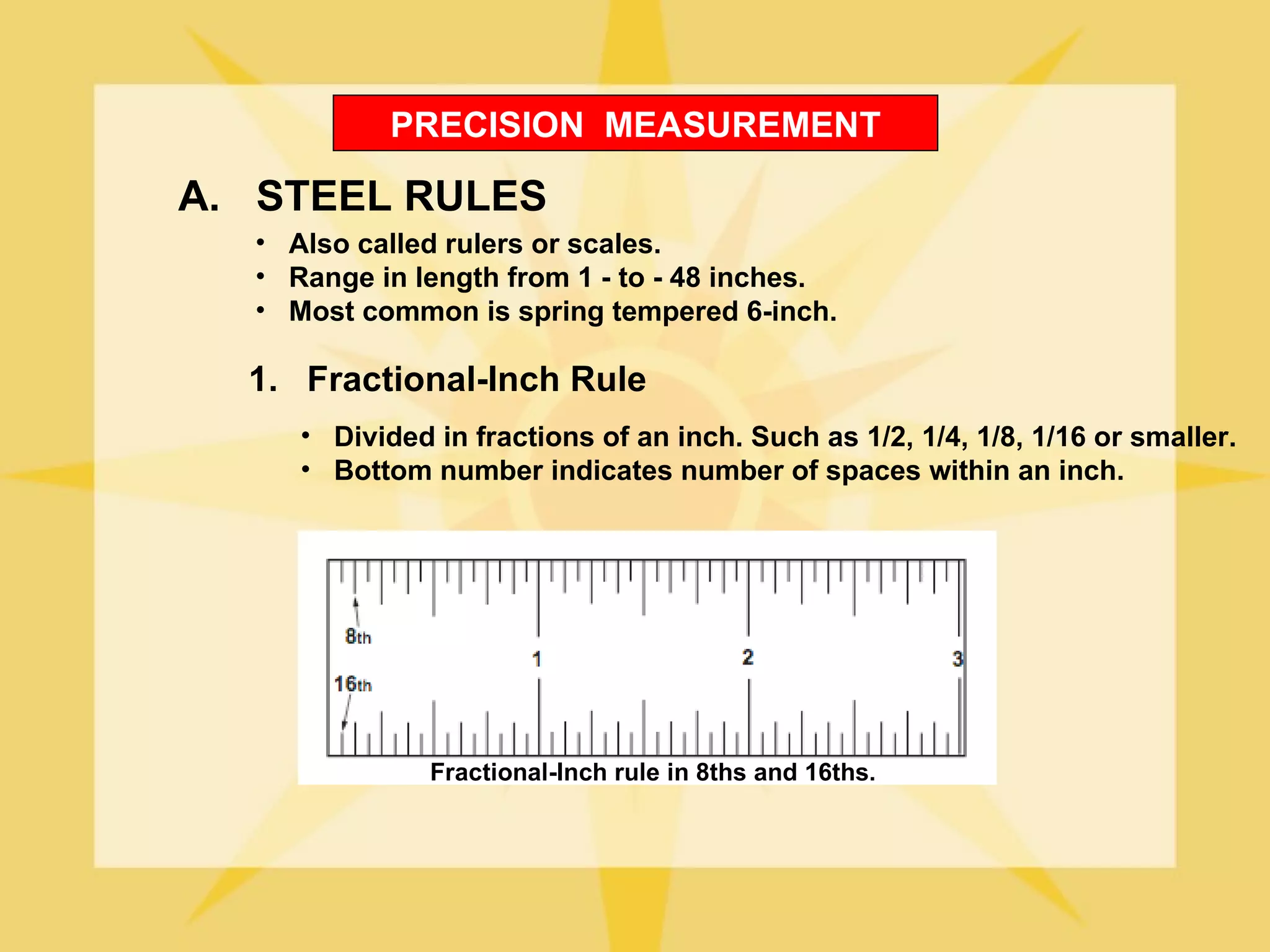

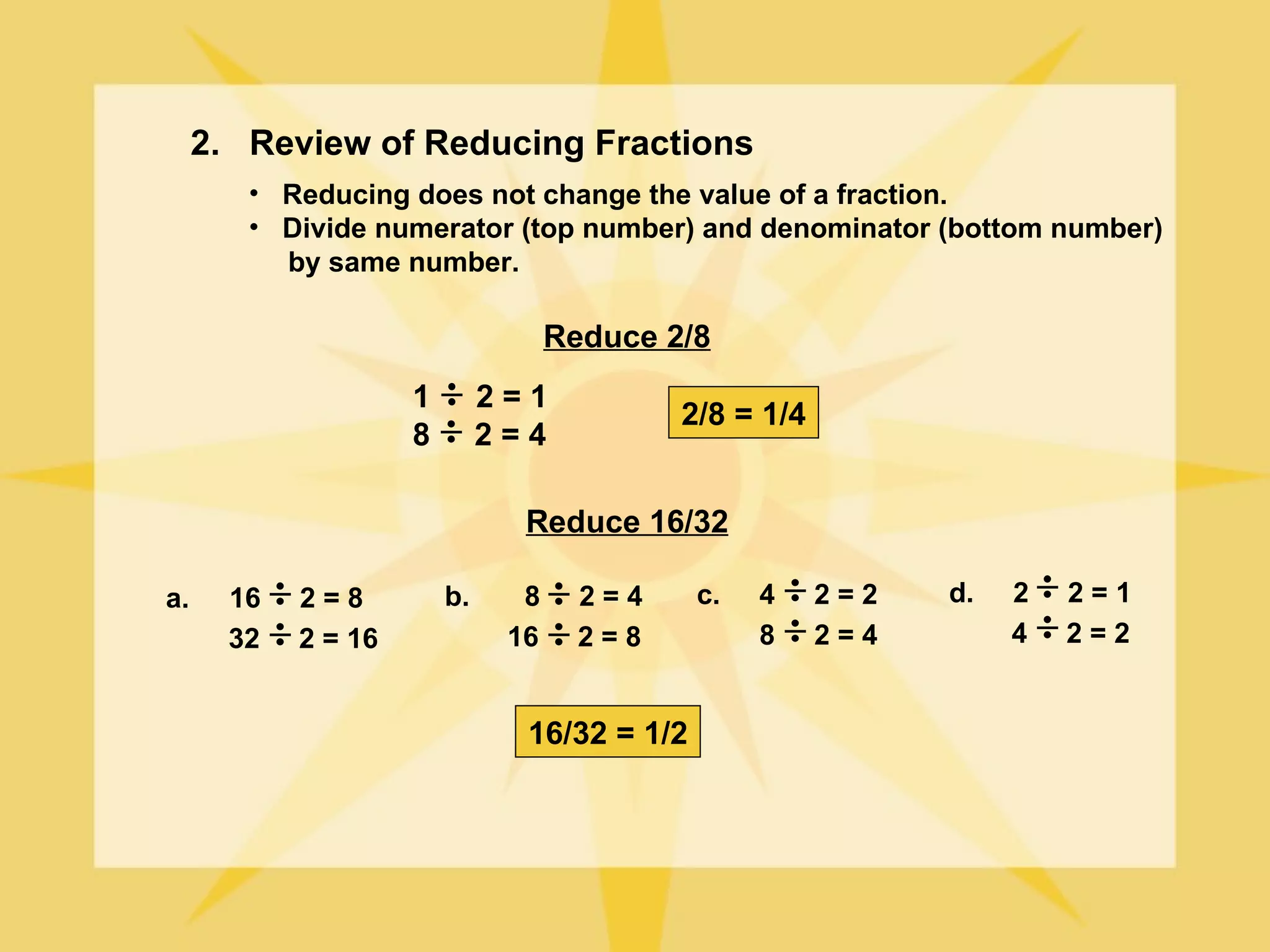

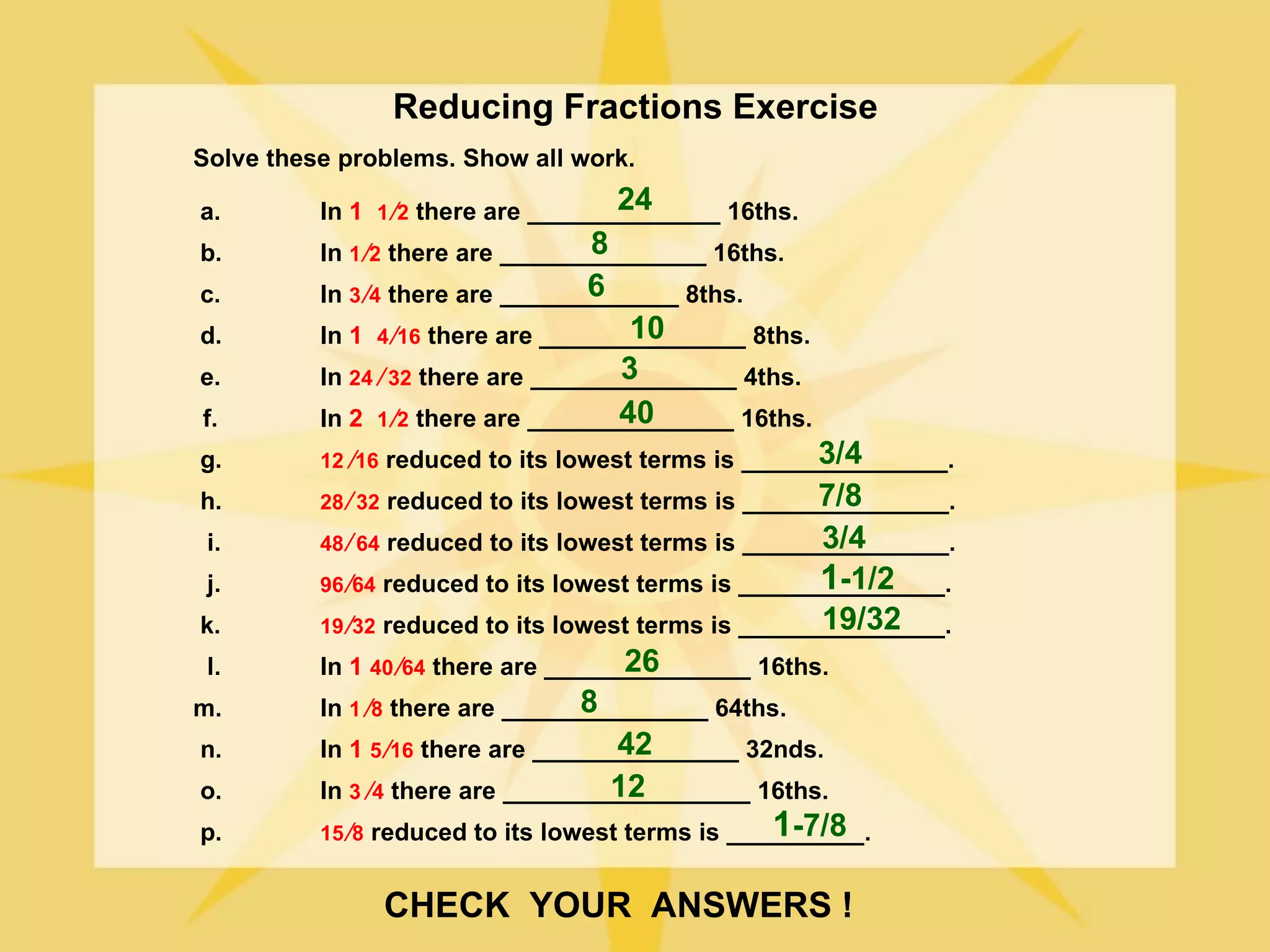

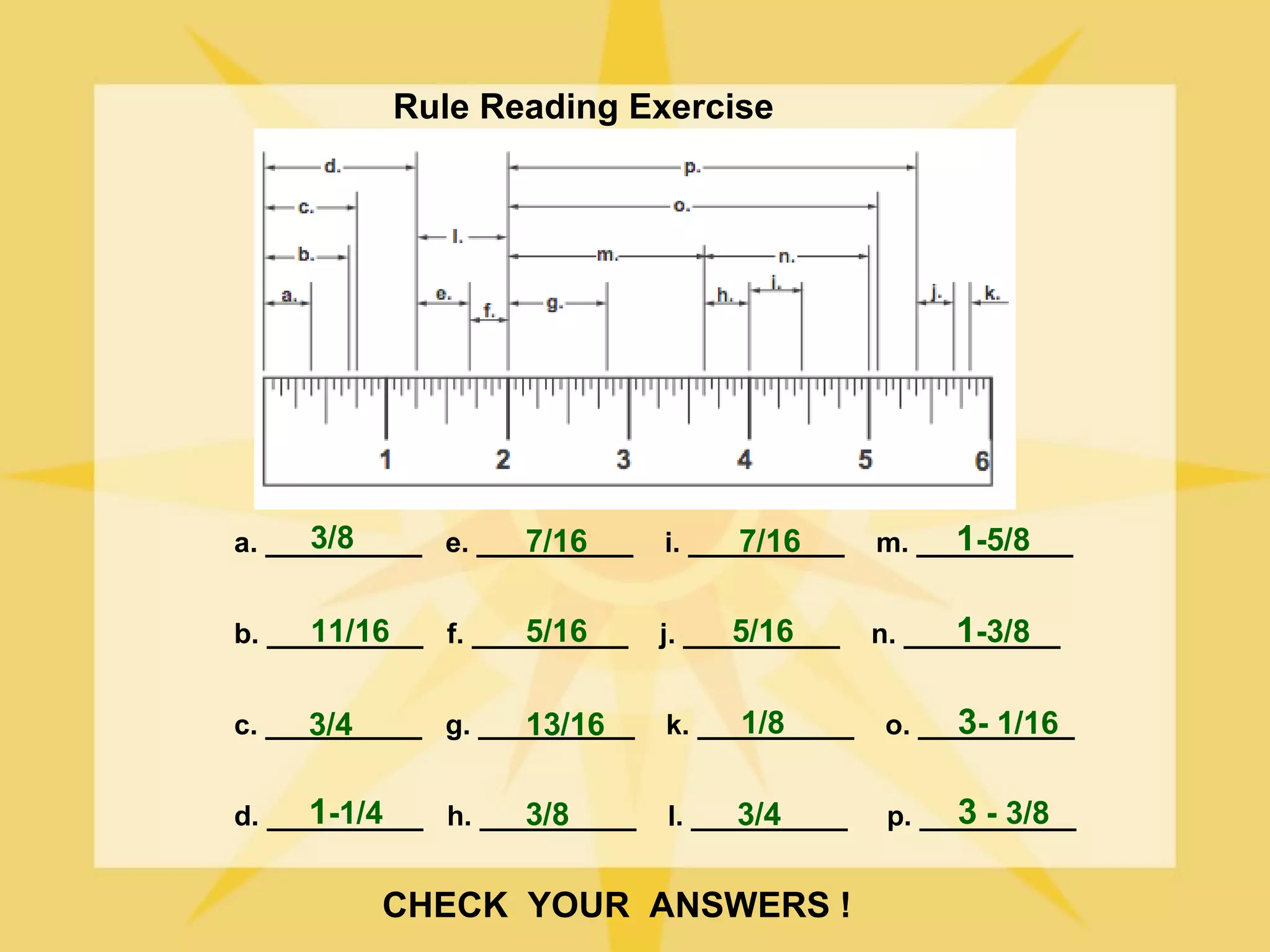

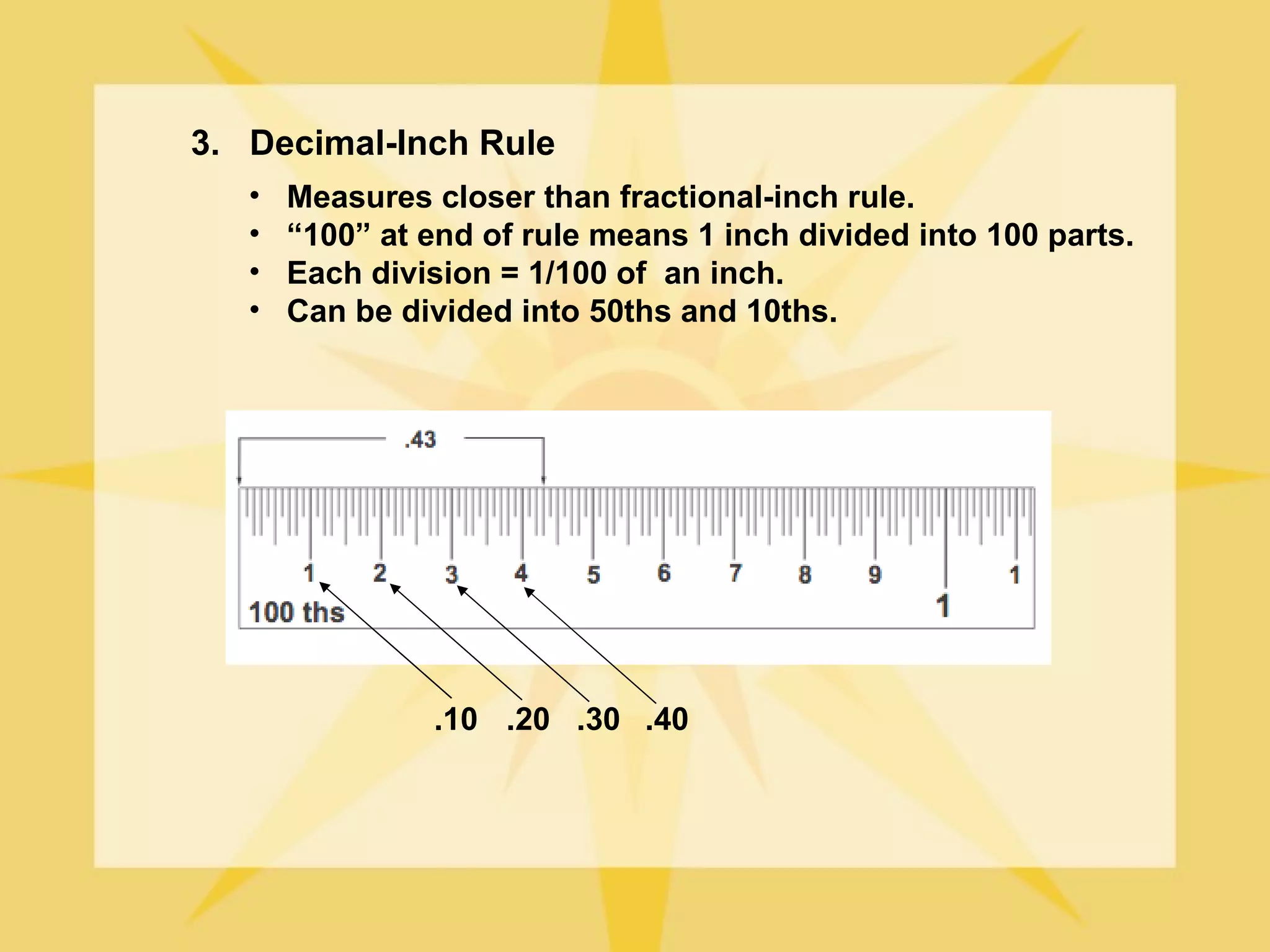

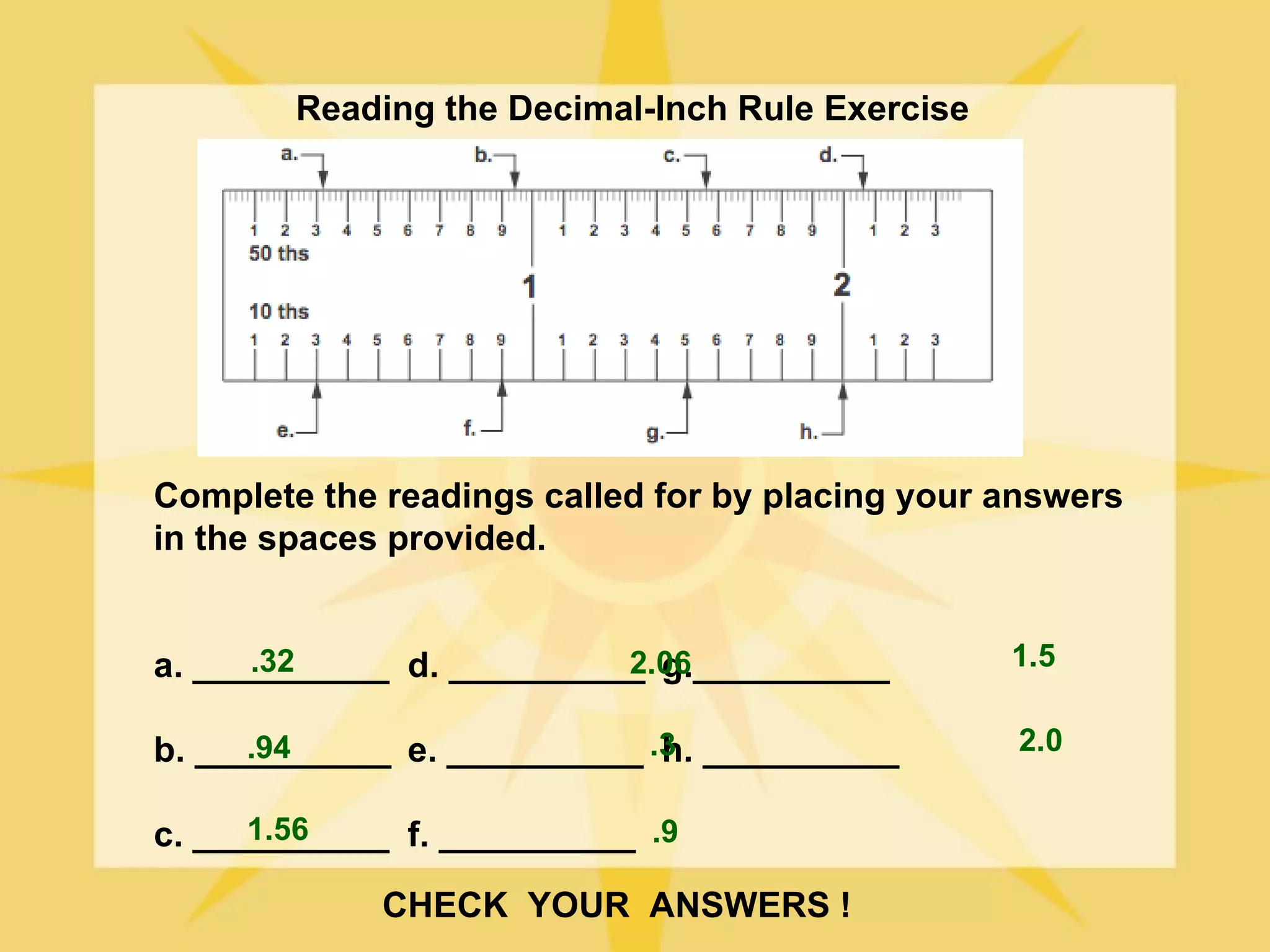

