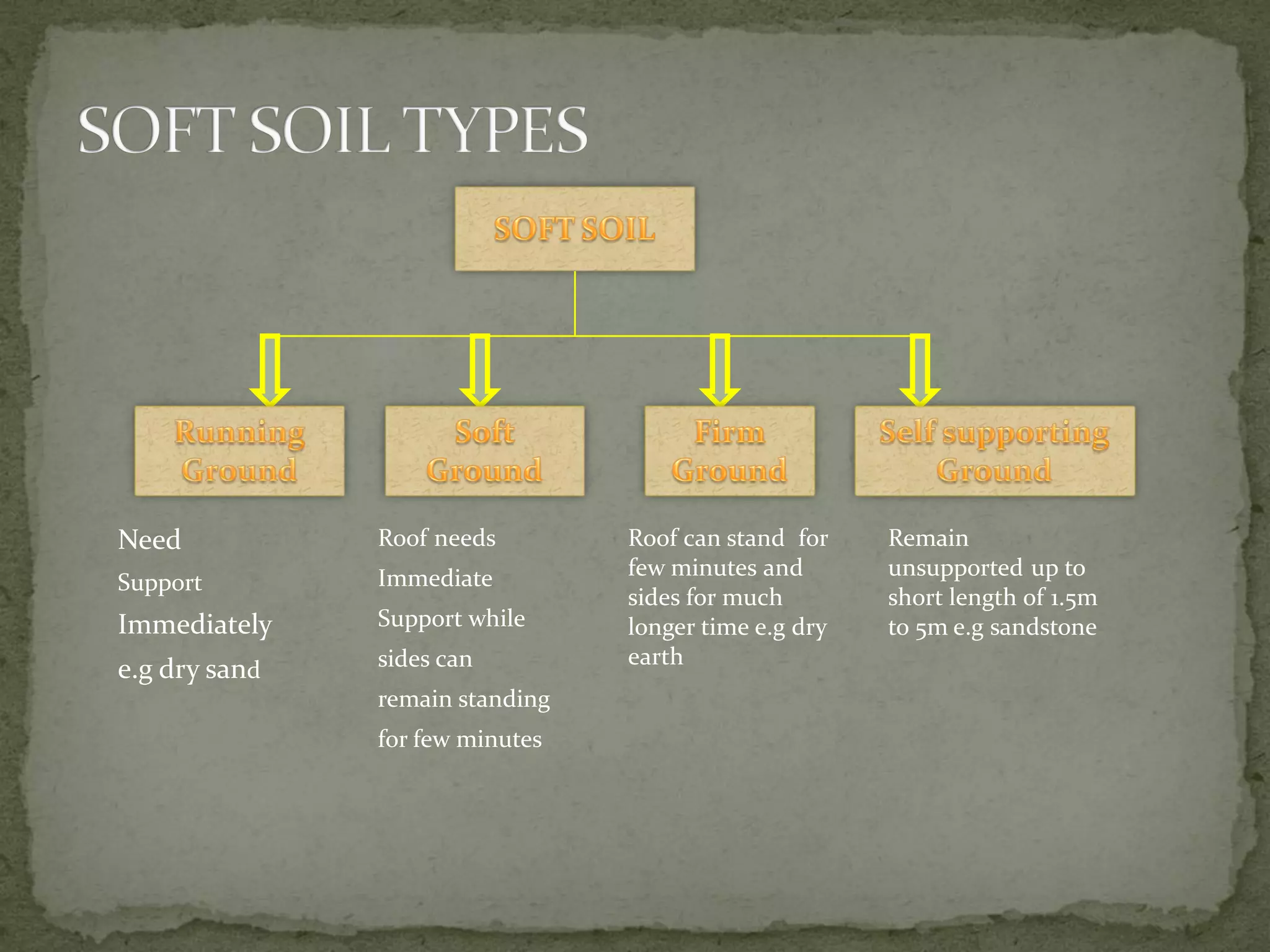

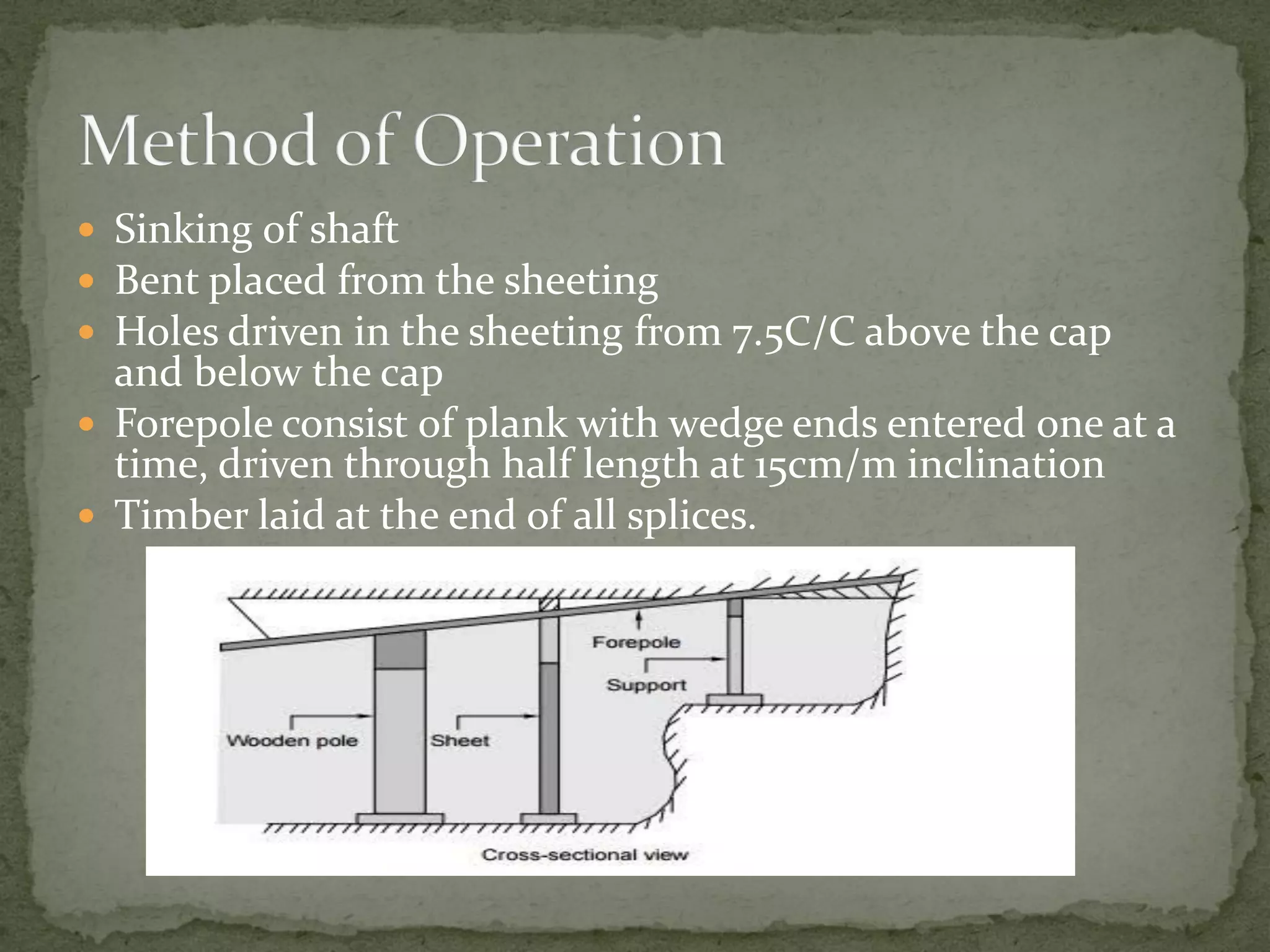

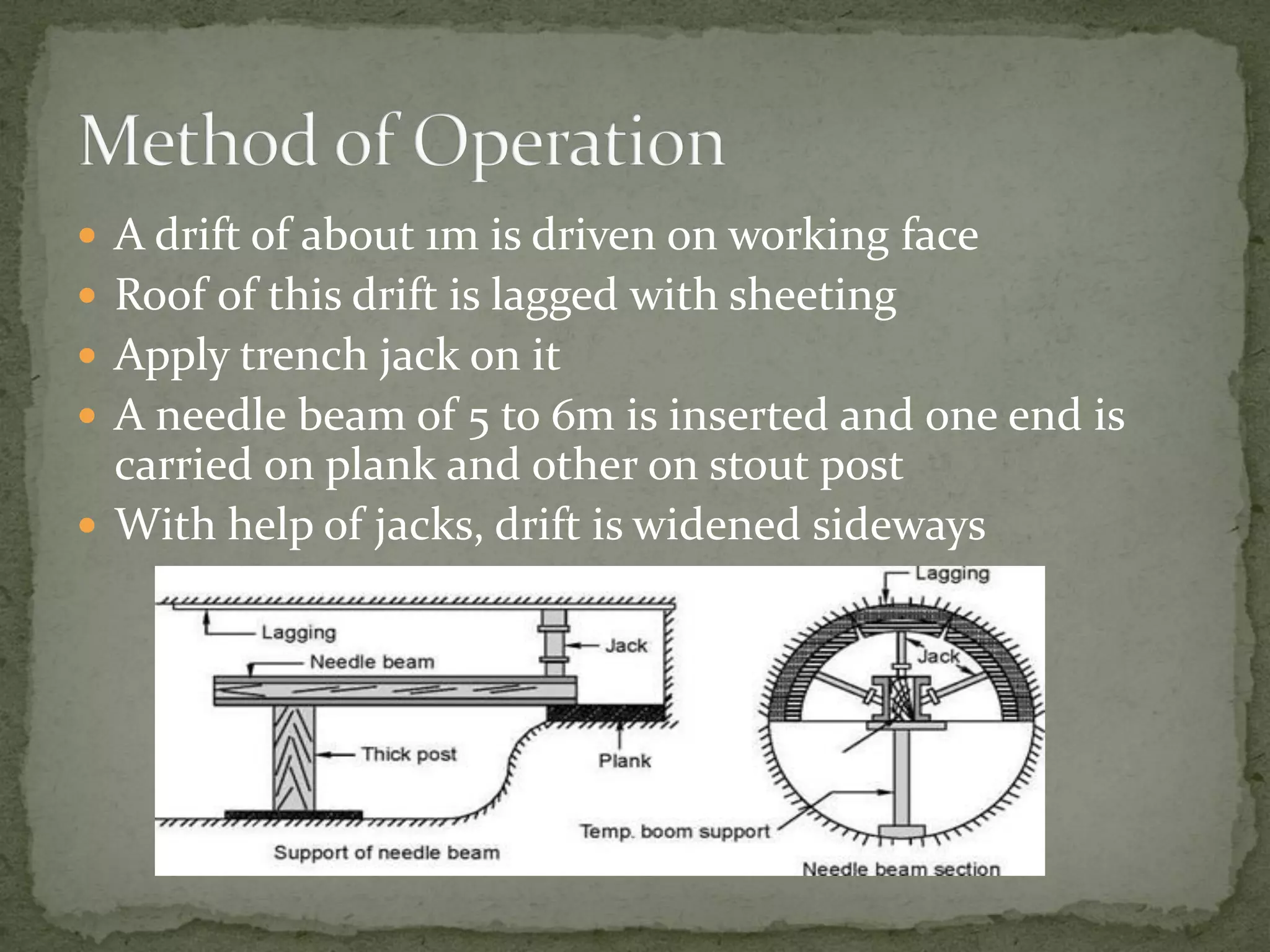

