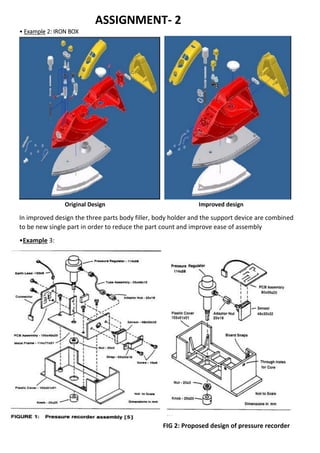

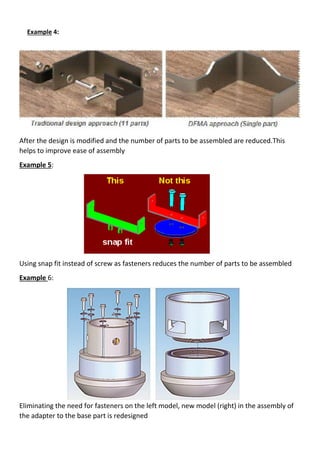

The document discusses five examples of product improvement through standardization, including the smart plug for enhanced control, standardized plain packaging for tobacco products, and uniformity in DVD players. It also identifies products that improve assembly ease, such as a redesigned motor drive assembly and innovative fastening methods. Furthermore, it highlights methods to reduce design complexity, focusing on simplified mechanisms for better functionality.