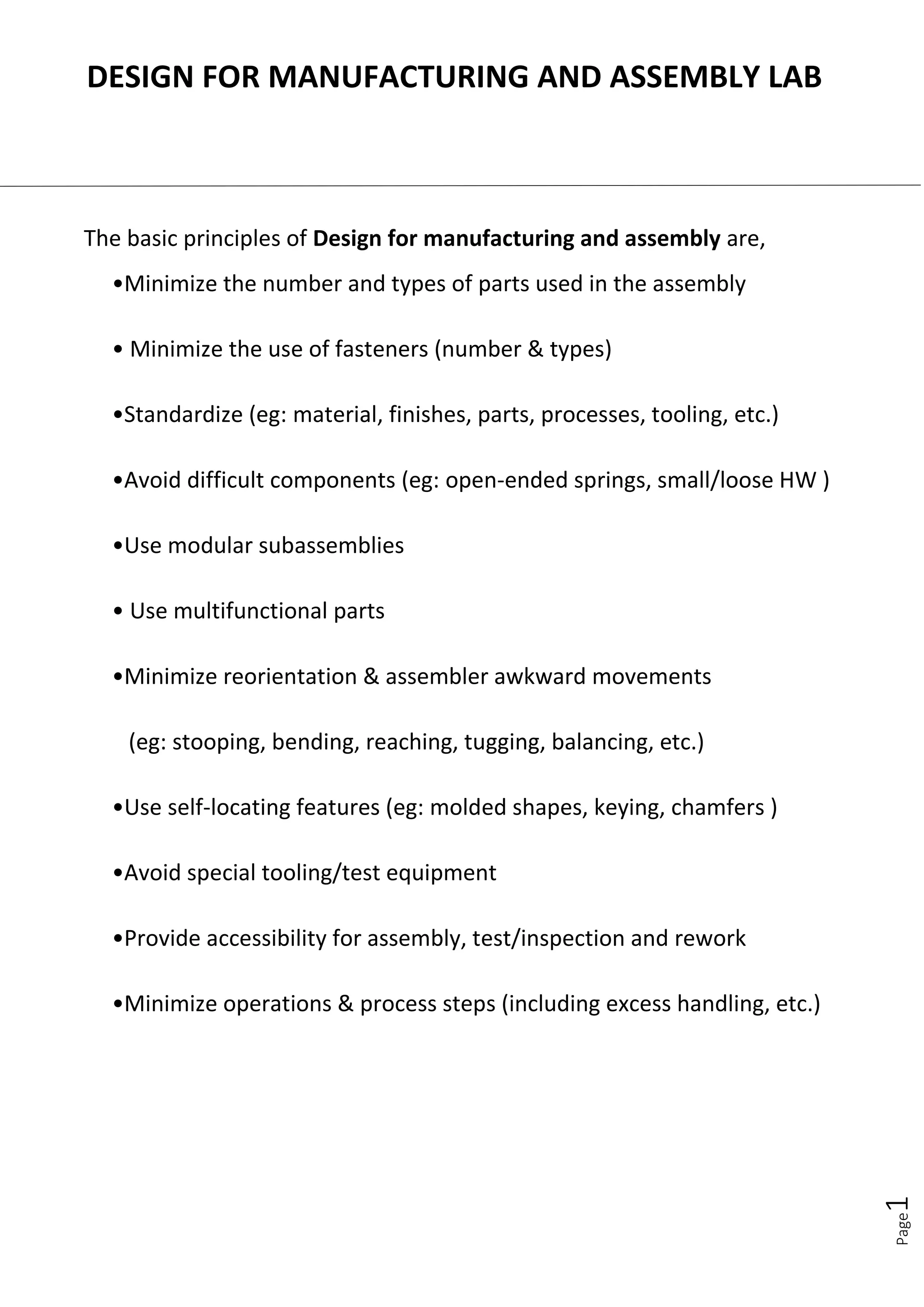

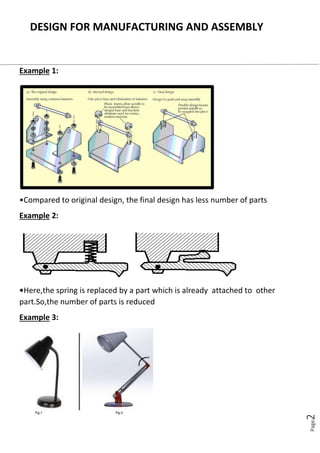

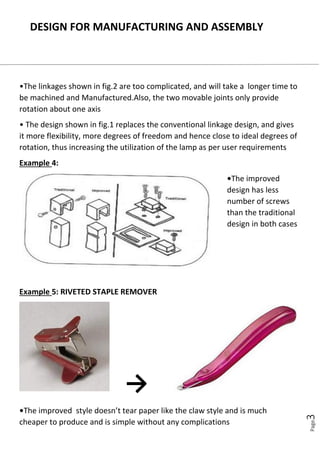

The document outlines the principles of design for manufacturing and assembly (DfMA), emphasizing the reduction of parts, standardization, and ease of assembly to enhance efficiency. It provides examples demonstrating improvements in design, such as decreasing the number of parts and simplifying components for cost-effectiveness. Key strategies include using modular designs, multifunctional parts, and ensuring accessibility in the assembly process.