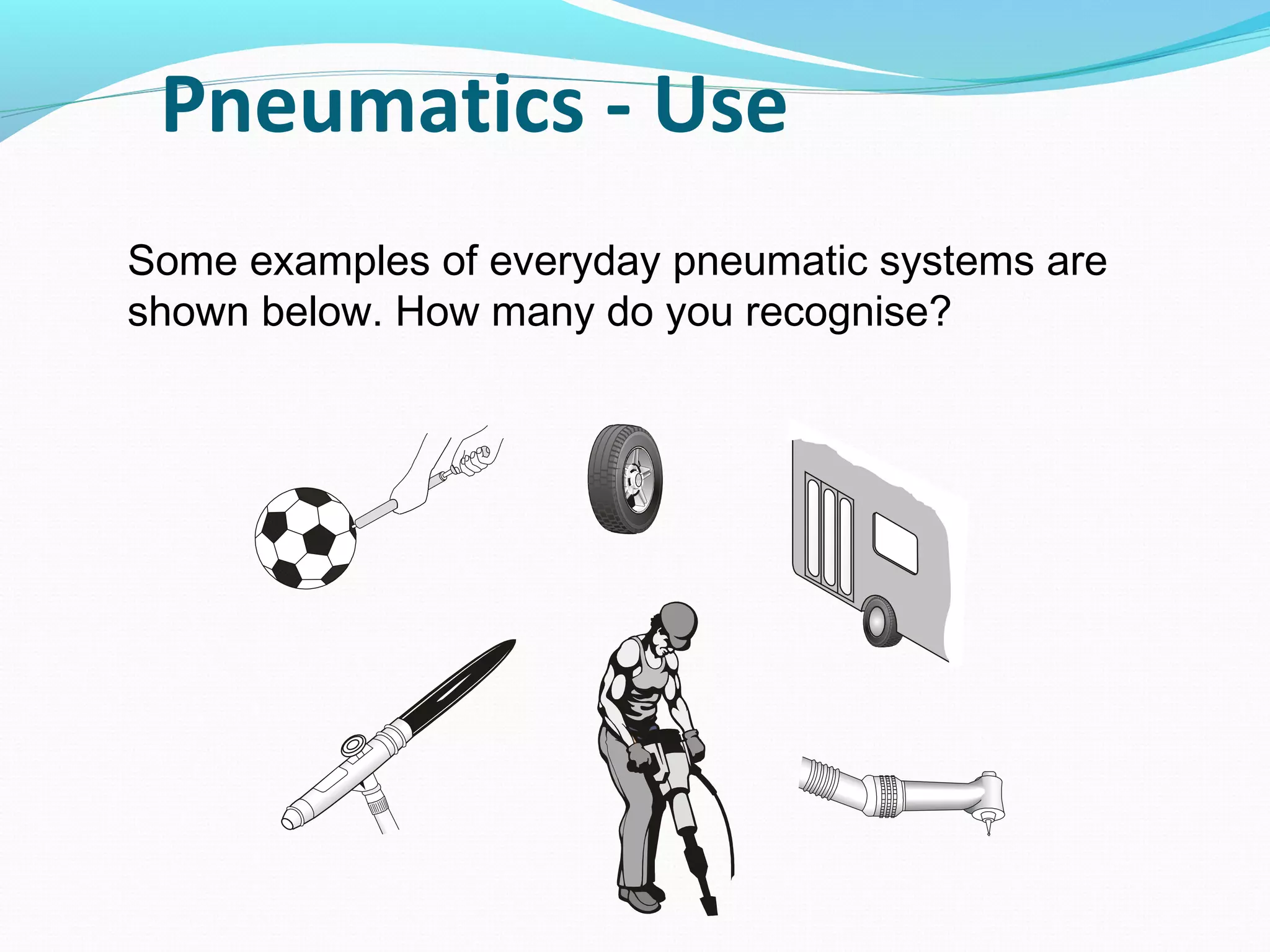

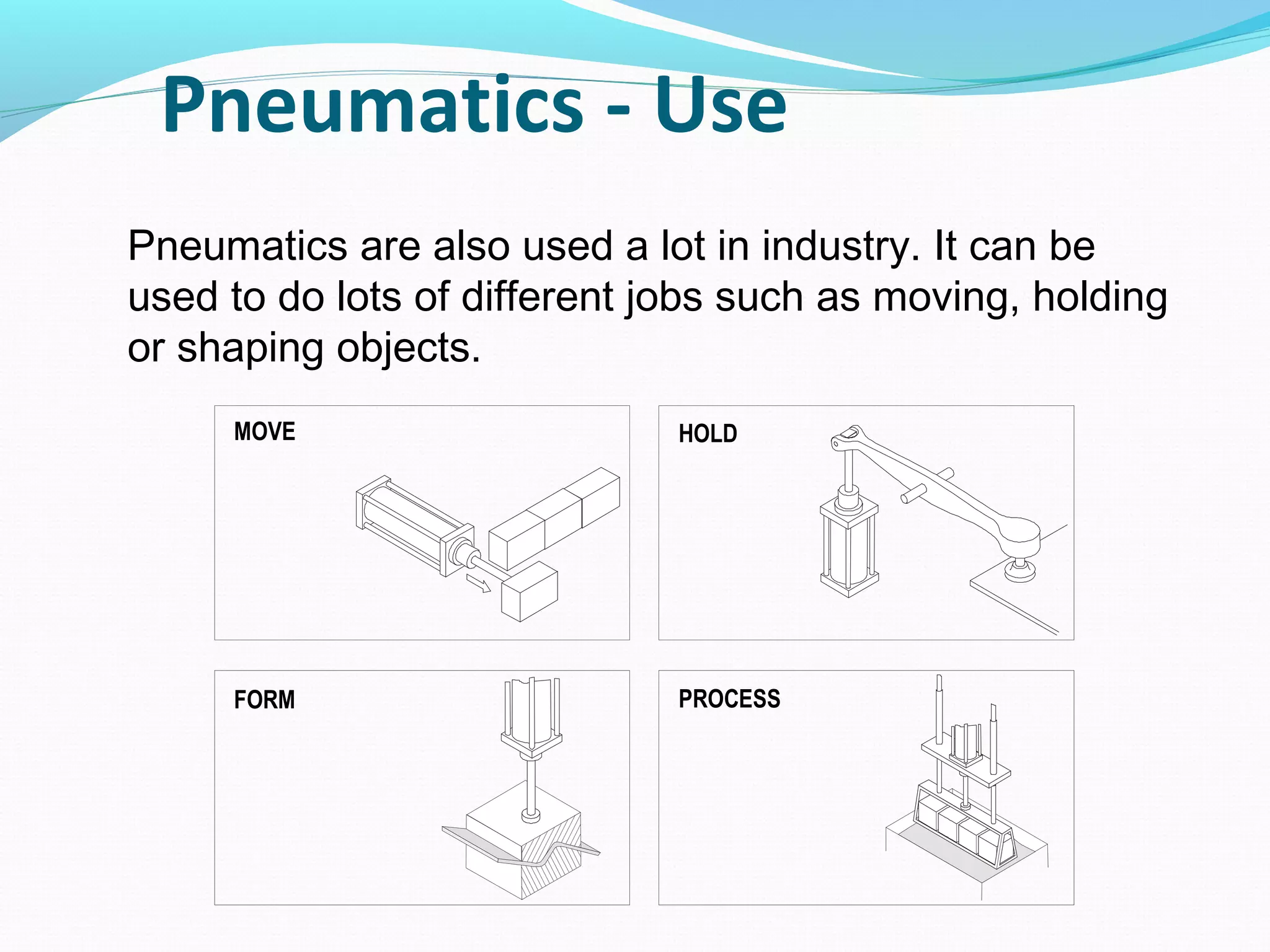

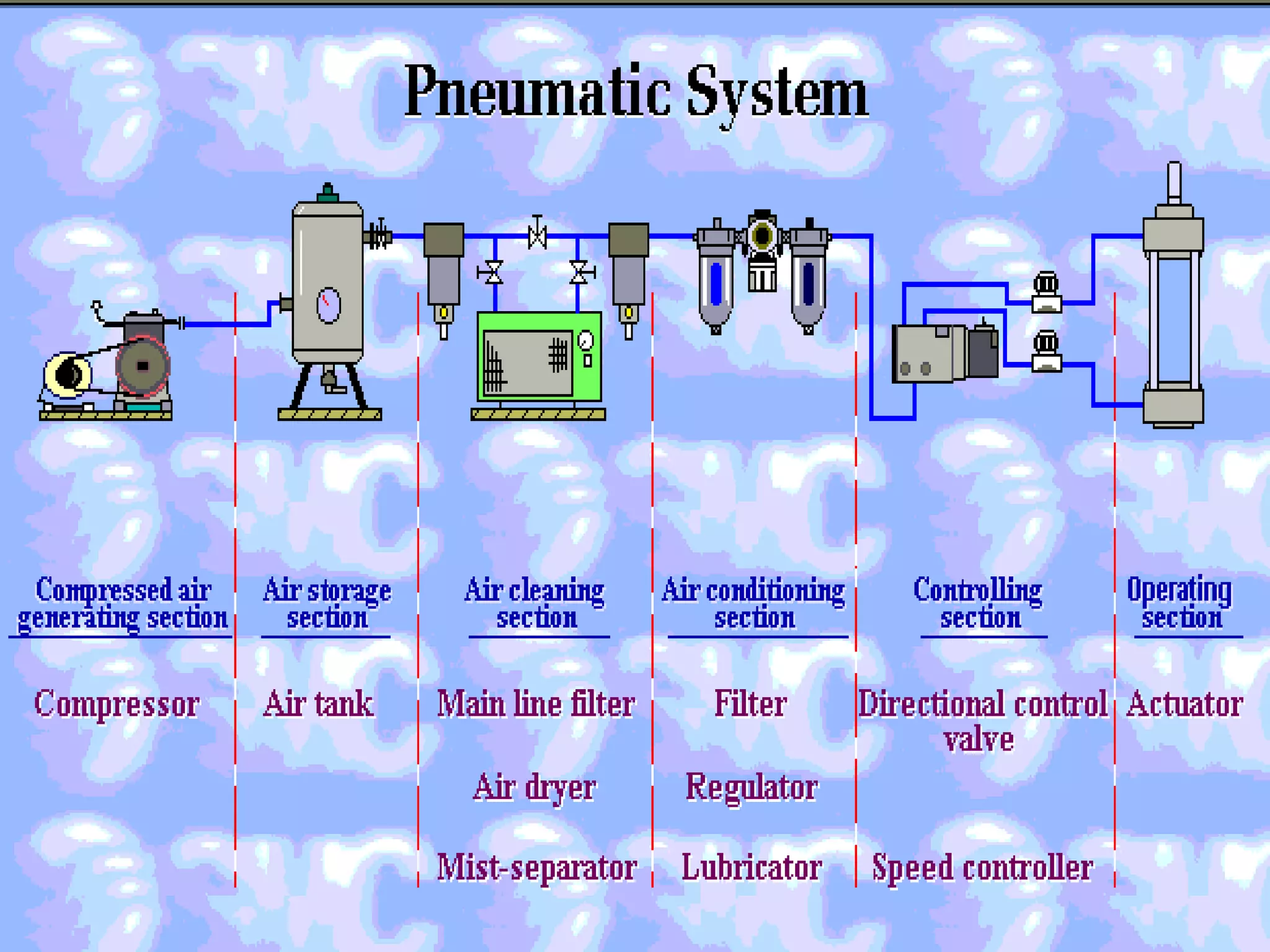

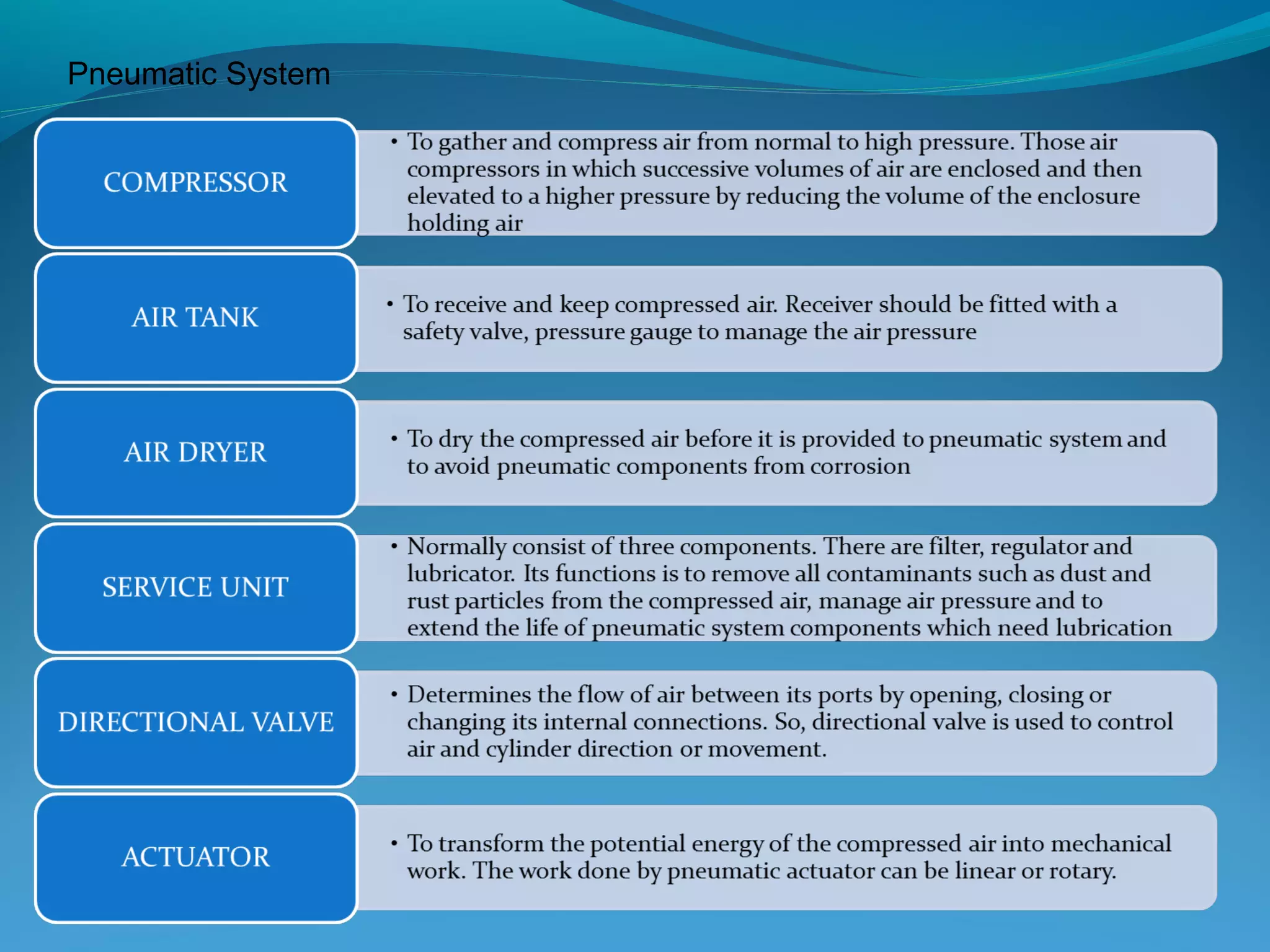

