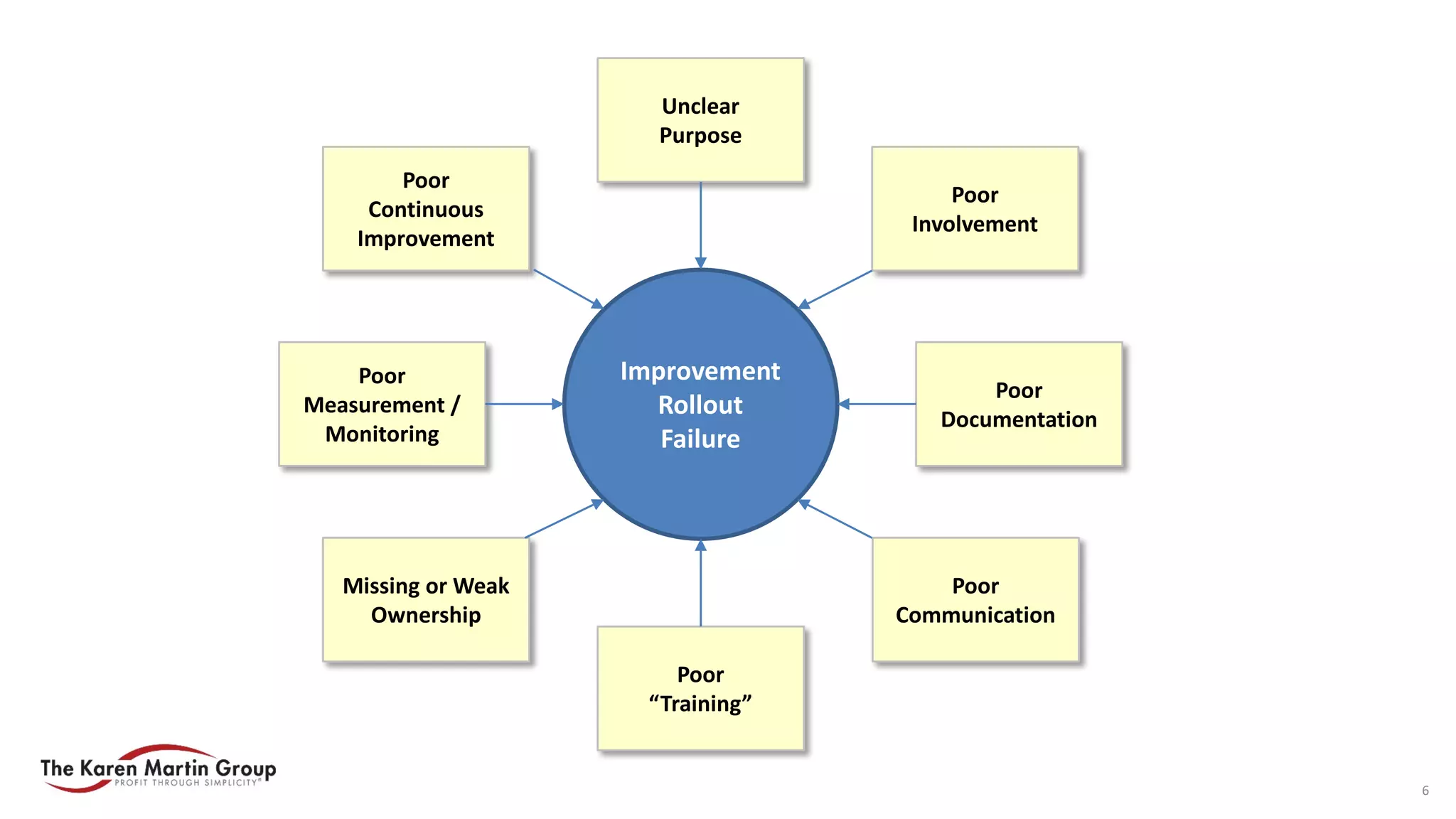

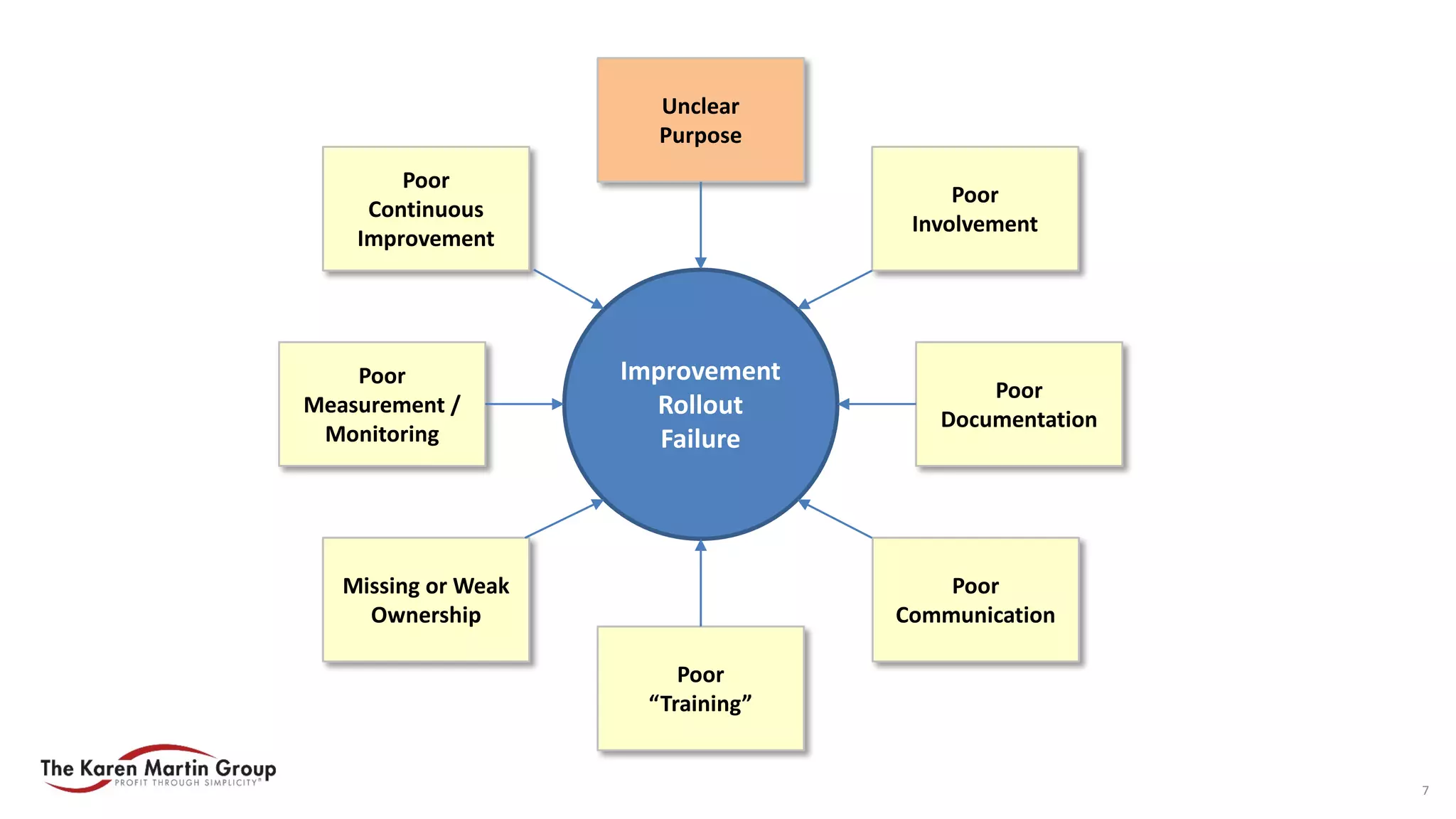

