (JP); Satoshi INOUE, Aichi (JP) (73) Assignees: DENSO CORPORATION, Kariya-shi (JP); MITSUBISHI PLASTICS, INC., Tokyo (JP) (21) Appl. No.: 13/650,908 (22) Filed: Oct. 12, 2012 Related U.S. Application Data (60) Division ofapplication No. 12/243.278, filed on Oct. 1, 2008, now Pat. No. 8,333,079, which is a continua tion ofapplication No. 10/644,859, filed on Aug. 21, 2003, now Pat.No. 7,497,089, which is acontinuation ofapplication No. PCT/JP02/01496, filed on Feb. 20, 2002. (30) Foreign Application Priority Data Feb. 21, 2001 (JP) ................................. 2001-045677 Apr. 10, 2001 (JP). 2001-11 1902 Jun. 25, 2001 (JP). ... 2001-191893 Sep. 26, 2001 (JP). ... 2001-293990 Dec. 14, 2001 (JP). ... 2001-382O29 Publication Classification (51) Int. Cl. F2SB 30/04 (2006.01) (52) U.S. Cl. CPC ...................................... F25B 30/04 (2013.01) USPC ............................... 62/112: 62/238.3; 62/101 (57) ABSTRACT An adsorption heatpump using a heat source having a lower temperatureand an adsorbent which hasa large difference in wateradsorptionamountin adsorption/desorptionandcanbe regenerated at a low temperature. An adsorption heat pump includingan adsorbate, an adsorption/desorption parthaving anadsorbentforadsorbateadsorption/desorption,a vaporiza tion part foradsorbate vaporization connected to the adsorp tion/desorption part, and a condensation part for adsorbate condensation connected to the adsorption/desorption part, wherein the adsorbent, when examined at 25°C., gives a water vaporadsorption isotherm which, in the relative vapor pressure range of from 0.05 to 0.30, has a relative vapor pressure region in which a change in relative vapor pressure of0.15 results inachangein wateradsorptionamountof0.18 g/g or larger. 53 5 CONDENSER 3 51 52 12 | w/ - - - - - -- - ---- -- - --- ------ ----- -- -w 14 116 33 34 212 11 3O 2 ASRCN 26 COUMN 21 A. 21 15 DYK CK7 l YN213ra 21 2 A3 3OO ,Lungwani (JP)Aichi,Muungo

- 3. PatentApplication Publication Apr. 18, 2013 Sheet 2 of 12 US 2013/0091879 A1 mo CN Co C O re cy d CN r d C cy c n O Y- C O o C Od C IP/P) LNnoWY NOILagosov

- 4. Patent Application Publication Apr. 18, 2013 Sheet 3 of 12 US 2013/0091879 A1 s ssss :

- 5. PatentApplication Publication Apr. 18,2013 Sheet 4 of 12 US 2013/0091879 A1 3 S. S s 5 u S ;: s S S

- 6. Patent Application Publication Apr. 18, 2013 Sheet 5 of 12 US 2013/0091879 A1 f s S.5. 5 i.

- 7. Patent Application Publication Apr. 18, 2013 Sheet 6 of 12 US 2013/0091879 A1 3 S s VO CY d N l c CN c s s IP/P) LNnoWW Nordosov :

- 8. PatentApplication Publication Apr. 18, 2013 Sheet 7 of 12 US 2013/0091879 A1 3.sSN

- 9. US 2013/0091879 A1Apr. 18, 2013 Sheet 8 of12PatentApplication Publication |#|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||?||||||||||||||||||||||||| |

- 10. PatentApplication Publication Apr. 18,2013 Sheet 9 of 12 US2013/0091879 A1 3 s S s 3 OY

- 11. Patent Application Publication Apr. 18, 2013 Sheet 10 of 12 US 2013/0091879 A1 ssssi

- 12. Patent Application Publication Apr. 18, 2013 Sheet 11 of 12 US 2013/0091879 A1 y o O ced O 5 S A. on 3O t O O i

- 13. Patent Application Publication Apr. 18, 2013 Sheet 12 of 12 US 2013/0091879 A1 s CN f se o CN Co cy d n o r d d d c d C

- 14. US 2013/009 1879 A1 ADSORPTION HEAT PUMP AND USE OF ADSORBENT ASADSORBENT FOR ADSORPTION HEAT PUMP TECHNICAL FIELD 0001. The present invention relates to an adsorption heat pump employing a specific adsorbent and use ofthe specific adsorbent as an adsorbent for an adsorption heat pump. BACKGROUND ART 0002. Inanadsorptionheatpump, theadsorbenthavingan adsorbate, e.g., water, adsorbed thereon is heated to desorb the adsorbate in order to regenerate the adsorbent, and the adsorbent dried is cooled to a temperature to be used for adsorbateadsorptionbefore beingusedforadsorbateadsorp tion again. 0003. Absorption type heatpumps in which waste heat or heathaving a relatively high temperature (120° C. orhigher) is utilized as a heat Source for adsorbent regeneration have already come into practical use. However, since the heat obtained from cogeneration apparatus, fuel cells, cooling waterforautomotiveengines, Solarenergy, orthe likegener ally has a relatively low temperature of 100° C. or below, it cannot be utilized as a heat Source for driving theabsorption typeheatpumpspresentlyinpracticaluse. Ithasbeendesired to effectivelyutilizelow-temperaturewasteheatof100°C.or lower, especially from 60° C. to 80°C. In particular, there is a strong desire forthepractical usethereofin motor vehicles which generate waste heat in large quantities. 0004. In adsorptionheatpumps, the adsorptionproperties required of adsorbents vary considerably depending on the temperatures ofutilizable heat sources even though the heat pumps operate on the same principle. Forexample, the tem peratures of higher-temperature-side heat Sources are from 60° C. to 80° C. in the case of waste heat from gas engine cogeneration and from Solid polymer type fuel cells and are from 85°C. to 90° C. in the case ofcooling water for auto motive engines. The temperatures of cooling-side heat Sources also vary depending on theplaces where the appara tus is installed. For example, the cooling-side heat Source temperatures in the case ofmotor Vehicles are temperatures obtained with the radiators, while thosein buildings, houses, and the like are the temperatures of water-cooling towers, river water, etc. Namely, the operating temperatures for an adsorptionheatpumpareas follows. Inthecaseofinstallation in buildings orthe like, thelower-side temperatures are from 25°C. to35°C.andthehigher-sidetemperaturesarefrom 60° C. to 80°C. In the case ofinstallation in motorvehicles or the like,the lower-sidetemperaturesareaboutfrom 30°C. to 45° C. and thehigher-side temperatures areabout from 85°C. to 90° C. There is hence a desire for an apparatus capable of being operated even with a small temperature difference between the lower-temperature-side heat source and the higher-temperature-side heat source so as to effectively uti lizewasteheat. An adsorbentto beapplied to Such apparatus is also desired. 0005 Typical adsorbents knownasadsorbents foradsorp tion heat pumps are Zeolite 13X andA-form silica gel. 0006 Recently, zeolites are being investigated, such as a mesoporous molecular sieve (e.g., FSM-10) synthesized using the micellar structure of a Surfactant as a template (Japanese Patent Laid-Open No. 178292/1997)and aporous aluminum phosphate molecular sieve for use as a desiccant Apr. 18, 2013 material commonly referred to as AlPO (Japanese Patent Laid-Open No. 197439/1999). 0007. It has already been reported that the temperature dependence of adsorption properties is important for the adsorbents foradsorption heatpumps (Kagaku Kogaku Ron bun-shti, Vol. 19, No. 6 (1993), pp. 1165-1170). There is a report therein that SG3 (manufactured by Fuji Silysia Ltd.) shows a large temperature dependence and SG1 (manufac tured by the same) does not. 0008 Furthermore, it has been reported that the adsorp tion performance ofAlPO-5, which is a porous aluminum phosphate molecularsieve, depends on temperature. Specifi cally, theadsorptionperformanceat 25°C. and thatat30°C. are shown (Colloid Polym Sci, 277 (1999) pp. 83-88). Like wise, the temperature dependence of AlPO-5 has been reported;adsorptionisotherms obtained inanadsorptionpro cess at 20°C., 25°C., 30° C., 35° C., and 40° C. are shown (Dai-16-kai Zeoraito Kenkyi Happyo Kai Koen Yoko-Shii, p. 91; Nov. 21 and 22, 2000). 0009 Useofvarious adsorbents inadsorptionheatpumps is being investigated. However, our investigations revealed that there is yet room for improvement in adsorption perfor mance so as to enable application to an apparatus capable of being operated even with a small temperature difference between the lower-temperature-side heat source and the higher-temperature-side heat Source. DISCLOSURE OF THE INVENTION 0010. In orderforanapparatustosufficiently operateeven when the atmosphere Surrounding the adsorbent has rela tively high temperatures, it is necessary to adsorb the adsor bate at a low relative vapor pressure. In order to reduce the sizeofan apparatus by reducingtheamount oftheadsorbent to be used, the amount of an adsorbate adsorbed onto and desorbed from theadsorbent shouldbelarge. Furthermore,in order to utilize a low-temperature heat source for adsorbate desorption (adsorbent regeneration), it is necessary that the desorption temperature is low. Namely, itisimportantthatan adsorbent for use in adsorption heat pumps is one which (1) adsorbsan adsorbateatalow relativevaporpressure (capable ofhigh-temperature adsorption), (2) attains a large adsorp tion/desorption amount, and (3) is capable ofadsorbate des orption at a high relative vapor pressure (capable of low temperature desorption). 0011. The invention has been achieved for the purpose of providing an efficient adsorption heat pump which employs an adsorbent capableofadsorbateadsorption/desorption in a low-relative-vapor-pressure region. 0012 Another objectofthe invention is to provide use of an adsorbent capableofadsorbateadsorption/desorption in a low-relative-vapor-pressure region as an adsorbent for adsorption heat pumps. 0013 Still anotherobjectofthe invention is toprovidean adsorption heatpump having practically effectiveadsorption performance. 0014. The invention provides, in one aspect thereof, an adsorption heat pump which comprises an adsorbate, an adsorption/desorptionparthavinganadsorbent foradsorbate adsorption/desorption, a vaporization part for adsorbate vaporization which has been connected to the adsorption/ desorption part, and a condensation part for adsorbate con densation which has been connected to the adsorption/des orptionpart,whereintheadsorbent,whenexaminedat25°C., givesa watervaporadsorptionisotherm which,in the relative