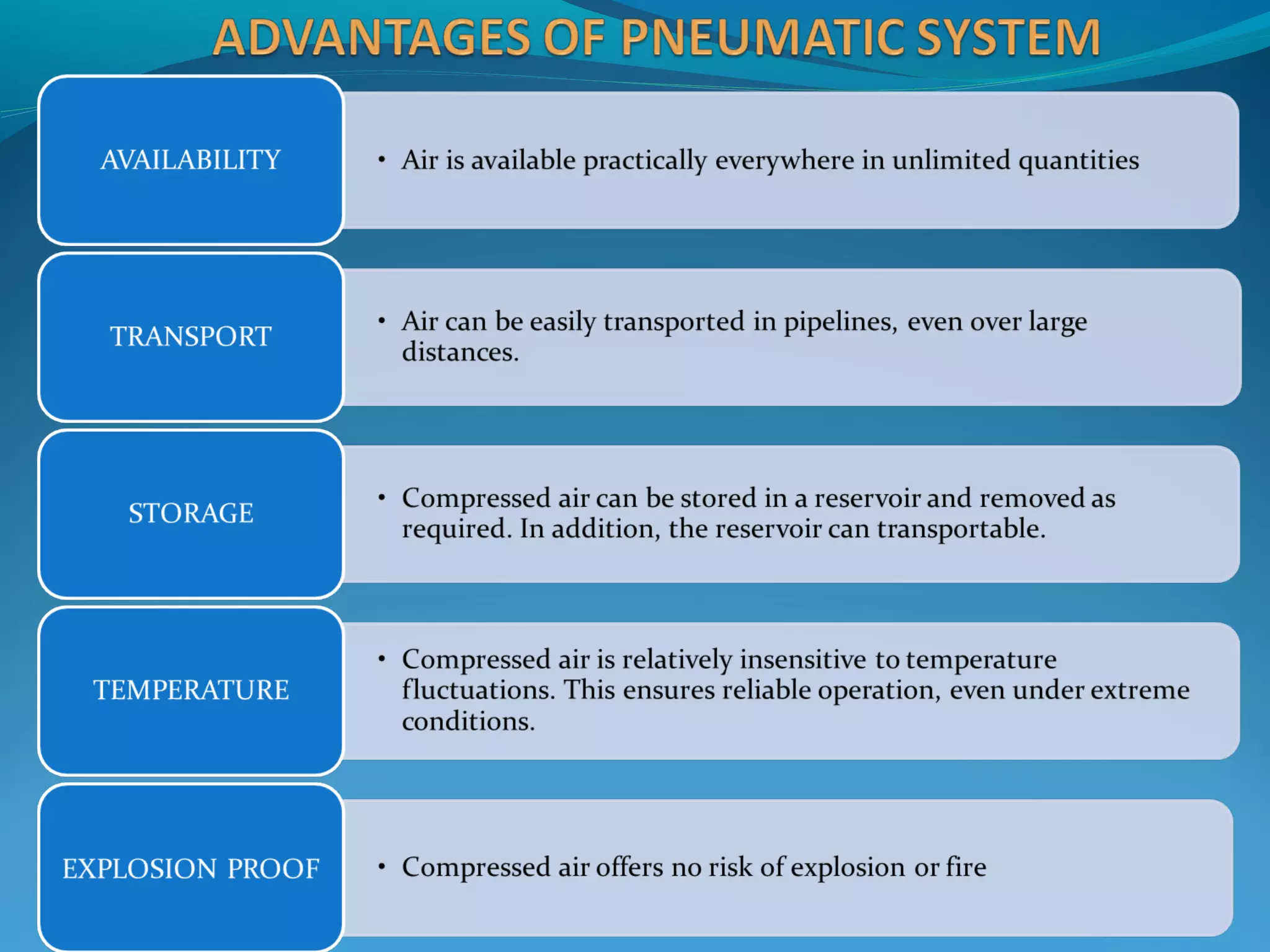

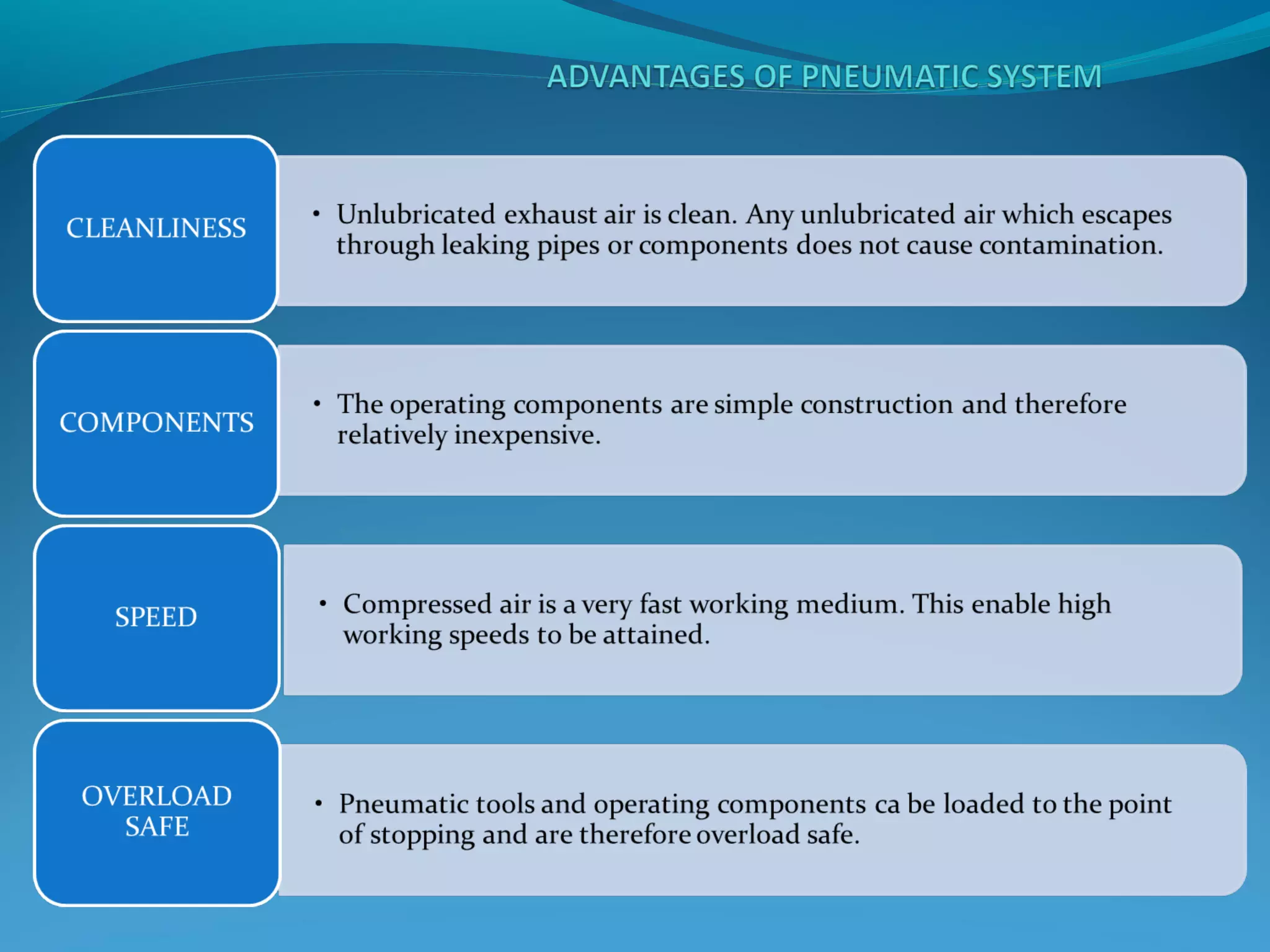

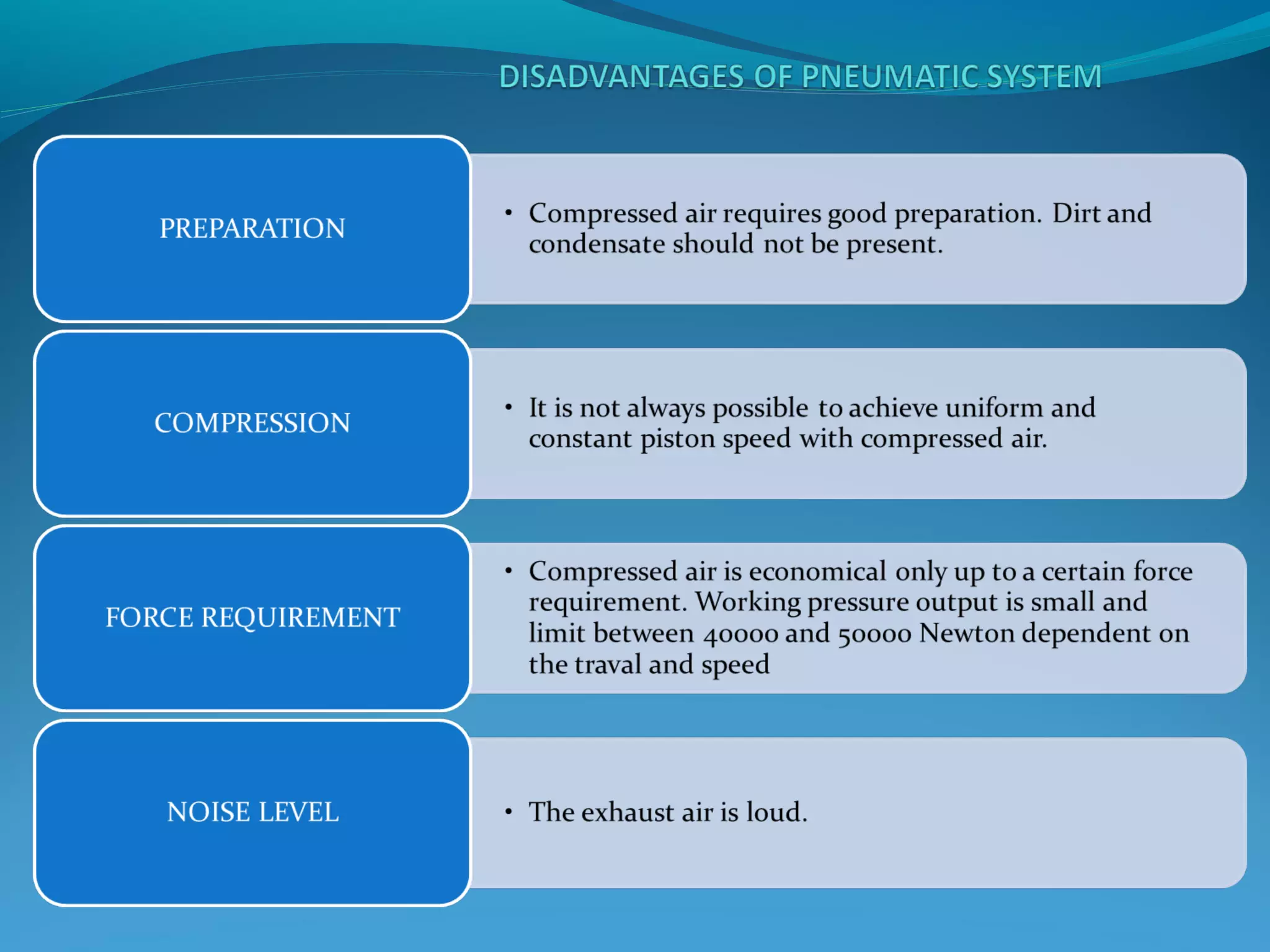

