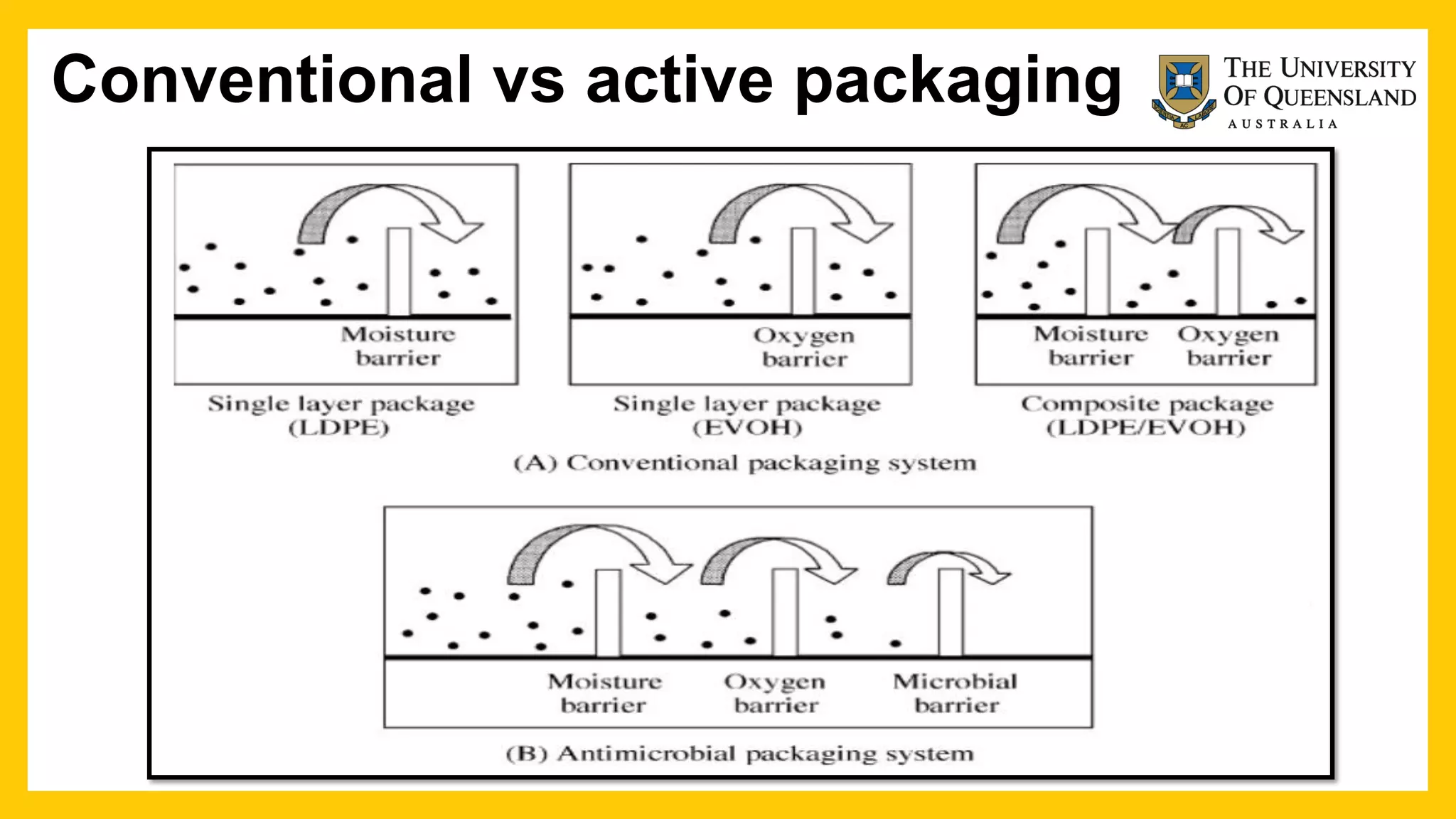

This document discusses incorporating antimicrobial agents into food packaging films to inhibit pathogenic and spoilage microorganisms. It describes various antimicrobial agents from natural, plant, animal and microbial sources that can be added to packaging films, and mechanisms by which they damage microbes, such as disrupting proteins, cell membranes, DNA and causing oxidative damage. Both conventional packaging and active packaging incorporating antimicrobials are compared. Methods for adding antimicrobials directly to films or as sachets or coatings are outlined. Examples of reductions in bacteria and extended shelf life are provided. Challenges including temperature susceptibility and regulations are noted.