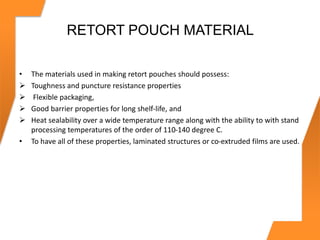

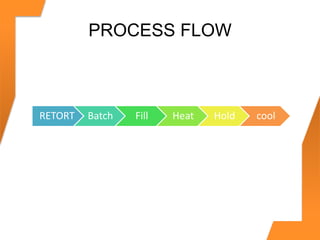

The document discusses various packaging types and systems, emphasizing aseptic, intelligent, and retort packaging. Aseptic packaging maintains sterile environments for pre-sterilized products, while retort packaging provides a cost-effective solution for shelf-stable foods. Intelligent packaging systems monitor food conditions during transport and storage, using indicators to assess quality and freshness.