- 15. US 2013/009 1879 A1 vaporpressurerange offrom0.05to 0.30,hasarelative vapor pressure region in which a change in relative vapor pressure of0.15 results ina changeinwateradsorptionamountof0.18 g/g or larger. 0015 The invention further provides, in another aspect thereof, useoftheadsorbent describedaboveasanadsorbent foradsorption heat pumps. 0016. Instillanotheraspectthereof,theinventionprovides an adsorption heat pump which comprises an adsorbate, an adsorption/desorptionparthavinganadsorbent foradsorbate adsorption/desorption, and a vaporization/condensation part foradsorbatevaporization/condensation whichhasbeencon nectedtotheadsorption/desorptionpart,characterizedinthat the adsorbent comprises a Zeolite containing aluminum, phosphorus, and a heteroatom in the framework structure. 0017. Ina furtheraspectthereof, theinventionprovidesan adsorption heatpump which comprises (a) an adsorbate, (b) an adsorption/desorption parthavingan adsorbent foradsor bate adsorption/desorption, (c) a vaporization part foradsor bate vaporization which has been connected to the adsorp tion/desorptionpart,and(d)acondensationpartforadsorbate condensation which has been connected to the adsorption/ desorption part,characterizedinthattheadsorbentcomprises aZeolitecontainingaluminum,phosphorus,andsiliconin the frameworkstructure,andthatthezeolitegivesa Si NMR spectrum in whichthe integrated intensityareaforthesignals atfrom-108ppmto -123 ppm is notmorethan 10%basedon theintegratedintensityareaforthesignalsatfrom -70ppmto -123 ppm. 0018. Furthermore; the present inventors directed atten tion to the factthatin theadsorption/desorption parts ofheat pumps, the operating temperature during adsorbate adsorp tion differsfromthat duringadsorbatedesorption.The inven tors made intensive investigations in view ofthe fact. As a result, they have found that a heat pump having practically usefuladsorptionperformanceis oneemployinganadsorbent in which the value of a specific difference in adsorption amountdeterminedfrom (1) anadsorption isotherm obtained at an adsorption/desorption part temperature during adsorp tion operation and (2) a desorption isotherm obtained at an adsorption/desorption part temperature during desorption operation is within a given range. The invention has been achieved based on this finding. 0019. Namely, in still a further aspect thereof, the inven tion provides the following. 0020. An adsorption heat pump which comprises (a) an adsorbate, (b)anadsorption/desorptionparthaving an adsor bent for adsorbate adsorption/desorption, (c) a vaporization part foradsorbate vaporization which has been connected to theadsorption/desorptionpart,and(d)acondensationpartfor adsorbate condensation which has been connected to the adsorption/desorption part, characterized in that 0021 (1) the adsorbent comprises a zeolite containing at least aluminum and phosphorus in the framework structure, and 0022 (2) the adsorbent is a water vaporadsorbenthaving a region in which theadsorption amount difference as deter mined with the following equation is 0.15 g/g orlargerin the rangein whichtherelative vaporpressure(p2bduringadsorp tion operation in theadsorption/desorption part is from 0.115 to 0.18 and the relative vaporpressure (p1b during desorption operation in the adsorption/desorption part is from 0.1 to O.14: Adsorption amountdifference=O2-91 Apr. 18, 2013 0023 wherein 0024 Q1=adsorption amount at (p1b as determined from a water vapor desorption isotherm obtained at a temperature (T3) used for desorption operation in the adsorption/desorption part 0.025 Q2-adsorption amount at (p2b as determined from a water vapor adsorption isotherm obtained at a temperature (T4) used for adsorption operation in the adsorption/desorption part, 0026 provided that 0027 (p1b (relative vapor pressure during desorption operation in the adsorption/desorption part) equilib rium water vaporpressure at the temperature ofcoolant (T2) cooling the condenser/equilibrium water vapor pressureatthetemperatureofheatmedium (T1)heating the adsorption/desorption part 0028 (p2b (relative vapor pressure during adsorption operation in the adsorption/desorption part) equilib rium vapor pressure at the temperature of cold (T0) generated in the vaporization part/equilibrium vapor pressure at the temperature of coolant (T2) cooling the adsorption/desorption part 0029 (wherein T0=5 to 10° C., T1=T3=90° C., and T2=T4=40 to 45° C.). BRIEF DESCRIPTION OF THE DRAWINGS 0030 FIG. 1 is a diagrammatic view ofanadsorption heat pump 0031 FIG. 2isawatervaporadsorptionisotherm (25° C.) forSAPO-34 (manufactured by UOP LLC) in Example 1. 0032 FIG. 3 is a Si-MAS-NMR spectral chart for SAPO-34 (manufactured by UOP LLC) in Example 1. 0033 FIG. 4 isawatervaporadsorption isotherm (25°C.) forthe Zeolite ofExample 2. 0034 FIG. 5 is an Si-MAS-NMR spectral chart for the ’zeoliteofExample 2. 0035 FIG. 6isawatervaporadsorptionisotherm (25° C.) forthe Zeolite ofExample 3. 0036 FIG. 7 is water vapor adsorption isotherms for SAPO-34 (manufactured by UOP LLC) in Example4 which were obtainedin adsorptionprocess at 40°C. and desorption process at 90° C. 0037 FIG. 8 is water vapor adsorption isotherms for SAPO-34 (manufactured by UOP LLC) in Example4 which were obtainedin adsorptionprocess at 45° C. and desorption process at 90° C. 0038 FIG.9 isawatervaporadsorptionisotherm (25° C.) forthe Zeolite ofReference Example. 0039 FIG. 10 is a Si-MAS-NMR spectral chart forthe Zeolite ofReference Example. 0040 FIG. 11 is a water vaporadsorption isotherm (25° C.) forA-form silica gel in Comparative Example 2. 0041 FIG. 12 is a water vaporadsorption isotherm (30° C.) forALPO-5 in Comparative Example 3. 0042. In thefigures, numeral 1 denotes an adsorption col umn, 2 an adsorption column, 3 an adsorbate piping, 4 a vaporizer, 5 a condenser, 11 a heat medium piping, 111 a cooling-water inlet, 112 a cooling-wateroutlet, 113a warm water inlet, 114 a warm-wateroutlet, 115 a switching valve, 116 a Switching valve, 21 aheat medium piping, 211 a cool ing-waterinlet,212acooling-wateroutlet,213awarm-water inlet, 214 a warm-water outlet, 215 a switching valve, 216 a switchingvalve,30anadsorbatepiping,31acontrol valve,32 a control valve, 33 acontrol valve, 34 acontrol valve, 300 an