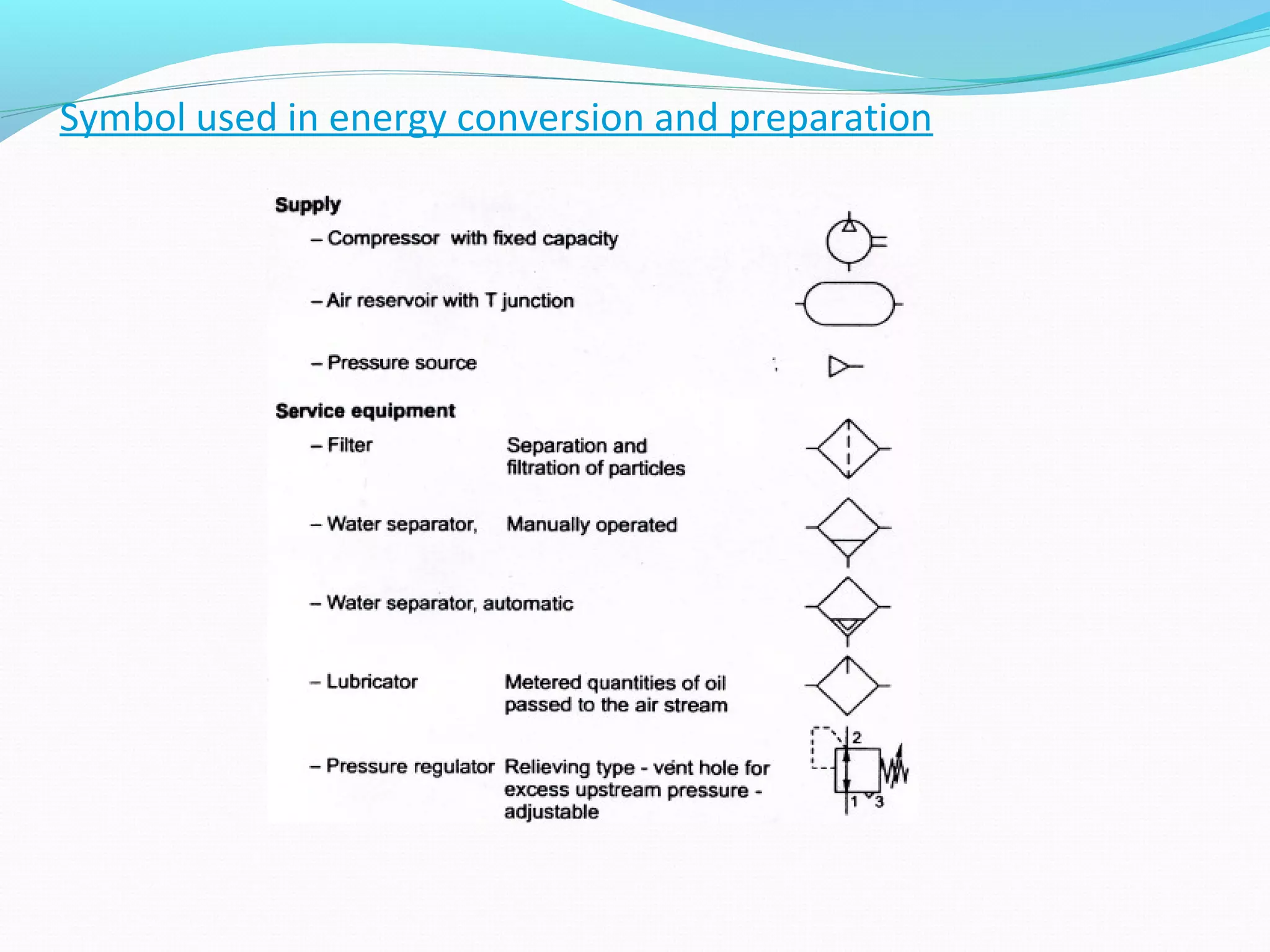

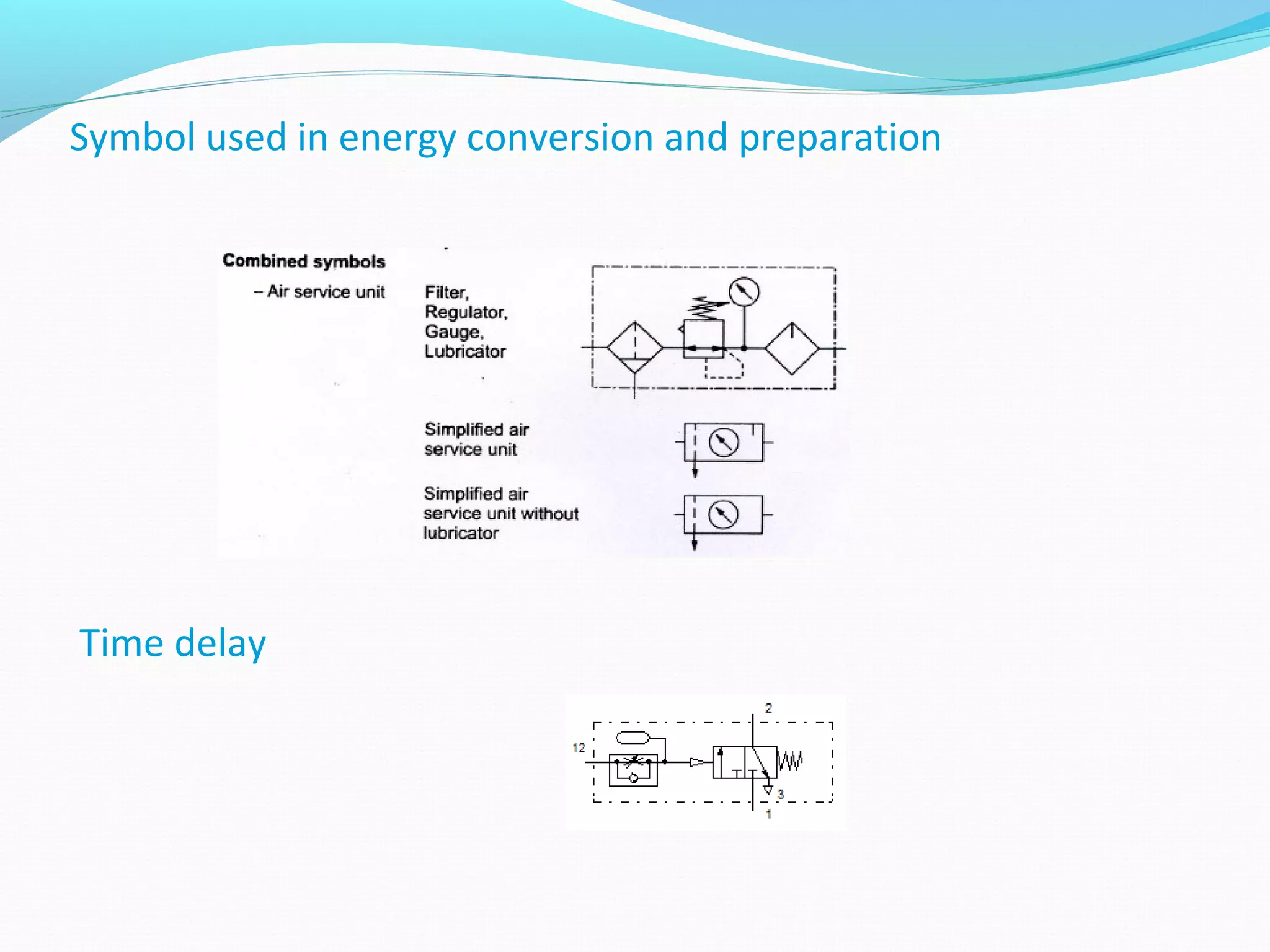

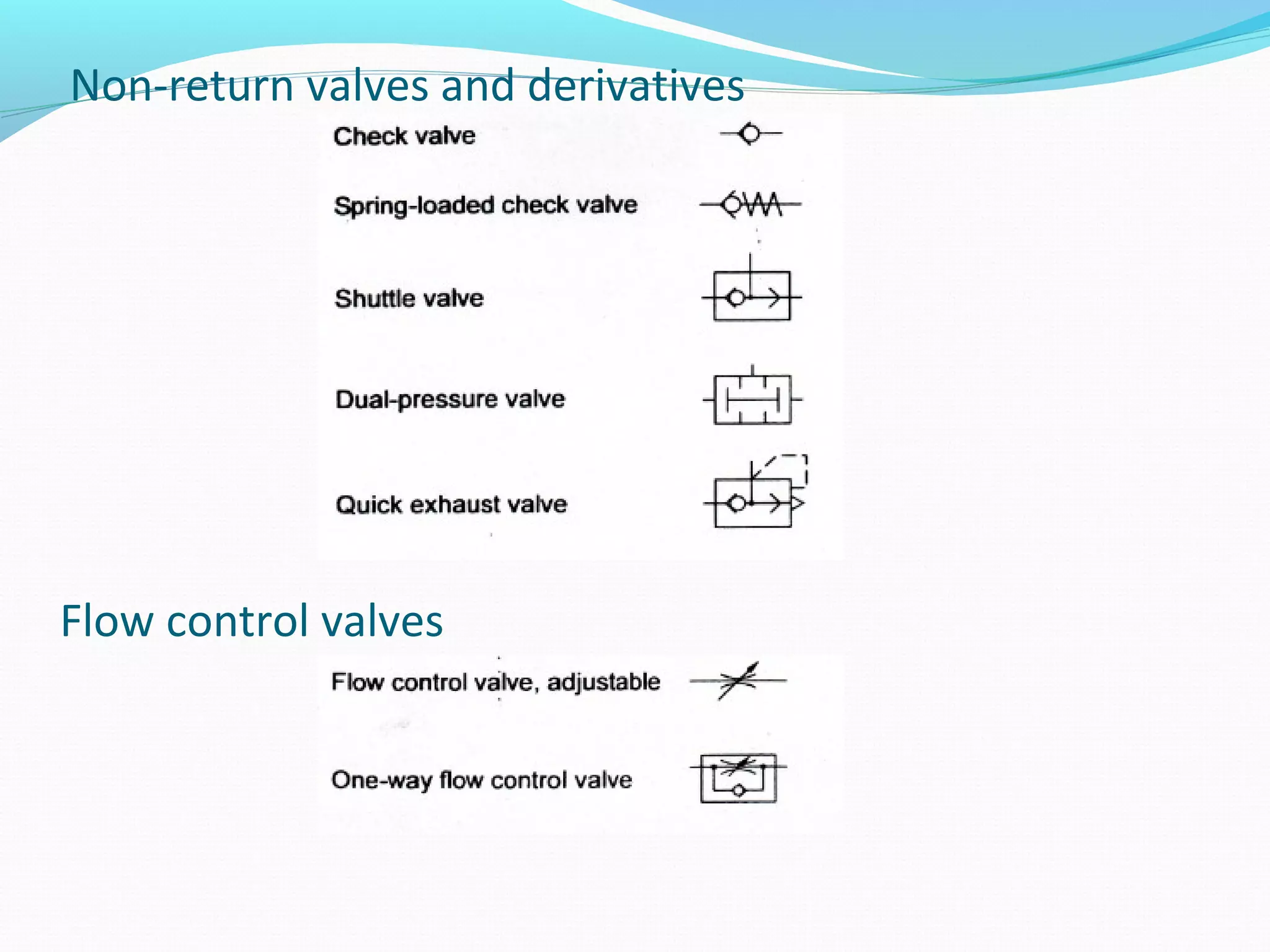

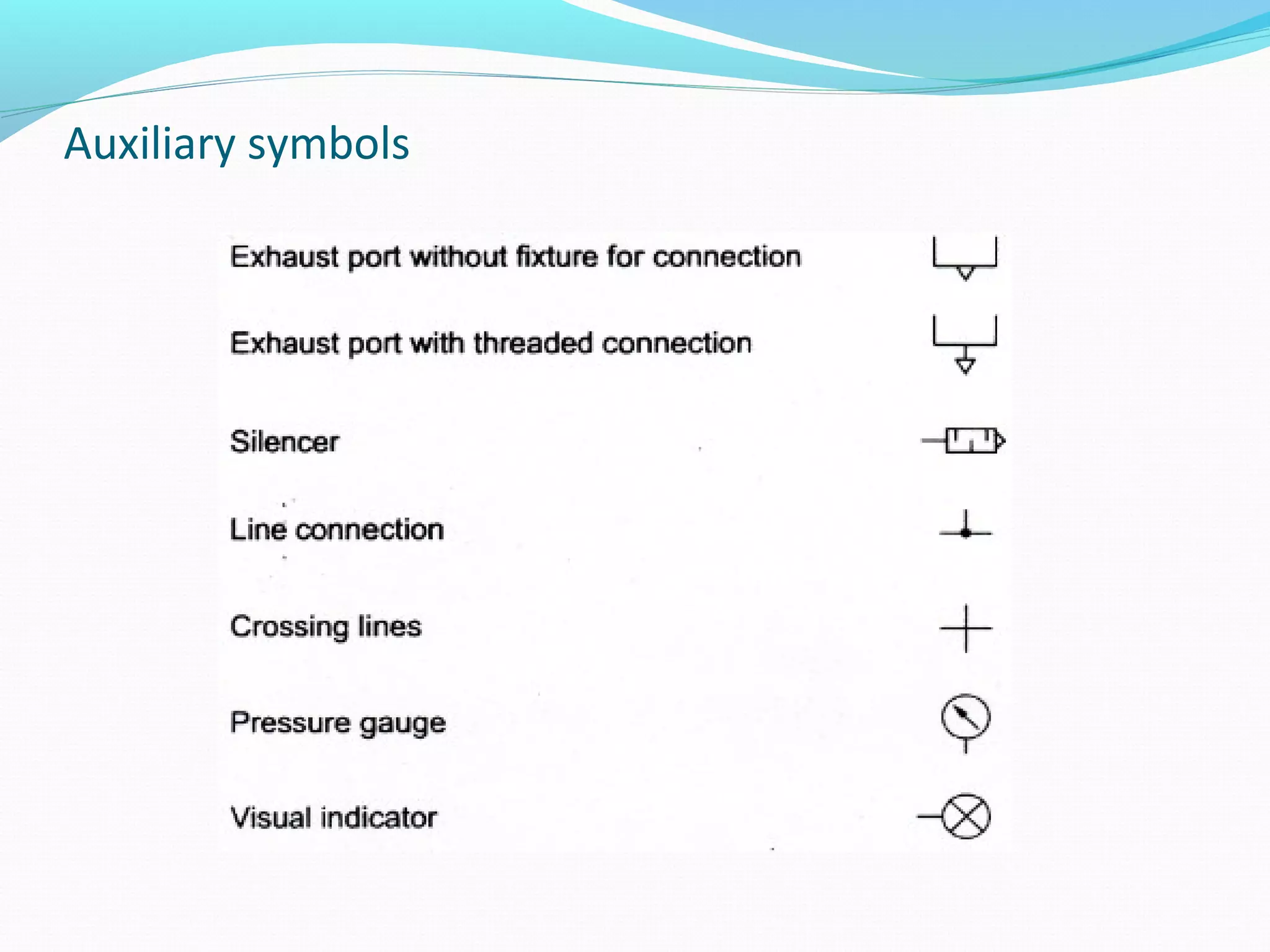

