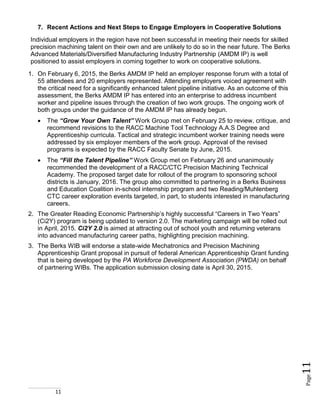

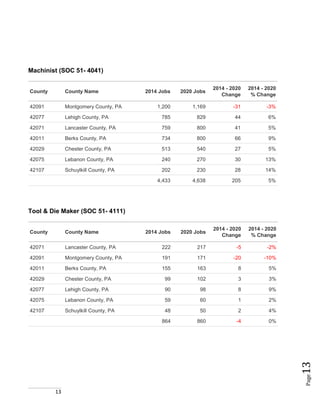

The document discusses precision machining occupations in Berks County and surrounding counties in Pennsylvania. It finds that these occupations, including computer-controlled machine tool operators, CNC machine tool programmers, machinists, and tool and die makers, are in high demand in the region and will see employment growth between 2014 and 2020. However, there is currently a shortage of qualified candidates for these roles. The document analyzes regional employment trends, job listings, demographics, and feedback from employers to demonstrate a need to expand the "talent pipeline" through training programs to meet the long-term demand for skilled workers in precision machining occupations.

![6

Page6

3. Regional Age Demographics by Occupation

“New skilled workers will be needed not only to keep pace with expected growth in U.S.

manufacturing production but also to replace professionals who are expected to retire from the

U.S. labor force…it can be assumed that around [27% of current] machinists will retire before

2020.” †

Bureau of Labor Statistics Quarterly Census of Employment and Wages (QCEW) data

confirms that the regional workforce for these occupations is becoming increasingly lop-sided

when considering the age demographic. 56.1% of the current regional workforce occupying

precision machining occupations is 45 years or older compared to 46% of the regional

workforce in all industries.

By 2020, 26.6% of the current precision machining workforce in the seven county region will be

near, at, or above retirement age. This will result in nearly 2,000 precision machining jobs

that could be affected and in need of replacement. Add to this the 340 new jobs expected

by 2020 and an effective succession of 32% of the regional precision machining workforce will

be required. The critical need for an expanded pipeline is evident.

Age 2014 Jobs

2014

Percent

● 14-18 39 0.5%

● 19-24 539 7.1%

● 25-34 1,255 16.4%

● 35-44 1,520 19.9%

● 45-54 2,249 29.5%

● 55-64 1,637 21.4%

● 65+ 396 5.2%

Total 7,635

† Source: Excerpts from “The U.S. Skills Gap: Could It Threaten a Manufacturing Renaissance?” H. Sirkin, M. Zinser, & J. Rose. The Boston

Consulting Group.

4. Pipeline

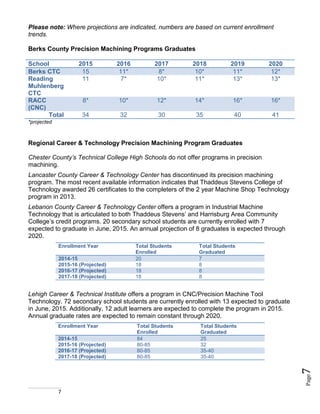

In September, 2014 a survey of Berks County educational providers was conducted to gauge

the enrollment in precision machining programs. According to the two Berks County Career &

Technology Centers, 68 adult and secondary school students are currently enrolled with 26

due to graduate by June, 2015.

Reading Area Community College (RACC) reports graduating on average 20 CNC Operator

Certificate program completers annually but this number has fluctuated based on

unemployment levels and financial aid availability. Future numbers could be negatively

impacted by the lack of subsidizing grant funds and company tuition assistance.](https://image.slidesharecdn.com/a0c04fbb-917a-4fef-aa3d-88a3eb2624fa-150721163139-lva1-app6891/85/Precision-Machining-Abstract_Final-6-320.jpg)