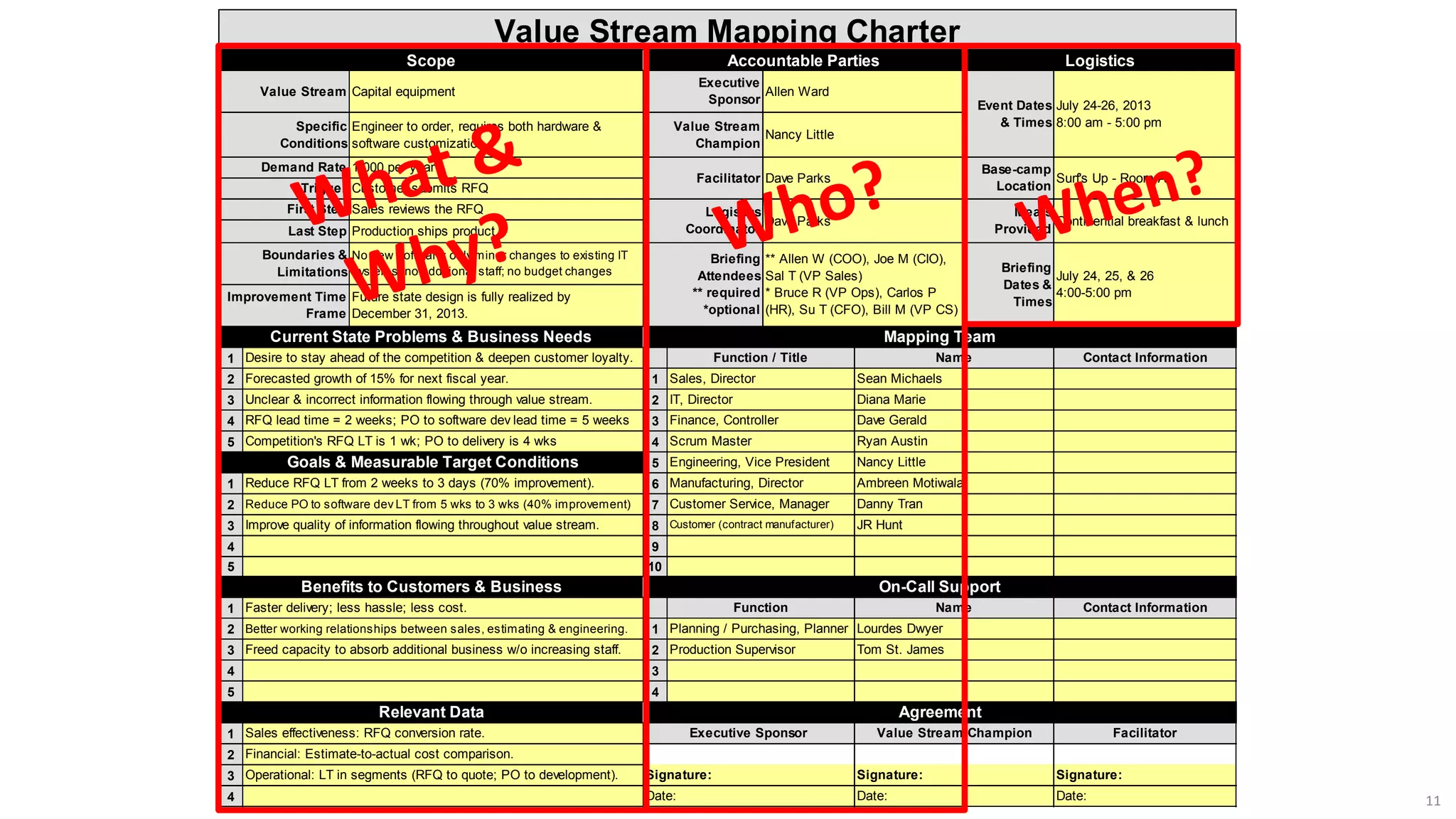

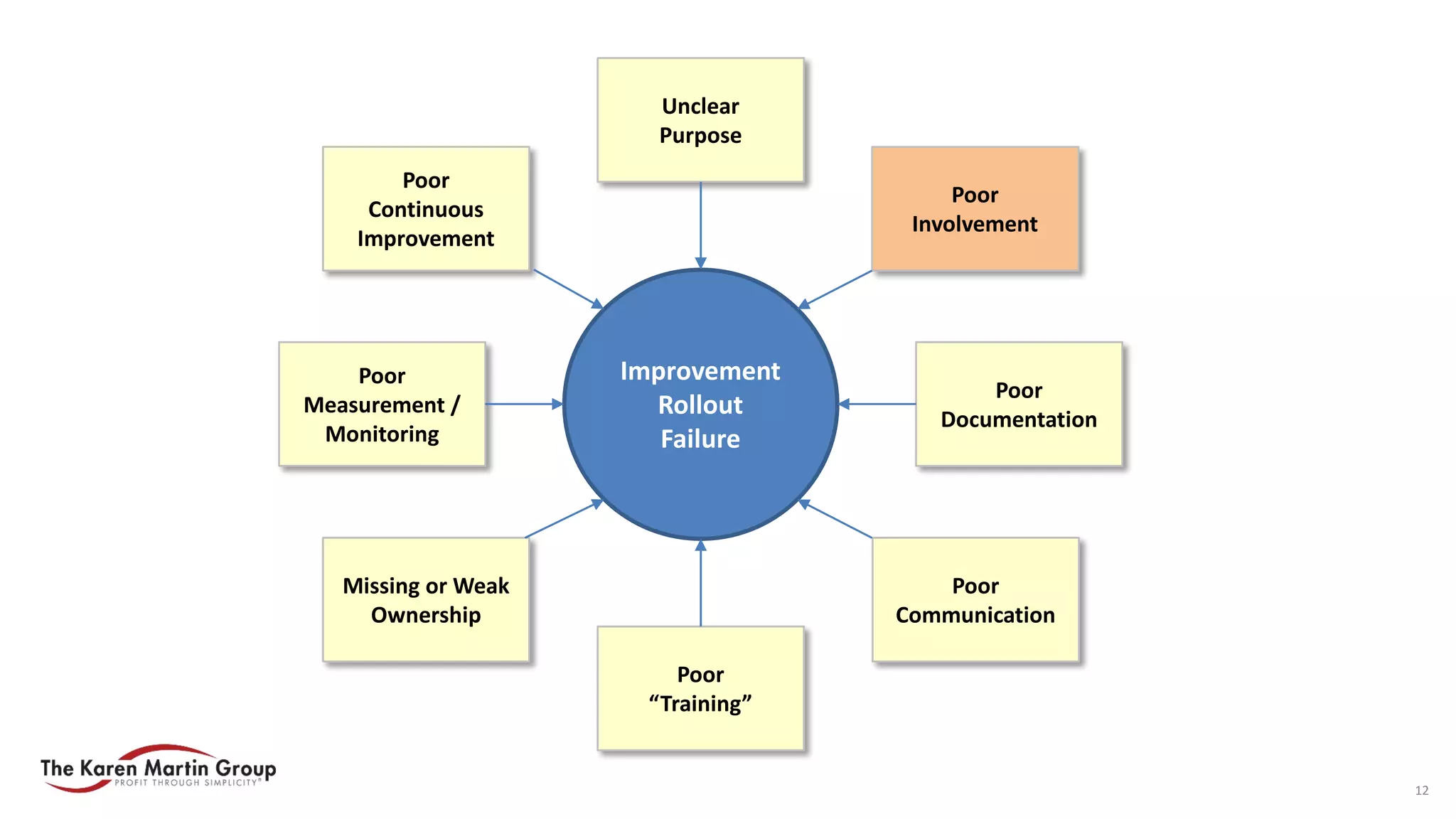