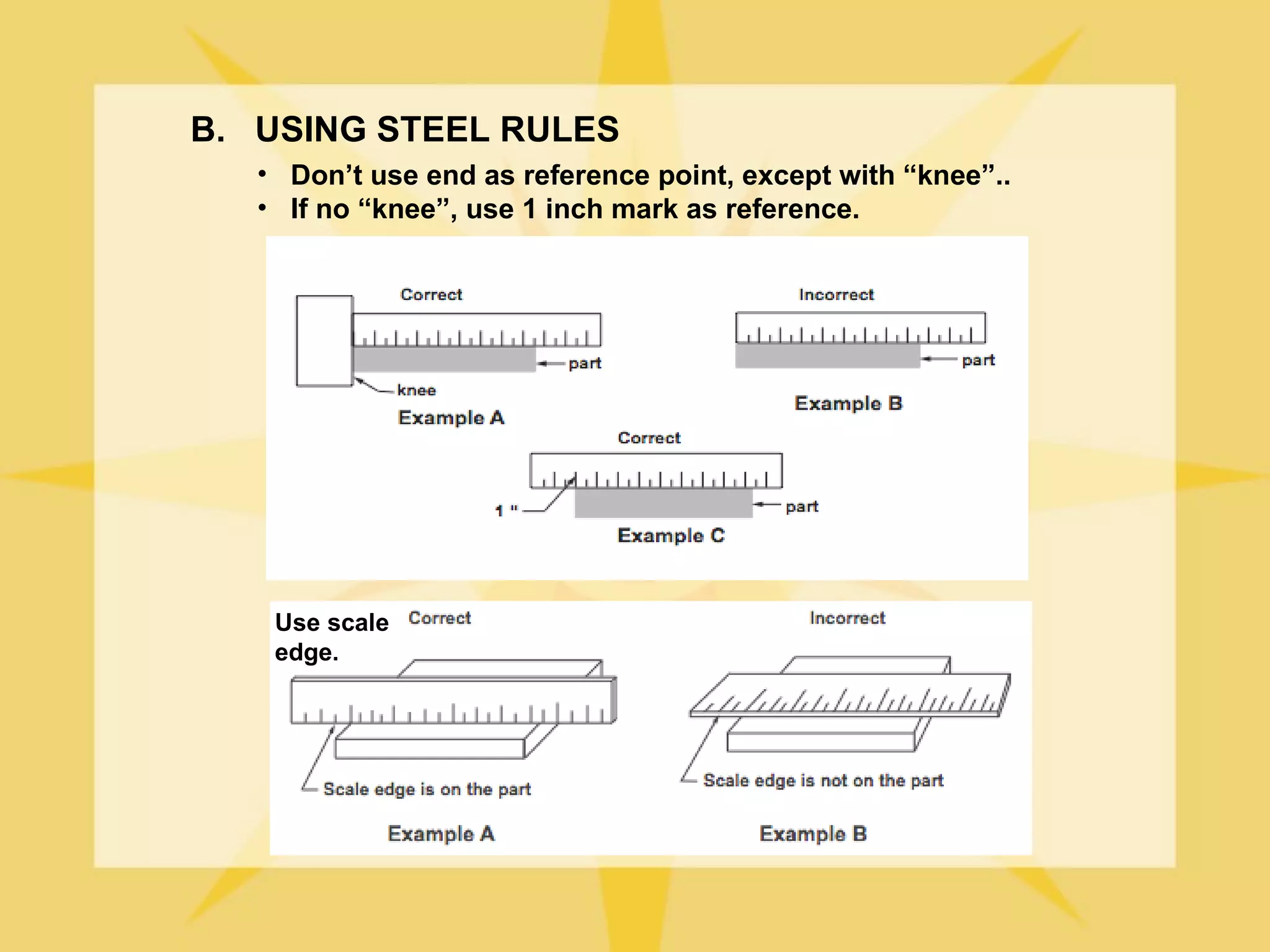

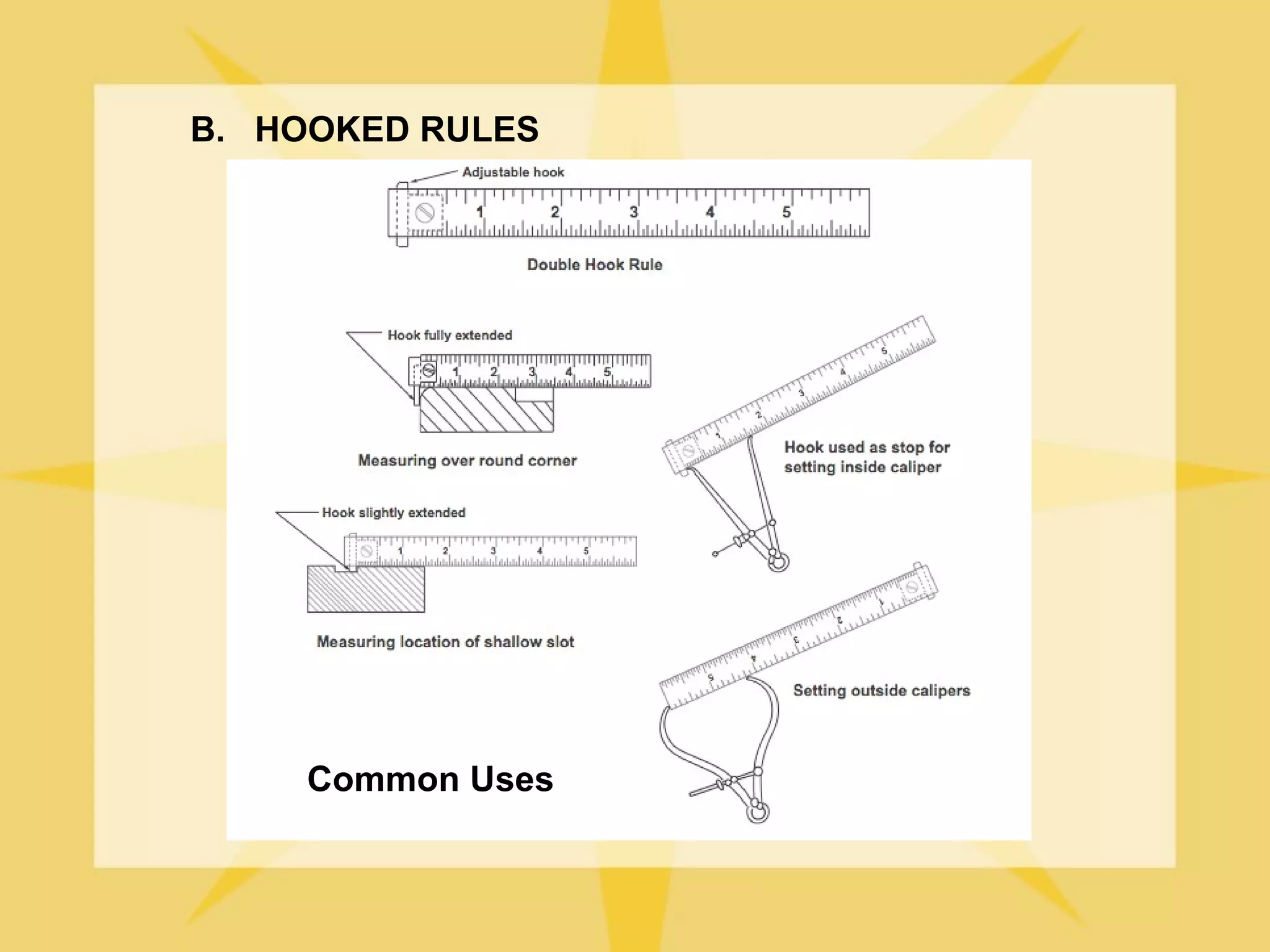

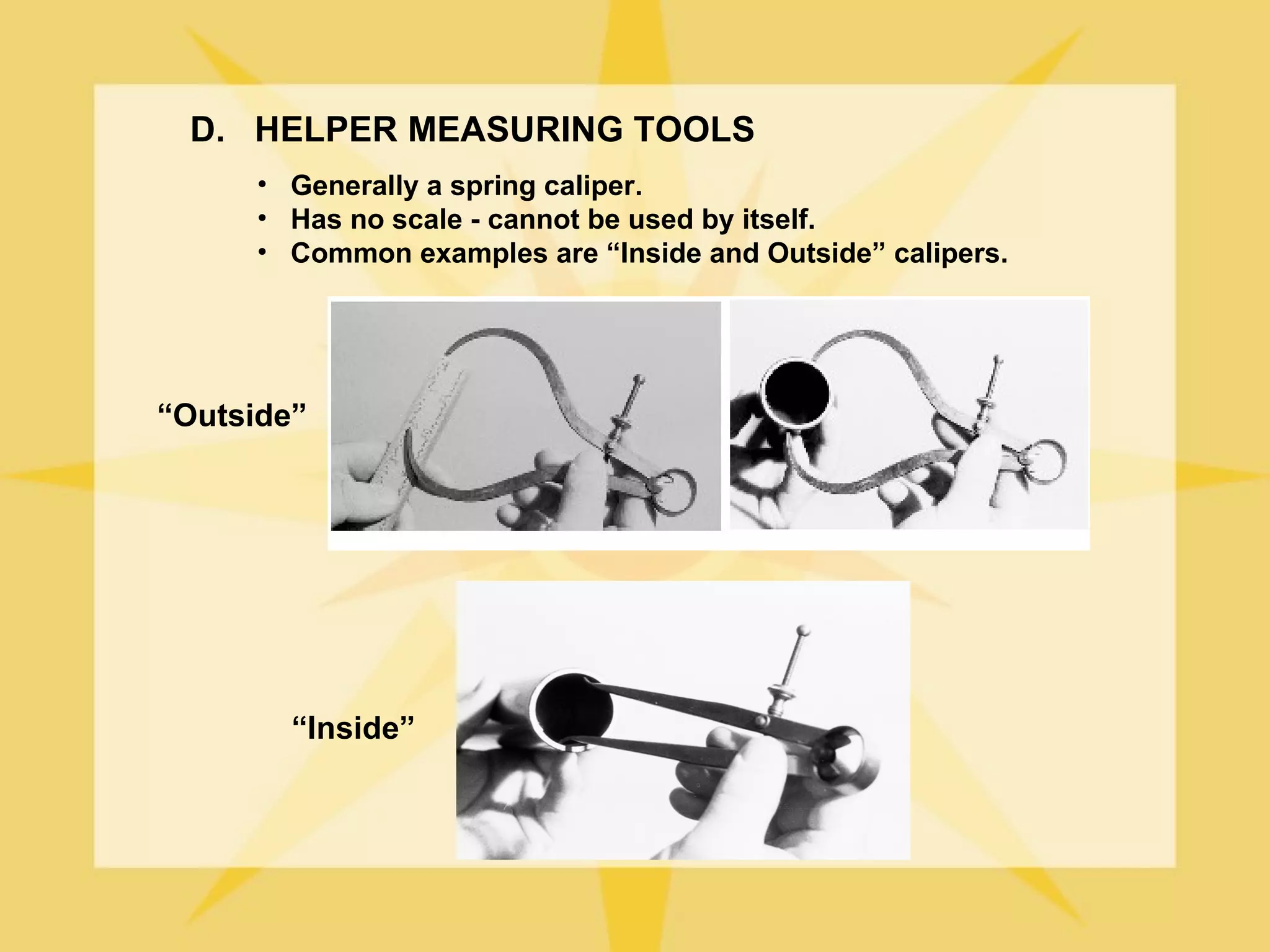

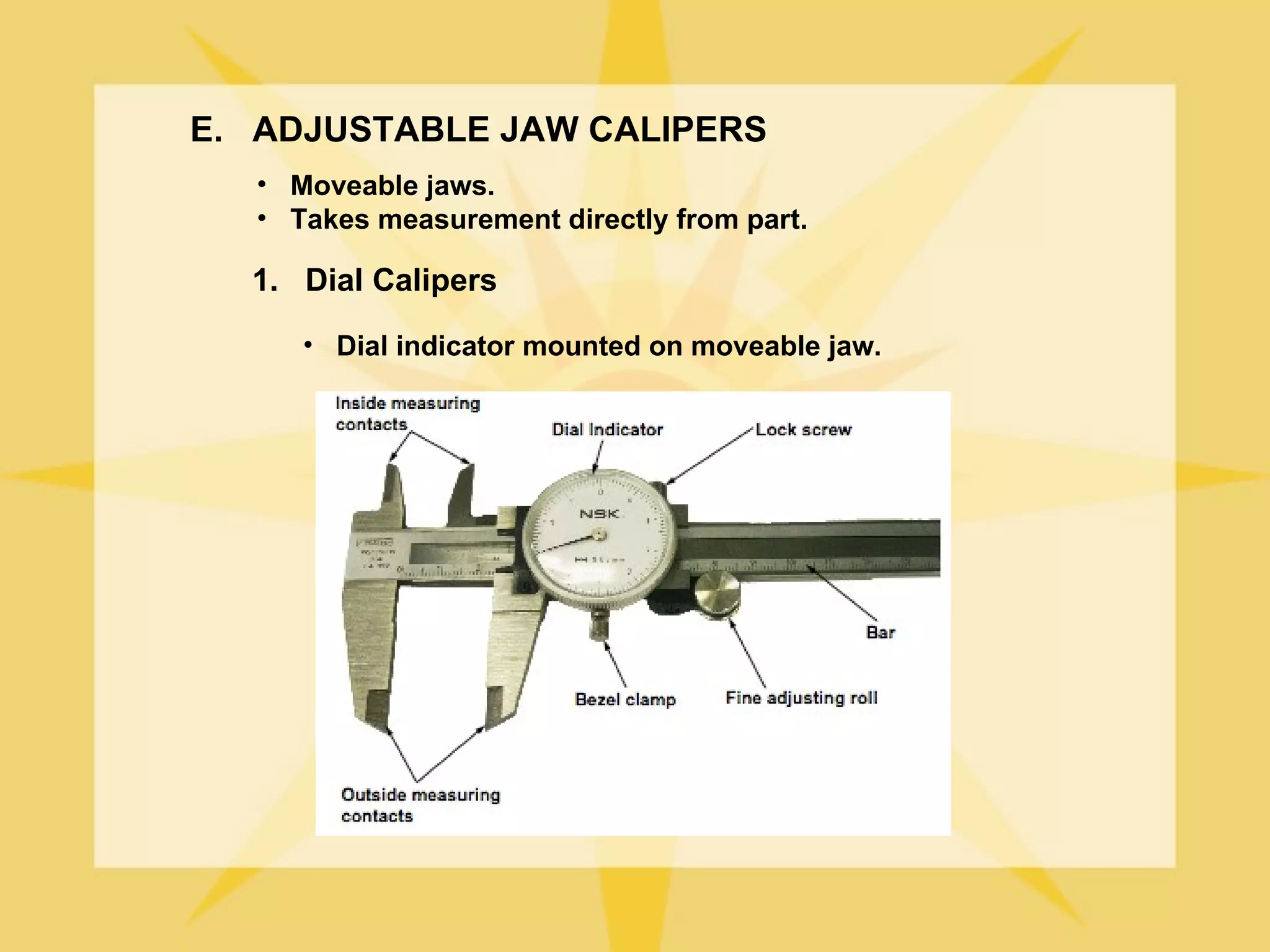

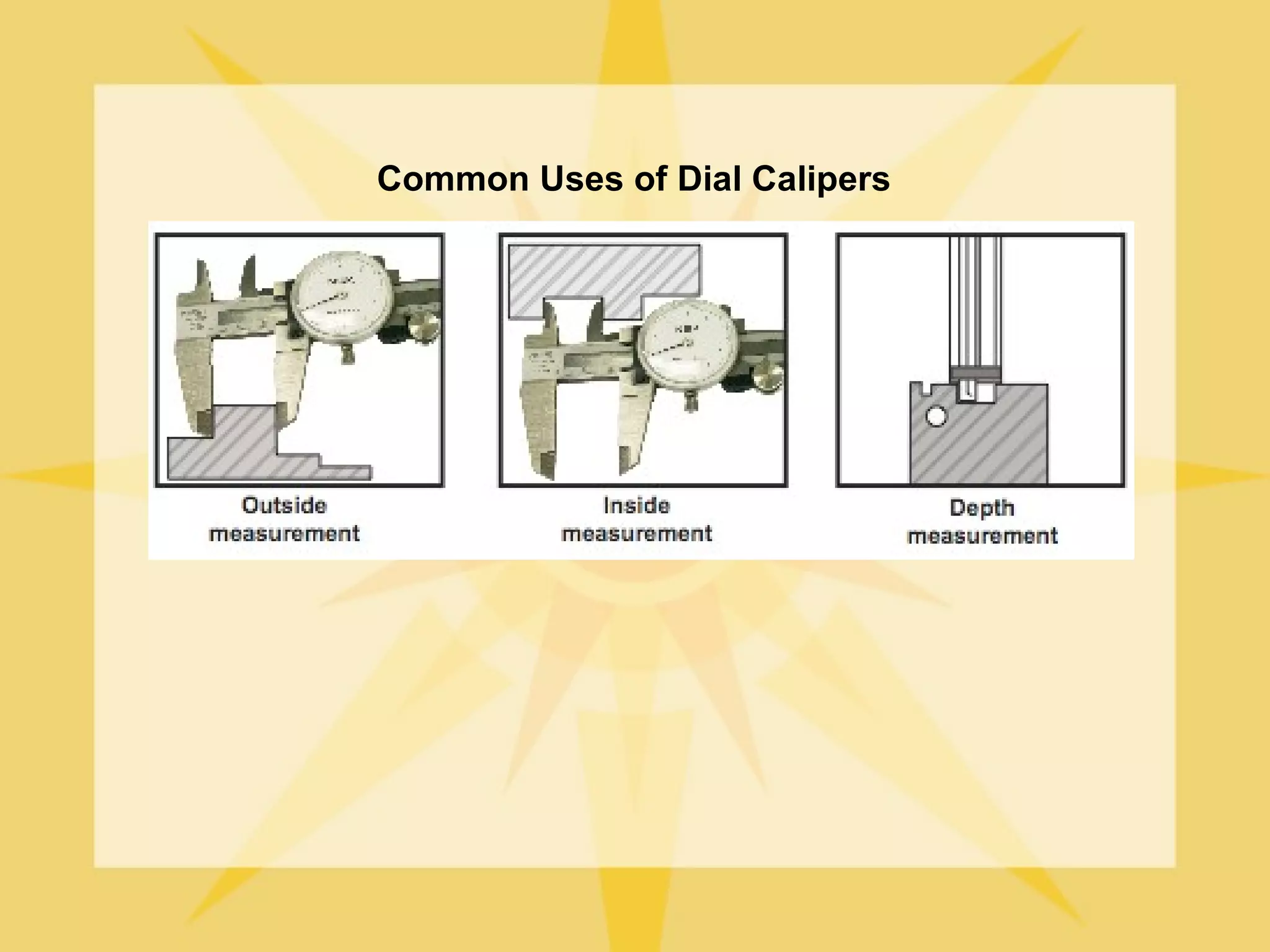

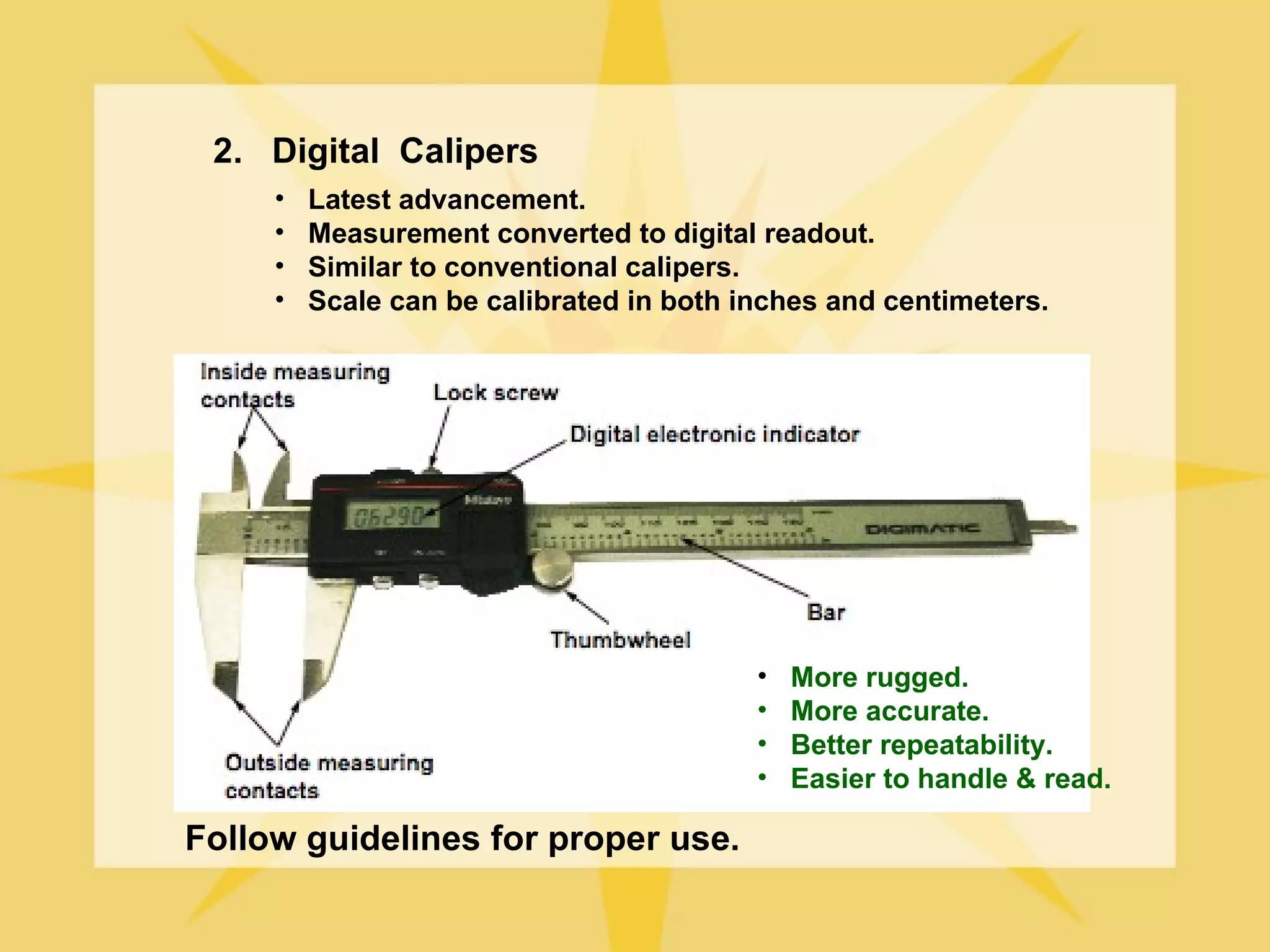