- 16. US 2013/009 1879 A1 indoor unit, 301 a pump, 41 a cold-waterpiping (inlet), 42 a cold-water piping (outlet), 51 a cooling-water piping (inlet), and 52 a cooling-water piping (outlet). BEST MODE FOR CARRYING OUT THE INVENTION 0043 detail. The invention will be explained below in more <Structure ofAdsorption Pumps 0044 First, thestructureofadsorption heat pumpswill be explained usingtheadsorption heatpump shown in FIG. 1 as an example. 0045 An adsorption heat pump is constituted mainly of: an adsorbate; an adsorption/desorption part (adsorption col umns 1 and 2) which is packed with an adsorbent capable of adsorbate adsorption/desorption and serves to transfer the heat generated by adsorbate adsorption/desorption to a heat medium (hereinafterthe adsorption/desorption part is some times referred to as adsorption columns); a vaporization part (vaporizer 4) which serves to take out the cold obtained by adsorbate vaporization; and a condensation part (condenser 5)whichservesto releaseoutwardtheheatobtainedbyadsor bate condensation. 0046. The vaporizer 4 contains a coolant (water in this embodiment) and is in a hermetically sealed state, with the inside being nearly vacuum. This vaporizer 4 is equipped inside with a heat exchanger 43 for heat exchange between the coolant and a heat medium (in this embodiment, a fluid obtained by mixingwaterwithanethyleneglycol-basedanti freeze) whichhas undergone heatexchange in an indoorunit 300 with the airblowing into the room. 0047. The adsorption columns 1 and 2 have, disposed therein, aheat exchangerhaving an adsorbentadhered to the surface thereoforpacked therein. The condenser 5 has, dis posed therein, a heat exchanger 53 forcooling and condens ing the vaporcoolant (watervapor)released from theadsorp tion column 1 or2 with a heat medium which has been cooled with, e.g., the outside air. 0048. The adsorption columns 1 and 2, which are packed with an adsorbent, are connected to each other by an adsor batepiping30.This adsorbatepiping30hascontrolvalves31 to 34 disposed therein. In theadsorbate piping, theadsorbate is present in the state ofthe vaporofthe adsorbate or in the form ofa mixture ofthe liquid and vapor ofthe adsorbate. 0049. To theadsorbate piping30 havebeen connected the vaporizer 4 and the condenser 5. The adsorption columns 1 and 2 have been connected in parallel arrangement to the vaporizer4andthecondenser5. Betweenthecondenser5and the vaporizer4 is disposeda returnpiping 3 for returning the adsorbate condensed by the condenser (preferably conden sate water resulting from regeneration) to the vaporizer 4. Numeral 41 denotes an inlet for cold water serving as a cooling output from the vaporizer4, and numeral 51 denotes a cooling-water inlet for introducing cooling water into the condenser 5. Numerals 42 and 52 denote a cold-water outlet and a cooling-water outlet, respectively. The cold-water pip ings 41 and 42 are connected to an indoor unit 300 for heat exchange with an indoor space (space to be air-conditioned) and to a pump 301 forcirculating cold water. 0050. Aheat medium piping 11 andaheat medium piping 21 have been connected respectively to the adsorption col umn 1 andtheadsorptioncolumn2.Theheatmediumpipings Apr. 18, 2013 11 and 21 have switching valves 115 and 116 and switching valves 215 and 216, respectively, disposed therein. A heat medium serving as a heating source or cooling source for heating orcooling theadsorbent in theadsorption columns 1 and 2 is caused to flow through the heat medium pipings 11 and 21, respectively. The heat medium is not particularly limited as long as it can effectively heat/cool the adsorbent packed in the adsorption columns. 0051 Warm wateris introduced through an inlet 113 and/ or inlet 213 by opening or closing Switching valves (three way valves) 115, 116, 215, and 216. The warm water intro ducedpassesthroughtheadsorptioncolumn 1 and/or2andis then discharged through an outlet 114 and/or outlet 214. Likewise, cooling water is introduced through an inlet 111 and/or inlet 211 by opening or closing the Switching valves 115,116,215,and216,passesthroughtheadsorptioncolumn 1and/or2,andisthendischargedthroughan outlet112and/or outlet 212. 0.052 The coolant piping which connects the vaporizer 4 to the adsorption columns 1 and 2 and the coolant piping which connects the condenser 5 to the adsorption columns 1 and 2 have control valves 31 to 34, which open or close the respectivecoolantpipings.Thesecontrol valves 31 to 34, the pump 301 for heat medium circulation, and the three-way valves 115, 116,215,and216forcontrollingtheflowofaheat medium are controlled by an electronic controller (not shown). 0053 To the heat medium piping 11 and/or 21 have been connectedanoutdoorunitdisposed soastobecapableofheat exchange with the outside air, a heat source which yields warm water, and a pump for heat medium circulation (all of these are not shown). The heat source is not particularly limited, and examples thereofinclude cogeneration appara tus, Such as automotive engines, gas engines, and gas tur bines, and fuel cells. In thecaseofautomotive use, preferred examples ofthe heat Source include automotive engines and automotive fuel cells. 0054 0055. The operation ofthe air conditioning system (ad Sorption heat pump) according to this embodiment will be outlinedbelow.Thepump301 isoperatedtocirculatetheheat medium through the indoor unit 300 and the vaporizer 4 to thereby vaporize the liquid coolant (preferably water) in the vaporizer4. Theheat medium is thuscooled to cool the airto be blown into the room. Simultaneously with this operation, thecontrol valves31 to34andthe three-way valves 115, 116, 215,and 216 areswitchedsothateitherofthe twoadsorption columns 1 and 2 is in the adsorption mode and the other adsorption column is in the desorption mode (regeneration mode). 0056 Specifically, in the case where the first adsorption column 1 is to be operated in the adsorption mode and the second adsorption column 2 is to be operated in the desorp tion mode, Valve Switching is conducted in the following manner. Thethree-wayvalve115 andthethree-way valve116 are regulated so as to establish connection to the cooling water inlet 111 side and the cooling-water outlet 112 side, respectively, while keeping thecontrol valve31 open andthe control valve 33 close. Simultaneously therewith, the three way valve215andthethree-way valve216are regulatedsoas to establish connection to the warm-water inlet 213 side and the warm-water outlet 214 side, respectively, while keeping the control valve 32 close and the control valve 34 open. <Outline ofAdsorption Heat Pump Operation>

- 17. US 2013/0091879 A1 0057. As a result, the coolant (water vapor) vaporized in thevaporizer4 flowsintothefirstadsorption column 1 andis adsorbed onto the adsorbent packed therein. During this adsorption,thetemperatureofthisadsorbentiskeptataround thetemperatureofthesurroundingairwiththe cooling water introduced through the inlet 111. 0058. On the other hand, warm water heated by a heat source (or the driving engine in the case ofapplication to a vehicle) is supplied to the second adsorption column 2 through the warm-waterinlet 213.As a result, theadsorbent in the second adsorption column releases the coolant which was adsorbed thereon in the adsorption mode. The coolant (water vapor) thus desorbed is cooledand condensed in the condenser5 for regeneration. 0059. After the lapse ofa given time period, the control valves 31 to 34 and the three-way valves 115, 116, 215, and 216 are switched, whereby the modes ofthe first adsorption column 1 and second adsorption column 2 can be shifted to the desorption mode and the adsorption mode, respectively. By repeatingsuch switchingatagiven interval,a continuous cooling operation can be conducted. <Adsorbents) 0060. One feature of the invention resides in the adsor bents used in the adsorption heat pumps. <Adsorbent 1> 0061 Anadsorbentintheinventionisanadsorbentwhich, when examined at 25°C., gives a water vapor adsorption isotherm which, in the relative vaporpressure range offrom 0.05 to 0.30, has a relative vaporpressure region in which a changeinrelativevaporpressureof0.15resultsinachangein wateradsorptionamount of0.18 g/g or larger,preferably 0.2 g/g or larger. This adsorbent preferably is one in which that change inwateradsorptionamount inthe rangeoffrom 0.05 to 0.20 is 0.18 g/g or larger, preferably 0.2 g/g or larger. 0062. Adsorbates areadsorbedas vapors onto adsorbents. A preferred adsorbent is a material which undergoes a large change in adsorbate adsorption amount in a narrow relative vapor pressure range. The reasons for this are as follows. Whensuchanadsorbentundergoingalargechangeinadsorp tionamountina narrow relative vaporpressurerangeis used, theamountoftheadsorbent necessary forobtainingthesame adsorptionamountunderthesameconditionscanbereduced and the adsorption heat pump can be operated even with a smaller temperature difference between the heat source for cooling and the heat source forheating. 0063. Thepreferenceforthatpropertyofanadsorbentwill becomeapparent from the following investigation. 0064. First, the operating vapor pressure range for an adsorption heat pump is determined by the desorption-side relative vaporpressure (p1a)andthe adsorption-siderelative vaporpressure (gp2a). The values ofq1 and p2 can be calcu latedusingthe followingequations.Therangeoffrom(p1ato (p2aistherelativevaporpressurerangeinwhichthepumpcan be operated. Desorption-side relative vaporpressure (pla)-equi librium vaporpressure (Tlow1)/equilibrium vaporpressure (Thigh) Adsorption-side relative vaporpressure (p2a)-equi librium vaporpressure (Tcool) equilibrium vaporpressure (Tlow2) Apr. 18, 2013 0065. Thesymbolshave the following meanings. 0066. Thigh (temperature of high-temperature heat Source): 0067 Temperature ofheat medium used for desorb ingadsorbate from adsorbentand thereby regenerat ing the adsorbent 0068 Tlow1 (temperature of low-temperature heat Source): 0069. Temperatureofadsorbateincondensationpart 0070 Tlow2 (temperature of low-temperature heat source): (0071 Temperature ofheat medium used forcooling regenerated adsorbentin preparation foradsorption 0.072 Tcool (temperature ofcold generated): (0073 Temperature ofadsorbate in the vaporization part, i.e., temperatureofcoldgenerated (0074 The equilibrium vapor pressure can be determined from temperature using an equilibrium vaporpressure curve for the adsorbent. (0075 Examples ofthe operating vaporpressure range in the case where the adsorbateis waterareshown below. When the high-temperature heat source temperature is 80° C. and the low-temperature heat source temperature is 30°C., then theoperating vaporpressurerange (p1a-p2a) is from0.09to 0.29. Likewise, when the high-temperature heat source tem perature is 60° C. and the low-temperature heat source tem perature is 30° C., then the operating relative water vapor pressure range (p1a-p2a) is from 0.21 to 0.29. Furthermore, in the case where waste heat from an automotive engine is utilized for operating an adsorption heat pump, the high temperatureheatsourcetemperatureandthelow-temperature heatsourcetemperatureareestimatedatabout90°C.and30° C. respectively, from a statement given in Japanese Patent Laid-OpenNo.2000-140625. Inthiscase,theoperatingrela tive vaporpressure range (p1a-p2a) is from 0.06 to 0.29. 0076. It canhence be thoughtthat inthecase wherewaste heat from gas engine cogeneration or from a solid polymer typefuelcellorautomotiveengineisutilizedforoperatingan adsorption heat pump, the operating relative vapor pressure range (cp1a-p2a)is from0.05to0.30,preferably from 0.06to 0.29.Namely,amaterialundergoingalargechangeinadsorp tion amount in this operating moisture range is preferred. Consequently, itispreferred to usea material which changes considerably inadsorptionamountinthe relativevaporpres surerangeofusuallyfrom 0.05 to0.30,preferably from 0.06 to 0.29. 0077. Forexample, thecasewherea coolingpowerof3.0 kW (=10.800kJ/hr)is to beobtainedwithanadsorptionheat pump issupposed.This valueof3.0kW isthecoolingability of air conditions for use in general motor vehicles. It is thought from investigations on the engine rooms of various motor vehicles thatthevolume ofan adsorption heatpump is desirably up to 15 liter. <Adsorption Amount Difference> (0078. Theweightofanadsorbentcapableofbeingpacked into a volume of 15 liter or smaller is then determined. (0079. The parts which should be mounted in the engine room include adsorption column main bodies, a vaporizer, a condenser, and control valves. It is necessary thattheseparts aremostlyunitedintoanassemblyhavingavolumeof15liter orsmaller. It is thoughtfromourinvestigationsthatthevapor izer,condenser,and valves can bearrangedina spaceVolume of4.5 liter. Consequently, the volume ofthe adsorption col umn main bodies is about 10.5 liter or smaller. Since the