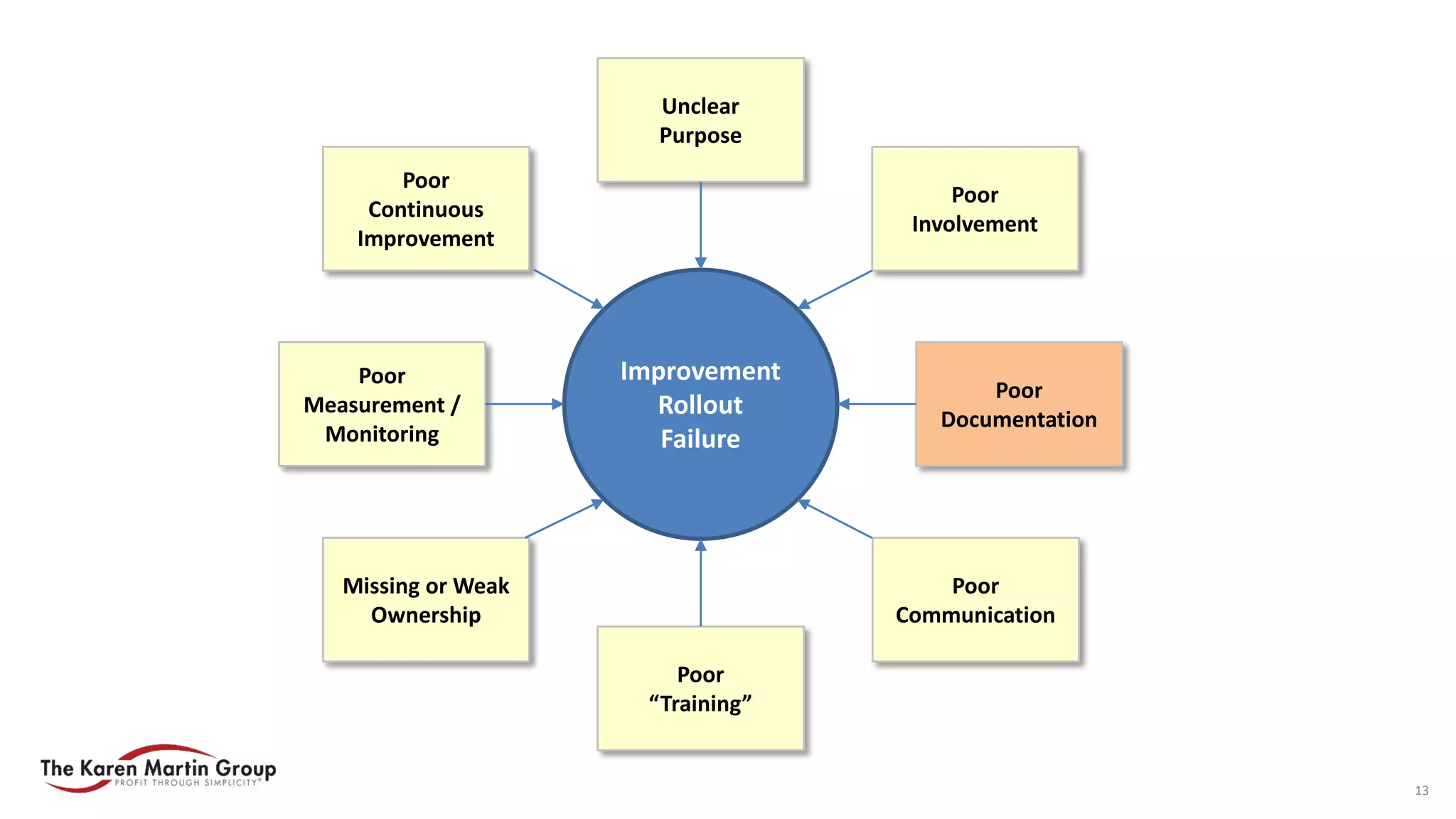

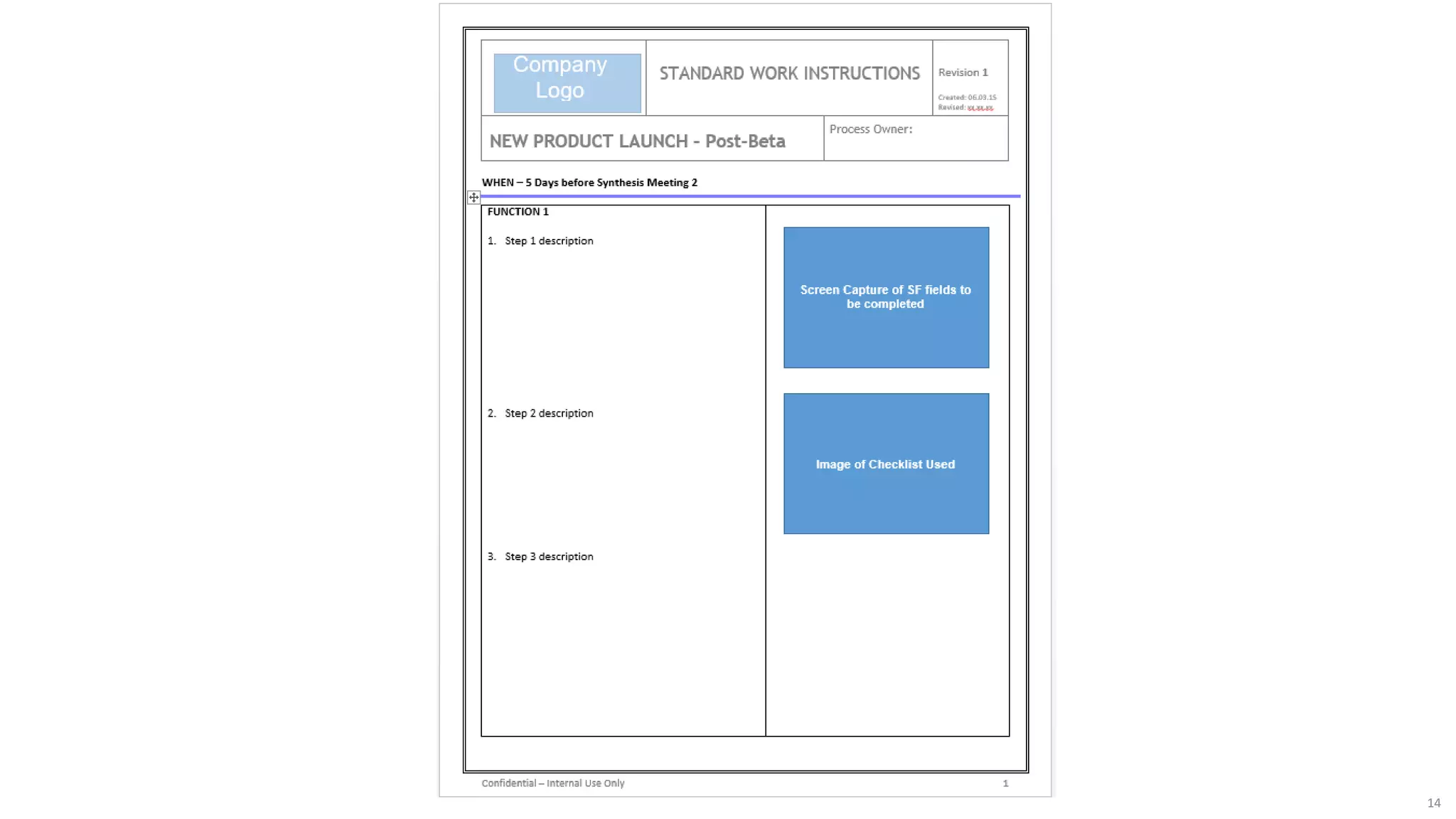

