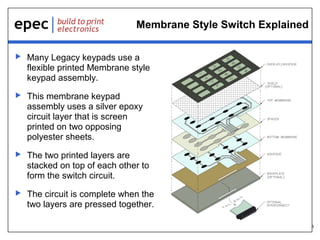

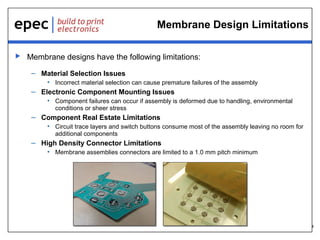

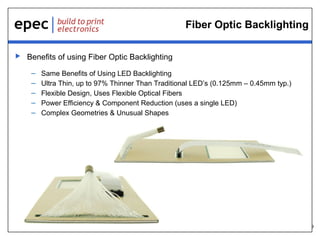

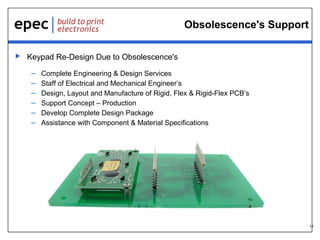

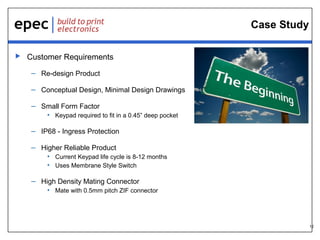

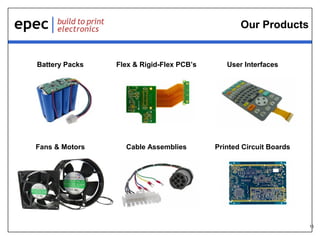

The document outlines a webinar by Epec Engineering focusing on redesigning legacy keypads for modern technologies, covering the transition to rigid, rigid-flex, and flex printed circuit boards (PCBs). It discusses the limitations of membrane-style keypads and the benefits of using PCB alternatives, including improved reliability and design flexibility, as well as the advantages of LED and fiber optic backlighting solutions. Additionally, Epec offers support for updating user interfaces and obsolescence-related redesigns with comprehensive engineering services.