- 18. US 2013/009 1879 A1 percentagepacking ofadsorbents in adsorption columns and the bulk density of adsorbents are usually about 30% and about 0.6 kg/liter, respectively, the weight of an adsorbent which can be packed (W) is about 10.5x30%x0.6–1.89 kg. 0080 Properties required ofadsorbents will be explained neXt. 0081. Thecooling power Rofan adsorption heat pump is expressed by the following equation A. R=(W-AOm"AH/T)'m, 0082 InequationA,W represents the weight oftheadsor bent packed into each adsorption column (one side); AQ represents the equilibrium adsorption amount amplitude whichresults undertheconditionsforadsorptionanddesorp tion, i.e., the adsorption amount difference (Q2-Q1); m rep resentsadsorptionamplitudeefficiency,whichshowsthepro portion of the actual adsorption amplitude in the time between Switching operations to the equilibrium adsorption amplitude AQ: AH represents the latent heat ofvaporization (equation A) ofwater; T represents the time period between operations of Switchingto theadsorption modeordesorption mode; andm, represents heat mass efficiency fortakingaccount oftheheat mass losscausedbythetemperaturechanges oftheadsorbent andheatexchangers between thetemperature ofwarm water and the temperature ofcooling water. I0083. As statedabove, Ris 3 kW andW is 1.89kg/2=0.95 kg. An investigation which was made previously by us revealed that an appropriate value oft is about 60 seconds, and it has been found that the values of AH, m, and m, are 2,500 kJ/kg, 0.6, and 0.85, respectively. Consequently, AQ is determined using equation (A). AQ = R/ Wfn fAH. ifn, = 3.0/0.95/0.6.f2500.60/0.85 = 0.149 kg/kg Namely, theadsorbenttobeused in theadsorptionheatpump for motor vehicles is one having a AQ of0.15 g/g or larger, preferably 0.18 g/g or larger, more preferably 0.20 g/g or larger. 0084. Although the adsorbent was explainedaboveon the assumption thattheadsorption heatpump is appliedto motor vehicles, it isamatterofcoursethatanyadsorbenthavingthe properties shown above can be sufficiently applied to other applications including stationary use. 0085. As a result of the investigations given above, the adsorbent foruse inan adsorption heatpump ofthe invention has been determined. I0086. The adsorbent which shows a water adsorption amount difference of 0.18 g/g or larger when the relative vaporpressure changes by 0.15 in the range offrom 0.05 to 0.30 is not particularly limited as long as it satisfies the property requirement. However, Zeolitesarepromising mate rials. In Zeolites, the pore volume, which contributes to adsorption, is governed by the framework density because Zeolitesarecrystalline. Zeolite 13X (framework density, 12.7 T/1,000 A), which is an example ofthe zeolites having the lowest framework density, has a maximum adsorption amountofabout0.30g/g.Consequently,whentheadsorption amountas measuredatthe lowerlimit ofrelative vaporpres sure of0.05, which is specifiedin theinvention, is larger than Apr. 18, 2013 0.15 g/g, then itis impossibleto obtain anadsorption amount differenceof0.18 g/g. Therefore, theadsorption amountat a relative vapor pressure of0.05, as determined from a water vapor adsorption isotherm, is desirably 0.15 g/g or Smaller, preferably 0.12 g/g or smaller, more preferably 0.10 g/g or smaller, still more preferably 0.07 g/g or smaller, and still furtherpreferably 0.05 g/g or smaller. <Adsorbent 2D 0087 Another feature of an adsorbent in the invention resides inthattheadsorbentisawatervaporadsorbenthaving a region in which the adsorption amount differenceas deter minedwith the followingequation is 0.15 g/g orlargerin the range in which the relative vapor pressure (p2b) during adsorption operationintheadsorption/desorptionpartisfrom 0.115 to 0.18 and the relative vapor pressure (cp1b) during desorption operationintheadsorption/desorptionpartisfrom 0.1 to 0.14: Adsorptionamountdifference=O2-91 0088 wherein 0089 Q1=adsorption amount at (p1b as determined from a water vapor desorption isotherm obtained at a temperature (T3) used for desorption operation in the adsorption/desorption part 0090 Q2-adsorption amount at (p2b as determined from a water vapor adsorption isotherm obtained at a temperature (T4) used for adsorption operation in the adsorption/desorption part, (0.091 provided that 0092 (p1b (relative vapor pressure during desorption operation in the adsorption/desorption part) equilib rium water vaporpressure at the temperature ofcoolant (T2) cooling the condenser/equilibrium water vapor pressureatthetemperatureofheatmedium (T1)heating the adsorption/desorption part 0.093 (p2b (relative vapor pressure during adsorption operation in the adsorption/desorption part) equilib rium vapor pressure at the temperature of cold (T0) generated in the vaporization part/equilibrium vapor pressure at the temperature of coolant (T2) cooling the adsorption/desorption part 0094 (wherein T0=5 to 10° C., T1=T3=90° C., and T2=T4=40 to 45° C.). 0.095 Although the adsorption amount difference for the adsorbent in the invention is thus specified, a more preferred adsorbent satisfies the requirement which is specified under any ofthe following conditions (A) to (C). 0096 (A) T0 is 10° C. and T2 is 40° C. 0097 (B)TO is 5° C. and T2 is 40° C. 0.098 (C)T0 is 10° C. andT2 is 45° C. (0099. Theadsorbentperformancedescribedabovewill be explained below by reference to FIG. 1. 0100 First,anexplanation isgivenonthecaseofFIG. 1 in which the control valves 31 and 34 are closed and thecontrol valves 32 and 34 are opened. 0101. In this case, the adsorbent packed in the adsorption column2adsorbs thewatervaporsuppliedfromthe vaporizer 4 and thus heats up. During this adsorption, the adsorption column 2 is cooled and deprived ofheatby the heat medium (e.g., cooling water) which is passing through the heat medium pipes 211 and 21. The temperature of this heat