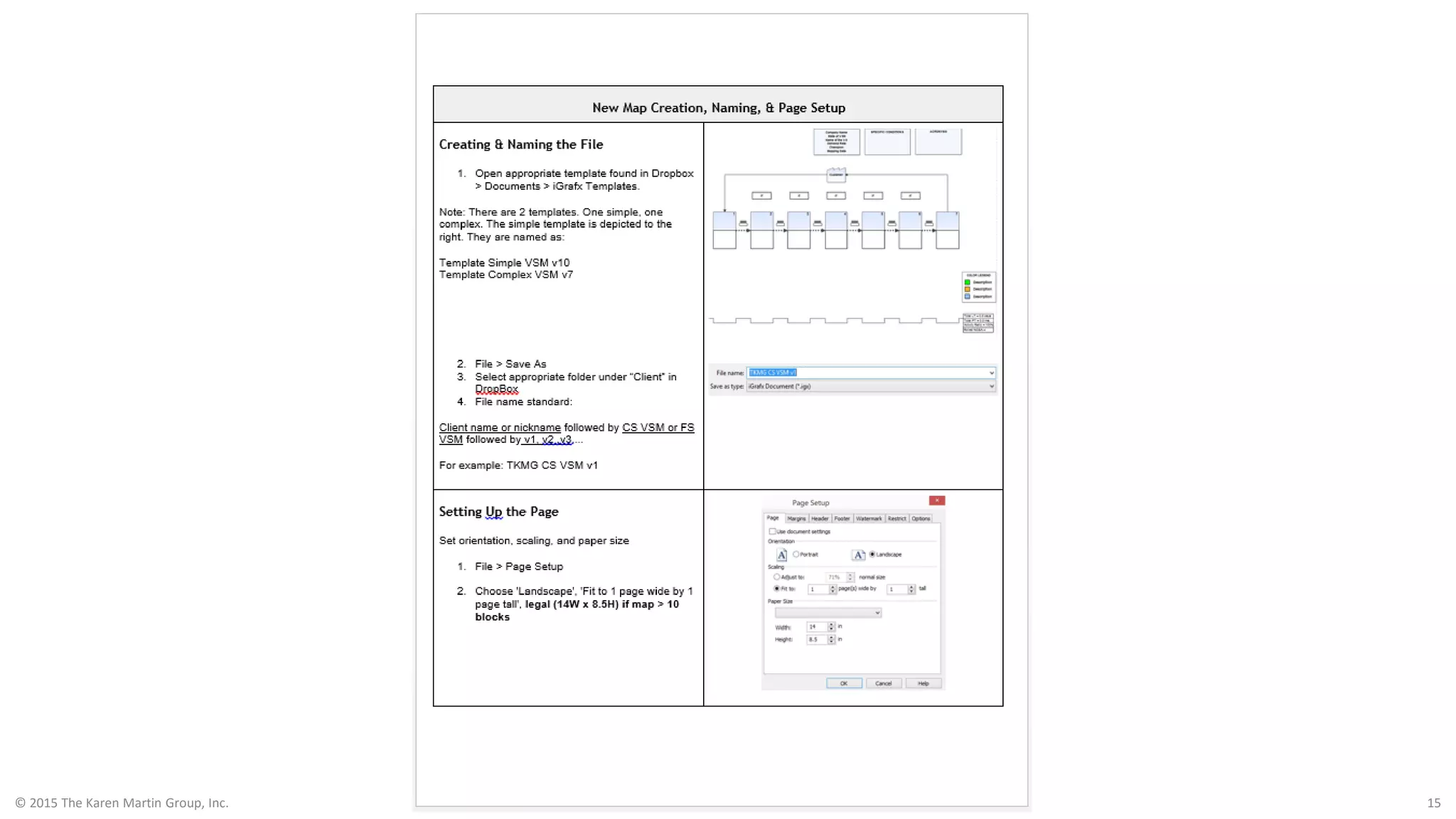

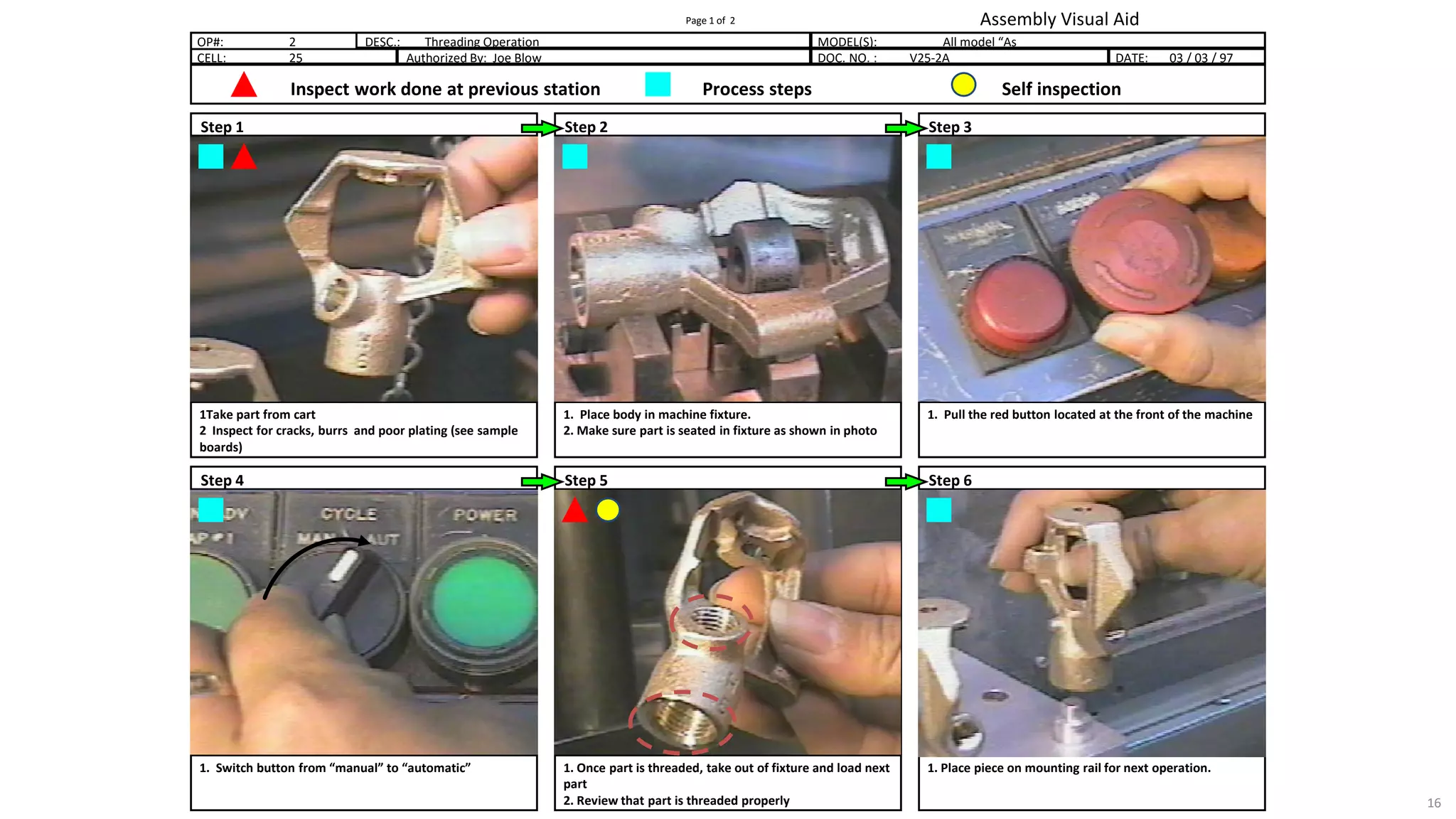

