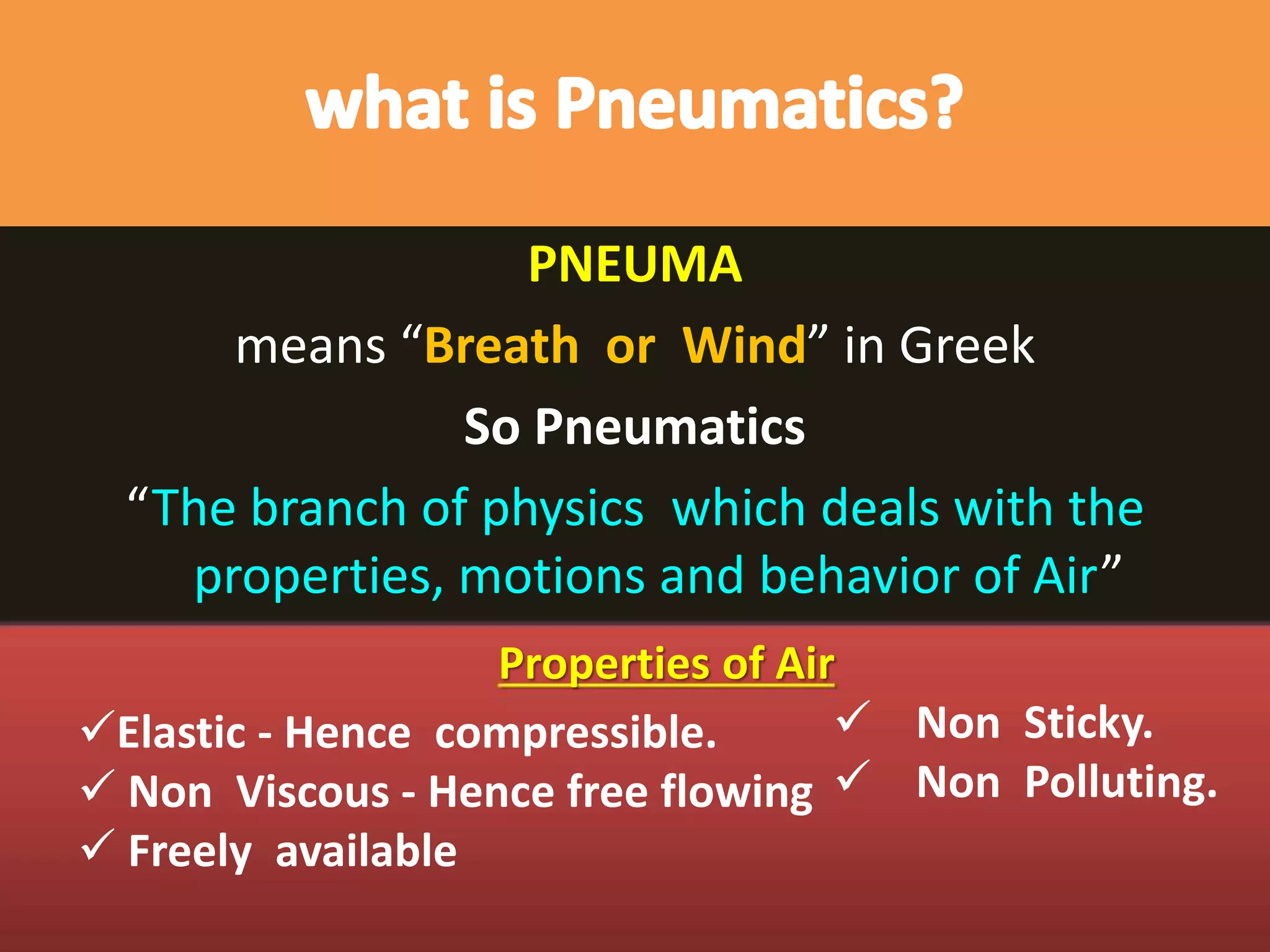

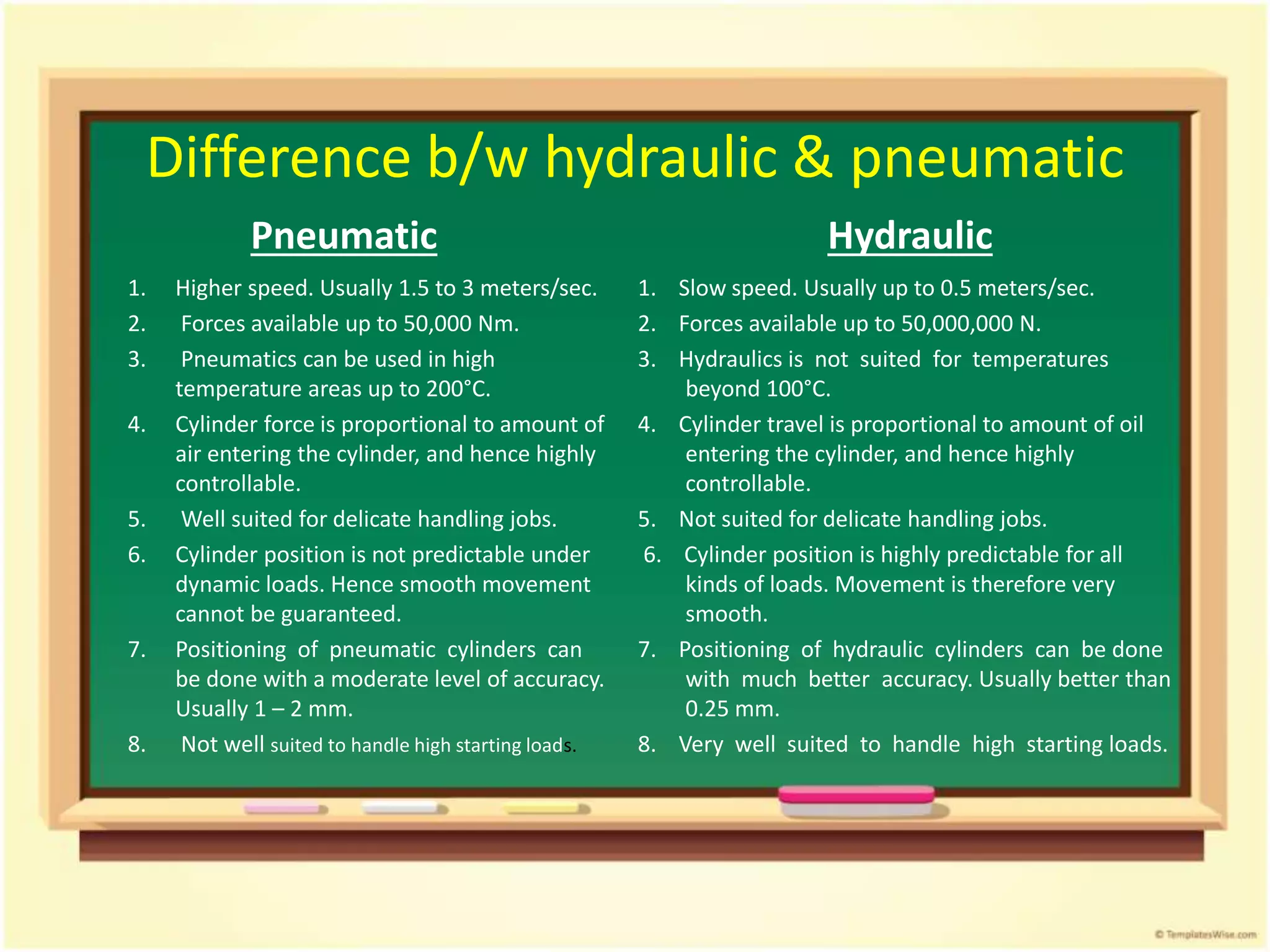

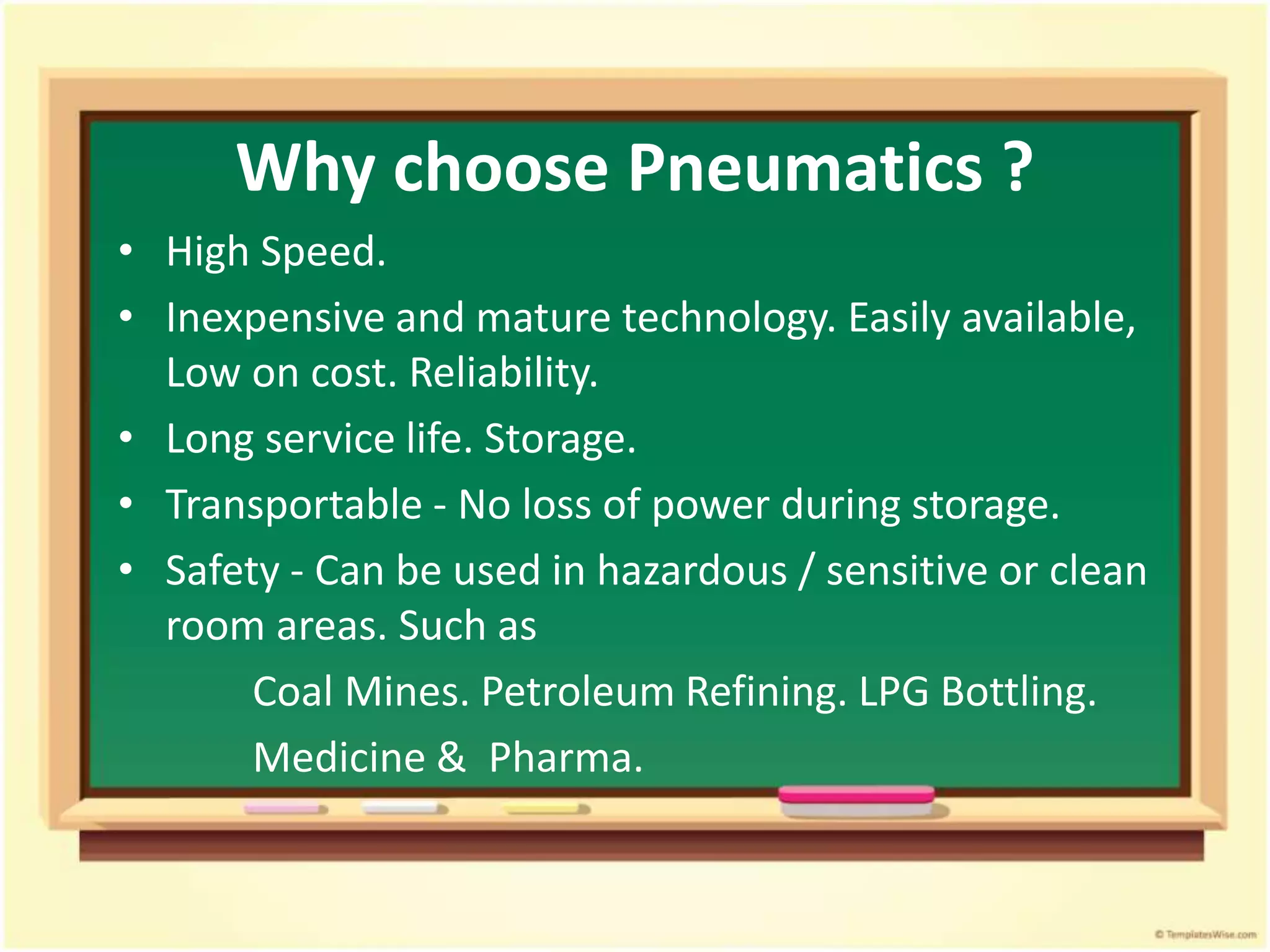

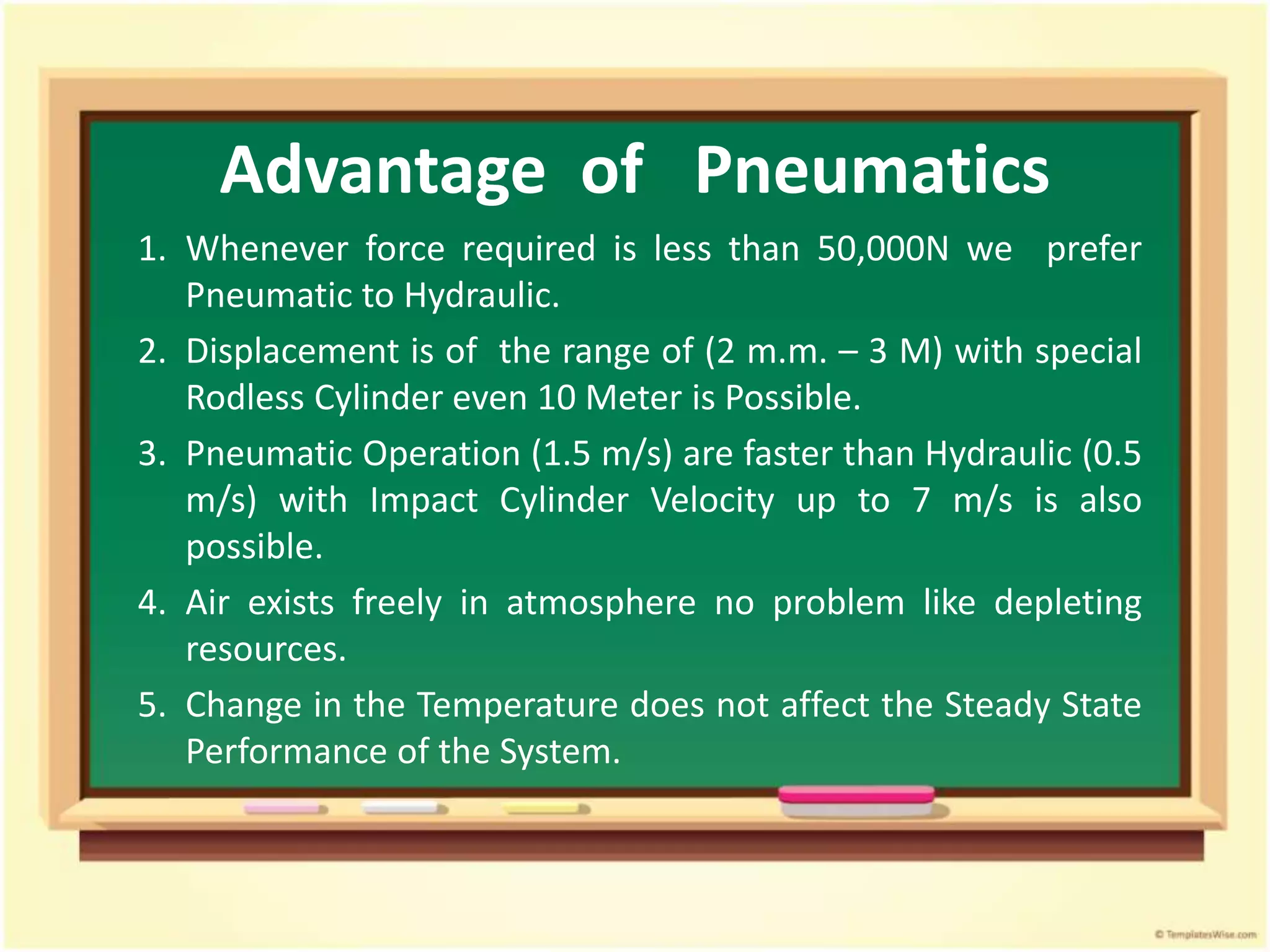

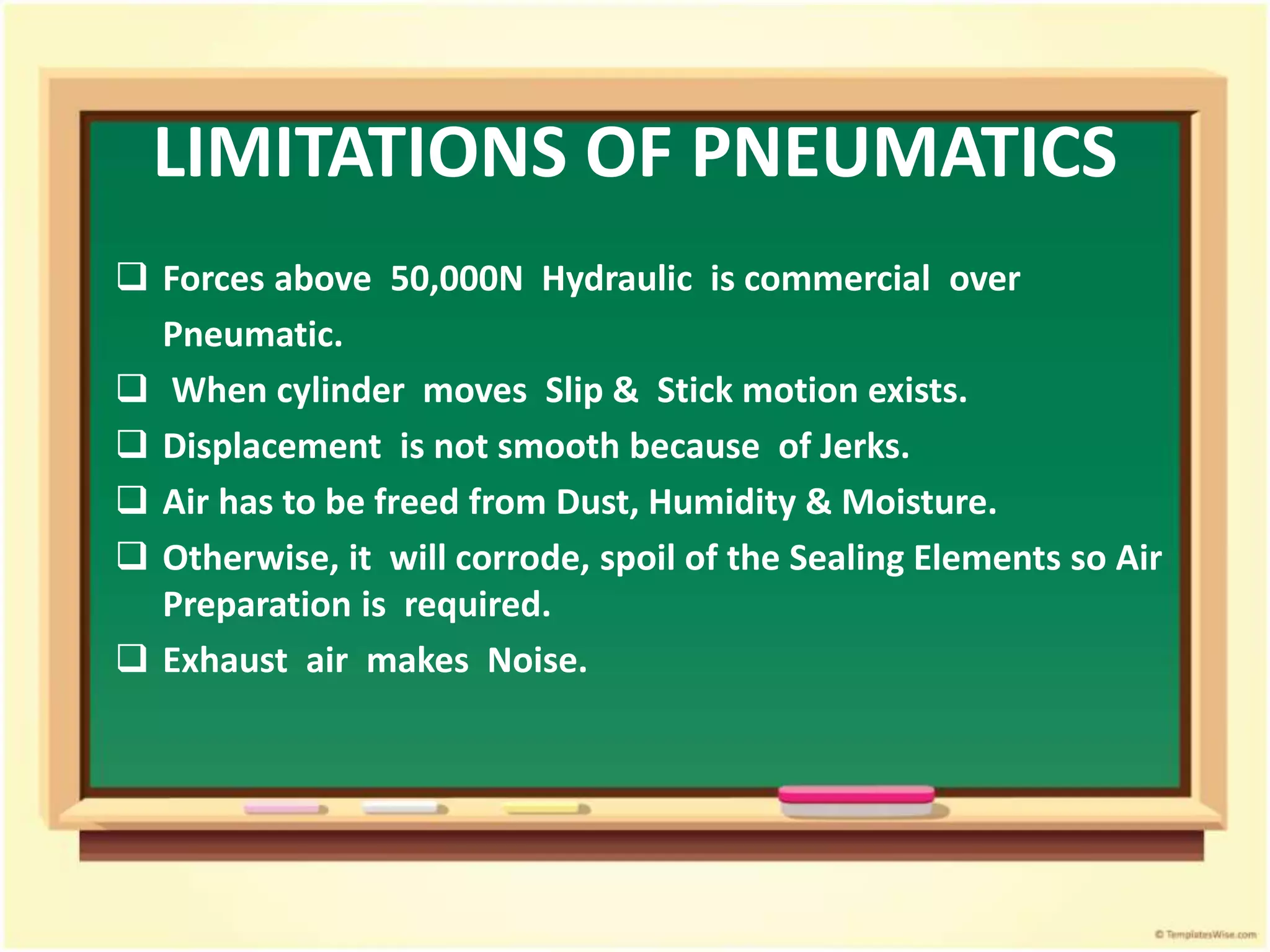

Pneumatic control technology emerged from the industrial revolution as a solution to the limitations of human power, offering advantages such as high speed, reliability, and suitability for delicate tasks. Pneumatics outperforms hydraulics in applications requiring forces less than 50,000 N and provides faster operation, though it has limitations like noise and the need for air preparation. Major applications of pneumatics include automotive production, food processing, and robotics, making it a versatile choice in various industries.

![Principal of Pneumatics

Boyle - Mariotte’s Law.

The product of Pressure and Volume of a given amount of gas is a constant,

provided the temperature remains constant

Charles’s & Gay - Lussac’s Law.

The volume of a gas is proportional to its absolute temperature, provided the

pressure remains constant.

-273 °C is the lowest possible temperature in the universe and is known as

absolute zero [0 °Kelvin].

Absolute temperature is measured in º Kelvin. A change of 1 °C results in a

change of 1 °K.

0 °C = 273 °K and 1 °C = 274 °K

(P1 x V1 = P2 x V2).](https://image.slidesharecdn.com/pneumatics1intro-200530062946/75/fundamentals-basics-of-pneumatic-system-11-2048.jpg)