- 19. US 2013/009 1879 A1 medium (cooling water), which is Supplied through the pipe 211 forcoolingtheadsorption column 2 (adsorption/desorp tion part), is referred to as T2. 0102 On theotherhand, the temperature ofthe vaporizer 4is regulated forthepurpose ofgenerating cold. Theadsorp tion-side relative vapor pressure (p2b in this operation is defined by the following equation. Adsorption-side relative vaporpressure (p2b=equilib rium watervaporpressure (TO) equilibrium watervaporpressure (T2) 0103 Equilibrium water vapor pressure (T0): equilib rium water vaporpressure at the temperature T0 ofthe vaporizer 4 0.104) Equilibrium water vapor pressure (T2): equilib rium water vaporpressure at the temperature T2 ofthe heat medium in the adsorption column 2 0105. On the otherhand, the adsorption column 1 during this operation is in the desorption (regeneration) mode. The adsorbent packed in the adsorption column 1 is regenerated by a regenerating heat Source (temperature of the heat medium forheating the adsorption/desorption part; this tem perature is referred to as T1). Thecondenser5 is cooled with the cooling water supplied through the heat medium pipe 51 andthereby condenses watervapor.Thedesorption-siderela tive vapor pressure S1 in this operation is defined by the following equation. Desorption-side relative vaporpressure plb=equilib rium vapor pressure (T2) equilibrium vapor pressure (Tl)) 0106 Equilibrium vapor pressure (T2): equilibrium vapor pressure at the temperature of the condenser 5 (equilibrium vapor pressure at the temperature T2 of the heat medium in the adsorption column 2) 0107 Equilibrium vapor pressure (T1): equilibrium vaporpressureat the temperature (T1) ofthe regenerat ing heat Source in the adsorption column 1 0108. An important point here is that in an adsorption column, the temperature during adsorption differs from the temperatureduring desorption (regeneration). Consequently, in the invention, the adsorption amount difference is deter mined from a desorption isotherm obtained at a desorption temperature and from an adsorption isotherm obtained at an adsorption isotherm. Specifically, it is calculated using the following equation. Adsorption amountdifference=O2-91 01.09 wherein 0110 Q1=adsorption amount at (p1b as determined from a water vapor desorption isotherm obtained at a temperature (T3) used for desorption operation in the desorption part 0111 Q2-adsorption amount at (p2b as determined from a water vapor adsorption isotherm obtained at a temperature (T4) used for adsorption operation in the adsorption/desorption part, (O112 provided that 0113 (p1b (relative vapor pressure during desorption operation in the adsorption/desorption part) equilib rium water vaporpressure at the temperature ofcoolant (T2) cooling the condenser/equilibrium water vapor pressureatthetemperatureofheatmedium (T1)heating the adsorption/desorption part 0114 p2b (relative vapor pressure during adsorption operation in the adsorption/desorption part) equilib Apr. 18, 2013 rium vapor pressure at the temperature of cold (T0) generated in the vaporization part/equilibrium vapor pressure at the temperature of coolant (T2) cooling the adsorption/desorption part 0115 (wherein T0=5 to 10° C., T1=T3=90° C., and T2=T4=40 to 45° C.). 0116. The adsorbent according to the invention has an adsorption amount difference, as determined with the equa tion shownabove,of0.15g/gorlarger, preferably 0.18g/gor larger. The largertheadsorptionamount difference,the more theadsorbentis preferred. However, whenavailable material Sources which satisfy Such performance are taken into account,theadsorption amountdifferenceis usually 0.50g/g, orSmaller, practically 0.40g/gorSmaller,especially 0.35g/g, or Smaller. 0117 Specifically, the adsorption amount difference is determinedthrough measurements made, forexample, under (1) conditions in which T0 is 10° C. and T2 is 40° C., (2) conditions in which T0 is 5° C. and T2 is 40° C., or (3) conditions in which T0is 10°C. andT2 is 45°C. Theadsorp tionamountdifferencethus determined maybe any value not below 0.15 g/g. 0118. The necessity ofthe adsorption amount difference of0.15 g/g orlarger is derived from the following investiga tion, which is made on the Supposition that the adsorption heat pump is applied to motor vehicles. <Adsorption Temperature, Description Temperature> 0119 First, an adsorption isotherm and a desorption iso therm are obtained at an adsorption temperature and a des orption temperature, respectively, because the adsorption amountdependsonthetemperatureduringadsorptionandthe temperature during desorption as stated above. 0.120. During adsorption, the adsorptioncolumn is cooled with cooling waterin orderto inhibit the column from being heatedupby adsorptionheat. Becauseofthis,thetemperature ofthe cooling water (T2) is almost equal to the adsorption temperature (T4). On the other hand, during desorption, the adsorption column requires desorption heatandthetempera tureofwarmwater(T1)isequaltothedesorptiontemperature (T3). I0121 Incidentally, heat medium temperatures in the adsorption heat pump are as follows: (1) the warm-water temperature is about 90° C. because it is a temperature obtained with theengine-cooling water; (2) the cooling tem perature is about from 40°C. to 45° C. because it is a tem perature obtained by heat exchange with the outside air; and (3) the temperature ofcold water necessary forgenerating a cold wind is about from 5 to 10° C. Namely, the cold-water temperature is about from 5 to 10°C. on the assumption that theadsorptionheatpump isappliedtogeneral motorvehicles in Japan. The cooling temperature is about 40°C. in Japan, and is about 45° C. in regions where theoutsideair tempera ture is high. 0.122 Consequently, the adsorption temperature (T4) is About from 40°C. to 45° C. and the desorption temperature (T3) is about 90° C. I0123. In theinvention, theadsorption temperatureand the desorption temperatureareemployedas indexestoadsorbent performance. The adsorbent is one which satisfies the requirement that the adsorption amount difference, as deter mined from at least one ofadsorption isotherms obtained at

- 20. US 2013/009 1879 A1 adsorption temperatures offrom 40°C. to 45° C. and from a desorption isotherm obtained at a desorption temperature of 90°C., is 0.15 g/g or larger. <Adsorption Amount Difference> 0.124. The adsorption amount difference (0.15 g/g or larger) is determined in the same manner as foradsorbent 1. 0.125. Although the adsorbent was explainedaboveon the assumption thattheadsorption heatpump is appliedto motor vehicles, it isamatterofcoursethatanyadsorbenthavingthe properties describedabovecanbesufficientlyappliedtoother applications including stationary use. 0126. It is noted that the adsorption amount difference accordingtotheinventionissatisfiedintherangeinwhichthe relativevaporpressureduringadsorptionoperation(p2binthe adsorption/desorptionpart is from 0.115 to 0.18 and the rela tive vapor pressure during desorption operation (p1b in the adsorption/desorption part is from 0.1 to 0.14. This range roughly corresponds to the range ofoperating relative vapor pressures foradsorption heat pumps. 0127. When the adsorbent has a region in which the adsorptionamountdifferenceis0.15g/gorlargerintherange in which (p1band p2bare from 0.115 to 0.18and (p1bis equal to or higher than (p2b, then this adsorbent is advantageous because theadsorption heat pump can be operated therewith even under severe temperature conditions which have been thought to be unabletobe used foroperatingadsorption heat pumps. 0128. Adsorbent 2 described above is selected from Zeo lites containing at least aluminum and phosphorus in the framework structure. <Adsorbent Materials 0129. The adsorbents in the invention preferably are Zeo lites. Especially preferred is a Zeolite containing aluminum, phosphorus, and a heteroatom in the framework structure. TheZeolitesheremaybenatural zeolites orartificial zeolites. Examples of the artificial zeolites include the aluminosili cates, aluminophosphates, and the like defined by Interna tional ZeoliteAssociation (IZA). I0130. Of the aluminophosphates, ALPO-5 is unsuitable for use as an adsorbent in the invention because it shows hydrophobic adsorption properties. For makingthis material suitableforuseasanadsorbentintheinvention, itispreferred to replace part ofthe aluminum and phosphorus with a het eroatom, e.g., silicon, lithium, magnesium, titanium, Zirco nium, Vanadium, chromium, manganese, iron, cobalt, nickel, palladium, copper, Zinc, gallium, germanium, arsenic, tin, calcium, or boron, in order to impart hydrophilicity. 0131 Preferred ofthose are Zeolites formed by replacing part of the aluminum and phosphorus with silicon, magne sium, titanium, Zirconium, iron, cobalt, Zinc, gallium, or boron. MostpreferredoftheseareZeolitesformedby replace ment with silicon; this kind ofZeolites are commonly called SAPO. The heteroatoms thus incorporated may be oftwo or more kinds. 0132 A preferred aluminophosphate among the Zeolites usable as adsorbents in the invention is a Zeolite which con tains aluminum, phosphorus, and a heteroatom in the frame work structure and in which the proportions of the atoms presentare representedby the followingexpressions (1), (2), and (3): O.OO1issO3 (1) Apr. 18, 2013 (wherein X represents the molarproportion oftheheteroatom intheframeworkstructuretotheSum ofaluminum,phospho rus, and the heteroatom in the framework structure); 0.3sysO.6 (2) (wherein y represents the molar proportion ofaluminum in theframeworkstructuretotheSum ofaluminum,phosphorus, and the heteroatom in the framework structure); 0.3szsO.6 (3) (wherein Z represents the molar proportion ofphosphorus in theframeworkstructuretotheSum ofaluminum,phosphorus, and the heteroatom in the framework structure). Among the proportions ofatoms present, the proportion of the heteroatom is preferably represented by the following expression (4): O.OO3sysO.25 (4) (wherein X is as defined above) and morepreferably representedby the followingexpression (5) O.OOSsysO2 (5) (wherein X is as defined above). 0.133 Preferred of the Zeolites containing aluminum, phosphorus, andaheteroatom in the frameworkstructureare ones in which the heteroatom is silicon atom and which give a Si-MAS-NMR spectruminwhichtheintegratedintensity areaforthesignalsatfrom-108ppmto-123 ppm isnotmore than 10%basedontheintegratedintensityareaforthesignals atfrom -70ppm to -123 ppm. That integrated intensity area ratio is more preferably 9.5% or less, especially preferably 9% or less. I0134) Furthermore, the Zeolitespreferablyareones which give a 'Si-MAS-NMR spectrum in which the integrated intensity area forthe signals at from -70 ppm to -92 ppm is notlessthan25%based ontheintegratedintensityareaforthe signals at from -70ppm to -123 ppm. That integrated inten sity area ratio is more preferably 50% or more. 0135). The Si-MAS-NMR spectra in the invention are ones obtained by a method in which a sample is stored in a water-containing desiccator at room temperature over a whole day and night to cause the sample to adsorb water to saturation and this sample is examined under the following conditions using tetramethylsilane as a reference material. 0.136. Apparatus: Chemagnetic CMX-400 0.137 Probe: 7.5 mm MAS Probe I0138 Resonance frequency: 79.445 MHz 0.139 Pulse duration: 5.0 microsecond 0140 Pulse series: single pulse 0141 Waiting time: 60 seconds 0.142 Revolution speed: 4,000 rps 0.143 A Si-MAS-NMR spectrum for a zeolite gives informationabout thecombined state ofsilicon in the Zeolite. From the positions and distribution ofpeaks, the combined state ofsilicon can be understood. 0144. Although a preferred zeolite in the invention con tainsaluminum,phosphorus,andsilicon, the silicon atoms in the zeolite are present as SiO, units. In a Si-MAS-NMR spectrum, the peakappearing at around -90 ppm is attribut able to silicon atoms each bonded, through oxygen atoms, to four atoms other than silicon atoms. In contrast, the peak appearingataround -110ppm is attributableto siliconatoms each bonded to four silicon atoms through oxygen atoms. Namely, when a Zeolitegives a spectrum in whichthepeakat