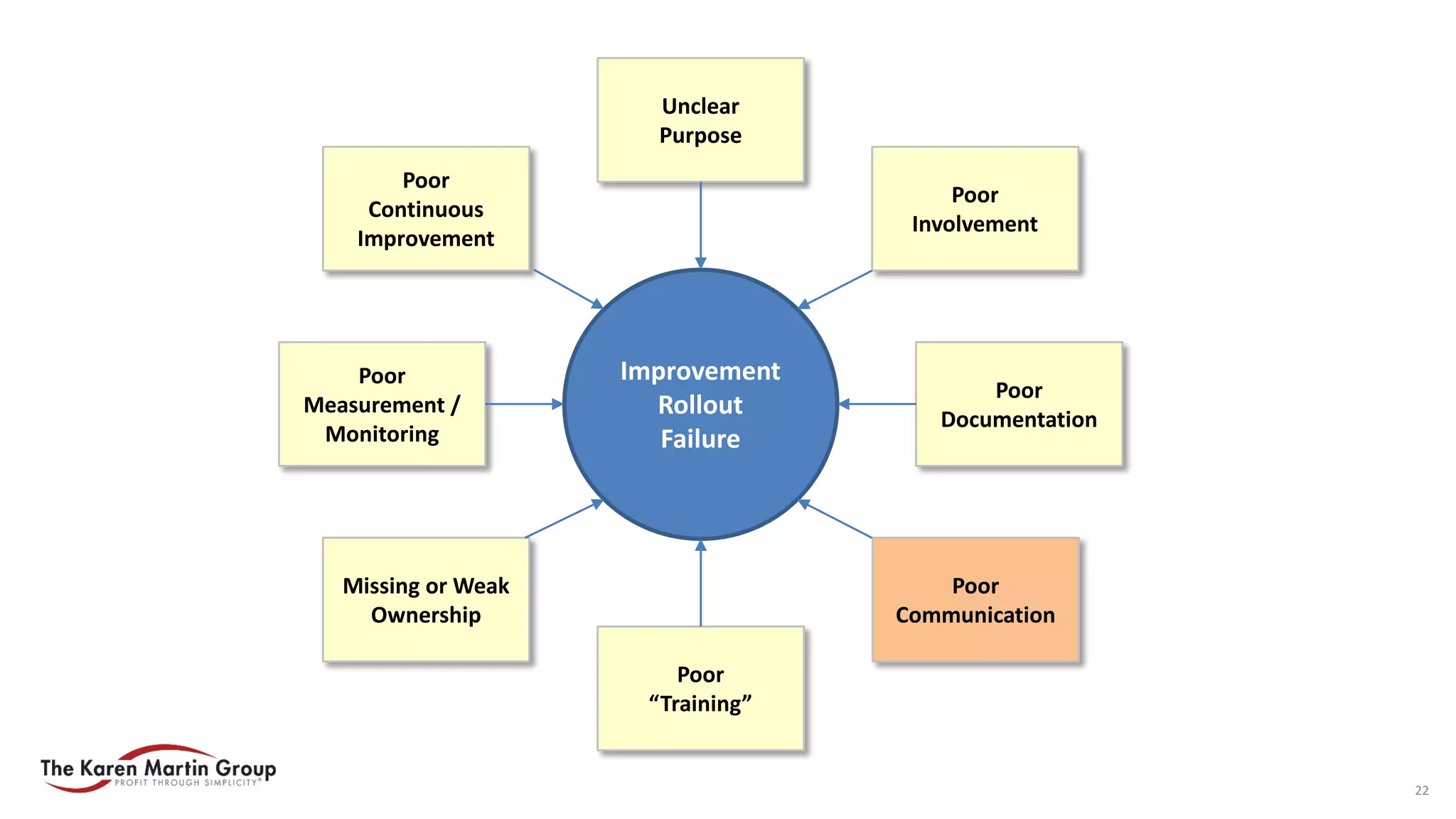

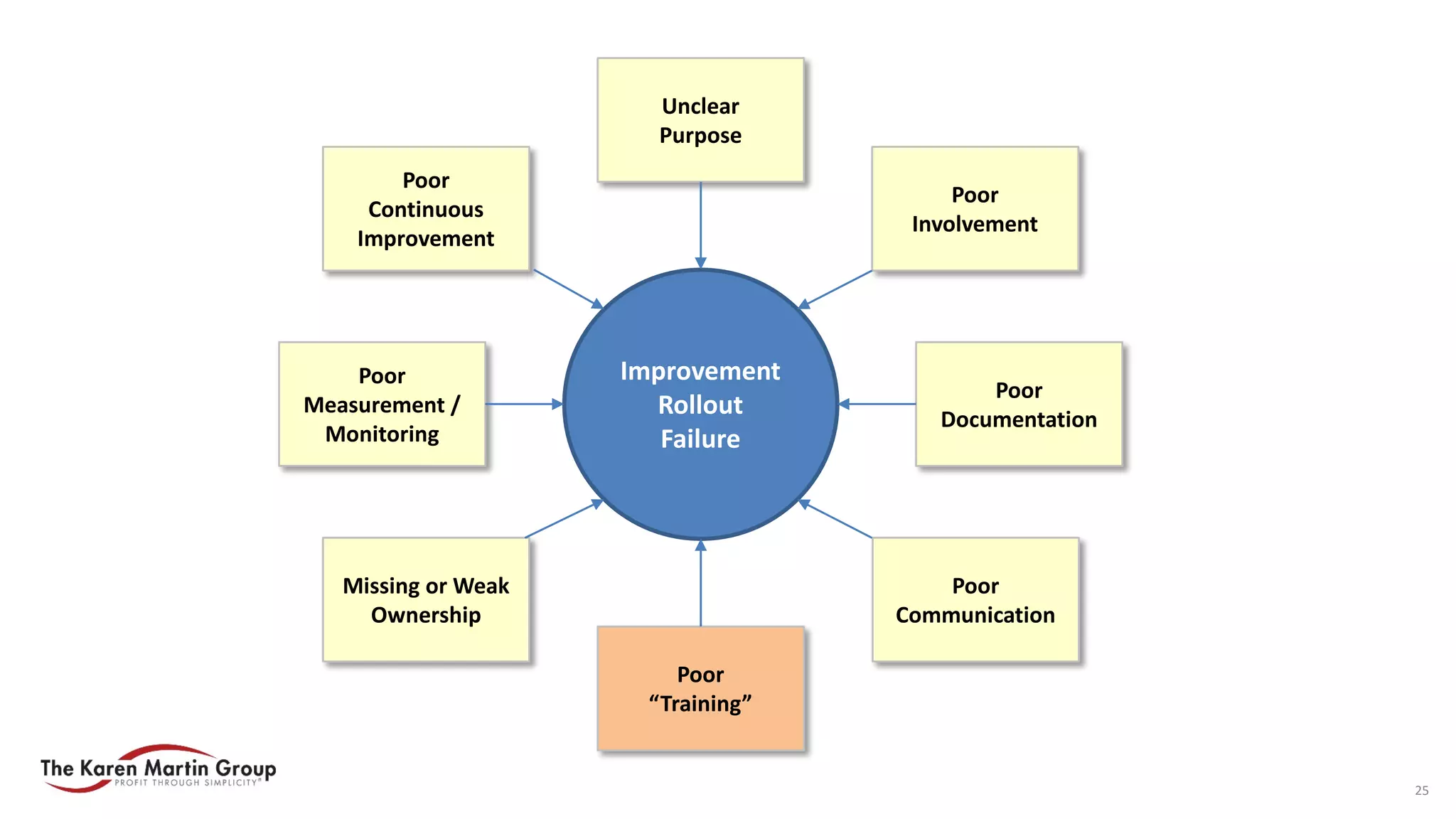

