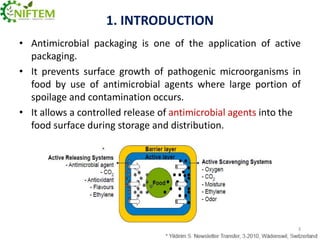

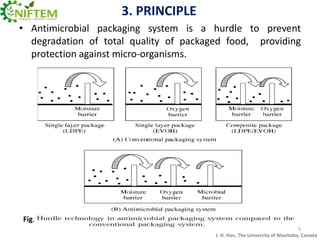

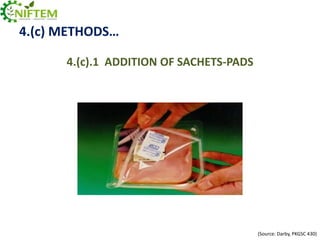

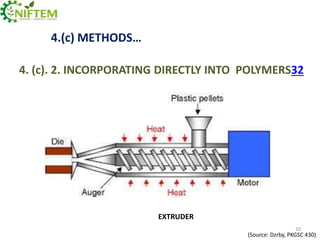

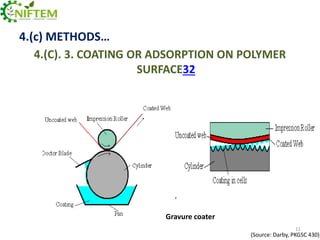

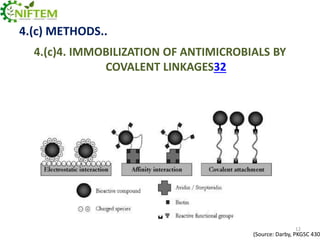

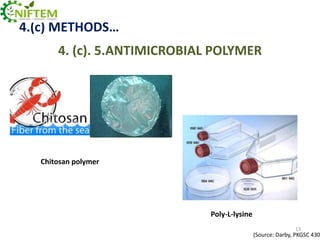

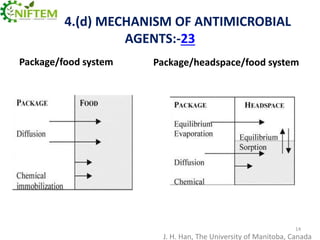

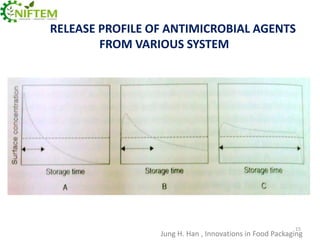

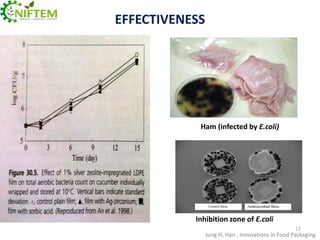

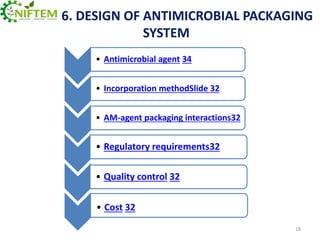

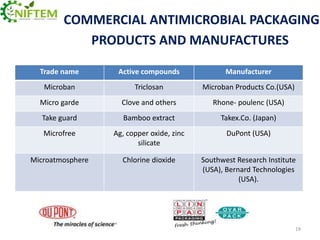

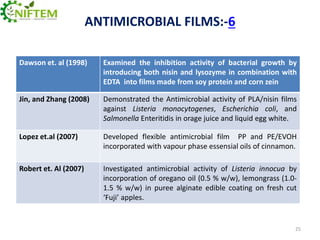

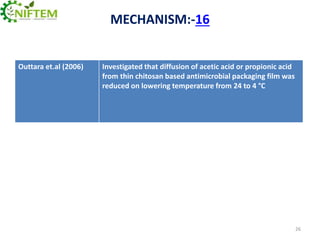

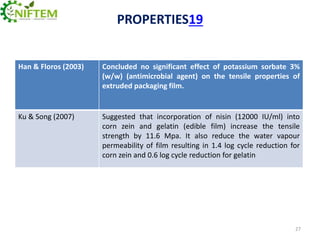

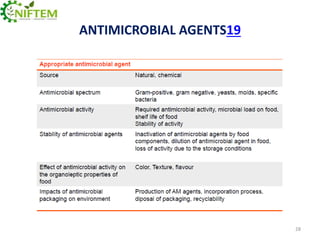

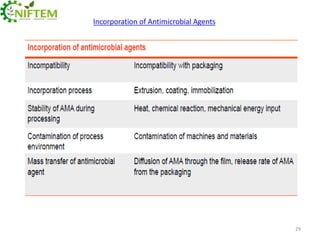

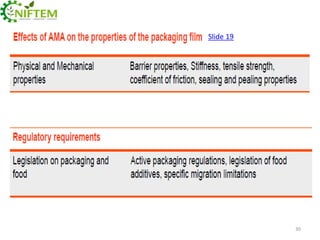

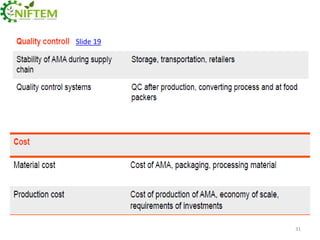

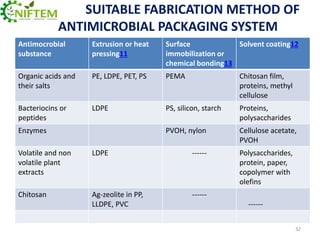

This document provides an overview of antimicrobial packaging. It discusses the objectives of antimicrobial packaging which is to prevent degradation of food quality by acting as a hurdle against microorganisms. The principles and various systems are explained, including composition of antimicrobial agents and films. Methods for incorporating antimicrobial agents like addition of sachets, direct incorporation, coating, immobilization and antimicrobial polymers are outlined. The document also reviews the mechanism of action, effectiveness, engineering properties and design considerations for antimicrobial food packaging systems.