- 21. US 2013/009 1879 A1 around -110ppm has a high intensity, this means that silicon atoms have gathered together, i.e., the silicon atoms in the Zeolite are in a lowly dispersed state. 0145 Zeolites giving such a spectrum tend to satisfy the requirement concerning adsorption properties according to the invention. This may be because the dispersion ofsilicon influences the adsorption properties of the Zeolites and a Zeolite having high silicon dispersion exhibits performance especially suitable foradsorbents for adsorption heat pumps as will be described later. 0146. On the other hand, the Zeolite to be used as an adsorbent in the invention preferably is one having a frame work density offrom 10.0 T/1,000 A to 16.0 T/1,000 A. Morepreferred isa zeolitein which the framework density is intherangeoffrom 10.0T/1,000A to 15.0T/1,000A.The term framework density herein means the number offrame work-constituting elementsotherthan oxygenper 1,000 A ofthe Zeolite; this value is governed by the structure ofthe Zeolite. 0147 Framework density correlates to pore volume. In general, whentheframeworkdensityishigh,theporeVolume is Small and this tends to result in an insufficient adsorption amount and poor performance in use as an adsorbent for adsorption heat pumps. On the other hand, when the frame work density is low, the Volume ofpores capable ofadsorp tionislarge.Althoughthisadsorbenthasan increasedadsorp tion amount, it tends to have a reduced density and poor strength. 0148 Examples of Zeolite structures satisfying the requirement concerning framework density include AFG, MER, LIO, LOS, PHI, BOG, ERI, OFF, PAU, EAB, AFT, LEV, LTN, AEI, AFR, AFX, GIS, KFI, CHA, GME, THO, MEI, VFI, AFS, LTA, FAU, RHO, DFO, EMT, AFY, and *BEA in terms of the code defined by IZA. Preferred examples thereofinclude AEI, GIS, KFI, CHA, GME, VFI, AFS, LTA, FAU, RHO, EMT,AFY, and *BEA. Preferredare Zeolites having the structure CHA, AEI, or ERI. Especially preferred ofthese is the structure CHA. 014.9 Thestructureofazeoliteisdeterminedbyobtaining anXRDpatternthroughpowderXRD(powderX-raydiffrac tion) and comparing this pattern with XRD patterns given in Collection OfSimulated XRD Powder Patterns For Zeolites (1996, ELSEVIER). 0150. Furthermore, therelationship between structureand framework density is described in Atlas OfZeolite Structure Tipes (1996, ELSEVIER), IZA. Framework density can hence be determined from the structure. 0151. Forexample, the silicoaluminophosphate known as SAPO-34, which contains atoms ofelements including sili con incorporated in the Zeolite framework structure, can be used as an aluminophosphate of the CHA structure. Thus, desired adsorption performance can be imparted. 0152 Although the adsorbents in the invention preferably areZeolitescontainingaluminum,phosphorus,andaheteroa tom inthe frameworkstructure, the Zeolites may bealumino silicates as long as they have the adsorbent properties describedabove. Inthiscase,partofthesiliconandaluminum (or with respect to the aluminum, all ofit) in the framework may have been replaced with otheratoms, e.g., magnesium, titanium, Zirconium, Vanadium, chromium, manganese, iron, cobalt, Zinc, gallium, tin, or boron. In case where alumino silicates have too small a silicon/aluminum molar ratio, abruptadsorption occurs in a region oftoo low humidities as in thecaseofZeolite 13X. Incasewherethat ratiois too large, Apr. 18, 2013 the aluminosilicates are too hydrophobic to sufficiently adsorb water. Consequently, the Zeolite to be used in the invention has a silicon/aluminum molar ratio of generally from 4 to 20, preferably from 4.5 to 18, morepreferably from 5 to 16. 0153. The Zeolites described above include ones having cation species exchangeable with other cations. In this case, examplesofthecationspecies includeproton,alkalielements Suchas LiandNa,alkalineearth elementssuchasMgandCa, rareearth elements such as LaandCe,transition metals such as Fe, Co, and Ni, and the like. Preferred are proton, alkali elements, alkaline earth elements, and rare earth elements. More preferred are proton, Li, Na, K, Mg, and Ca. These Zeolites may be used alone or used in combination oftwo or more thereofor in combination with another material such as silica, alumina, active carbon, or clay. 0154 Theadsorbentsintheinventionhaveaporediameter ofpreferably3Aorlarger,especially3.1Aorlarger.Thepore diameterthereofispreferably10Aorsmaller,especially8A orsmaller,morepreferably7.5Aorsmaller.Incasewherethe pore diameterthereofis too large, there is the possibility that adsorption might not occurat desired relative humidities. In case where the pore diameter thereofis too small, molecules of water used as an adsorbate tend to less diffuse in the adsorbent. 0155 The adsorbents in the invention preferably have a heat ofadsorption of from 40 kJ/mol to 65 kJ/mol. This is becauseSusceptibilitytodesorptionalsoisan importantprop erty for adsorbents for adsorption heat pumps in which it is required that desorption occurs with a heatsource of100° C. or lower. Susceptibility to desorption is inversely propor tional to adsorption force. Consequently, the heat ofadsorp tion, which is an indexto the degree ofadsorption, desirably isclose to thelatentheat ofcondensation ofwater. Theheat of adsorption for the adsorbents, which is not lower than the latent heat ofcondensation ofwater, may be 40 kJ/mol or higher. In case where the heat of adsorption is too high, desorption with a heat source of100° C. or lowertends to be difficult. Consequently, a Zeolite having a heat ofadsorption not lowerthanthelatentheat ofcondensationofwaterandnot higher than 65 kJ/mol is preferred. In this description, a differentialheatofadsorption was determinedthroughsimul taneous measurements of adsorption amount and heat of adsorption (measuring temperature, 25°C.) by the method described in a document (Colloid Polym Sci, 277 (1999) pp. 83-88), and thedifferentialheatofadsorption forthe adsorp tion amount range of from 0.005 mol/g to 0.01 mol/g was taken as the heat ofadsorption. 0156 An especially preferred example ofthe adsorbents for use in the invention is SAPO 34, which is an SAPO (silicoaluminophosphate) in a CHA form (framework den sity=14.6T/1,000 A). 0157 Processes forproducingthe Zeolite in the invention are not particularly limited as long as the Zeolite has the properties described above. For example, the Zeolite can be produced in the following manner according to the method described in Japanese Patent Publication No. 37007/1992, Japanese Patent Publication No. 21844/1993, Japanese PatentPublication No. 51533/1993, U.S. Pat. No.4,440,871, etc. A method ofsynthesizing SAPO-34 is described in U.S. Pat. No. 4,440,871.