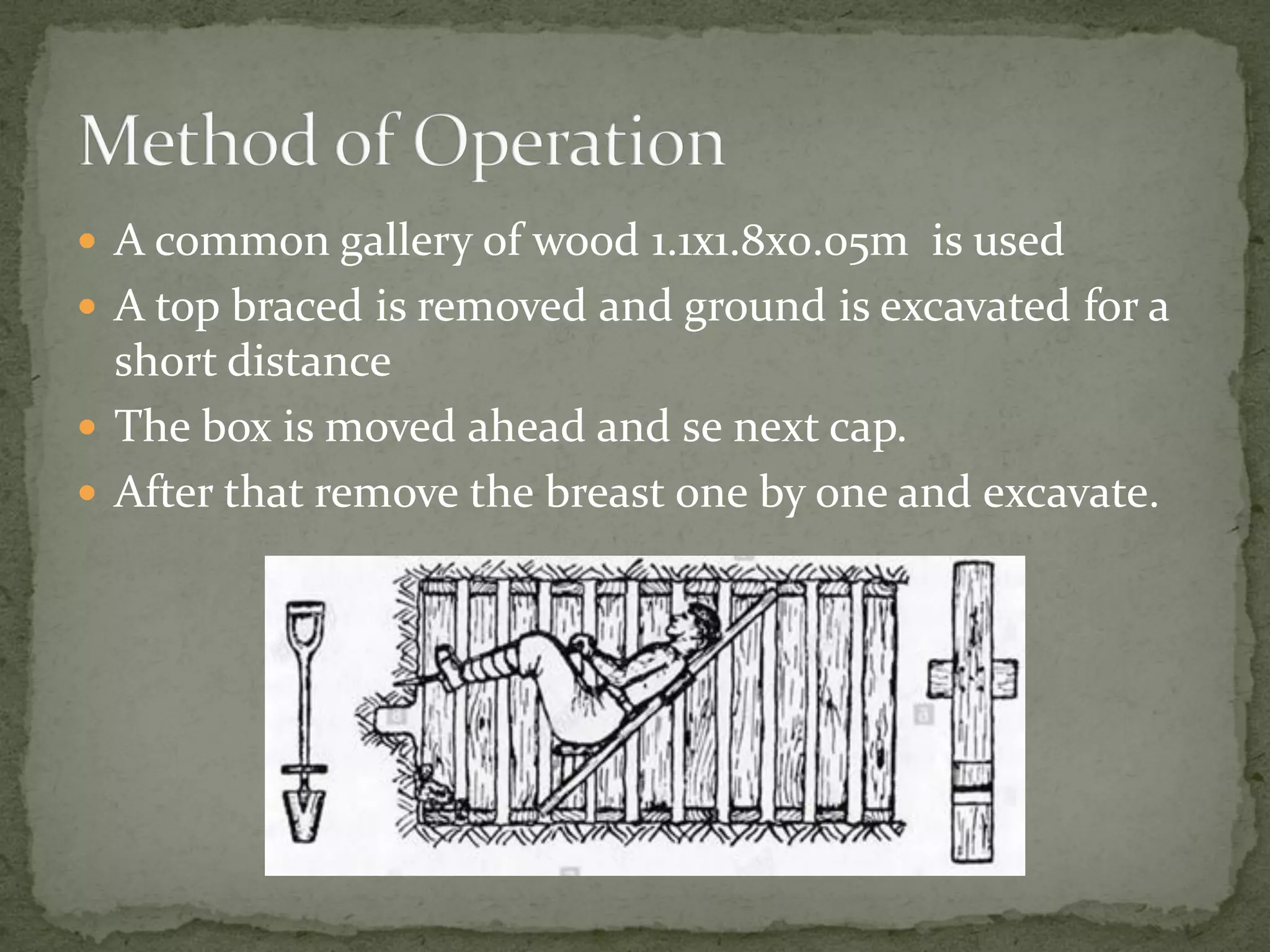

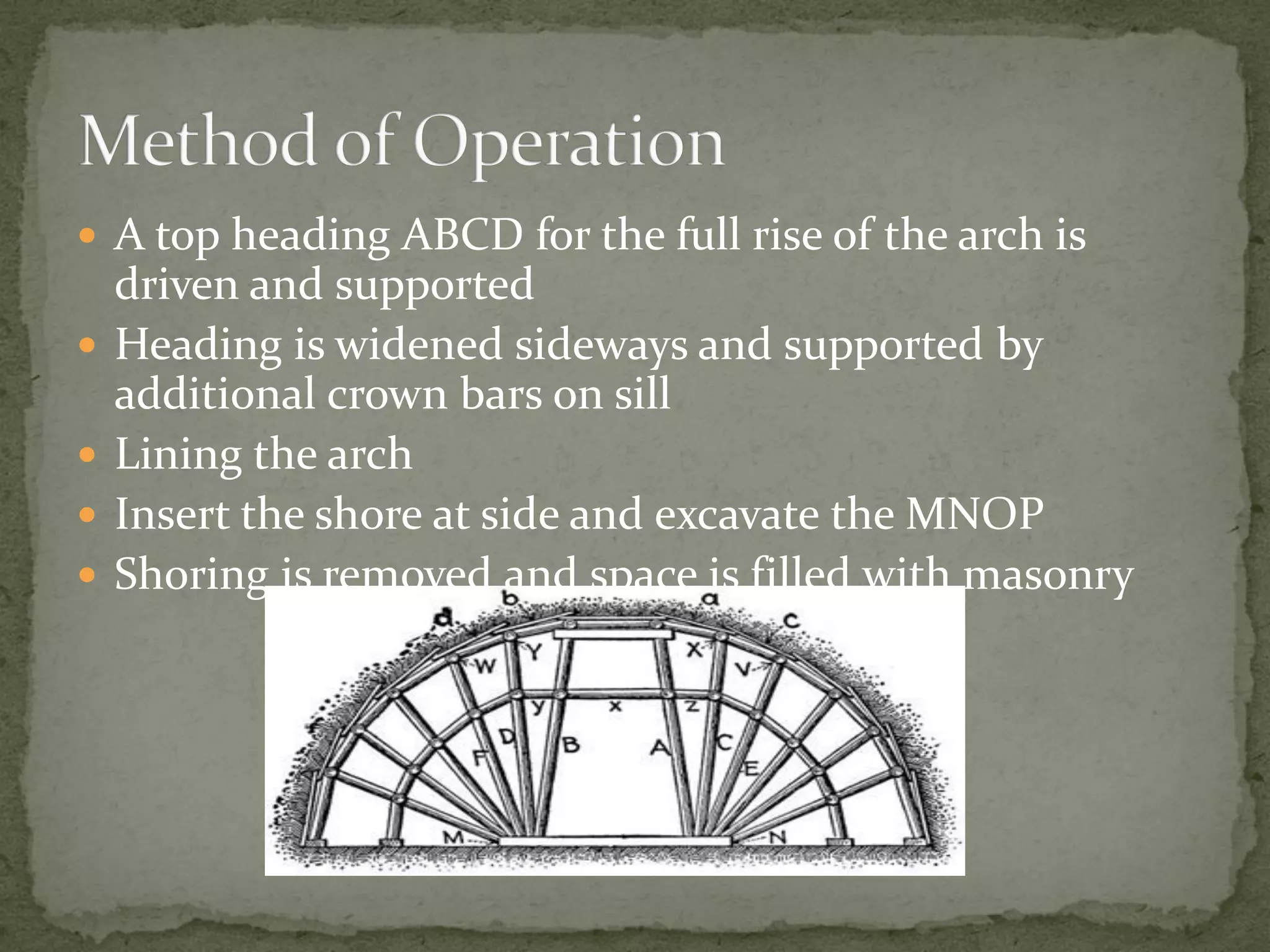

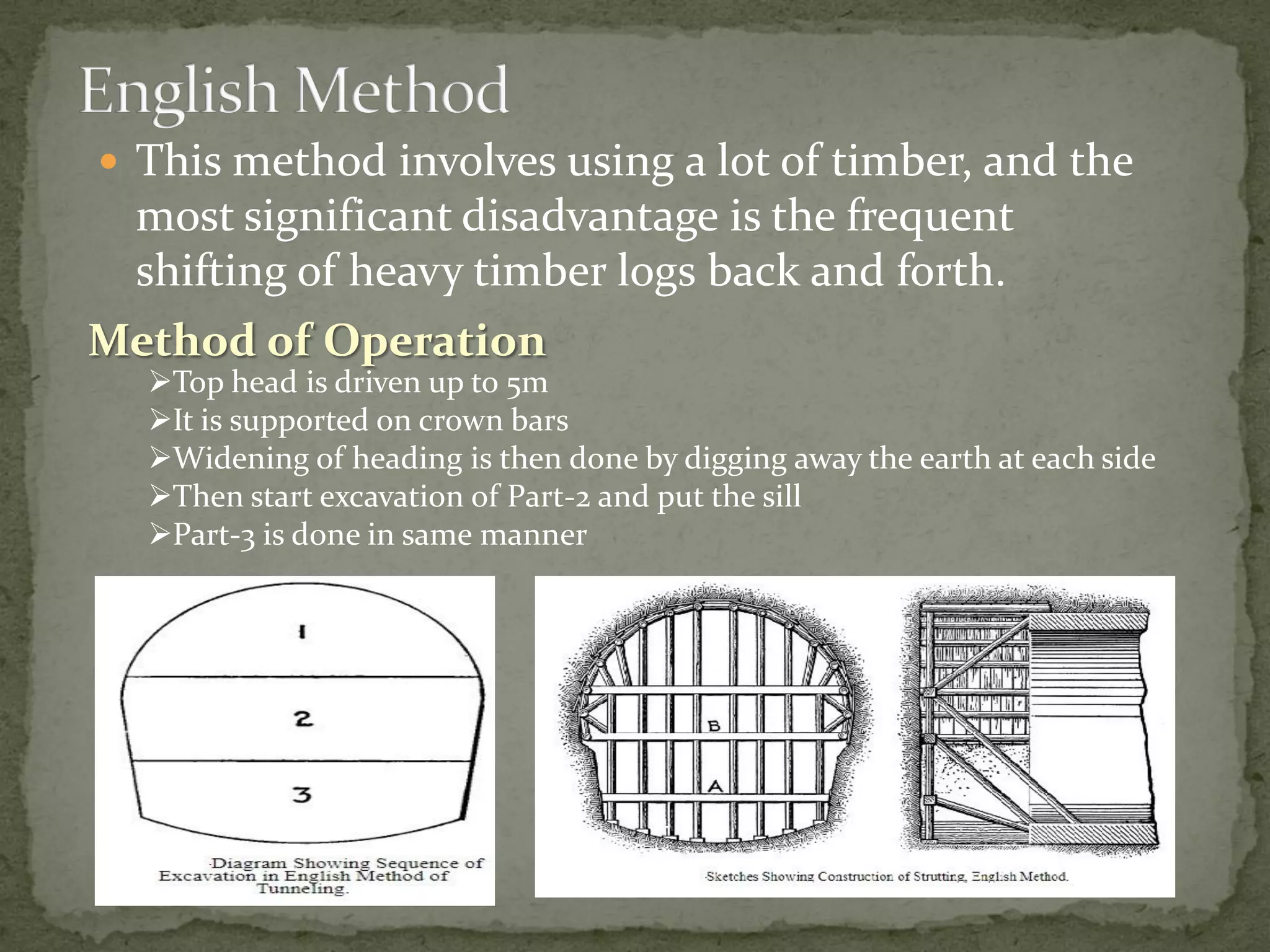