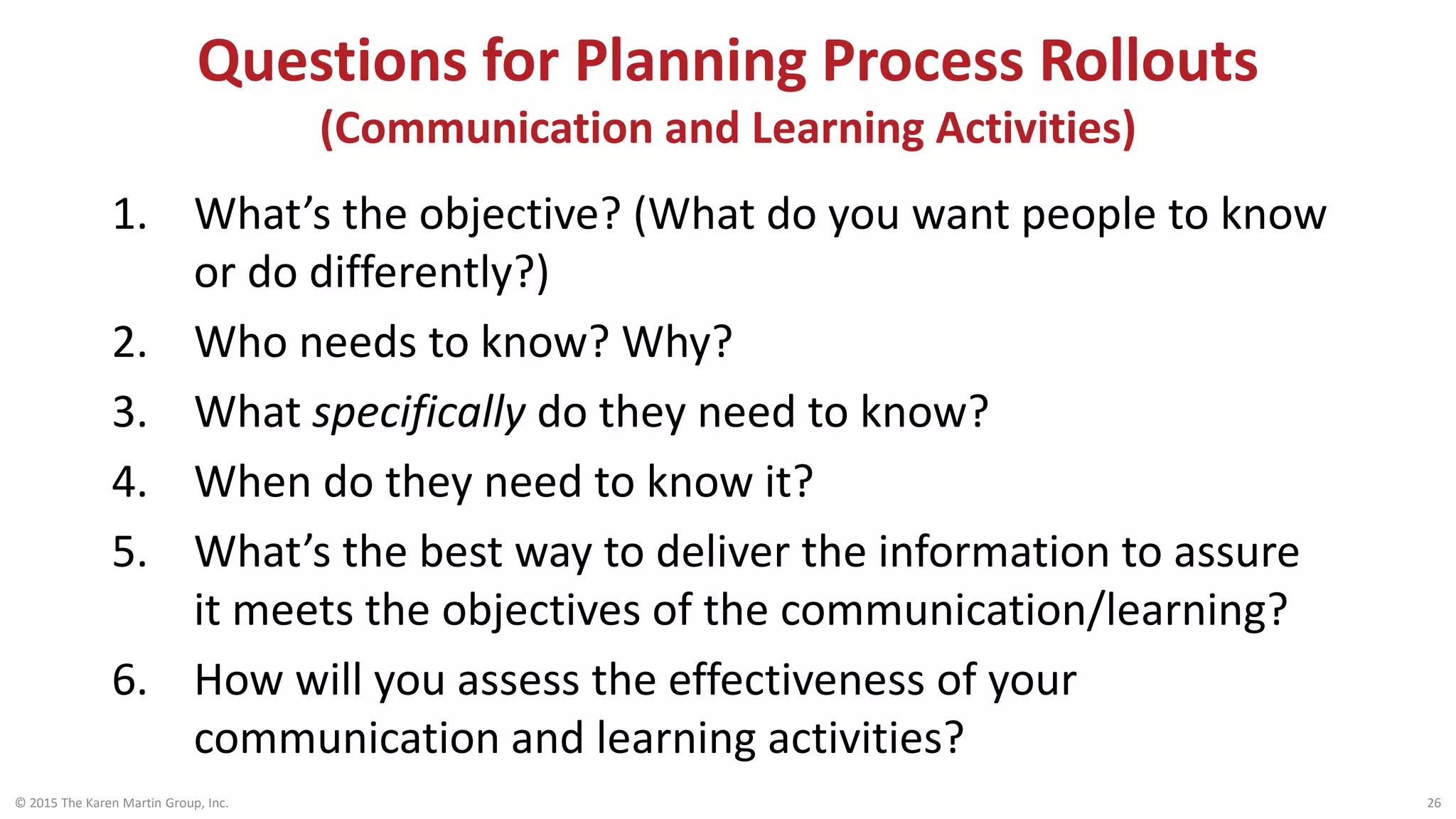

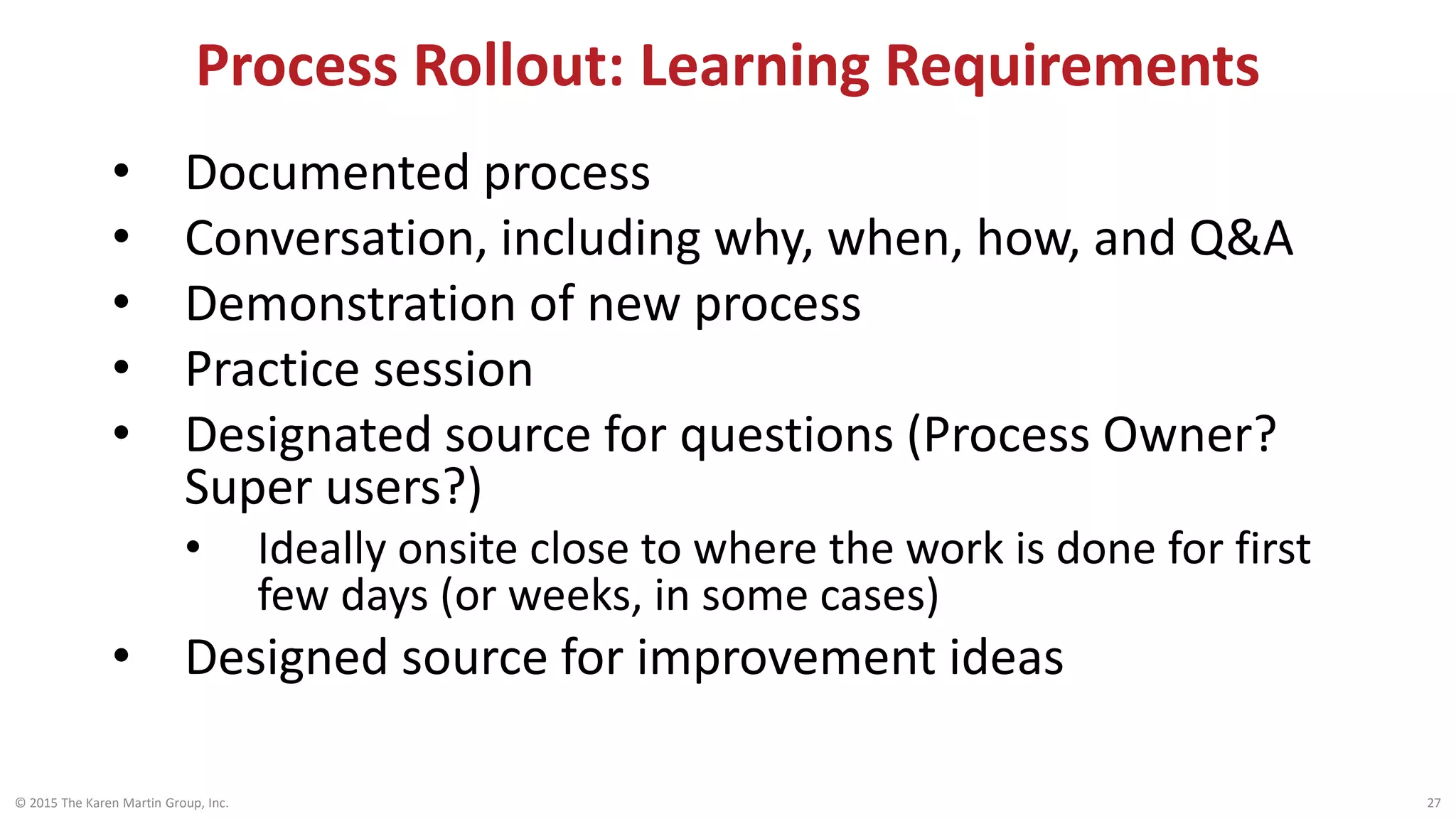