- 22. US 2013/009 1879 A1 0158. In particular, examples ofprocesses for producing the preferred Zeolite containing aluminum, phosphorus, and silicon atoms in the framework structure include the follow ing method. 0159 First, an aluminum source, silica source, phosphate Source, and template are mixed togetherto prepare an aque ous gel. 0160. As the aluminum source is used pseudoboehmite, aluminum isopropoxide, aluminum hydroxide, alumina Sol, Sodium aluminate, or the like. 0161. As the silica source is used fumed silica, silica sol, colloidal silica, waterglass, ethyl silicate, methyl silicate, or the like. 0162. As the phosphate source is used phosphoric acid. Aluminum phosphate also is usable. 0163 ASthetemplateis usedaquaternaryammonium salt Such as a tetramethylammonium, tetraethylammonium, tet rapropylammonium, or tetrabutylammonium, or a primary amine, secondary amine, tertiary amine, or polyamine. Such as morpholine, di-n-propylamine, tripropylamine, triethy lamine,triethanolamine, piperidine,cyclohexylamine,2-me thylpyridine, N,N-dimethylbenzylamine, N,N-diethyletha nolamine, dicyclohexylamine, N,N-dimethylethanolamine, choline, N,N'-dimethylpiperazine, 1,4-diazabicyclo(2.2.2) octane, N-methyldiethanolamine, N-methylethanolamine, N-methylpiperidine, 3-methylpiperidine, N-methylcyclo hexylamine, 3-methylpyridine,4-methylpyridine, quinuclid ine, N,N'-dimethyl-1,4-diazabicyclo(2.2.2)-octaneion, di-n- butylamine, neopentylamine, di-n-pentylamine, isopropylamine, t-butylamine,ethylenediamine, pyrrolidine, 2-imidazolidone, diisopropylethylamine, or dimethylcyclo hexylamine. 0164. Thesequenceofmixingan aluminum source, silica Source, phosphate source, and template varies depending on conditions. In general, however, a phosphate Source is first mixed with an aluminum Source,and the resultant mixture is mixedwithasilicaSourceandatemplate.Thecomposition of the aqueous gel is generally such that 0.02<SiO/POs.<20 and 0.02<SiO/Al2O30, preferably such that 0.04<SiO/ PO-10 and 0.04<SiO/Al2O310, in terms ofoxide molar ratio. The pH ofthe aqueous gel is from 5 to 10, preferably from 6 to 9. 0.165 Ingredients otherthan those shown above may suit ably coexistin theaqueousgel. Examplesofsuch ingredients includehydroxidesand salts ofalkali metalsoralkalineearth metals and hydrophilic organic solvents such as alcohols. 0166 The aqueous gel prepared is placed in a pressure vessel and held atagiven temperature, whilebeing stirred or allowedtostand,underthepressuregeneratedbythegelitself orunderagaspressure whichdoes notinhibit crystallization. Thus, hydrothermal synthesis is conducted. 0167 Conditions forthehydrothermalsynthesis includea temperature ofgenerally from 100° C. to 300° C., preferably from 120° C. to 250° C.Thereaction timeisgenerally from 5 hours to 30 days, preferably from 10 hours to 15 days. 0168 Afterthehydrothermal synthesis,thereactionprod uct is separated, washed with water, and dried. The organic matters contained therein are removedby burning oranother method to obtain a zeolite. 0169. In thecase where the Zeolite is processed for use as a water vapor adsorbent, care should be taken not to reduce the adsorption performance ofthe Zeolite. In general, how ever, an inorganic binder Such as alumina or silica is used to mold the Zeolite. Apr. 18, 2013 0170 Silica gel, mesoporous silica, alumina, active car bon, clay, or the like may be incorporated into the adsorbent besides the Zeolite according to the invention in order to impartdesiredwatervaporadsorptionpropertiestotheadsor bent. However, from the standpoint ofobtaining satisfactory adsorption propertiesat low relative vaporpressures,thepro portion oftheZeolite in theadsorbentaccordingto the inven tion is generally 60% by weightorhigher,preferably70% by weight or higher, more preferably 80% by weight orhigher. From the standpoint ofadsorption properties, it is most pre ferred to use the Zeolite alone as a water vapor adsorbent. 0171 For application to an adsorption heat pump or the like, the adsorbent is used after being processed by a known method so as to have a given strength, particle diameter, and shape according to the application. For example, the size of adsorbent particles Suitable foruse in adsorption heatpumps is about from 0.05 mm to 2 mm as disclosed in Japanese Patent Laid-Open No. 2001-38.188. In the case where the adsorbentisbondedtoan adsorption corewithan adhesiveas disclosed, in Japanese Patent Laid-Open No. 2000-18767, it is necessary thattheadsorbent particles have such a strength that they do not break when mixed with the adhesive and dispersed. <Method ofOperation> 0172 A method ofoperating an adsorption heat pump is explainedwithreferenceto FIG.1. Inthefirststep, thecontrol valves 31 and 34 are closed and the control valves 32 and 33 areopenedtotherebyoperatetheadsorptioncolumn 1 andthe adsorption column2intheregenerationmodeandtheadsorp tion mode, respectively. Furthermore, the switching valves 115, 116, 215,and 216are regulated to pass warm waterand cooling water through the heat medium pipe 11 and heat medium pipe 21, respectively. 0173 For example, in the case where the adsorption col umn2 istobecooled,coolingwaterwhichhasbeencooledby heatexchange with the outside air, river water, or the like by means ofa heat exchanger, e.g., a cooling column, is intro ducedthroughtheheat mediumpipe21 tocooltheadsorption column 2 usually to about 30 to 40° C. Furthermore, the control valve 32 is opened and, as a result, the water present in the vaporizer 4 vaporizes and the resultant water vapor flows into the adsorption column 2 and is adsorbed onto the adsorbent.The movementofwatervaporoccursbasedonthe differencebetweenthesaturation vaporpressureatthevapor ization temperature and the adsorption equilibrium pressure corresponding to the adsorbent temperature (generally from 20 to 50° C., preferably from 20 to 45° C., more preferably from 30 to 40° C.). As a result, cold, i.e., a cooling output, corresponding the heat of vaporization is obtained in the vaporizer 4. The adsorption-side relative vaporpressure (p2a is determined from the relationship between the temperature ofcooling water forthe adsorption column and thetempera tureofthecoldwateryieldedinthevaporizer(p2aisobtained by diving the equilibrium vaporpressure ofthe adsorbate at the temperature ofthe cold wateryielded in the vaporizerby the equilibrium vapor pressure ofthe adsorbate at the tem peratureofthecooling waterintheadsorption column). It is, however, preferred to operate so that (p2a is higher than the relative vapor pressures at which the adsorbent specified in the invention adsorbs a maximum amount of water vapor. This is because when (p2a is lower than the relative vapor pressures at which the adsorbent specified in the invention adsorbs a maximum amount ofwater vapor, then the adsorb

- 23. US 2013/009 1879 A1 ing ability of the adsorbent cannot be effectively utilized, resulting in an impaired operation efficiency. Although (p2a can be suitably selected according to the ambient tempera ture, etc., the adsorption heat pump is operated under Such temperature conditions that the adsorption amount at (p2a is generally 0.20orlarger, preferably 0.29 or larger, more pref erably 0.30 or larger. This adsorption amount is determined from an adsorption isotherm obtained at 25°C. 0.174. The adsorption column 1 in the regeneration mode is heated with warm water ofgenerally from 40 to 100° C. preferably from 50 to 98°C., morepreferably from 60 to 95° C., and comes to have an equilibrium vapor pressure corre sponding to the temperature range shown above. Condensa tion thus occurs atthe saturation vapor pressure at a conden sation temperature offrom 30 to 40°C. in the condenser 5 (this temperature is equal to the temperature ofthe cooling waterwith whichthecondenserisbeingcooled). Watervapor movesfrom theadsorption column 1 to thecondenser5and is condensed to water. The water is returned to the vaporizer 4 through the return piping 3. The desorption-side relative vapor pressure (p1a is determined from the relationship between the temperature ofcooling water for the condenser and the temperature ofwarm water (cp1 is obtainedby divid ing the equilibrium vapor pressure of the adsorbate at the temperature of the cooling water for the condenser by the equilibrium vapor pressure ofthe adsorbate at the tempera tureofthewarm water). Itis,however,preferredtooperate so that p1a is lower than the relative vaporpressers atwhich the adsorbentabruptlyadsorbs watervapor.Although (p1a canbe Suitably selected according to the ambient temperature, etc., theadsorption heatpump is operated underSuch temperature conditionsthattheadsorptionamountat(p1a isgenerally0.06 or smaller, preferably 0.05 or smaller. Incidentally, the adsorption heat pump is operated so that the difference between the adsorbate adsorption amount at (p1a and the adsorbate adsorption amount at (p2a is generally 0.18 g/g or larger,preferably 0.20g/gorlarger, morepreferably 0.25 g/g, orlarger. The first step is conducted in the mannerdescribed above. 0.175. Inthesubsequentstepasthesecond step,thecontrol valves 31 to 34 and the switching valves 115, 116, 215, and 216areSwitchedsoasto operatetheadsorptioncolumn 1 and the adsorption column 2 in the adsorption mode and the regeneration mode,respectively, whereby cold, i.e.,acooling output, can be obtained from the vaporizer4. By alternately conducting the first and second steps described above, the adsorption heat pump is continuously operated. 0176 An operation method was explained above with respect to an adsorption heat pump having two adsorption columns. However, any desired number of adsorption col umns may be disposed as long as any ofthe adsorption col umns can be made to retain the state of being capable of adsorbing the adsorbate by suitably desorbing the adsorbate adsorbed on the adsorbent. 0177 Adsorption heatpumps utilizeasa driving forcethe ability ofan adsorbent to adsorb and release an adsorbate. Although water, ethanol, acetone,and the like can beused as the adsorbate in, adsorption heat pumps, water is most pre ferred from the standpoints of safety, cost, and the large quantity oflatent head ofvaporization. 0.178 Theadsorptionheatpumps ofthe invention employ an adsorbentcapableofundergoinga large changein adsorp tion amount with a change in relative vapor pressure in a narrow range. The adsorption heat pumps arehence Suitable Apr. 18, 2013 for use in applications where apparatus size reduction is requiredandadsorbentpackingamountsarelimited. Suchas, e.g., air conditioning systems for vehicles. EXAMPLES (0179 The invention will be explained below in detail by reference to Examples, but the invention should not be con StruedasbeinglimitedbythefollowingExamples inanyway. 0180. In the following Examples, water vaporadsorption isotherms at 25°C. were obtained by examining the adsor bents forwater vaporadsorption properties underthe follow ing conditions. 0181 Adsorption isotherm analyzer: (manufactured by Bel Japan Inc.) Belsorb 18 0182 Temperature of high-temperature air chamber: 500 C. 0183) Adsorption temperature: 25°C. 0.184 Initial pressure introduced: 3.0Torr 0185. Numberofpoints forsettingpressureintroduced: O 0186 Saturated vapor pressure: 23.76 mmHg 0187 Equilibrium time: 500 sec 0188 Pretreatment: 300° C. 5-hour evacuation 0189 Ameasurementfordeterminingthedifferential heat ofadsorption was made under the following conditions. 0.190 Measuringapparatus:calorimeterandadsorption amount-measuring apparatus (manufactured by Tokyo Riko) 0191 Temperature ofmeasurement part: 25°C. 0.192 Temperature ofthermostatic chamber for vapor introduction: 30° C. Example 1 0193 A water vapor adsorption isotherm (25° C.) for SAPO-34(manufacturedbyUOP LLC) is shown in FIG.1. It can be seen from FIG. 1 that the adsorbent abruptly adsorbs water vaporat relative vaporpressures offrom 0.07 to 0.10, andthatthechange in adsorptionamountintherelative vapor pressure range offrom 0.05 to 0.20 is 0.25 g/g. (0194 SAPO-34 is a CHA-form silicoaluminophosphate: the CHA form has a framework density of 14.6 T/1,000 A3 anda pore diameterof3.8 A. (0195 A Si-MAS-NMR chart for SAPO-34 (manufac tured by UOP LLC) is shown in FIG. 3. The spectral chart shows thattheintegratedintensityareaforthesignalsat from -108 ppm to -123 ppm and the integrated intensity area for the signals at from -70 ppm to -92 ppm were 0.6% and 85.9%, respectively, basedon theintegratedintensity area for the signals at from -70 ppm to -123 ppm. Furthermore, the heat ofadsorption was found to be 58.6 kJ/mol. Example 2 0196. A CHA-form silicoaluminophosphate was pro duced in the following manner according to the method described in Japanese Patent Publication No. 37007/1992. (0197) To 18gofwaterweregraduallyadded 15.4gof85% phosphoric acid and 9.2 g of pseudoboehmite (containing 25% water; manufacturedby Condea). The resultant mixture was stirred.Tengramsofwaterwas furtheraddedtheretoand this mixturewasstirredfor 1 hour.This liquid is referredtoas liquidA. Separately from liquidA, a liquid was prepared by mixing4.1 goffumedsilica (Aerosil200), 11.6 gofmorpho