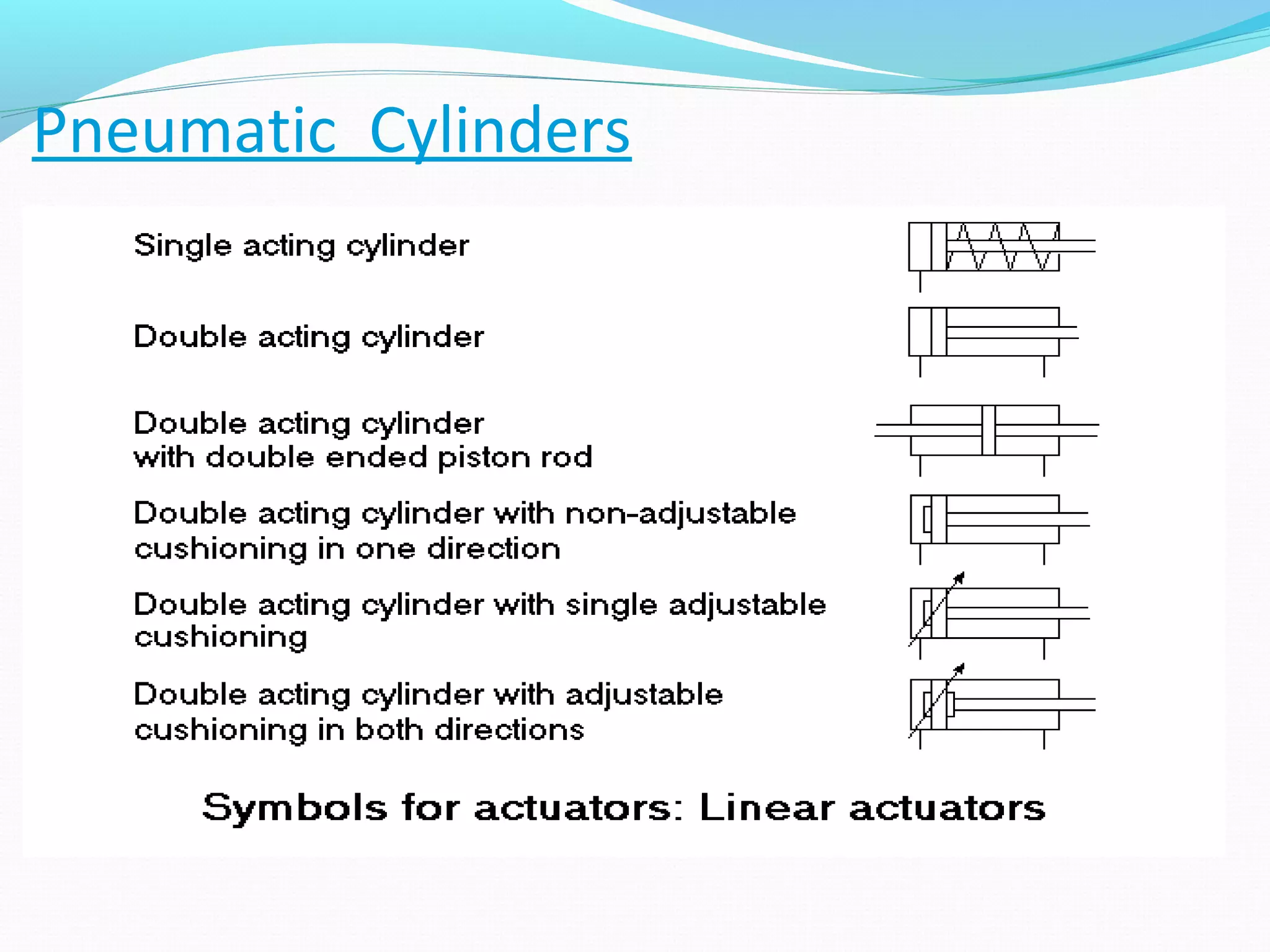

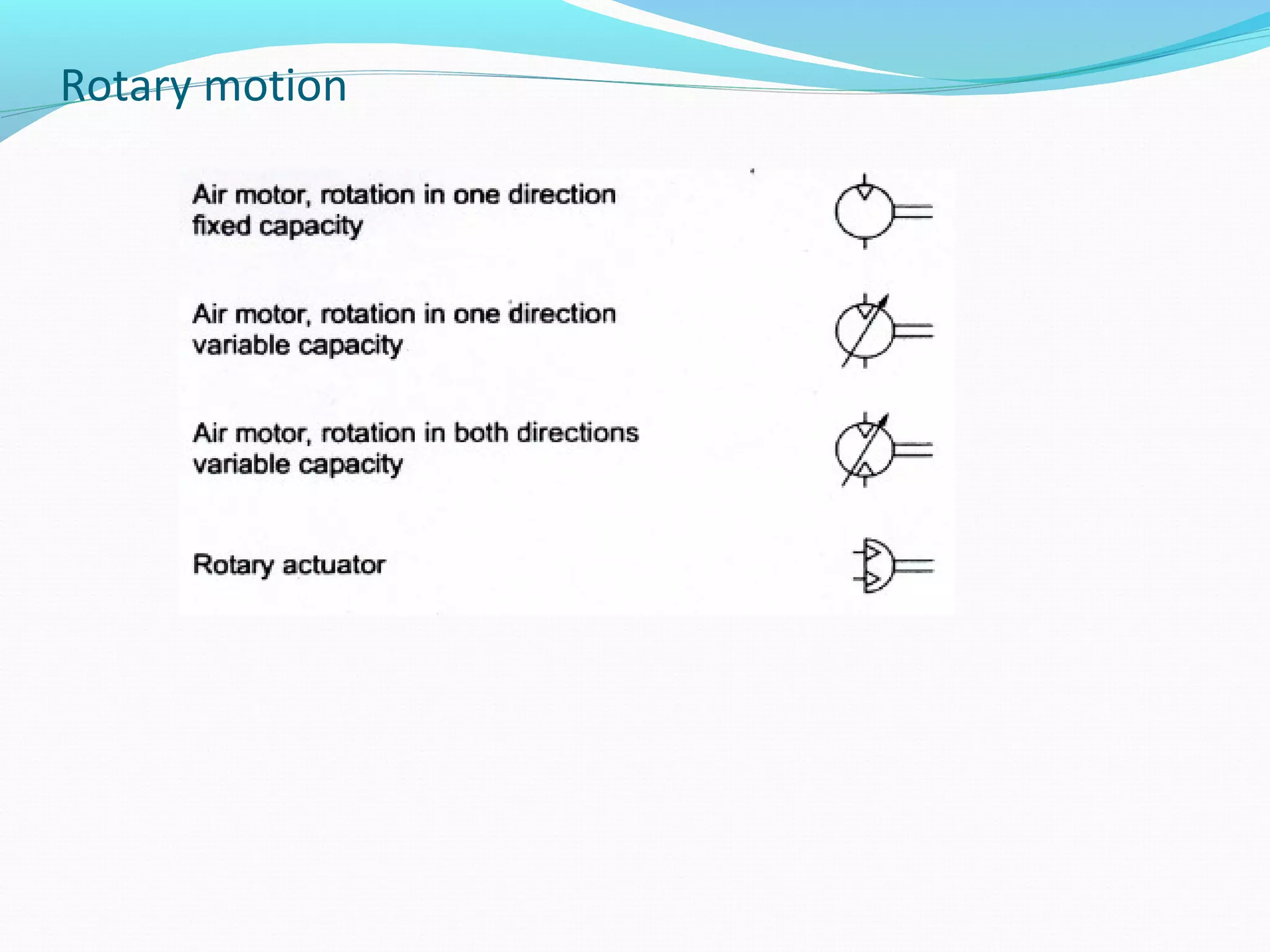

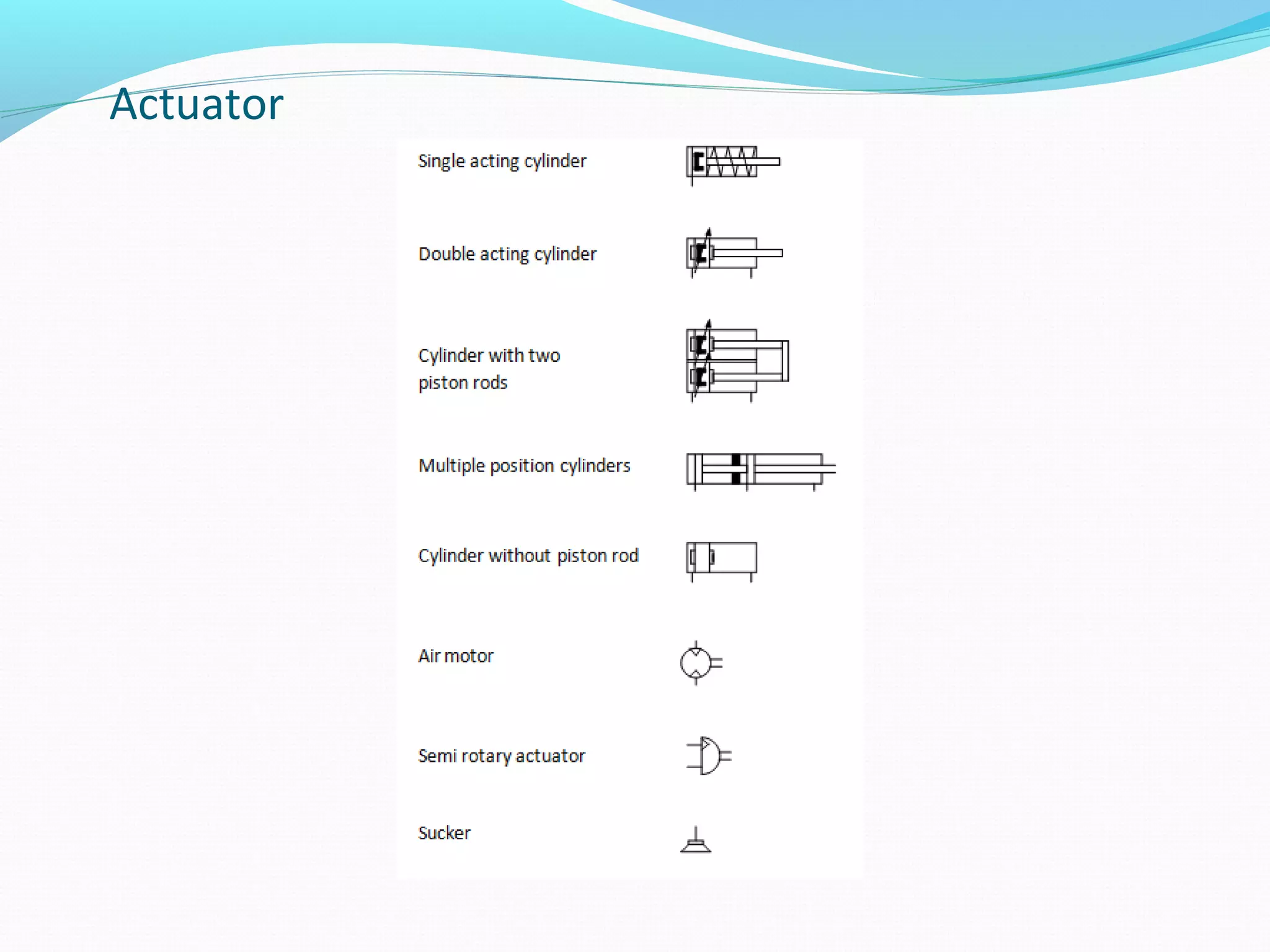

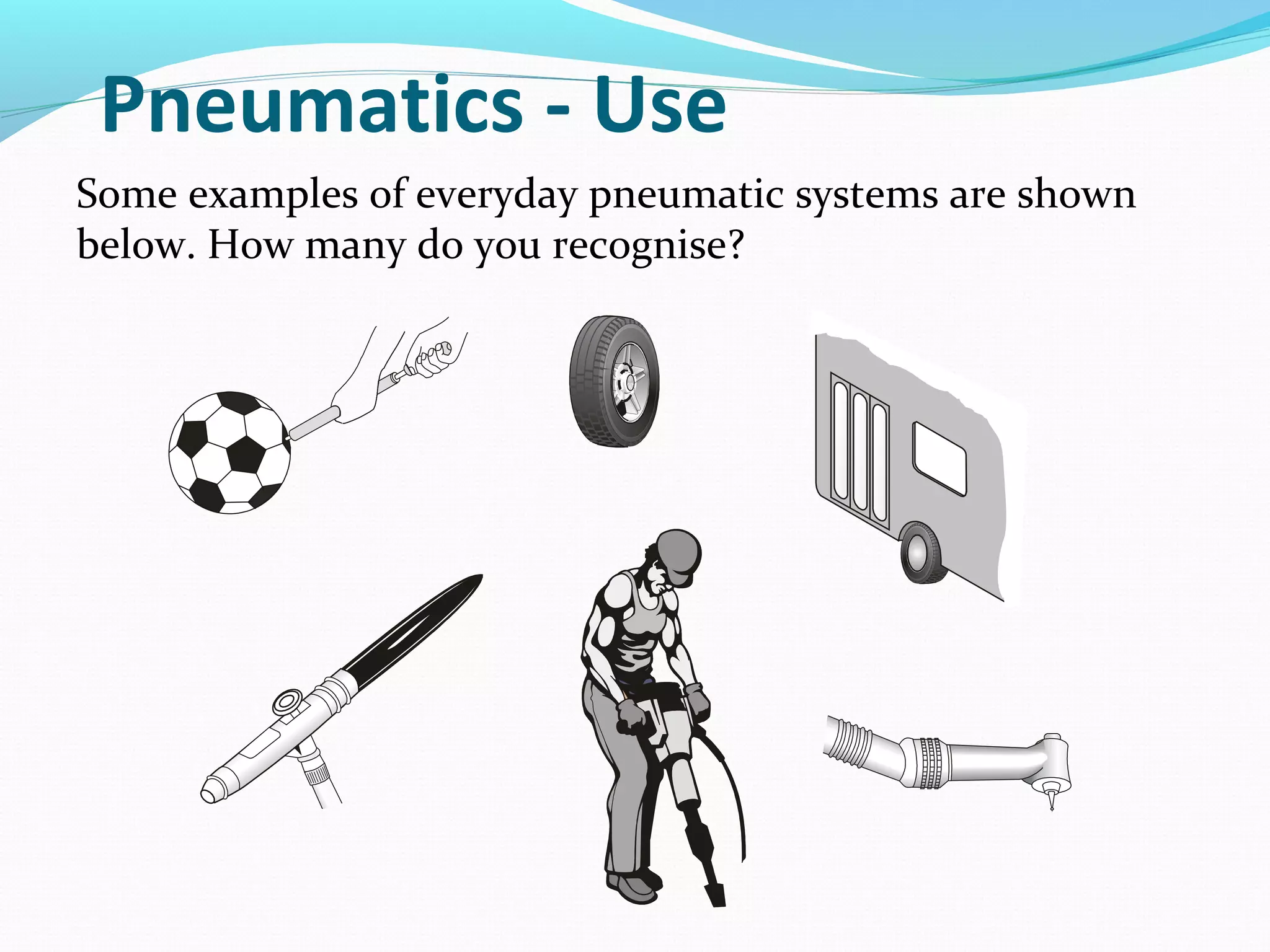

