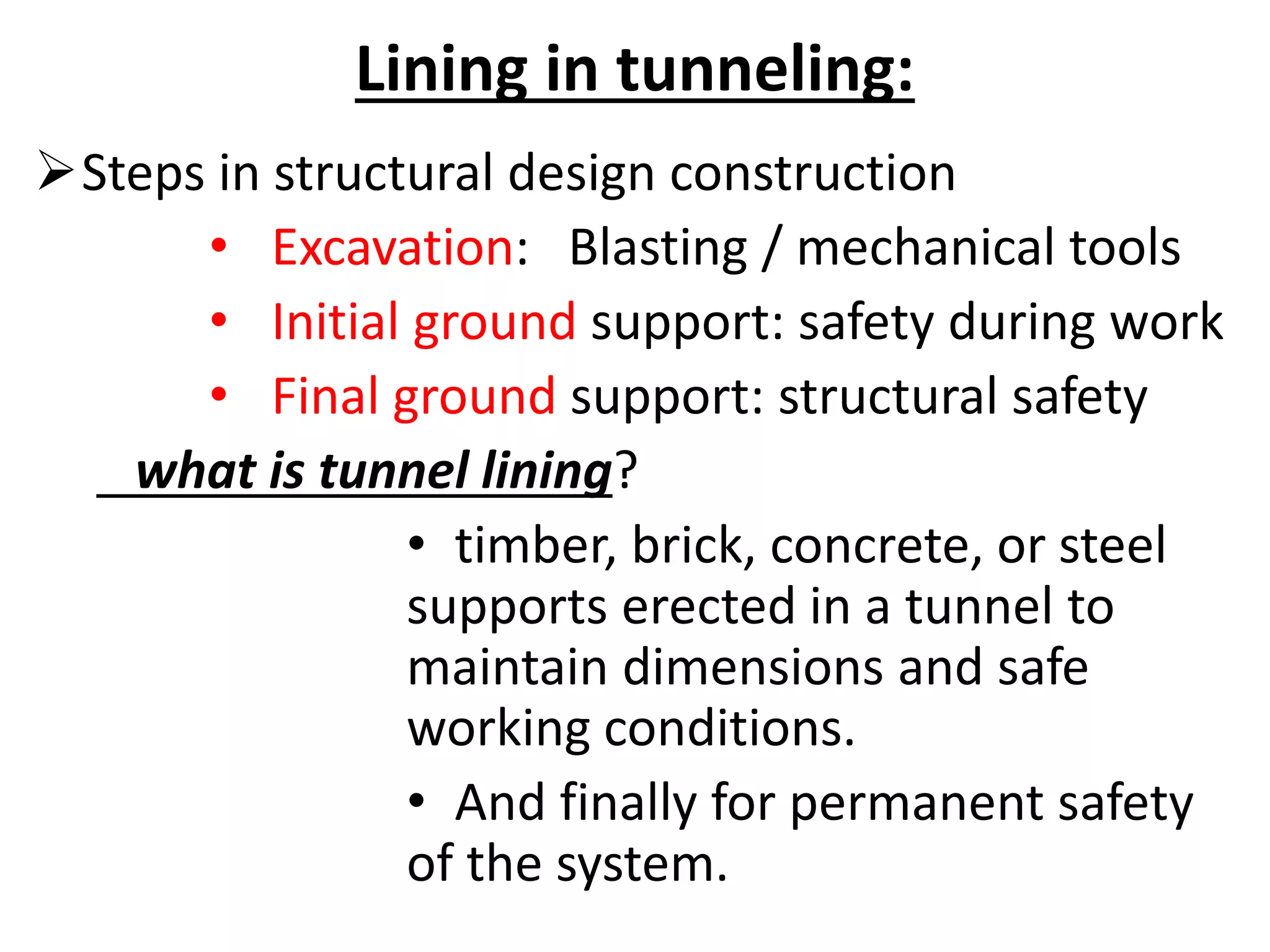

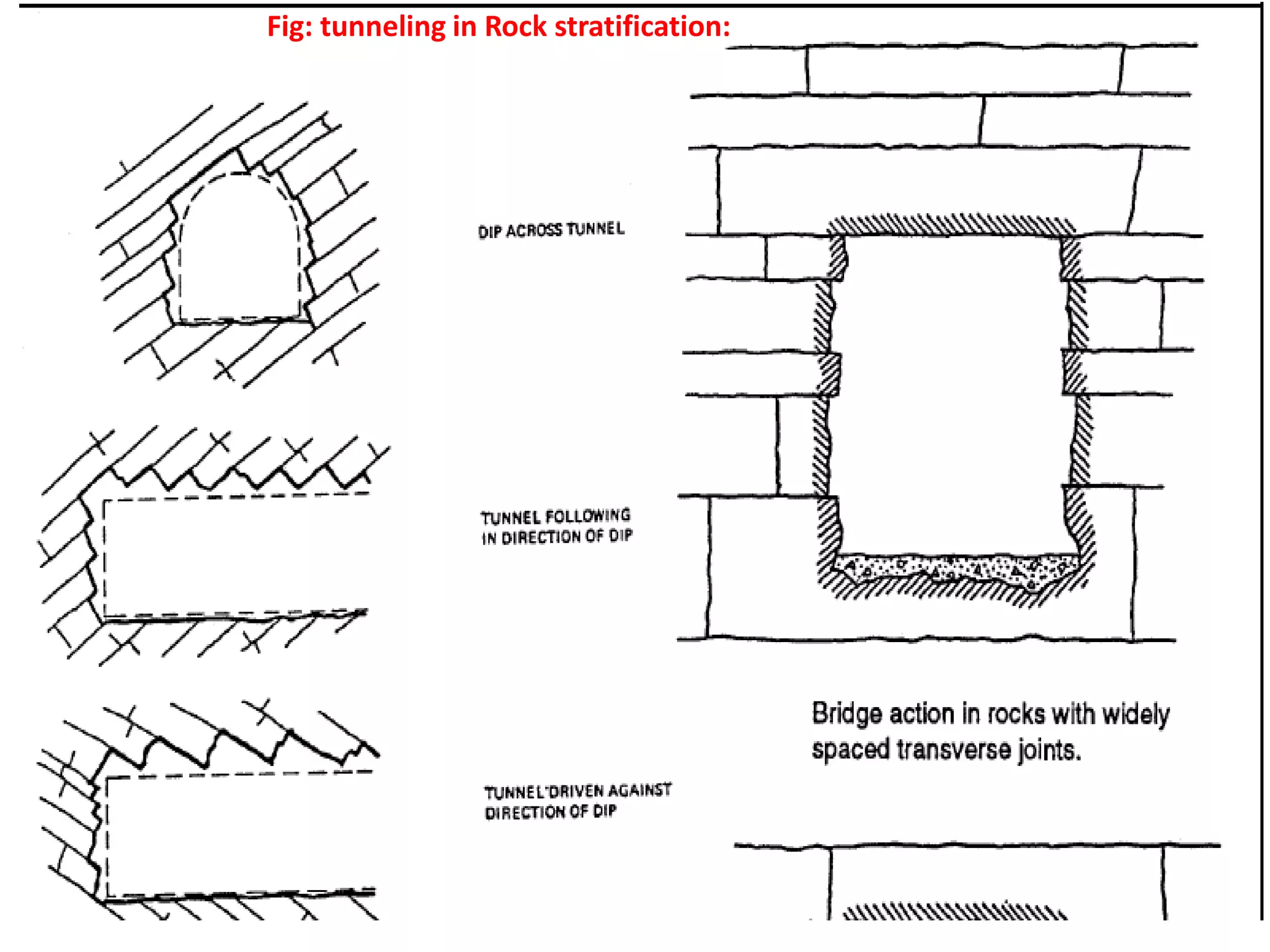

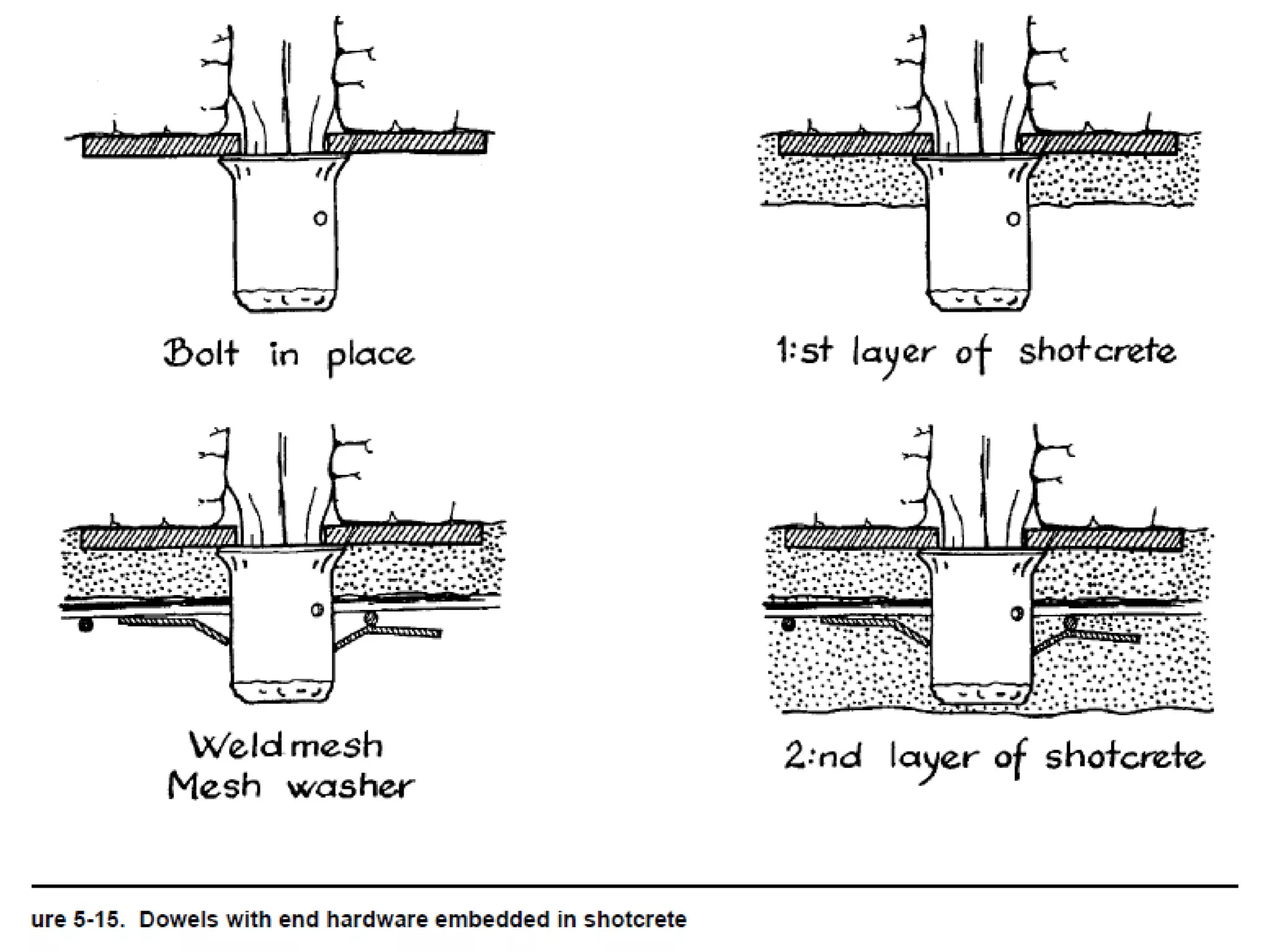

The document outlines the structural design of tunnel linings, discussing team roles, fundamental design approaches, and modes of failure. It covers types of linings, initial and final support designs, and various methodologies for selecting materials and reinforcing structures. Conclusively, it emphasizes the importance of safety, stability, and functionality in tunnel lining design, along with considerations regarding rock interaction and structural integrity.