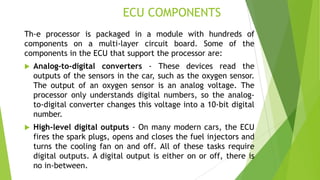

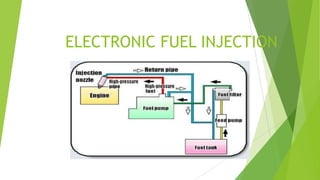

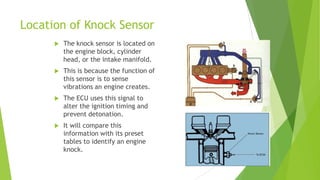

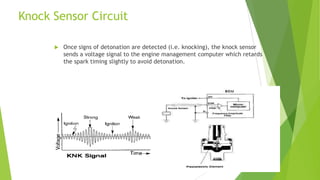

The document discusses control systems in automobiles, specifically focusing on electronic control units (ECUs) and knock sensors. It provides details on how ECUs act as the "brain" of a vehicle by collecting sensor data to control engine functions like fuel injection and spark timing. Knock sensors detect engine knocking through vibrations and send signals to the ECU to optimize ignition timing and prevent damage. Microcontrollers play an important role in both ECUs and knock sensors to process signals and precisely manage engine performance and emissions.