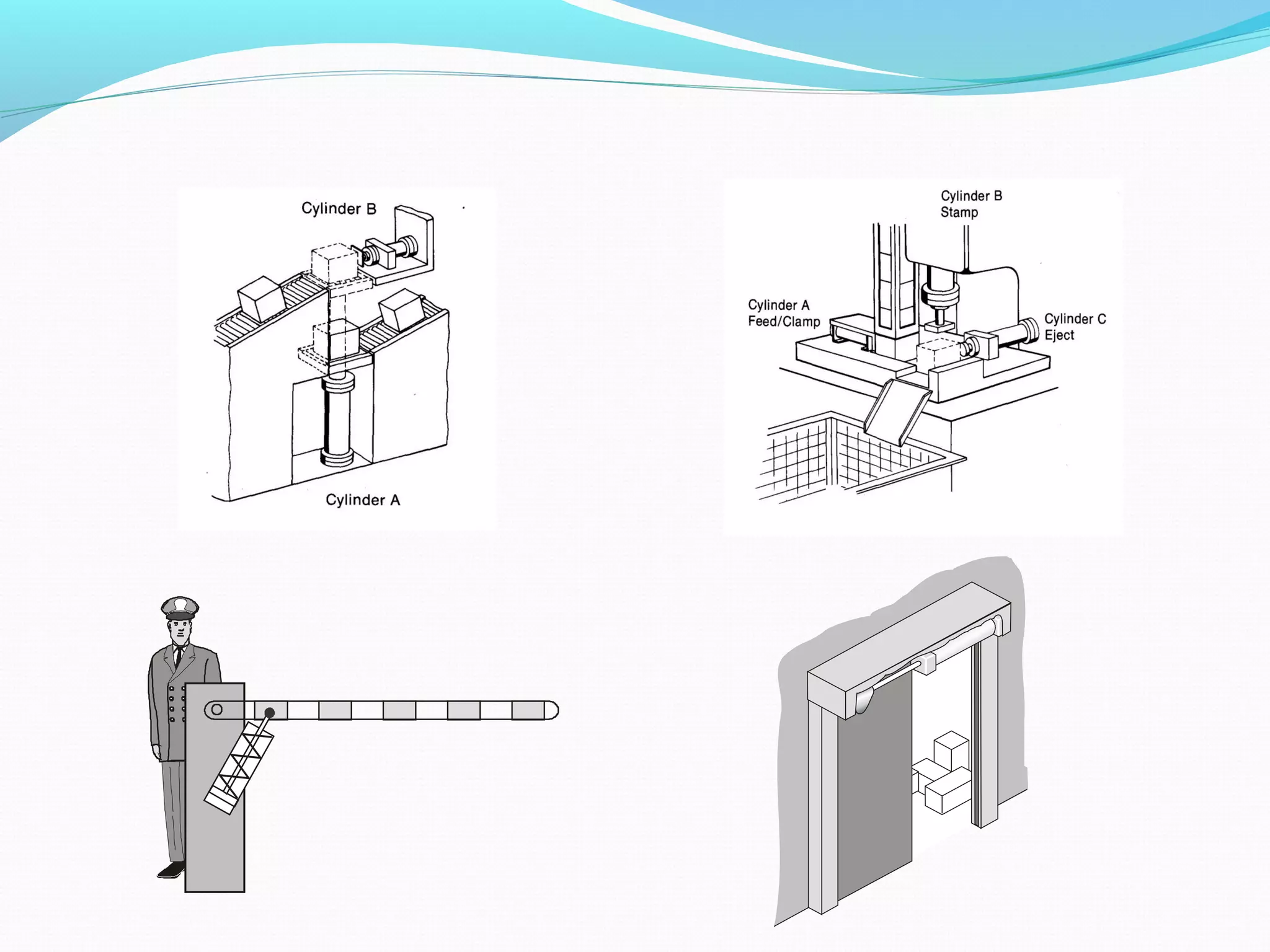

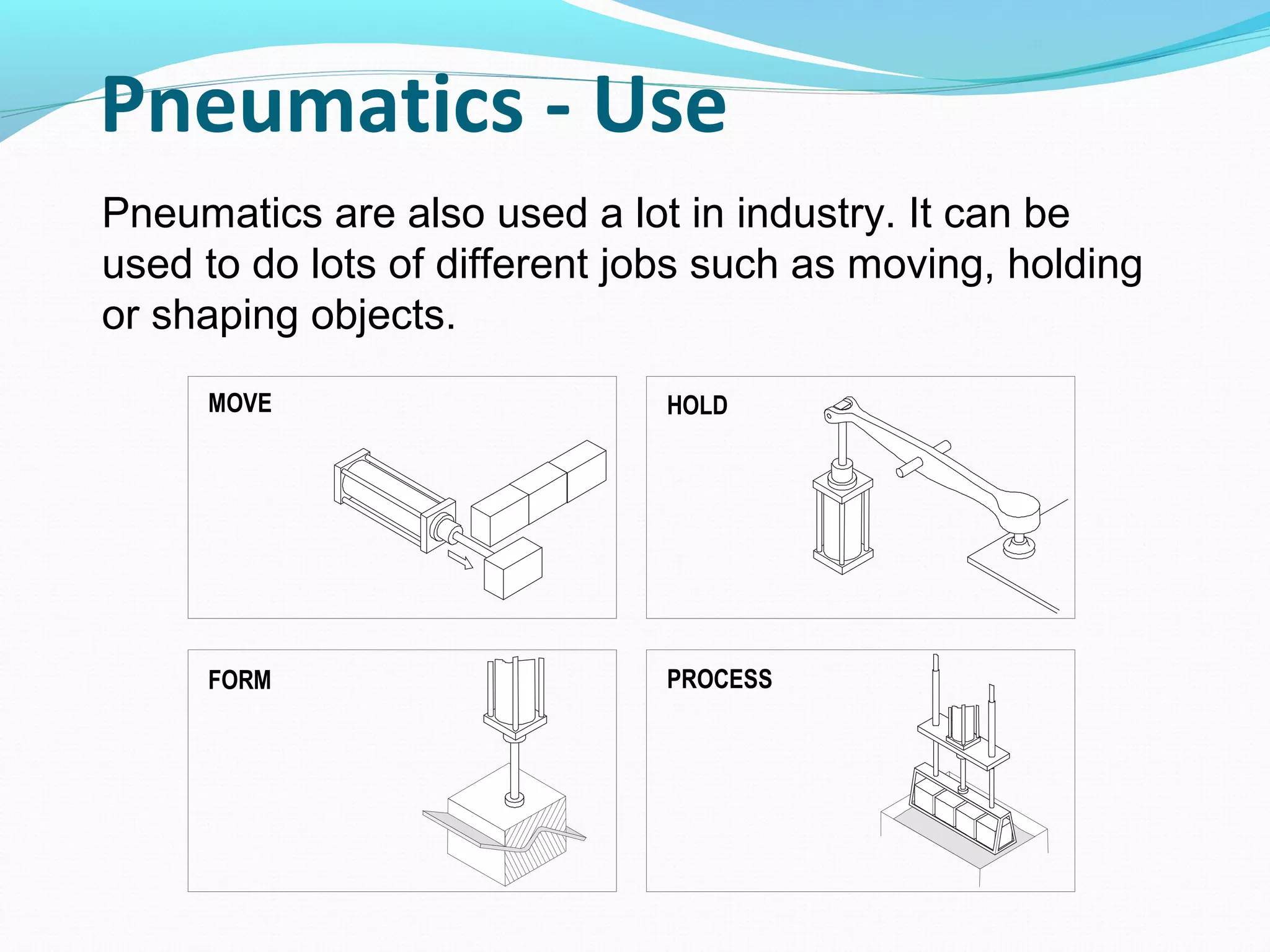

The document outlines safety rules for working with pneumatic and hydraulic systems, emphasizing the importance of wearing safety goggles and avoiding contact with compressed air. It explains the advantages of pneumatic systems, including their cleanliness, safety, reliability, economy, and flexibility, while also encouraging engagement through homework questions about their everyday uses in industry. Lastly, it discusses the fundamental concept of pneumatics and the standardized symbols used to represent pneumatic system elements.