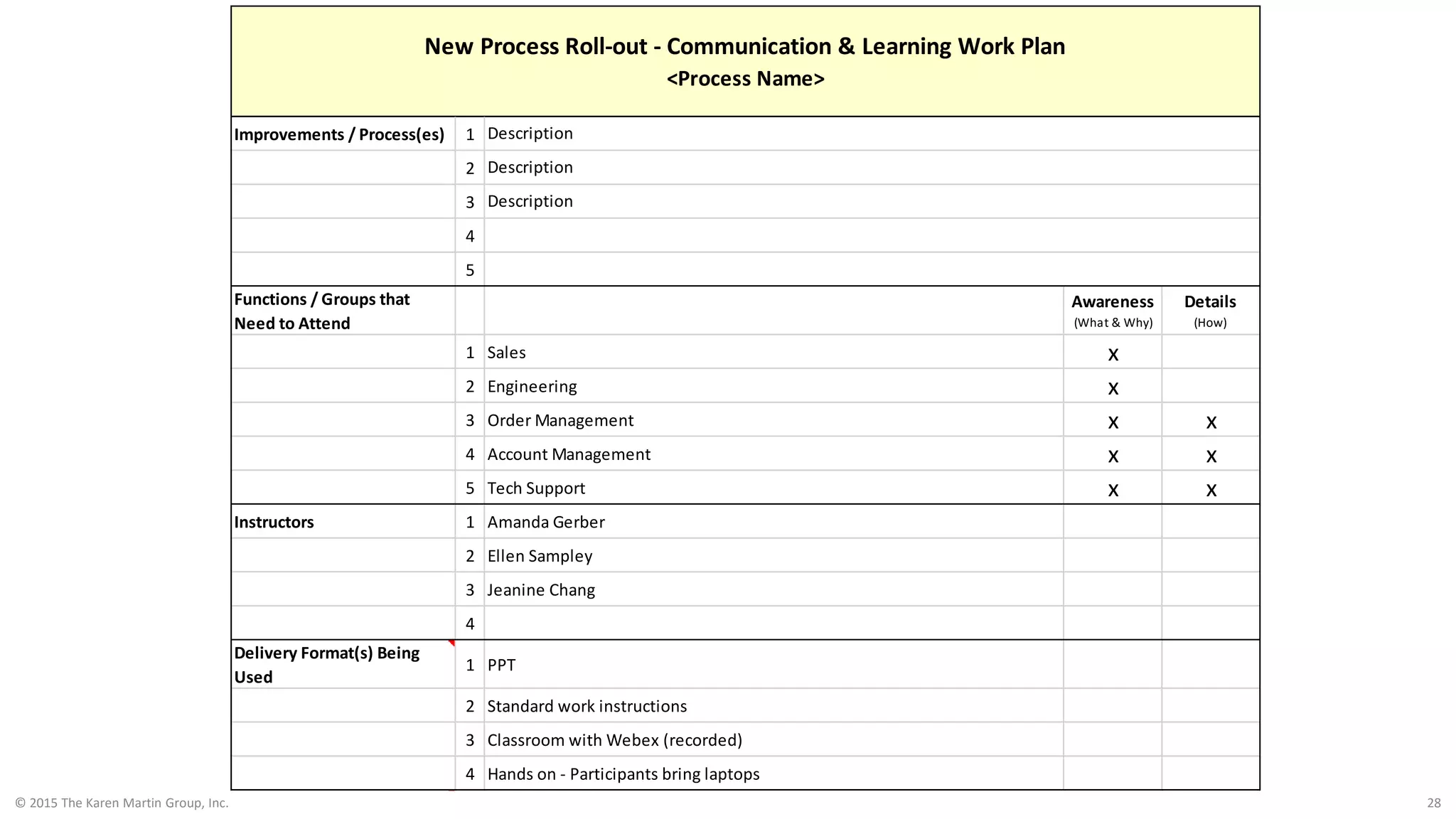

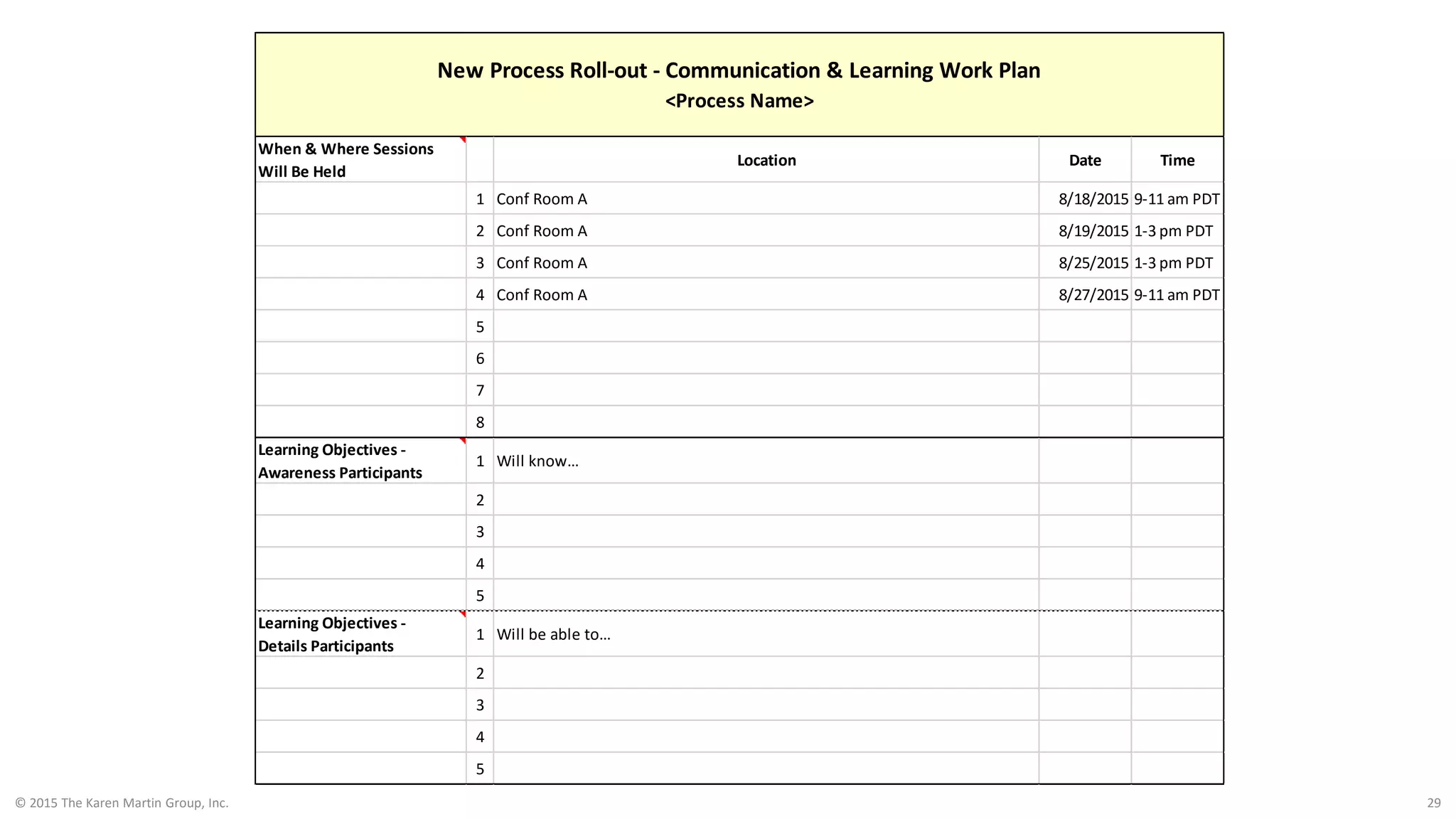