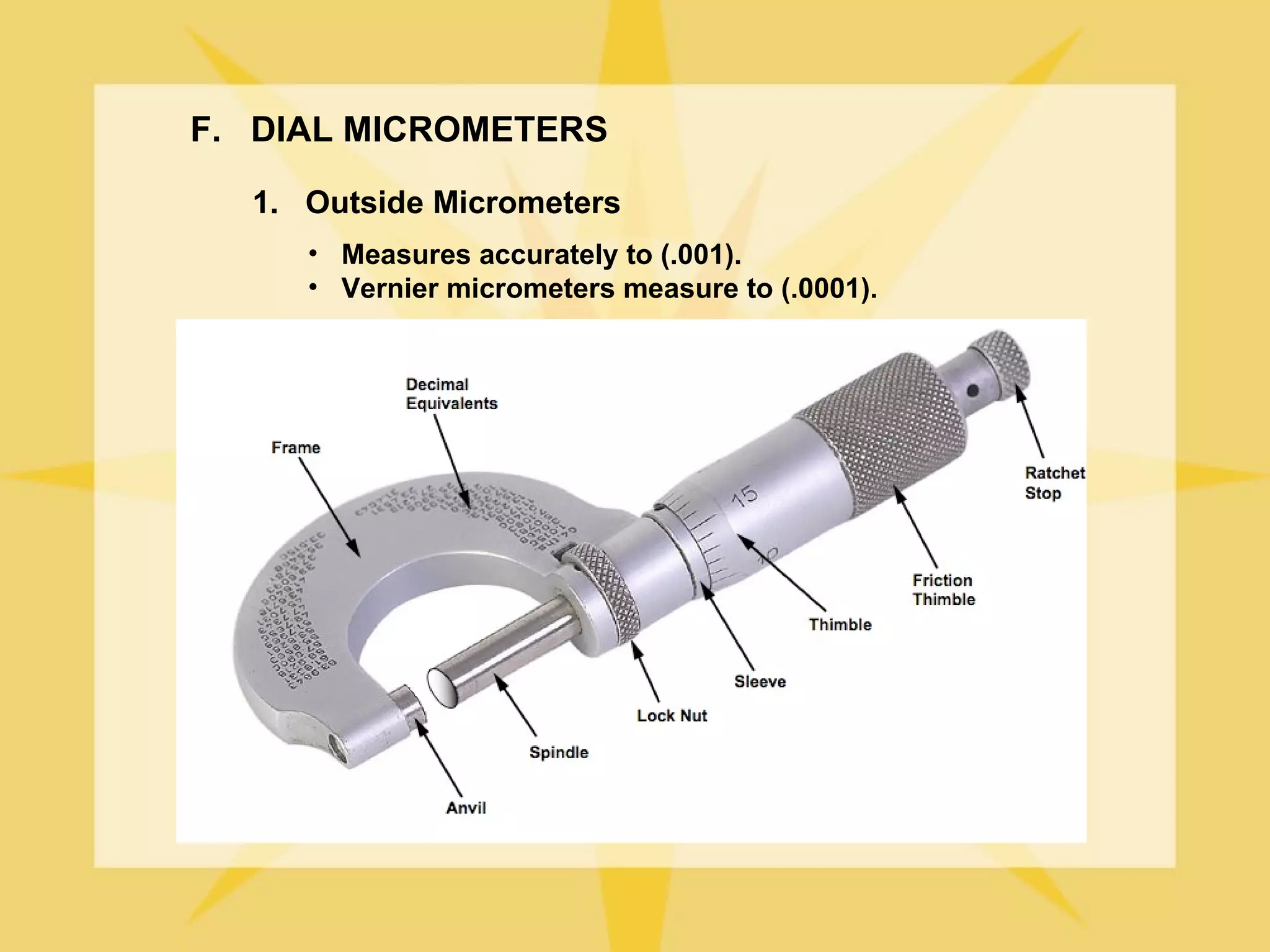

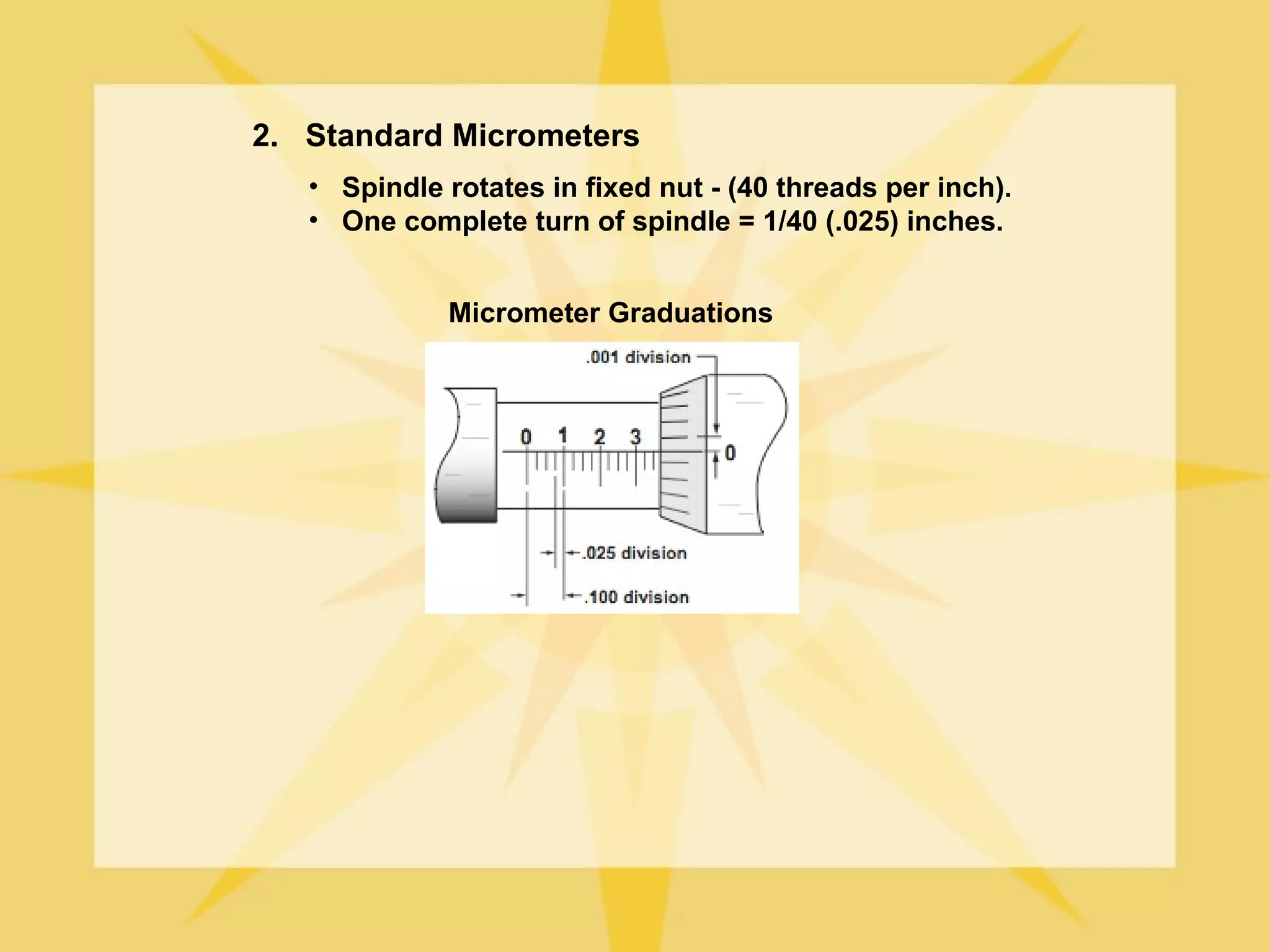

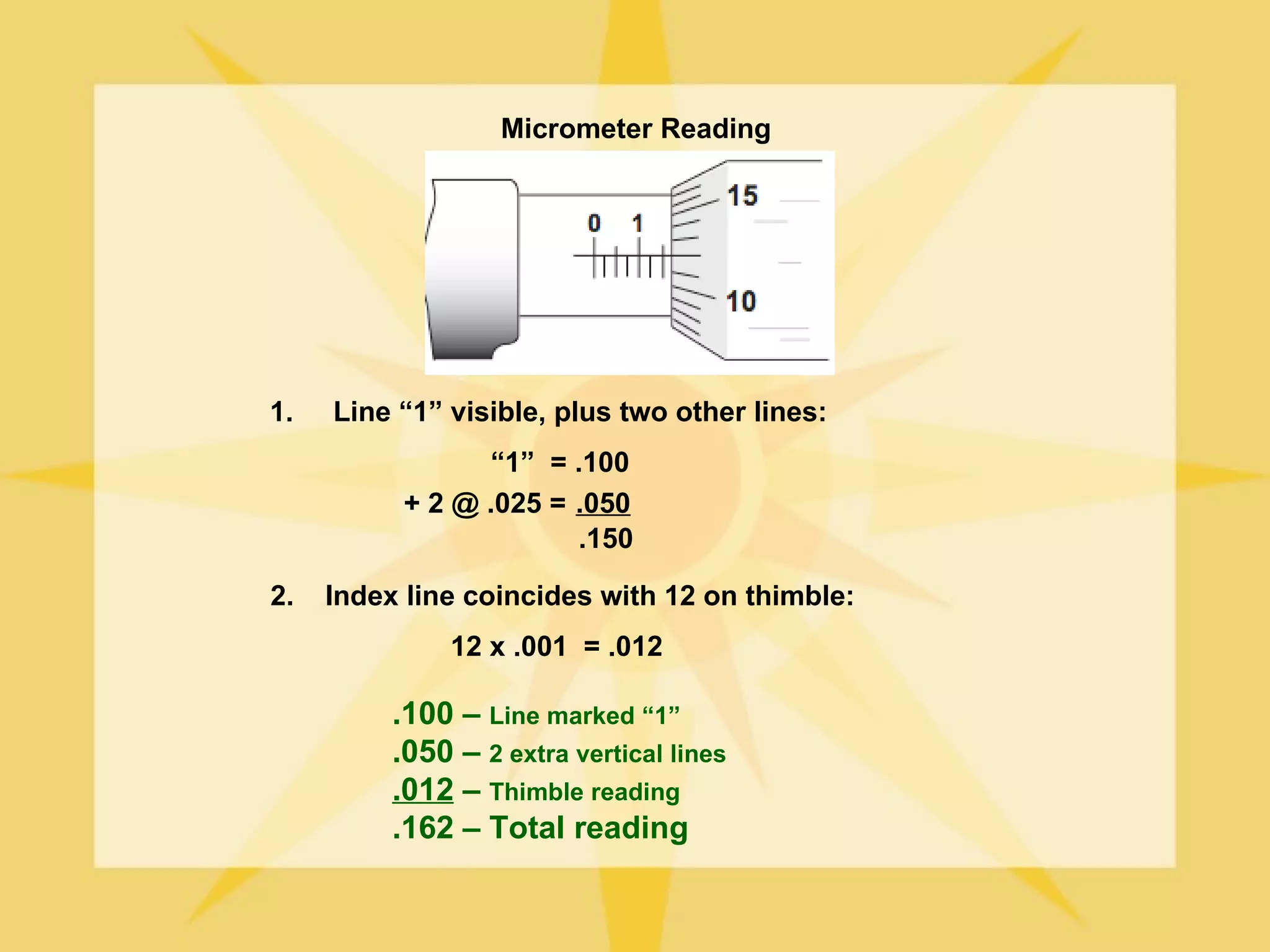

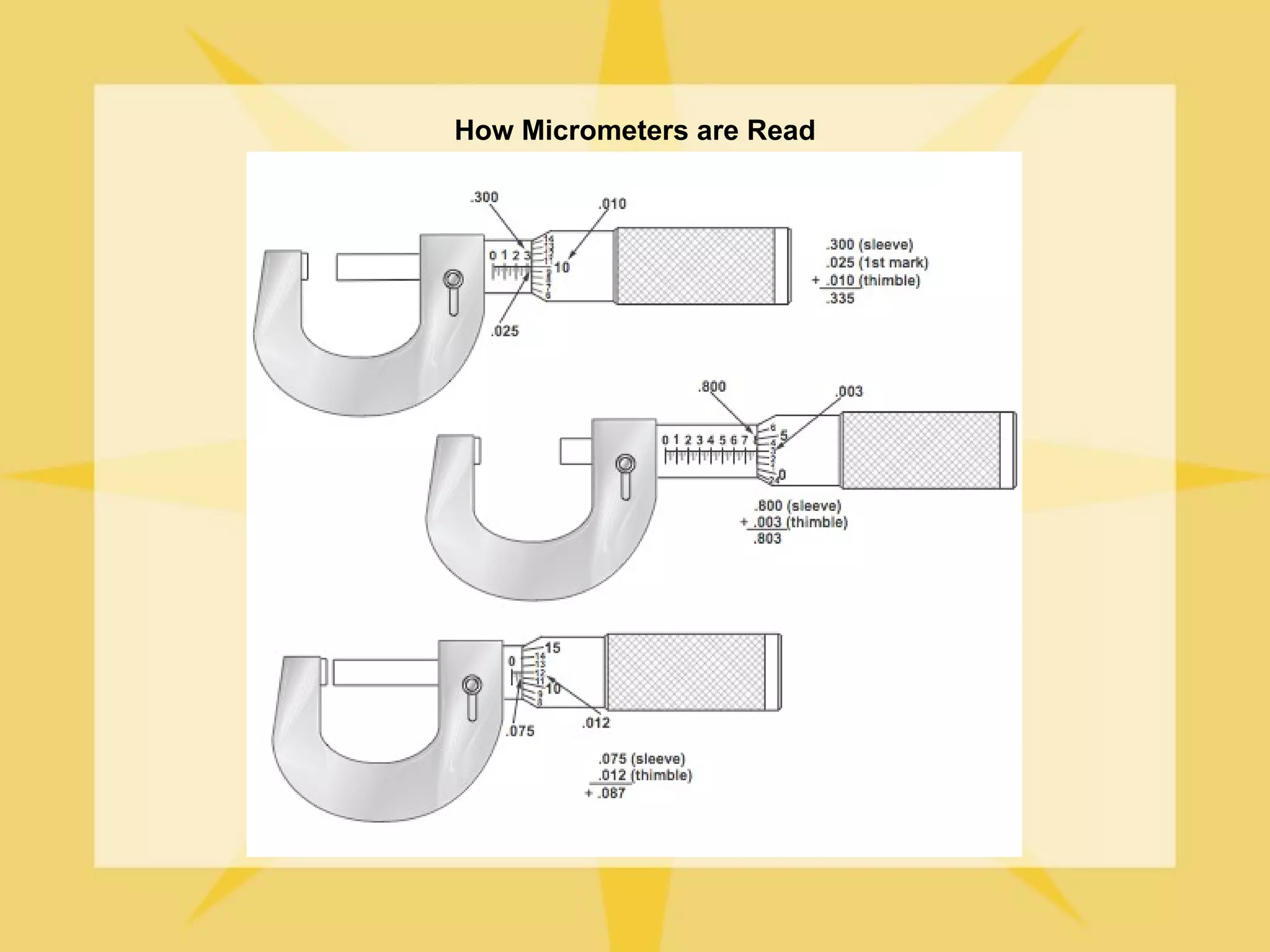

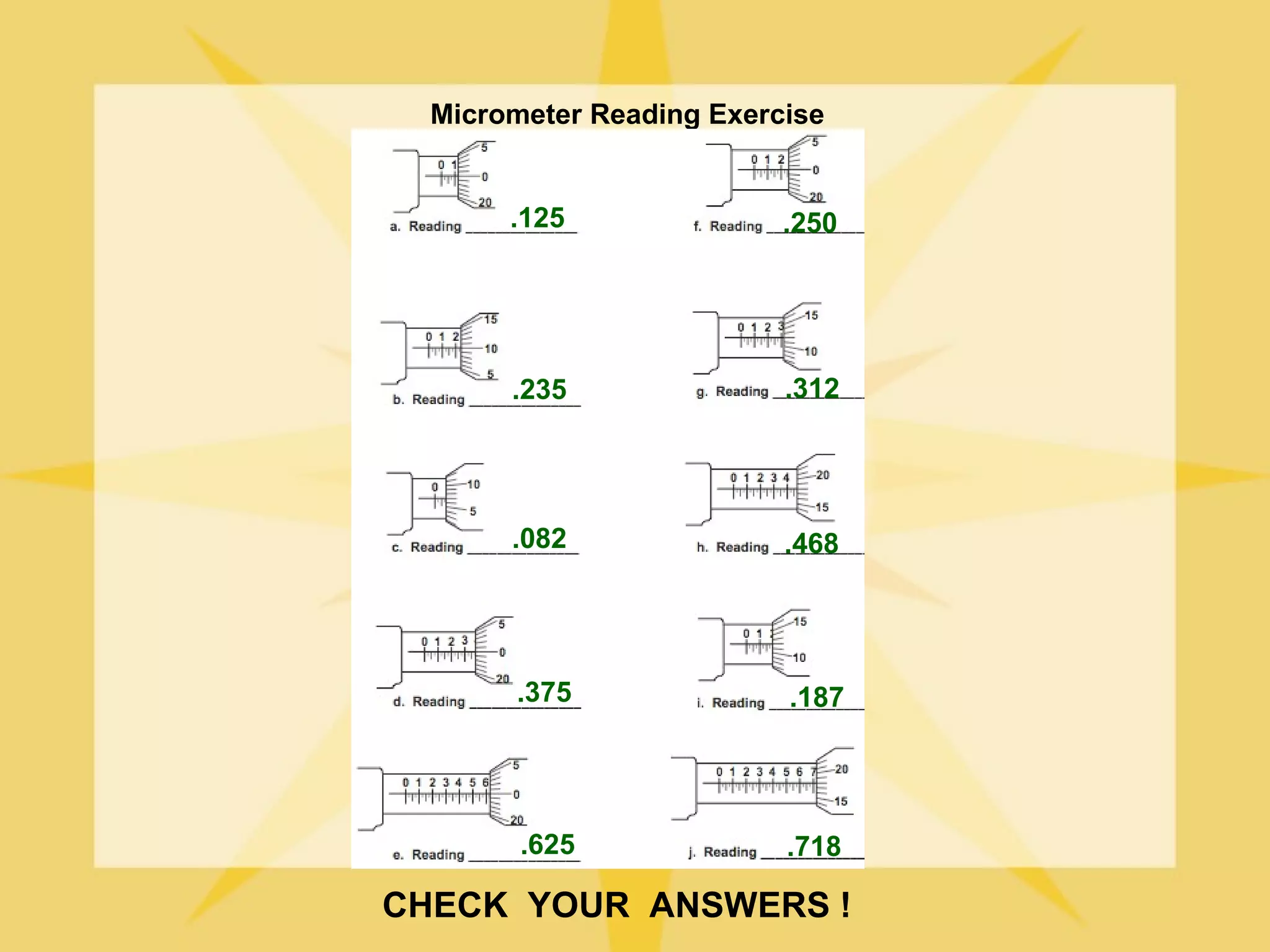