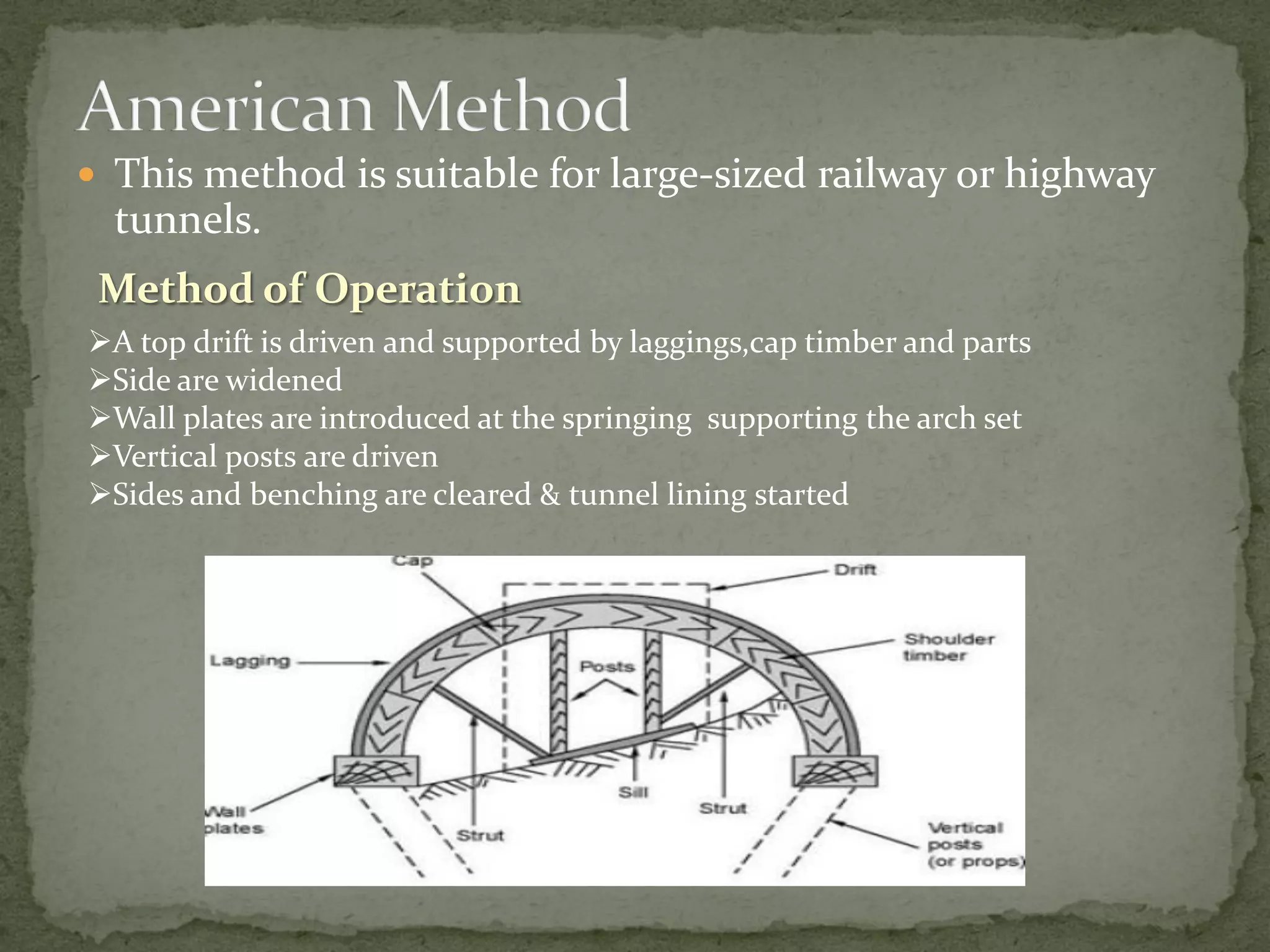

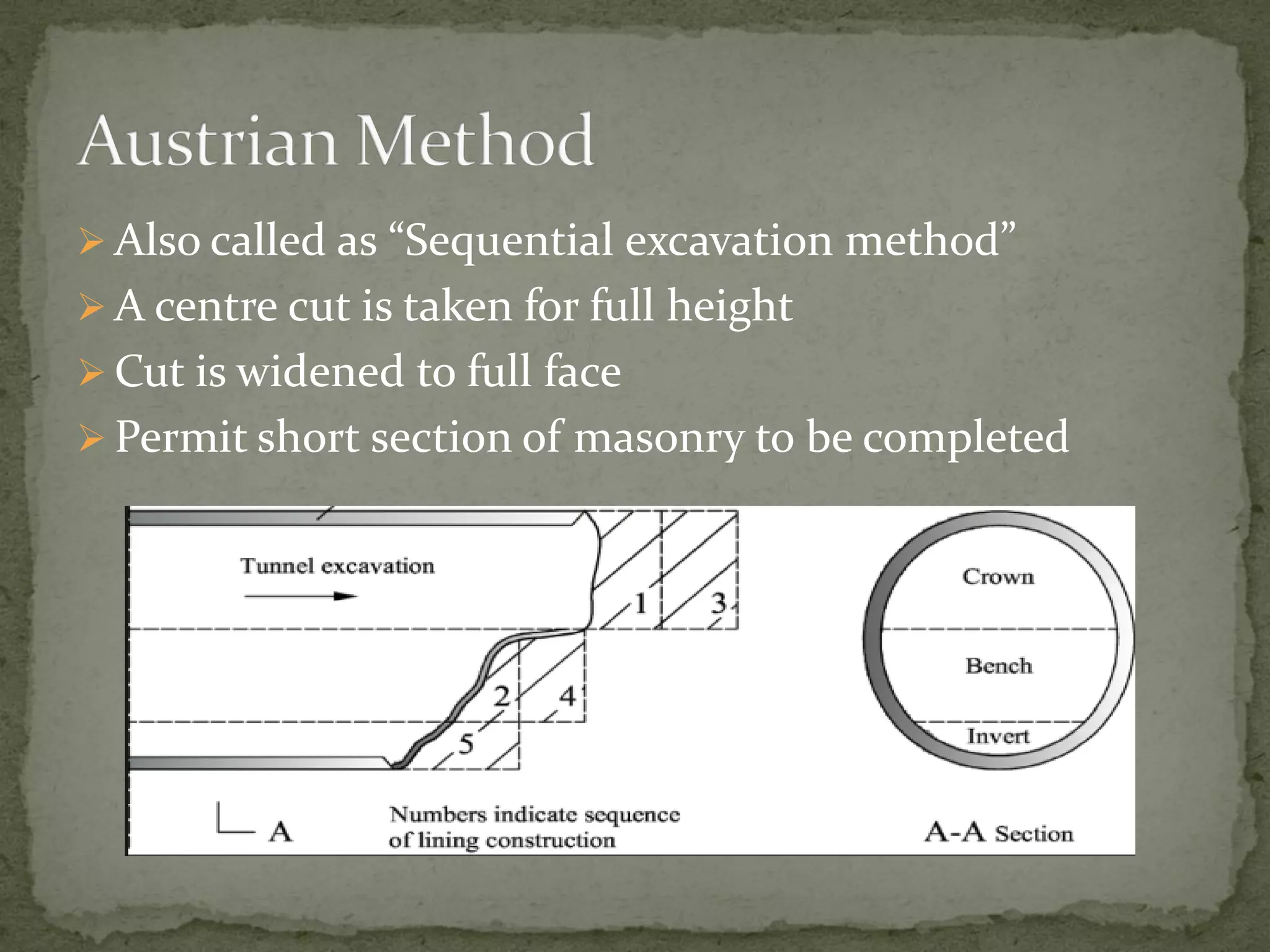

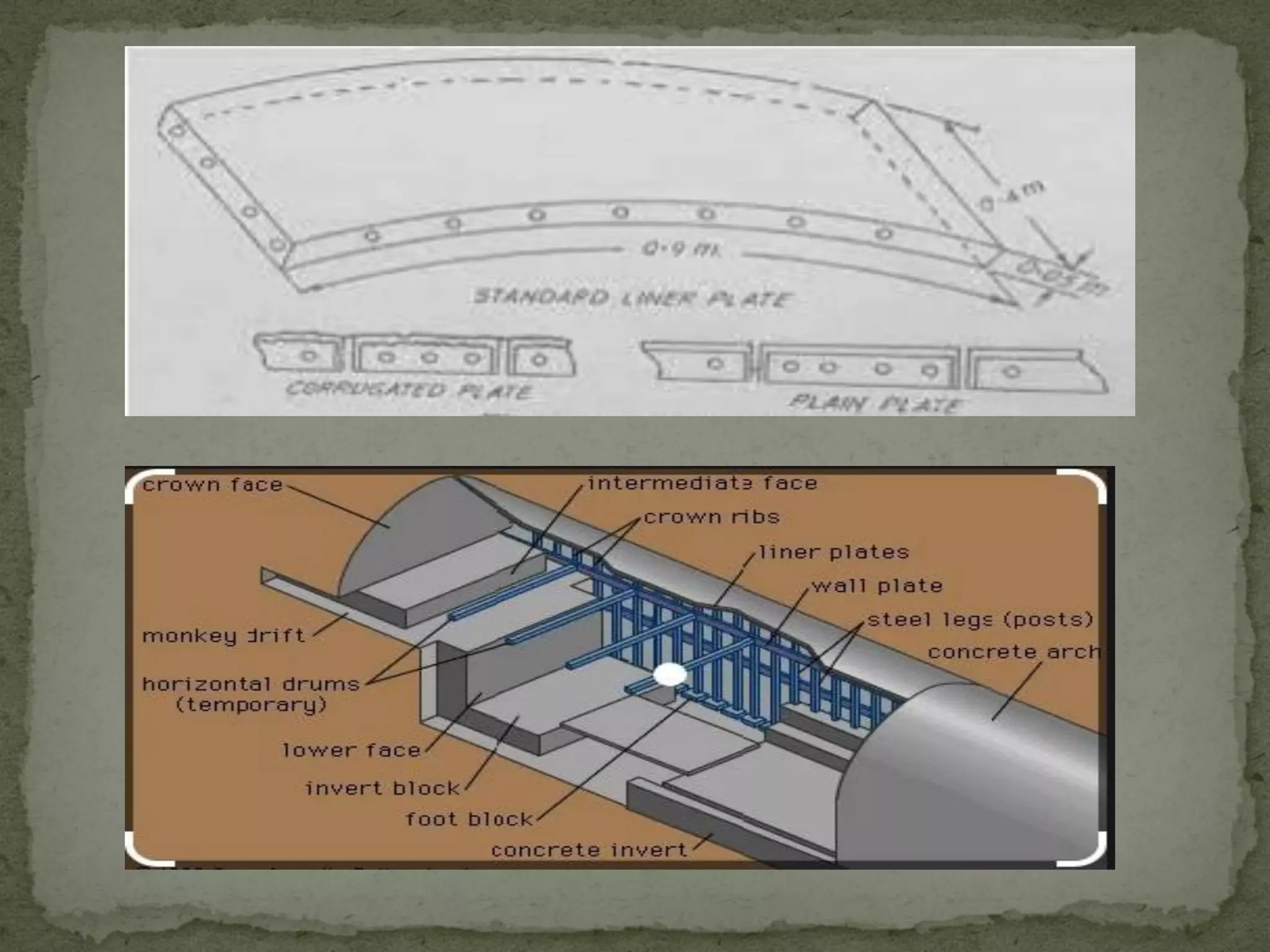

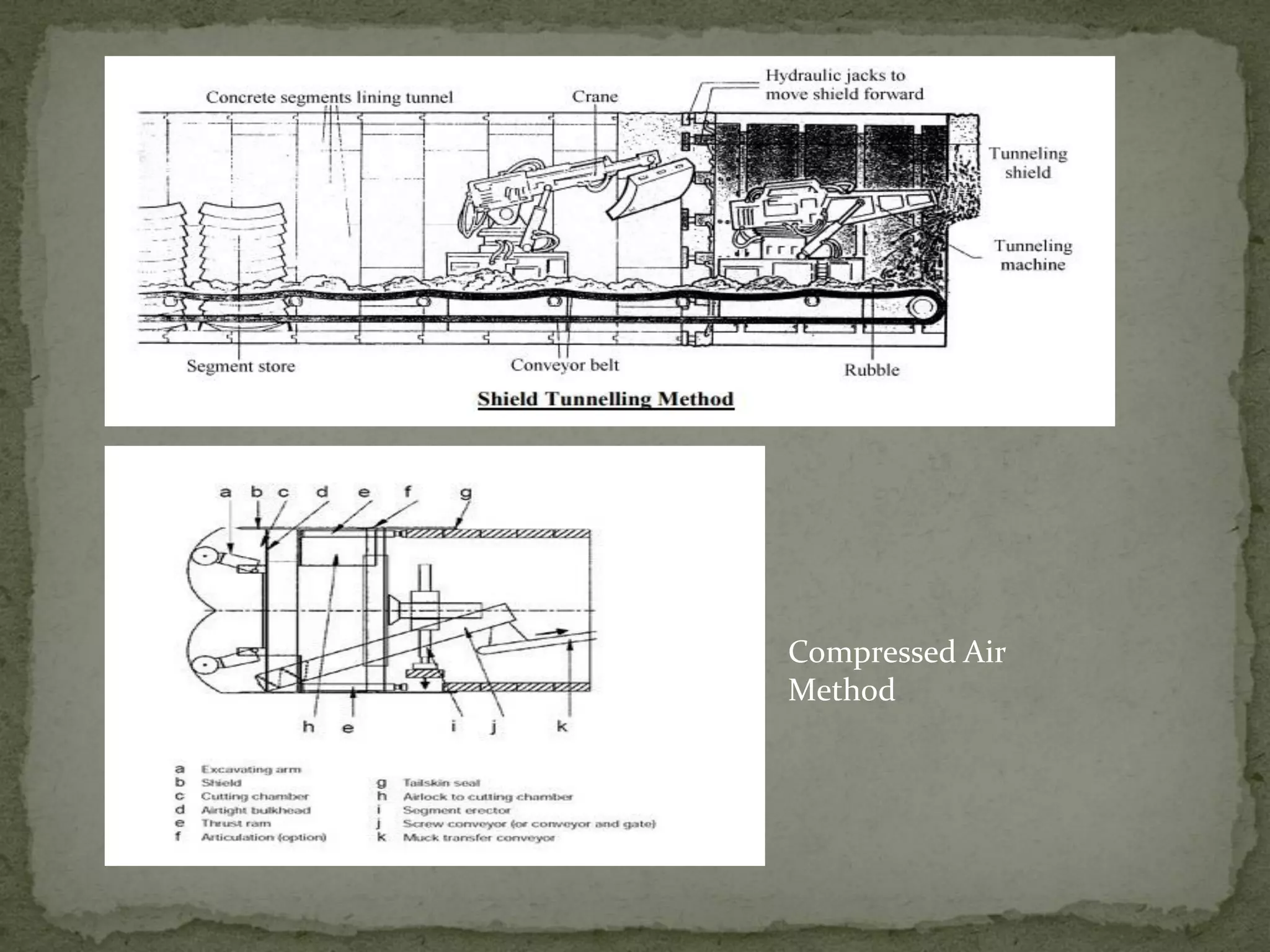

