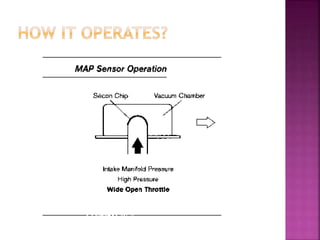

The MAP sensor monitors intake manifold pressure to help the engine control module regulate fuel injection for optimal engine performance and emissions. It detects changes in manifold pressure caused by throttle position and transmits pressure readings electronically to allow for real-time fuel mixture adjustments by the ECM. Proper MAP sensor function is important for fuel efficiency, power, and emissions as incorrect readings can cause over-fueling, under-fueling, or unstable engine operation.