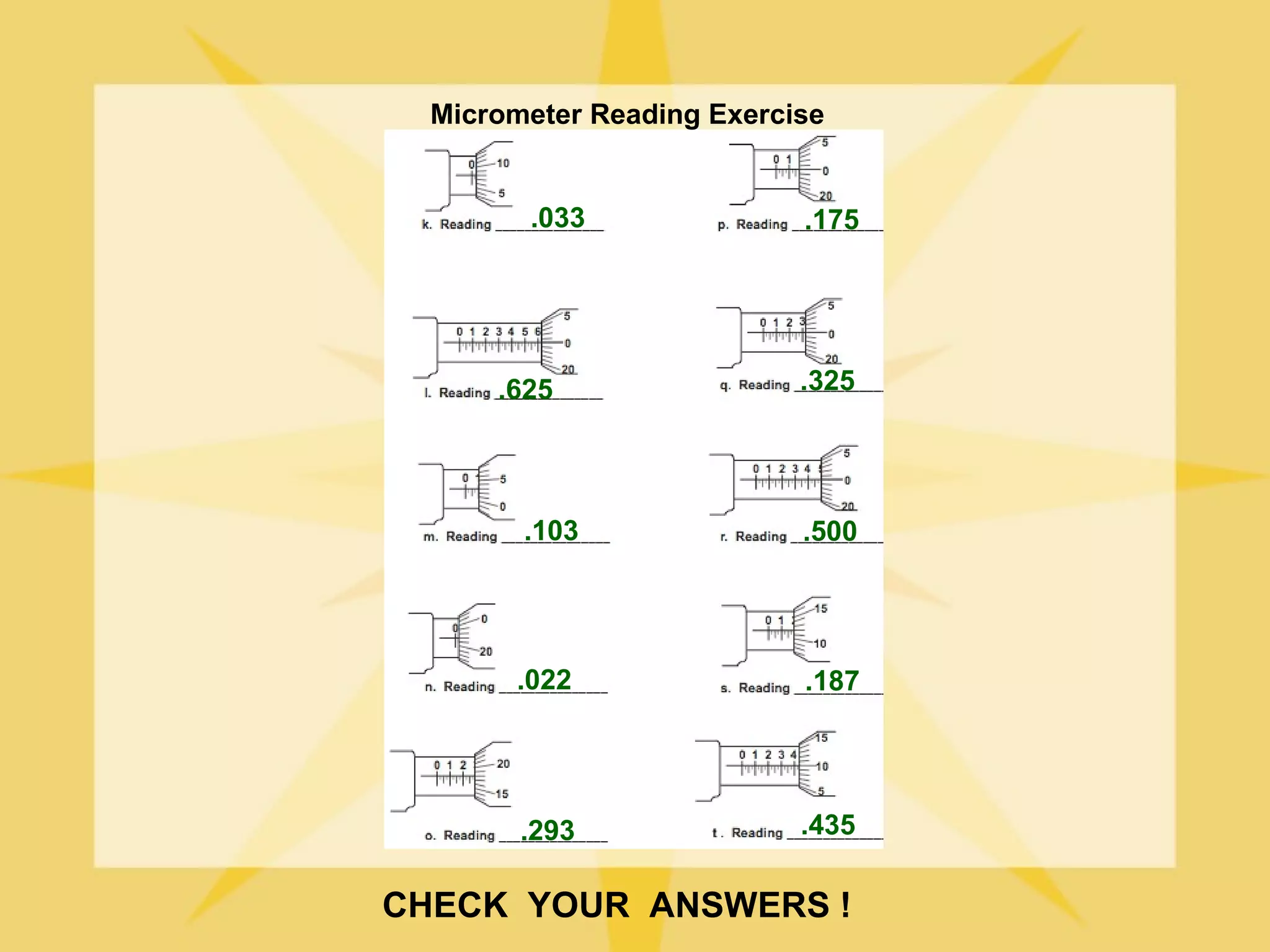

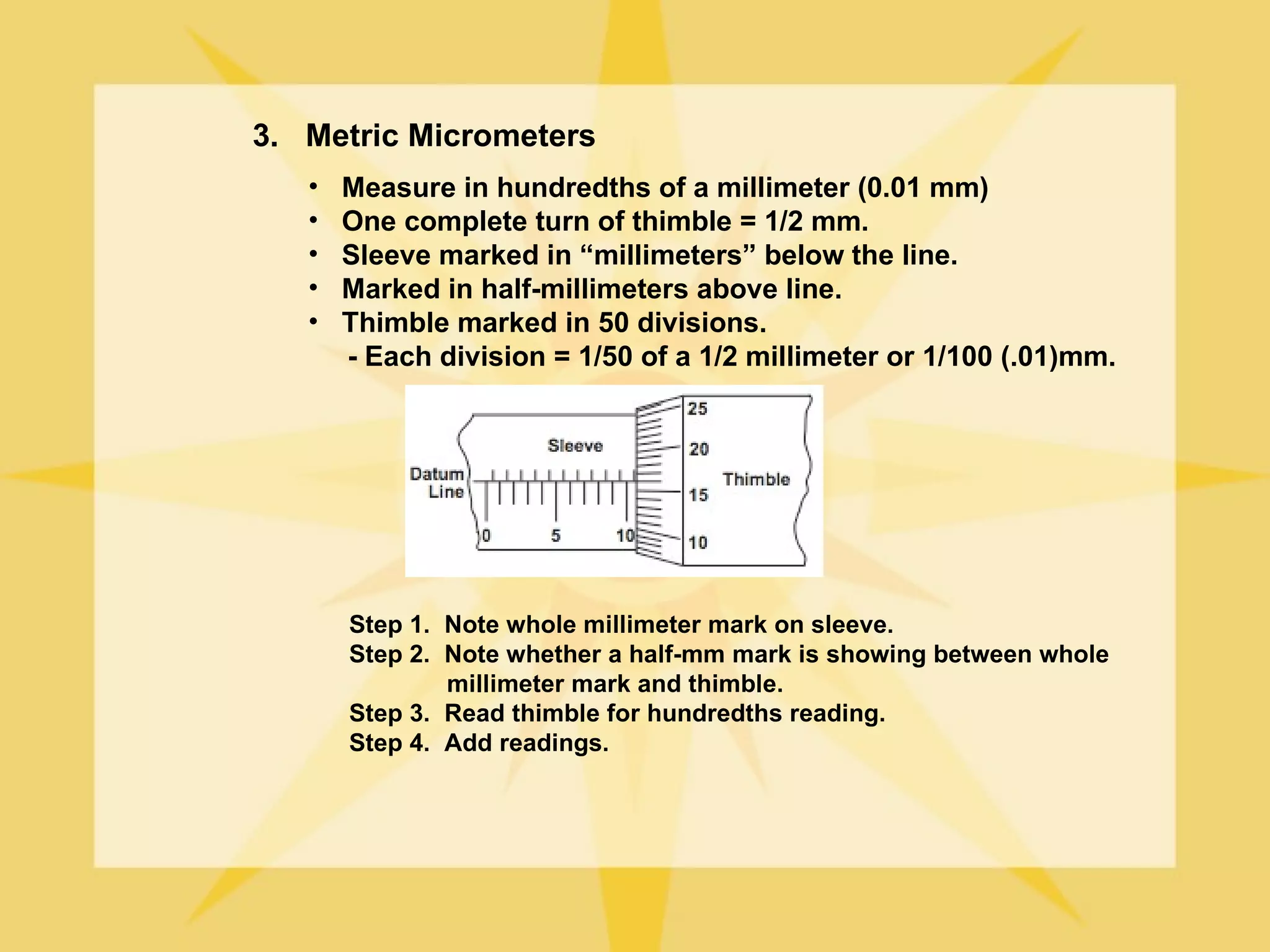

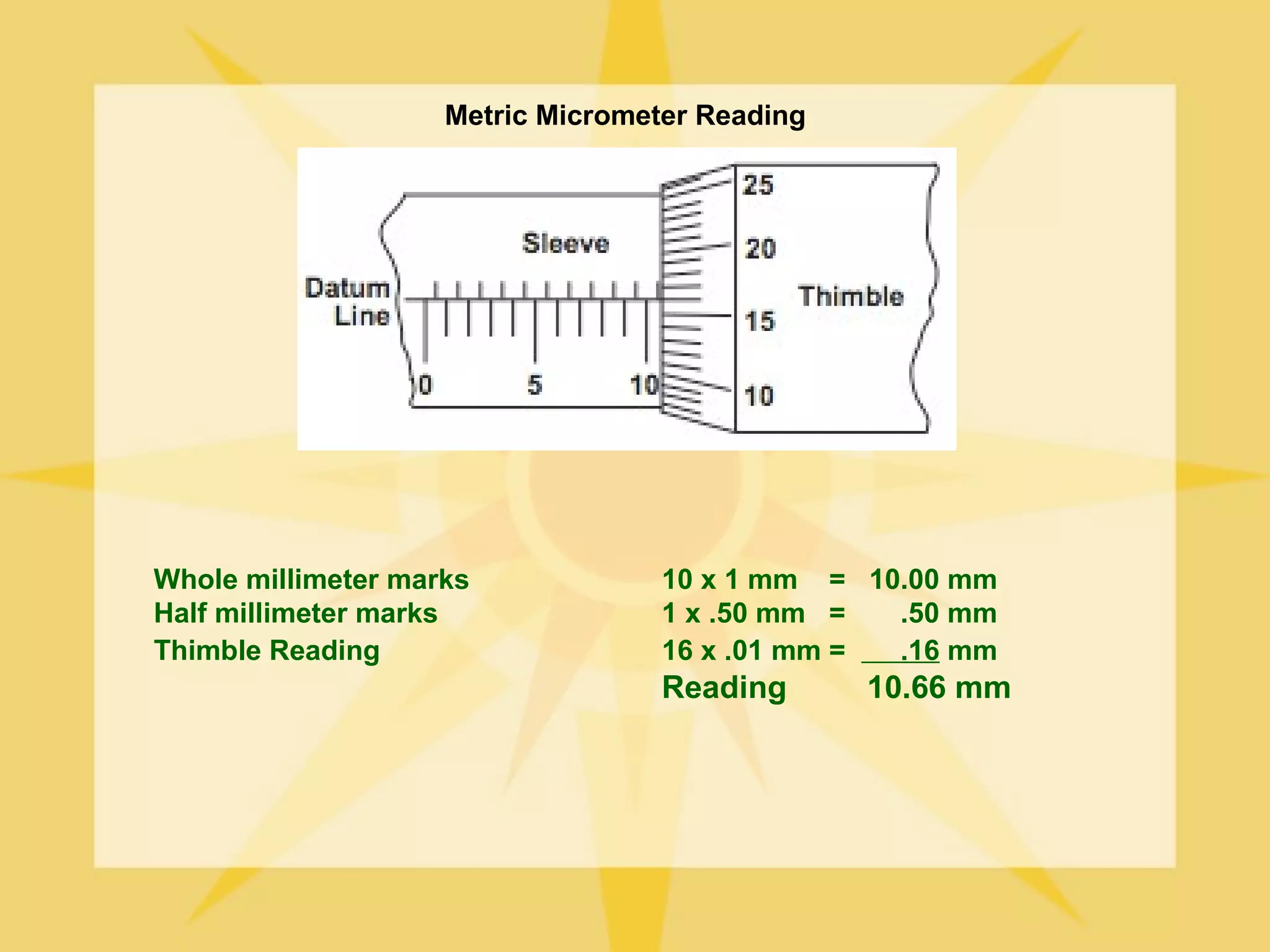

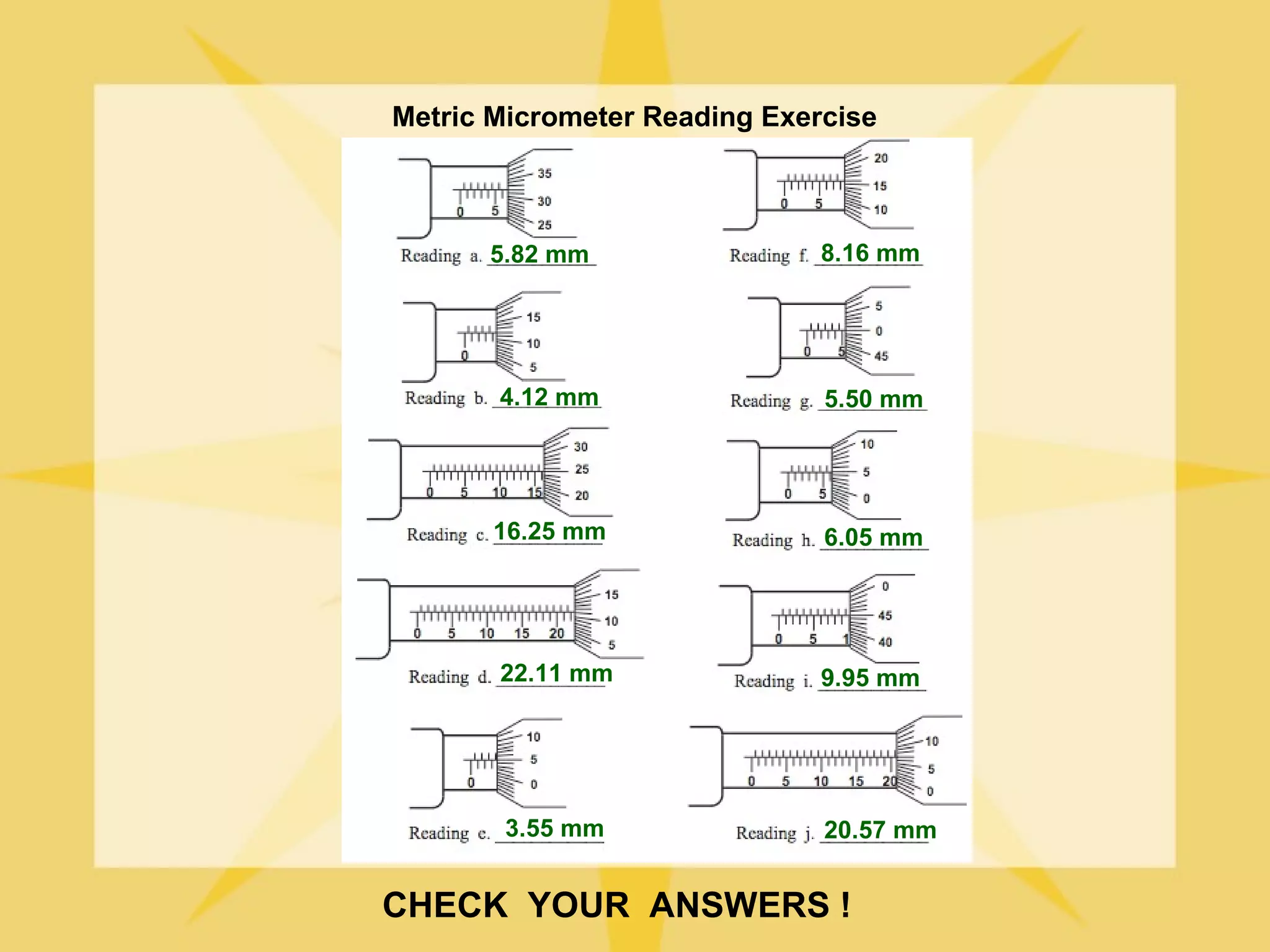

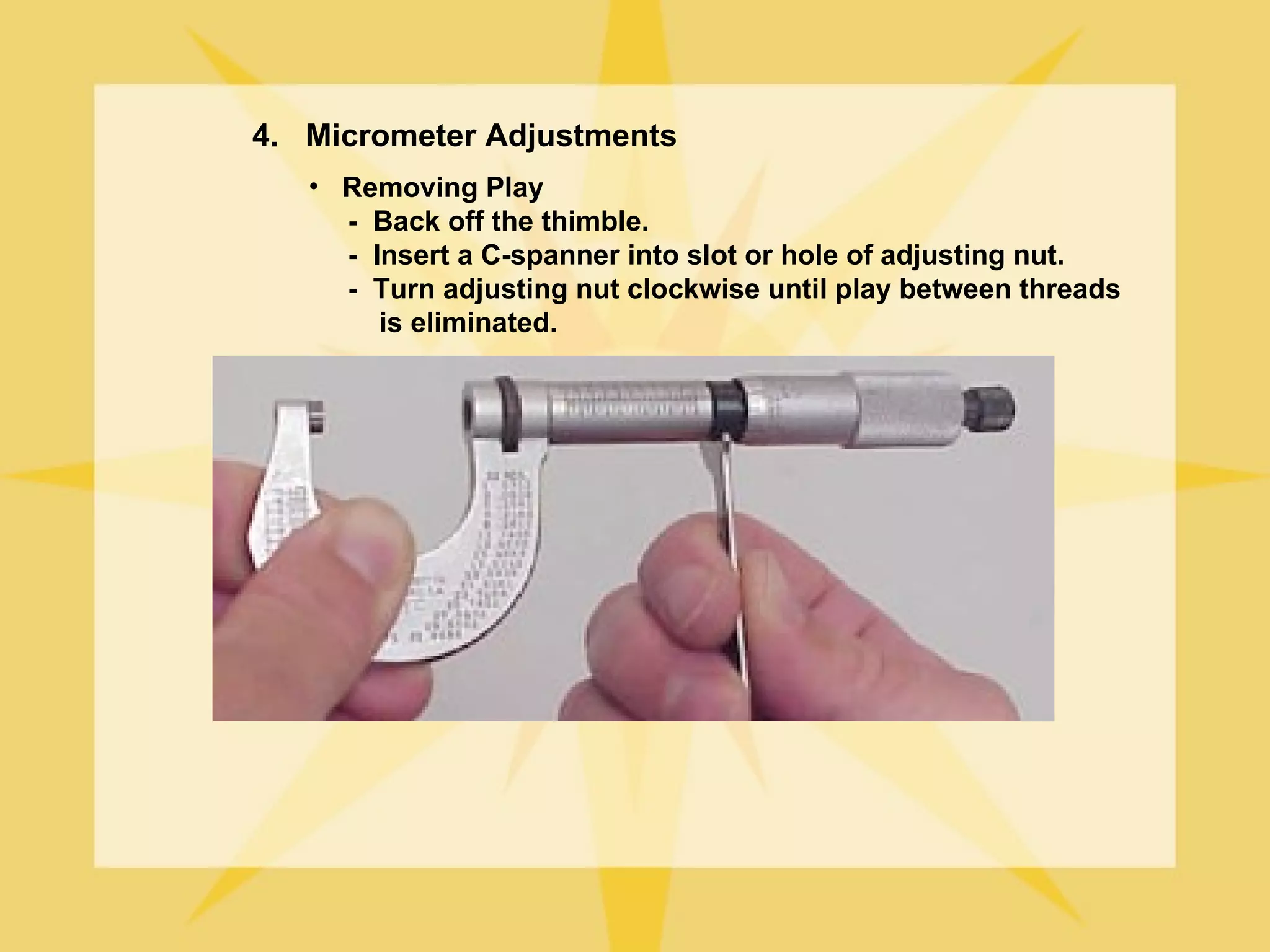

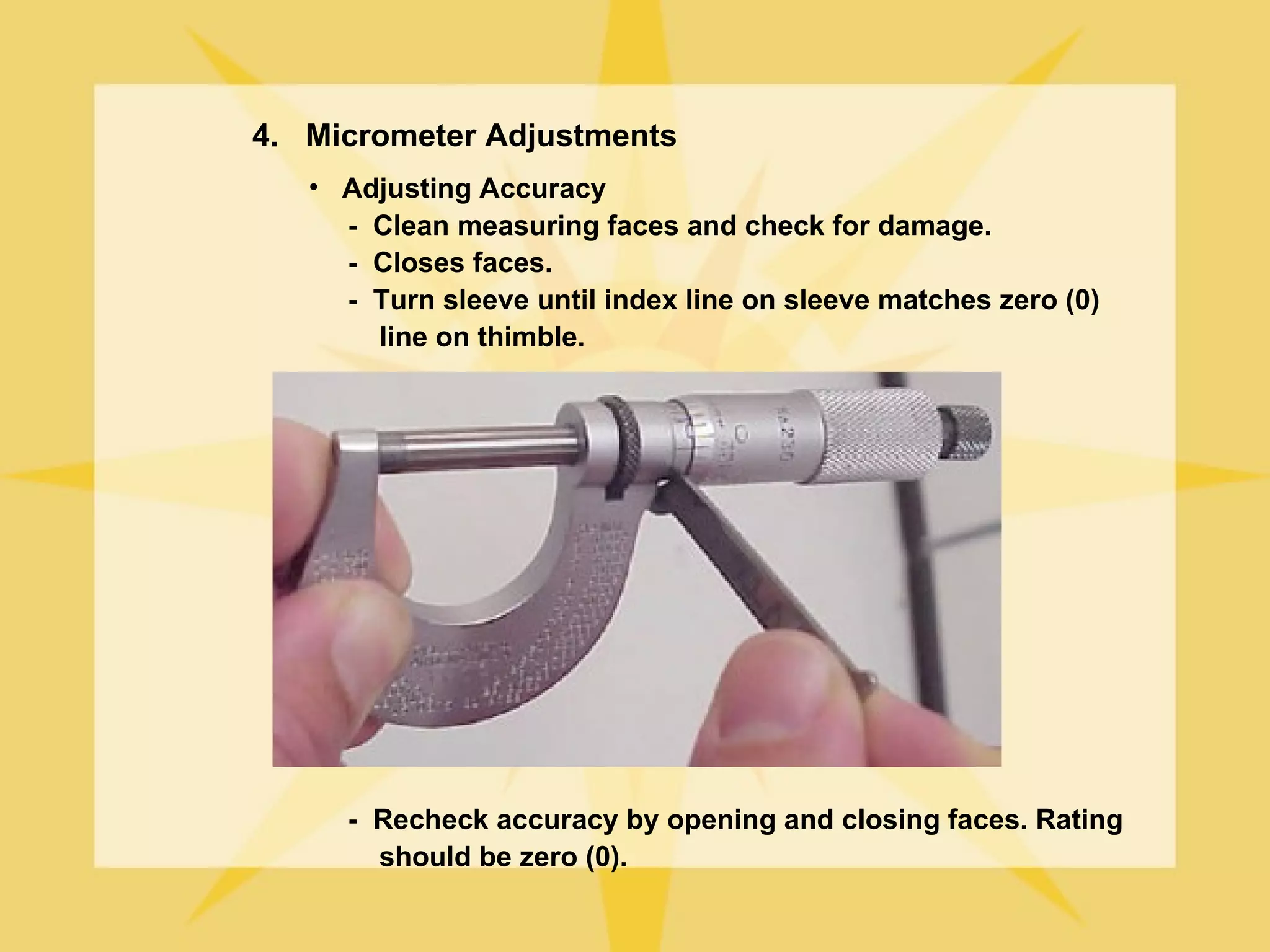