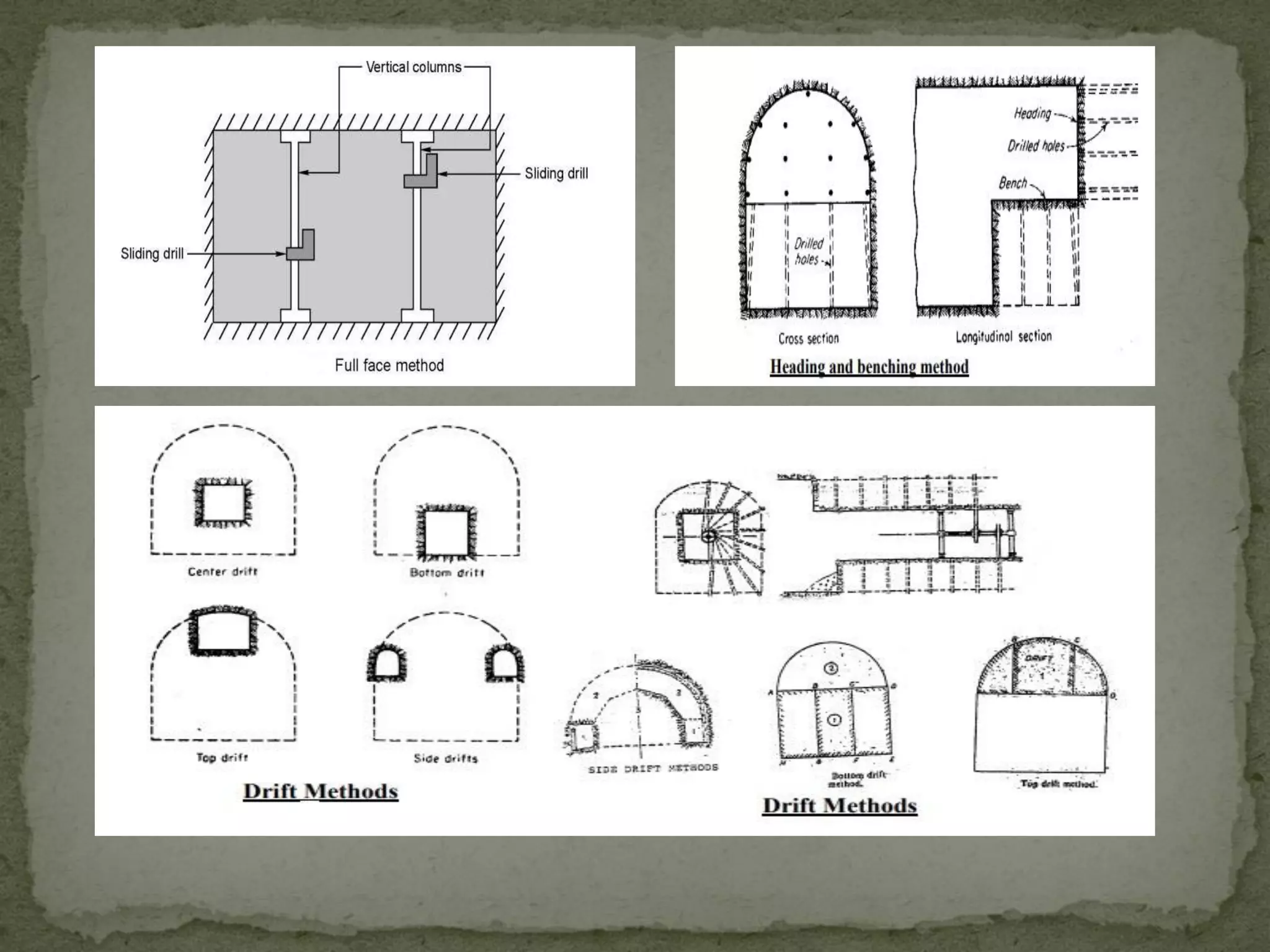

This document discusses various tunneling methods for soft and hard soils. It describes 9 different methods for tunneling in soft soils that require support, including the forepoling, needle beam, army, Belgian, English, American, Austrian, German, and Italian methods. It also discusses 3 main methods for tunneling in hard rocks or self-supporting soils: the linear plate method, shield method, and compressed air method. Each method is briefly described in 1-3 sentences. The document then provides more detailed explanations of the forepoling, needle beam, army, Belgian, English, and Italian methods.