- 24. US 2013/009 1879 A1 line, and 15 g ofwater. This liquid was gradually added to liquidA. Thereto was further added 24 g ofwater. This mix ture was stirred for 3 hours. 0198 The mixture obtained was introduced into a 200-cc stainless-steel autoclave containing a Teflon inner cylinder, and reactedby beingallowed tostandat200° C. for24hours. After the reaction, the reaction mixture was cooled and the Supernatant was removed by decantation to recover the pre cipitate. The precipitate obtained was washed with water three times, Subsequently taken out by filtration, and driedat 120° C. This precipitate was burnedat 550° C. for6 hours in an air stream to obtain a Zeolite. (0199 Analysis by powderXRD revealed that this zeolite was a CHA-form (framework density=14.6T/1,000A)sili coaluminophosphate. The framework density was deter mined from the structure by reference to Atlas ofZeolite Structure Tipes (1996, ELSEVIER), IZA. A sample wasdis Solvedin anaqueous hydrochloric acid solution with heating and this solution was subjected to ICP analysis. As a result, the proportions (molar proportions) ofthe aluminum, phos phorus, and silicon in the framework structure to the sum of these componentswerefoundtobeas follows: theproportion ofsilicon was 0.13, that ofaluminum was 0.49, and that of phosphorus was 0.38. 0200. An adsorption isotherm at 25°C. for this zeolite is shown in FIG. 4. It can be seen from FIG. 4 that this zeolite abruptly adsorbs water vapor at relative vapor pressures of from0.07to0.10,andthatthechangeinadsorptionamountin the relative vaporpressure range offrom 0.05 to 0.20 is 0.25 g/g. 0201 A Si-MAS-NMR spectral chart forthis zeolite is shown in FIG. 5. In this 'Si-NMR spectrum, the integrated intensity area for the signals at from -108 ppm to -123 ppm and the integrated intensity area for the signals at from -70 ppmto-92ppm were9.2%and 52.6%, respectively,basedon theintegratedintensityareaforthesignalsatfrom -70ppmto -123 ppm. Example 3 0202) To 128 g of water was added 72 g of aluminum isopropoxide. After the mixture was stirred, 38.76 g of85% phosphoric acid was added thereto and this mixture was stirred for 1 hour. To this solution was added 1.2 g offumed silica (Aerosil 200), followed by 89.3 g of 35% aqueous tetraethylammonium hydroxide (TEACH). The resultant mixture was stirred for3 hours. This mixture was introduced into a 500-cc stainless-steel autoclave containing a Teflon inner cylinder, and reacted at 185° C. for 60 hours with stirring at 100 rpm. After the reaction, the reaction mixture was cooledandthereaction product was separatedby centri fuging, washedwith water, and driedat 120°C. This reaction product was burned at 550° C. for 6 hours in an airstream to obtain a zeolite. 0203 Analysis by powder XRD revealed that this zeolite was a CHA-form silicoaluminophosphate (framework den sity=14.6T/1,000A).Asamplewasdissolvedinanaqueous hydrochloricacid solution withheatingand this solution was subjected to ICPanalysis.As a result, theproportions (molar proportions) ofthealuminum,phosphorus,and silicon in the framework structure to the Sum of these components were foundtobeasfollows: theproportionofsiliconwas 0.03, that ofaluminum was 0.50, and that ofphosphorus was 0.47. 0204 An adsorption isotherm at 25°C. for this zeolite is shown in FIG. 6. It can be seen from FIG. 6 that this zeolite Apr. 18, 2013 shows an adsorption isotherm similar to that ofthe Zeolite of Example2. Namely,this zeoliteabruptlyadsorbs watervapor at relative vapor pressures of from 0.07 to 0.10, and the change in adsorption amount in the relative vapor pressure range offrom 0.05 to 0.20 is 0.23 g/g. (0205 The heat ofadsorption was 58.2 kJ/mol. Example 4 (0206 SAPO-34 (manufactured by UOP LLC) was exam inedwithanadsorptionisothermanalyzer(Belsorb 18,manu facturedby BelJapan Inc.). In FIG. 7is shown an adsorption processwatervaporadsorption isothermat40°C. forSAPO 34. The examination for adsorption isotherm was conducted underthe conditions ofa high-temperatureair chambertem perature of50° C., adsorption temperature of40°C., initial pressure introduced of3.0Torr, number ofpoints for setting pressure introduced of 0, saturated vapor pressure of55.33 mmHg, and equilibrium time of500 seconds. 0207. On theotherhand, a desorption-process adsorption isotherm was obtained withagravimetric-methodadsorption amount analyzer including a magnetic levitation balance (manufactured by Bel Japan Inc.) and, connected thereto, a vapor introduction part comprising a gas generation part, pressure measurement part, and gas discharge part which were disposed in a thermostatic air chamber. In obtaining a desorption-processadsorptionisotherm,watervaporwas dis charged 50Torrby 50Torrata high-temperatureairchamber temperatureof120°C.andadesorptiontemperatureof90°C. to determine the weight changes. The results are shown in FIG. 7. 0208. Ontheassumptionthattheadsorbentisappliedtoan automotive air conditioning system for general motor vehicles, the conditions may includeT1=90° C., T2=40°C., and T0=10°C. It can be seen that under such conditions, the desorption-siderelative vaporpressure(p1 andtheadsorption siderelative vaporpressure(p2are0.11 and0.17, respectively, andthedifferenceinadsorptionamountbetween(p1 and p2is 0.21 g/g. This value is higher than the target adsorption amount difference of0.15 g/g. It can hence be seen that the automotive air conditioning system Sufficiently functions in general motor vehicles. 0209. WhenT1=90°C.,T2=40°C.,andT0=5°C., thenthe differencein adsorption amount between (p1=0.11 and (p2=0. 12 is 0.20g/g. This value is higherthan thetargetadsorption amountdifferenceof0.15g/g. Itcanhencebeseenthattheair conditioning system Sufficiently functions. 0210. Furthermore, it is presumed that in some regions, the cooling water temperatureT2 increases to around 45° C. due to severe ambient conditions. Conditions for obtaining T0=10° C. when T1=90° C. in this case are investigated. Belsorb was usedto obtain an adsorption-processadsorption isotherm at45°C. This isotherm is shown in FIG. 8 together with a desorption-process adsorption isotherm at 90°C. The examination for obtaining the adsorption isotherm at 45° C. was conductedundertheconditions ofahigh-temperatureair chamber temperature of 65° C., adsorption temperature of 45° C., initial pressure introduced of 3.0 Torr, number of points for setting pressure introduced of 0, Saturated vapor pressure of55.33 mmHg, and equilibrium time of500 sec onds. In the case where T1=90° C., T2=45° C., and T0=10° C., then the desorption-side relative humidity (p1 is 0.14. which is higherthan theadsorption-side relativehumidity (p2 of0.13.