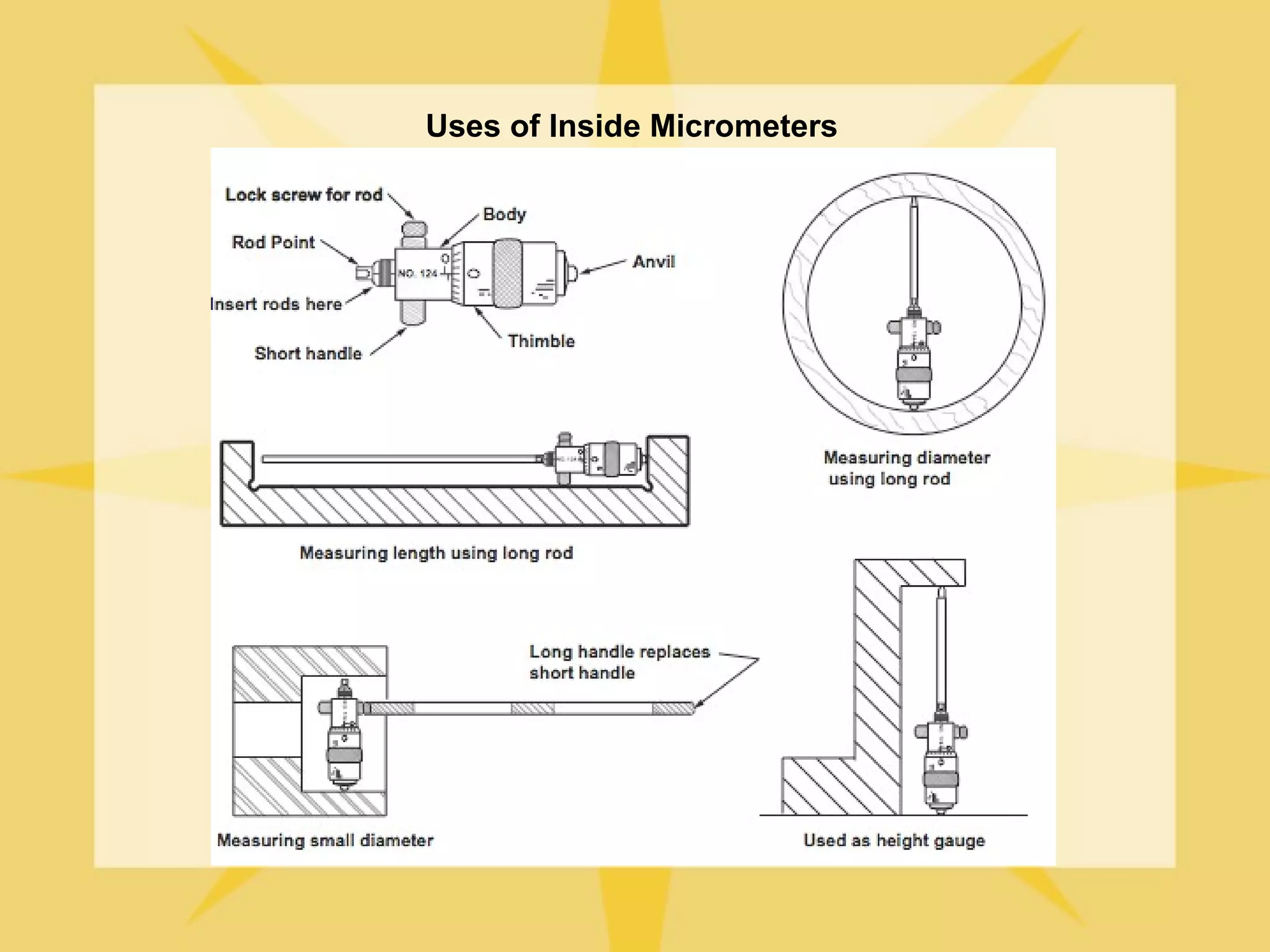

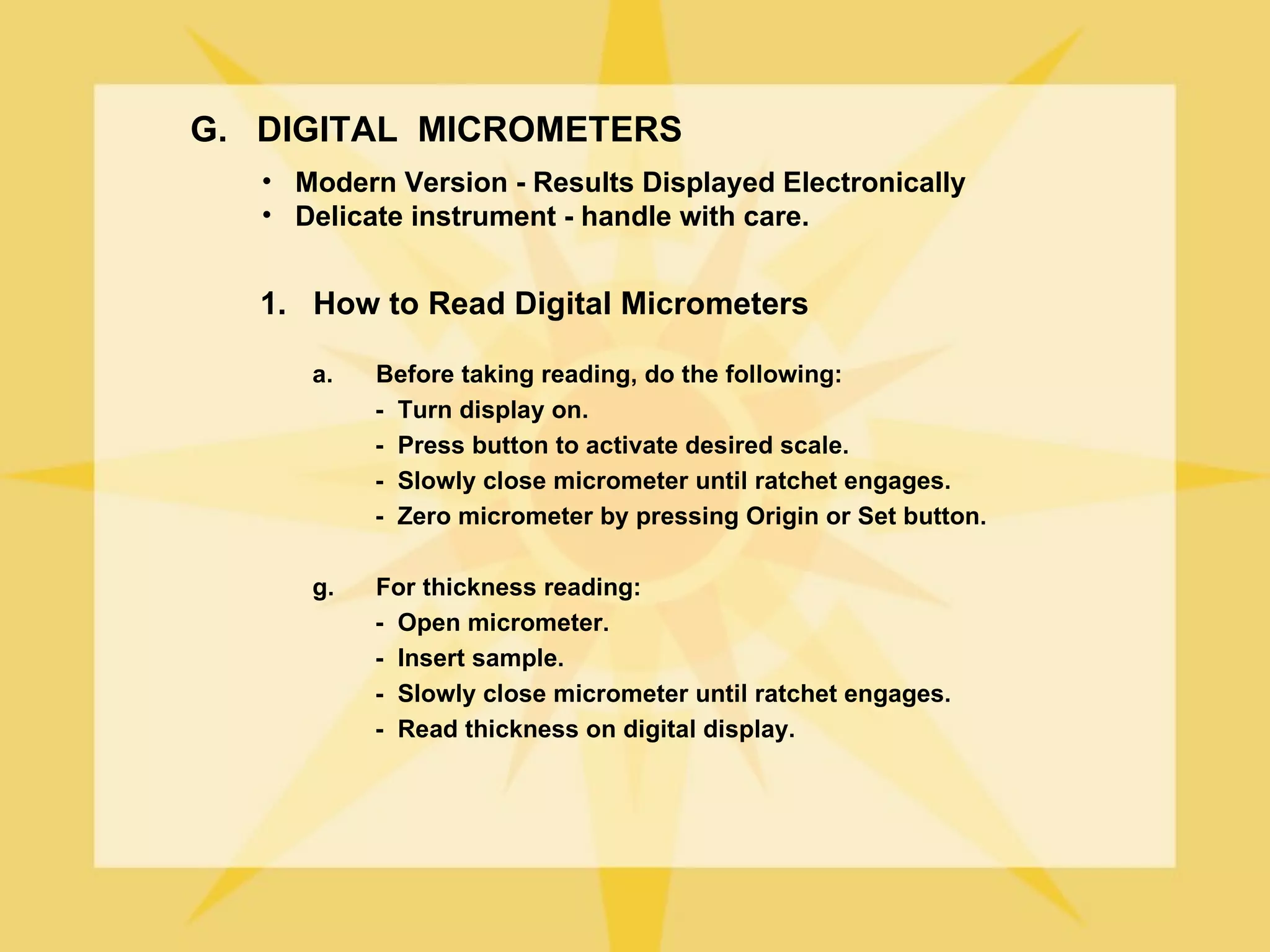

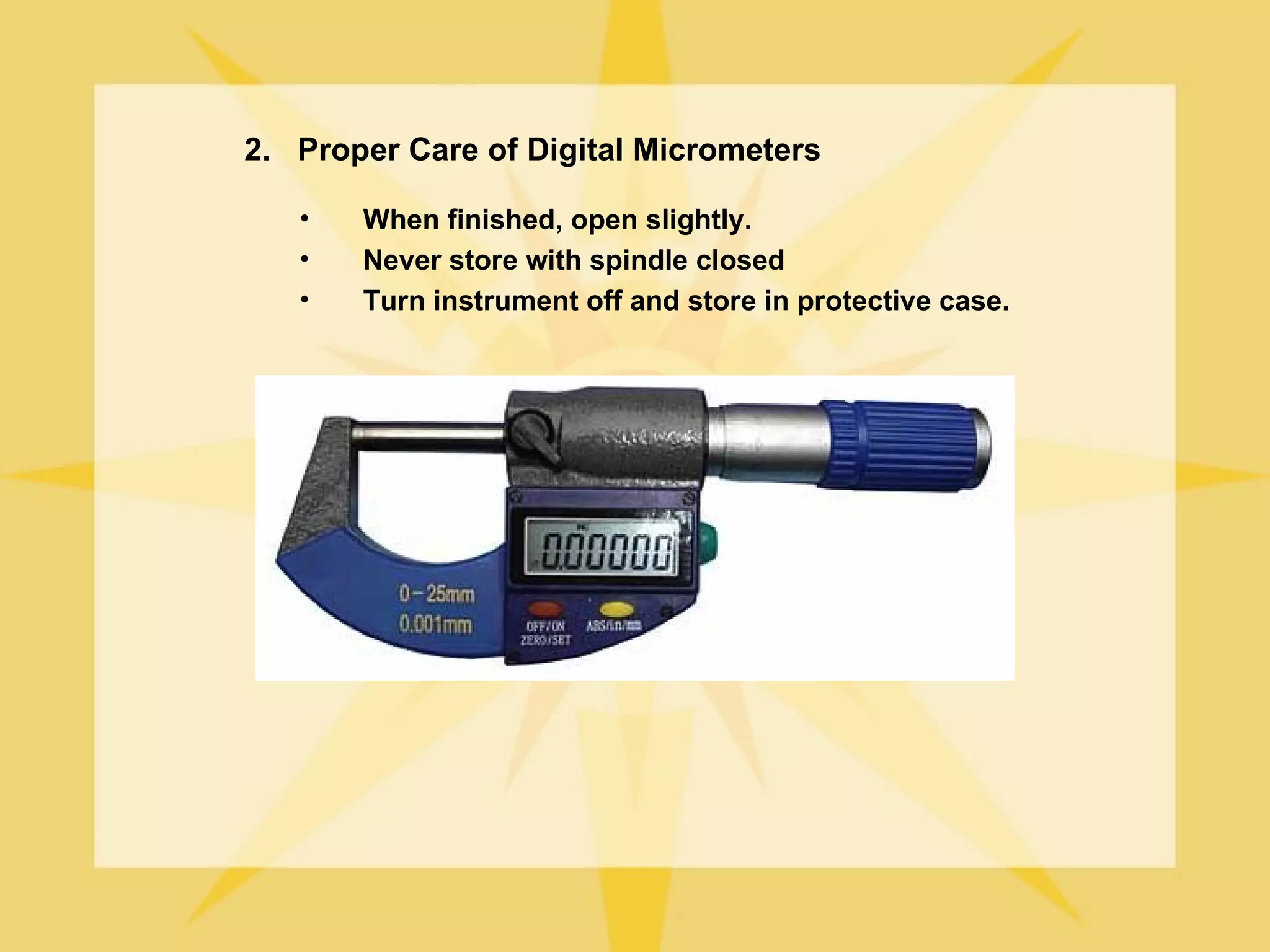

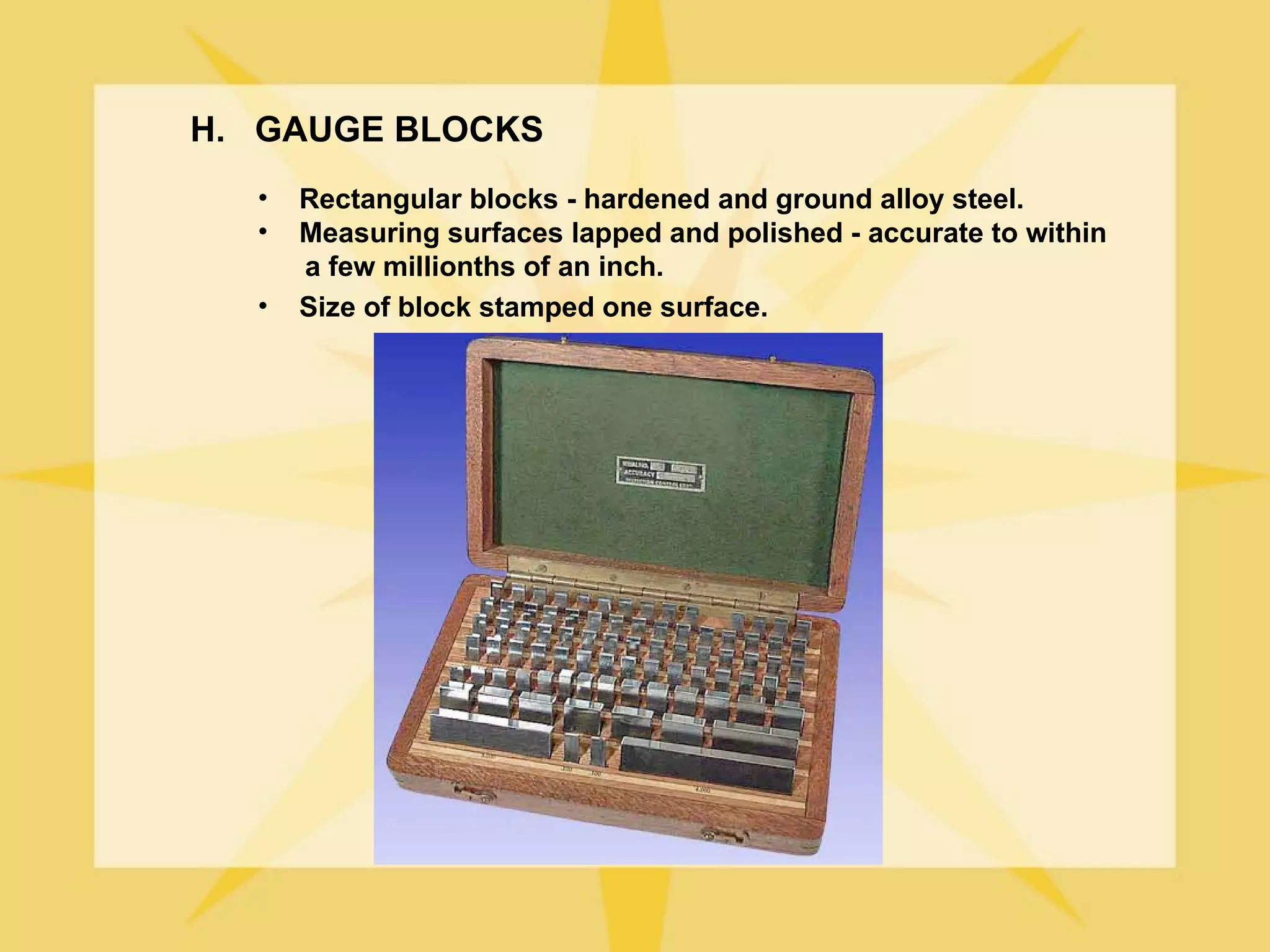

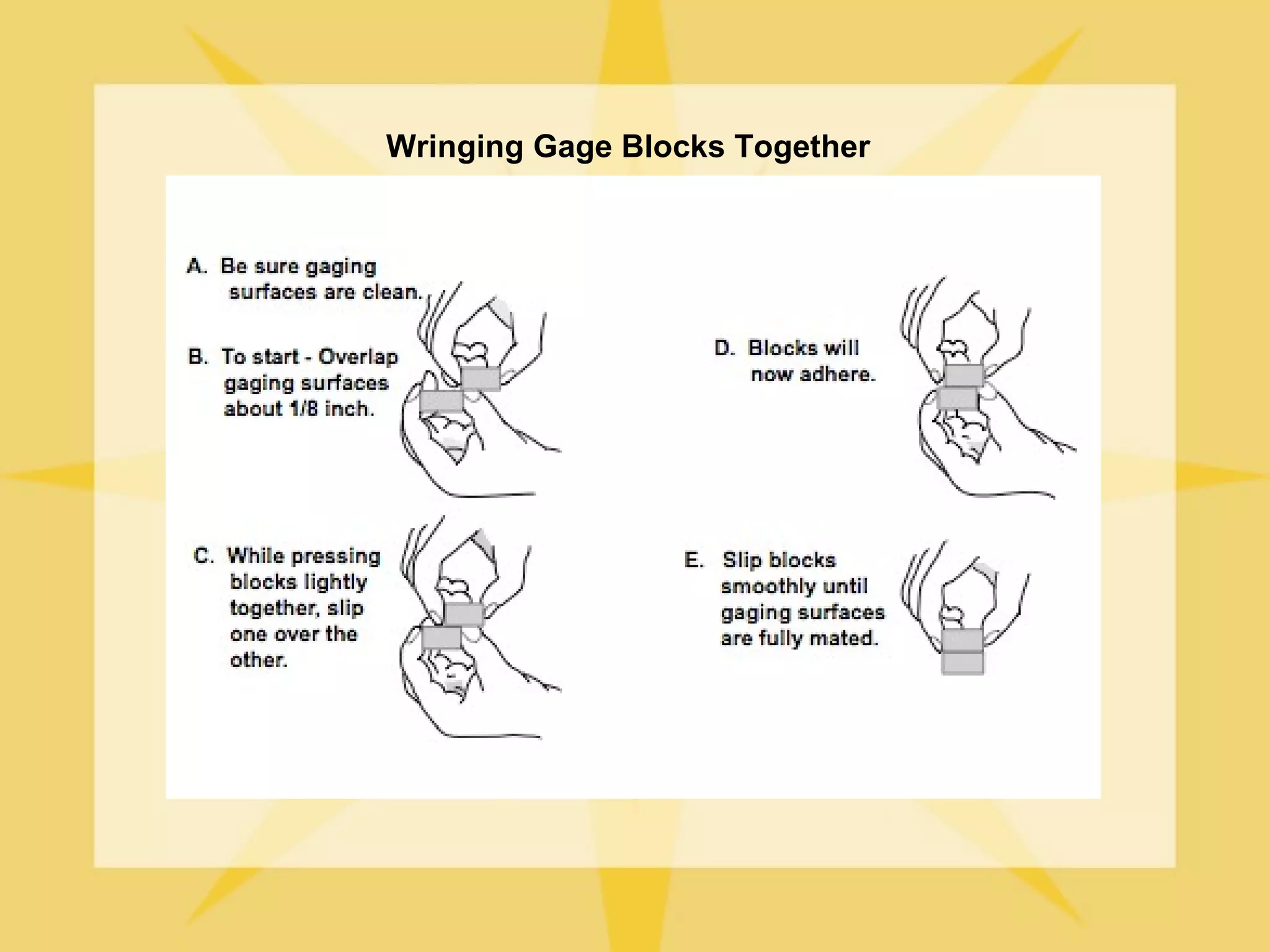

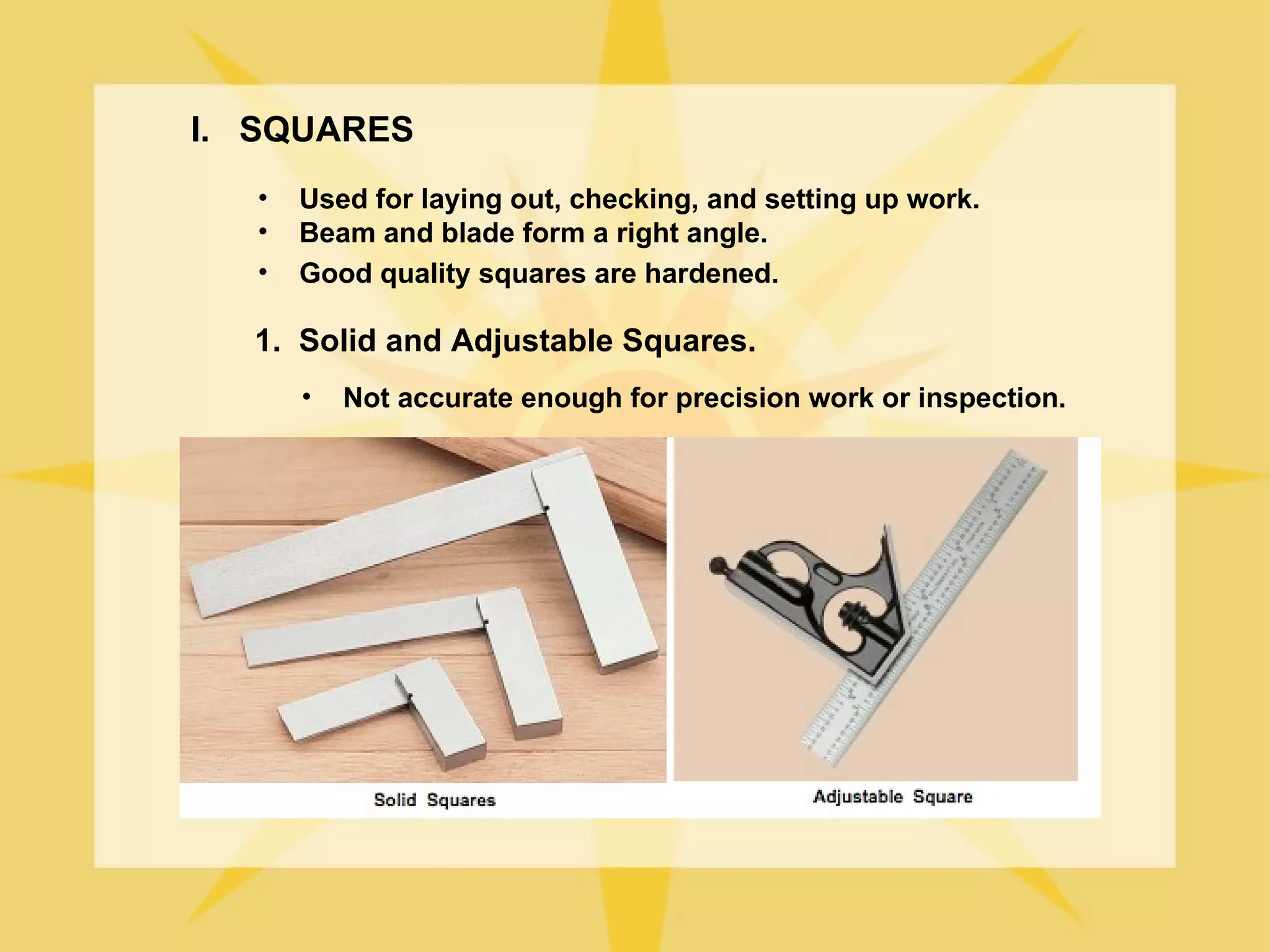

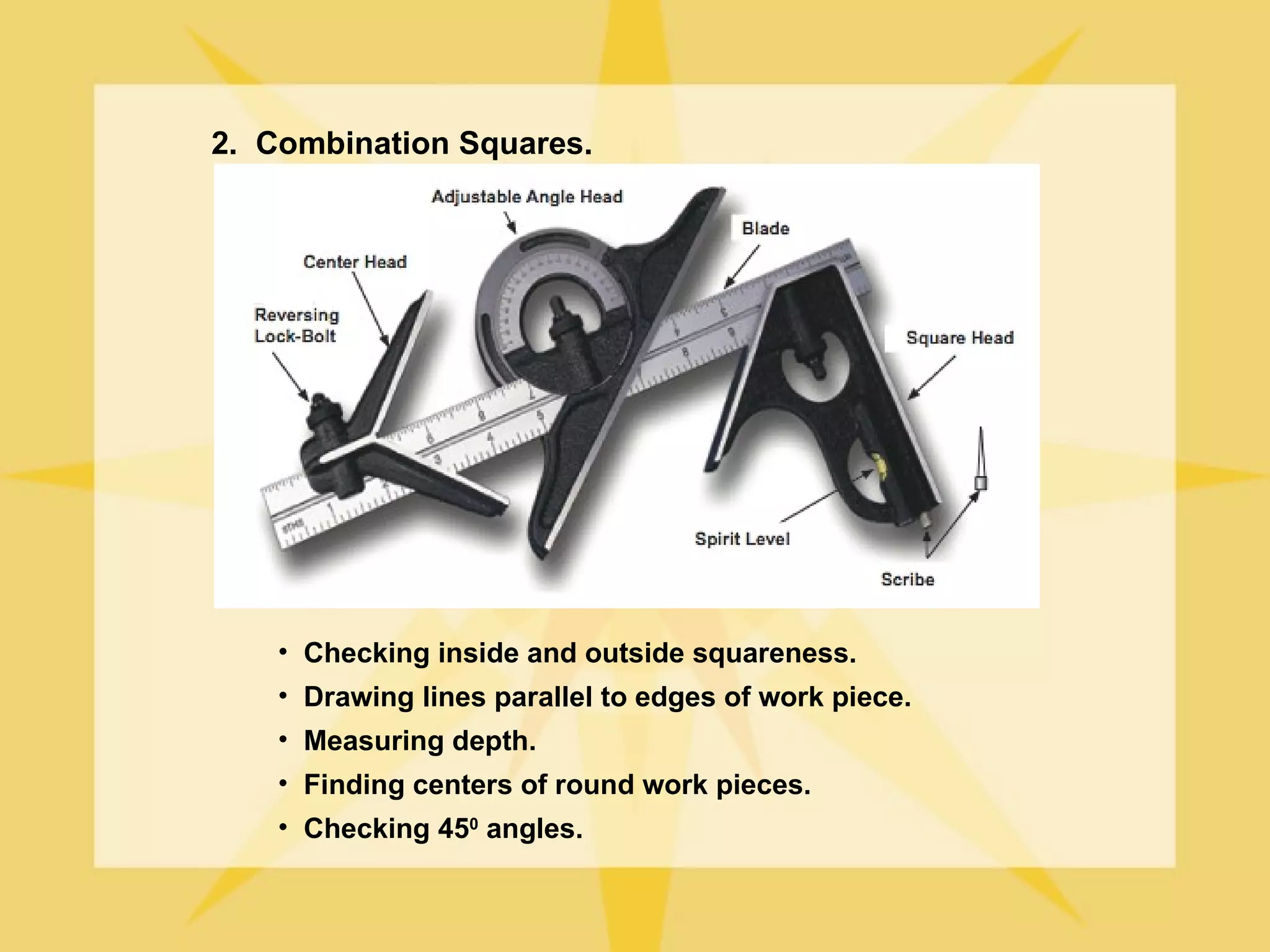

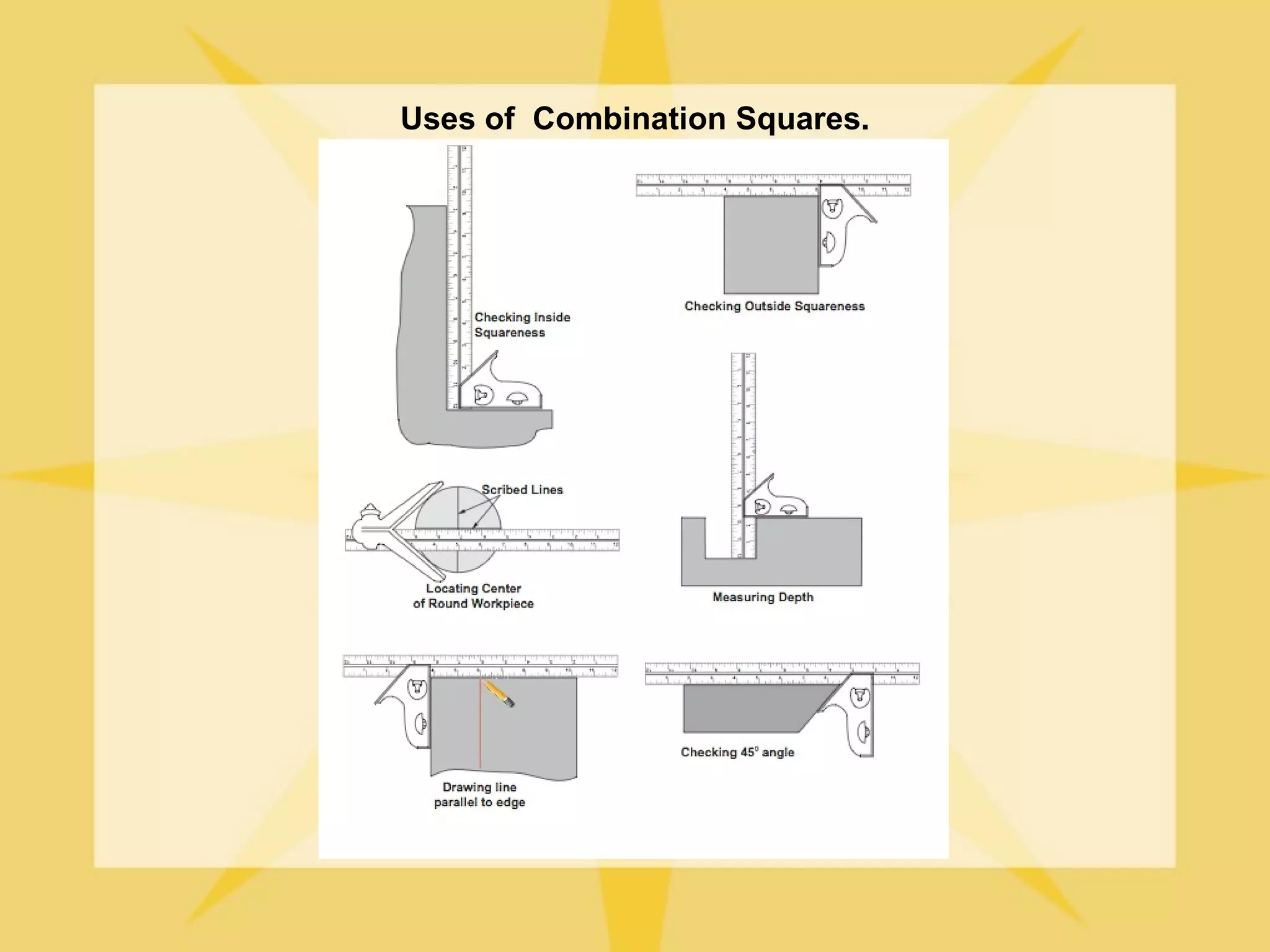

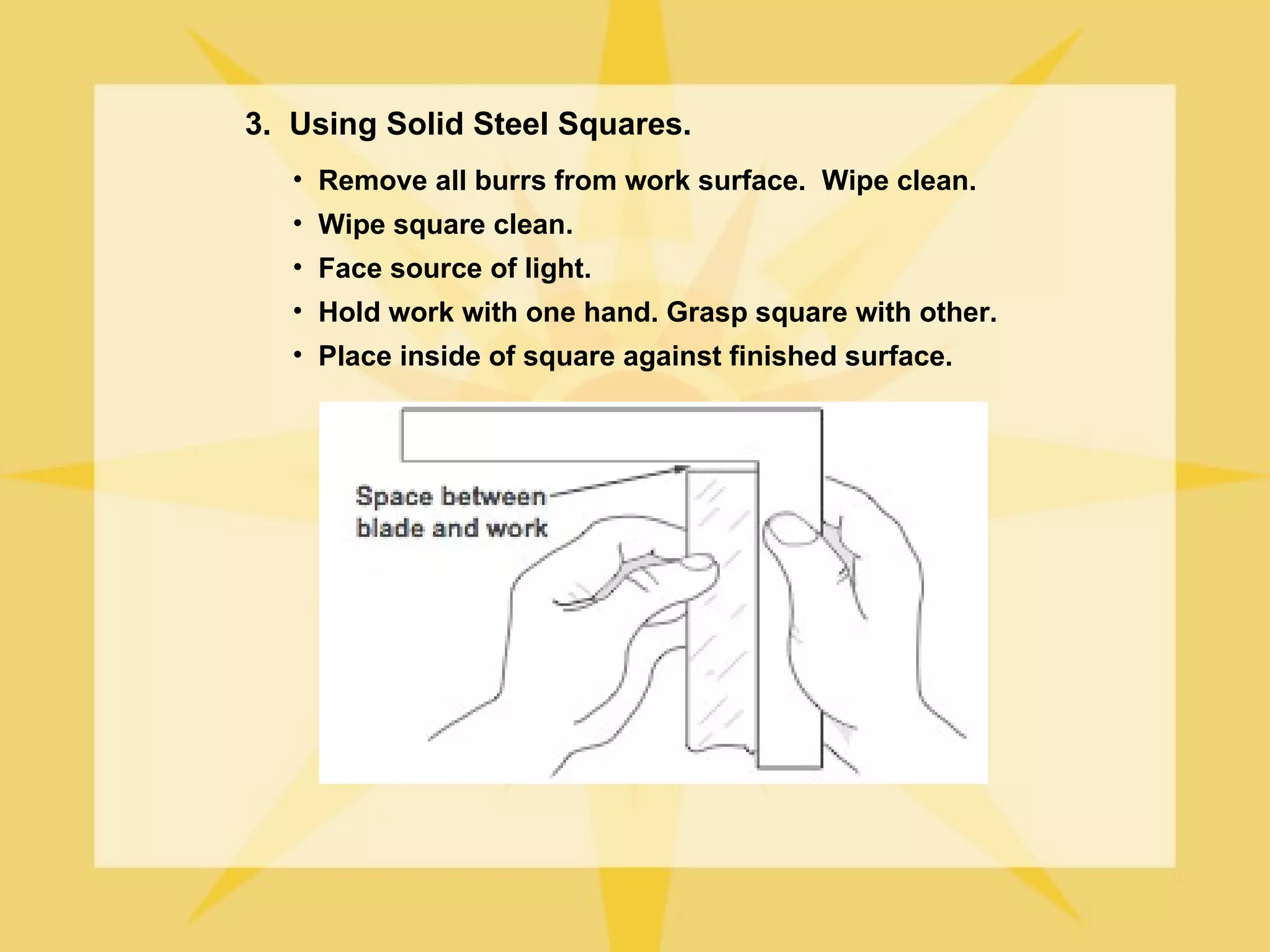

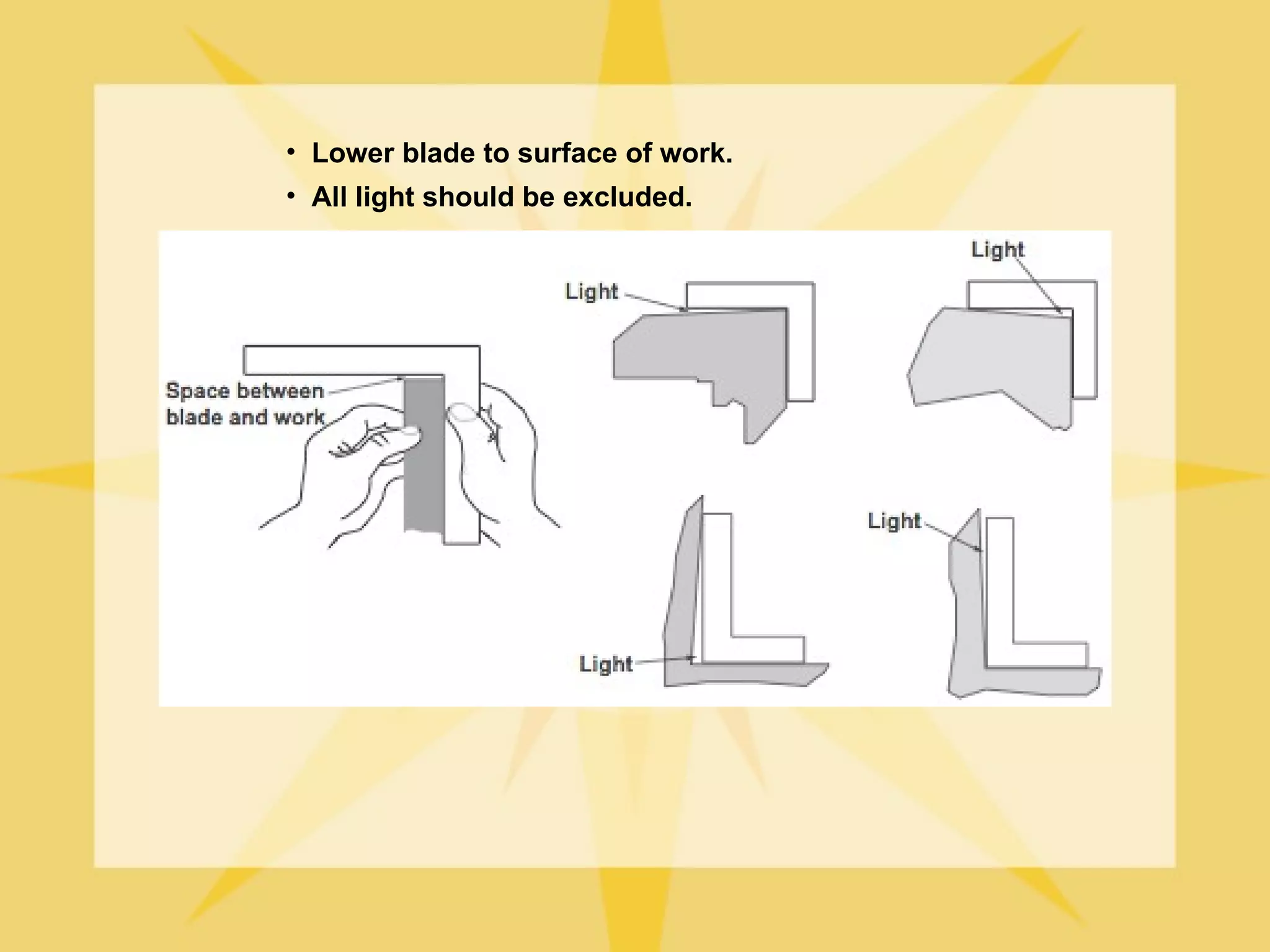

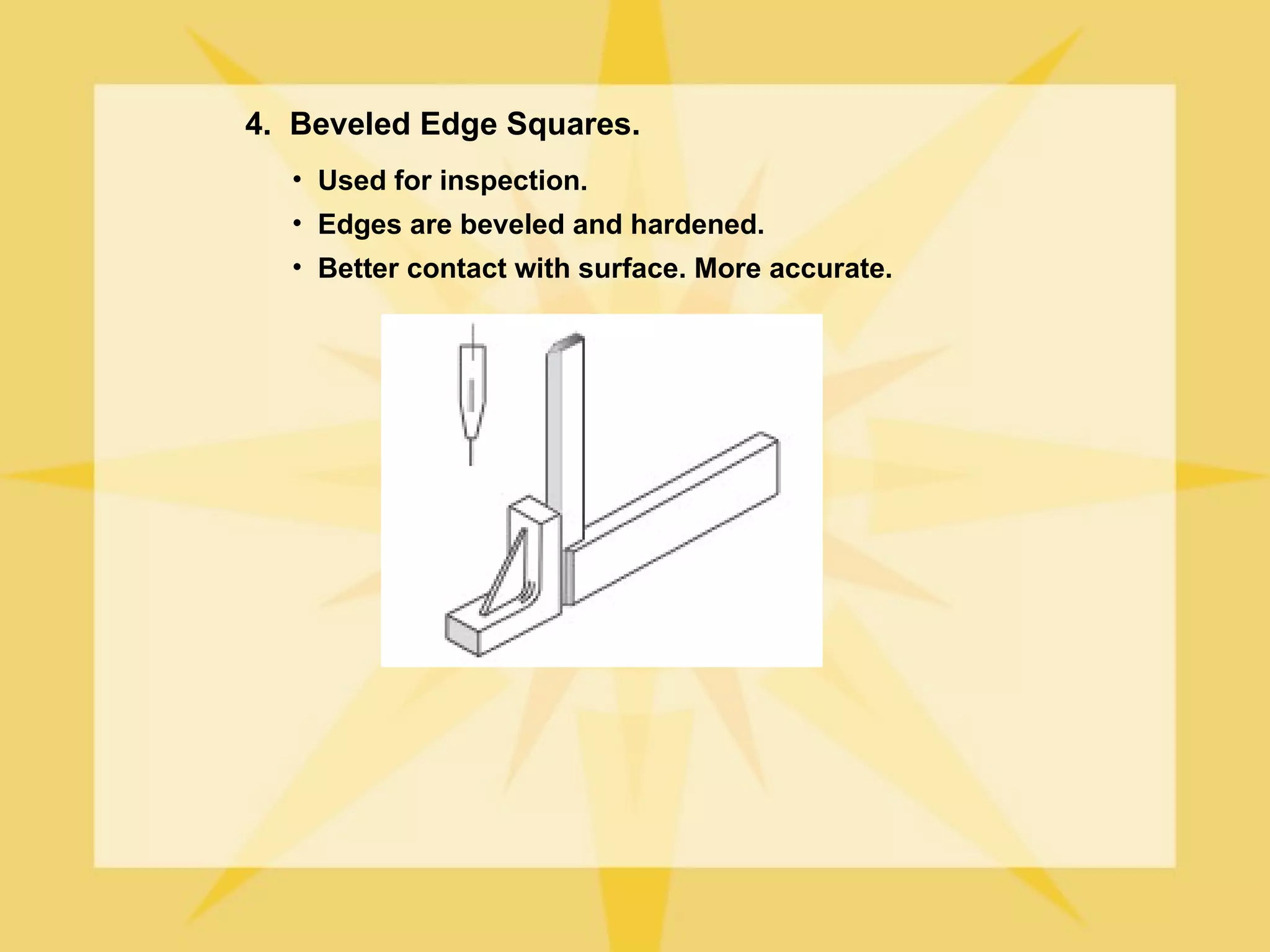

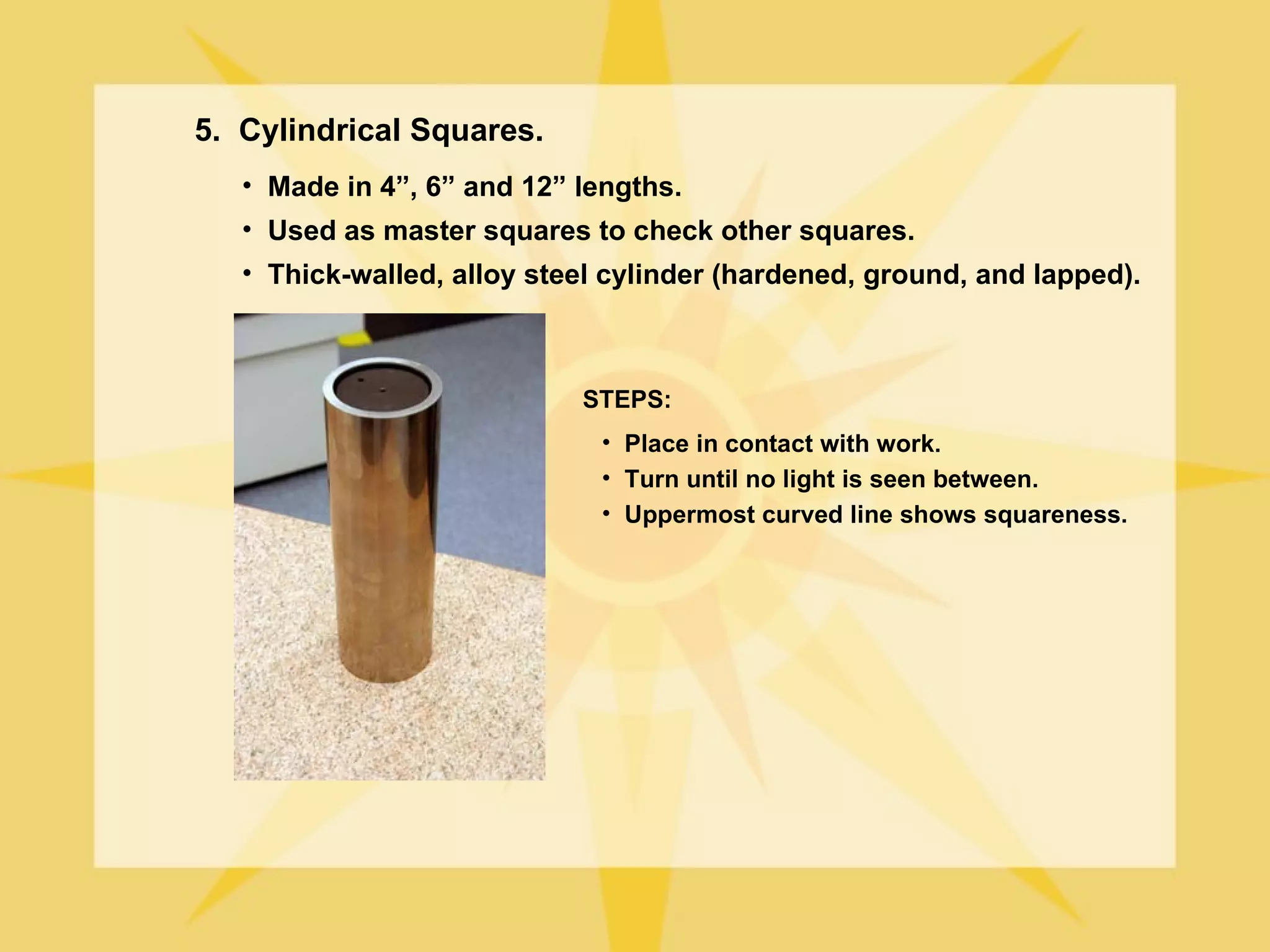

The document discusses various precision measurement tools including steel rules, fractional and decimal inch rulers, hooked rules, inside and outside calipers, dial and digital calipers, micrometers, gauge blocks, and squares. It provides details on how to use, read measurements from, and properly care for each type of tool. Examples and exercises are included to demonstrate how to perform measurements and calculations with fractions and in decimal and metric units.