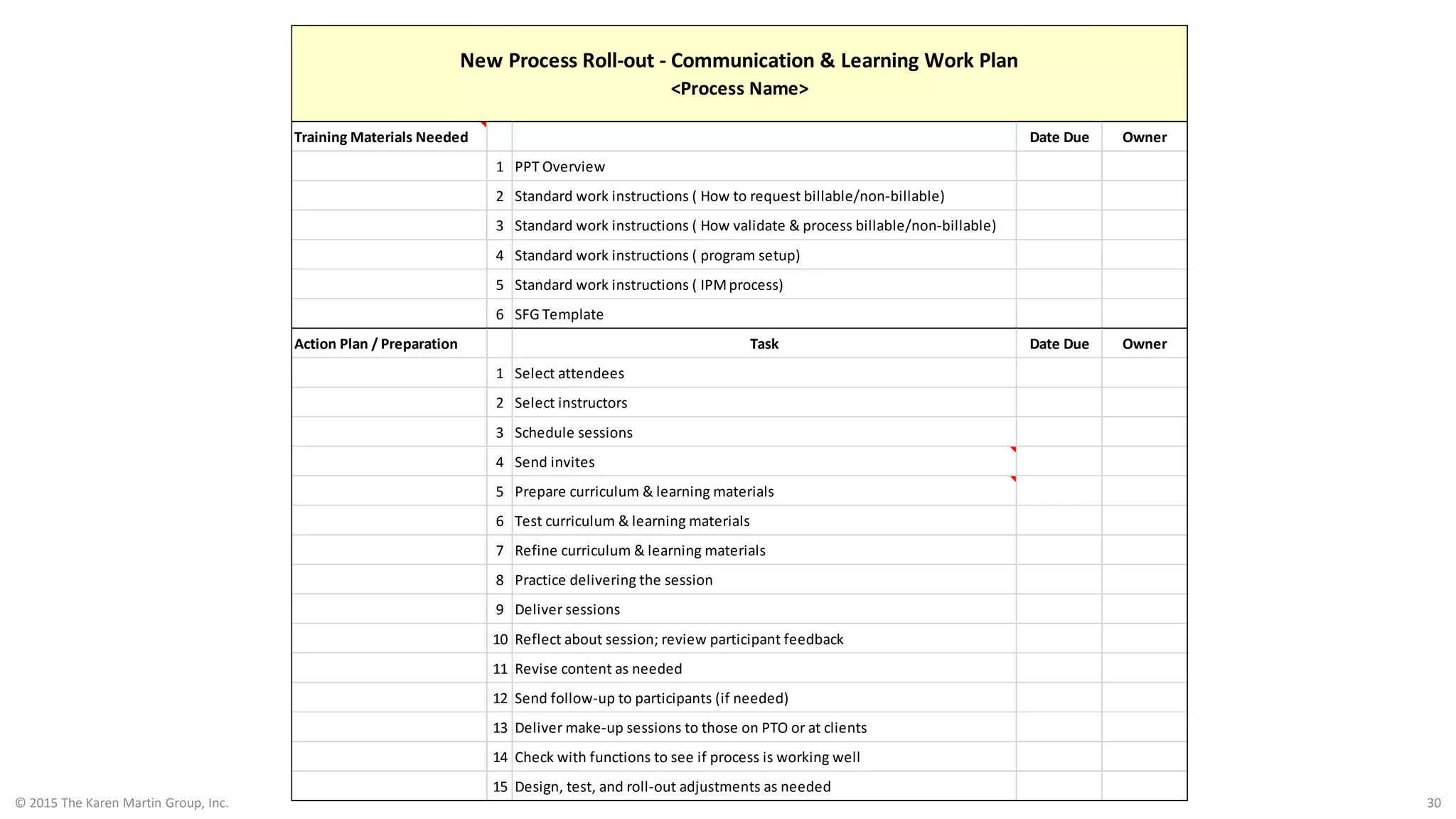

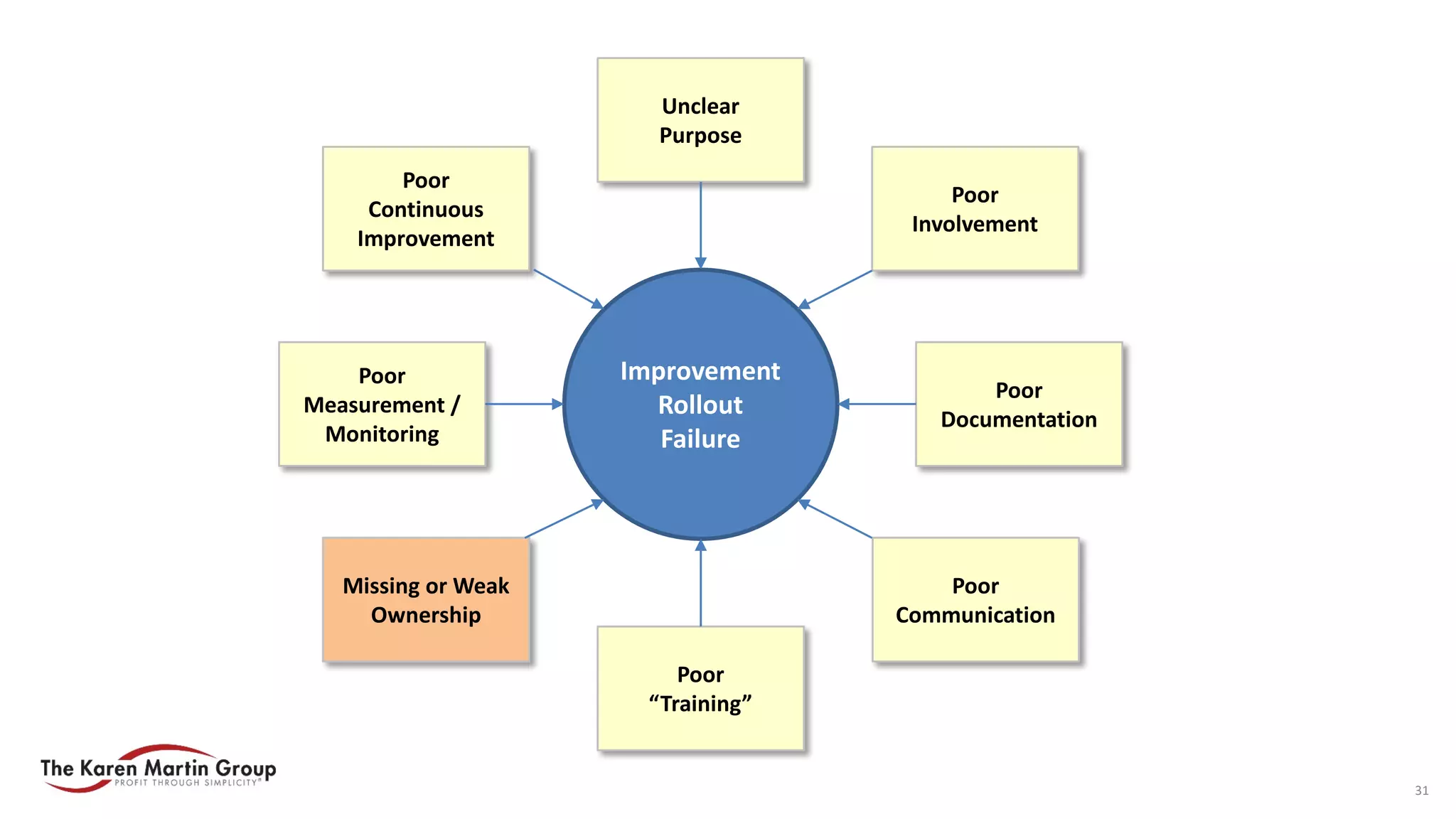

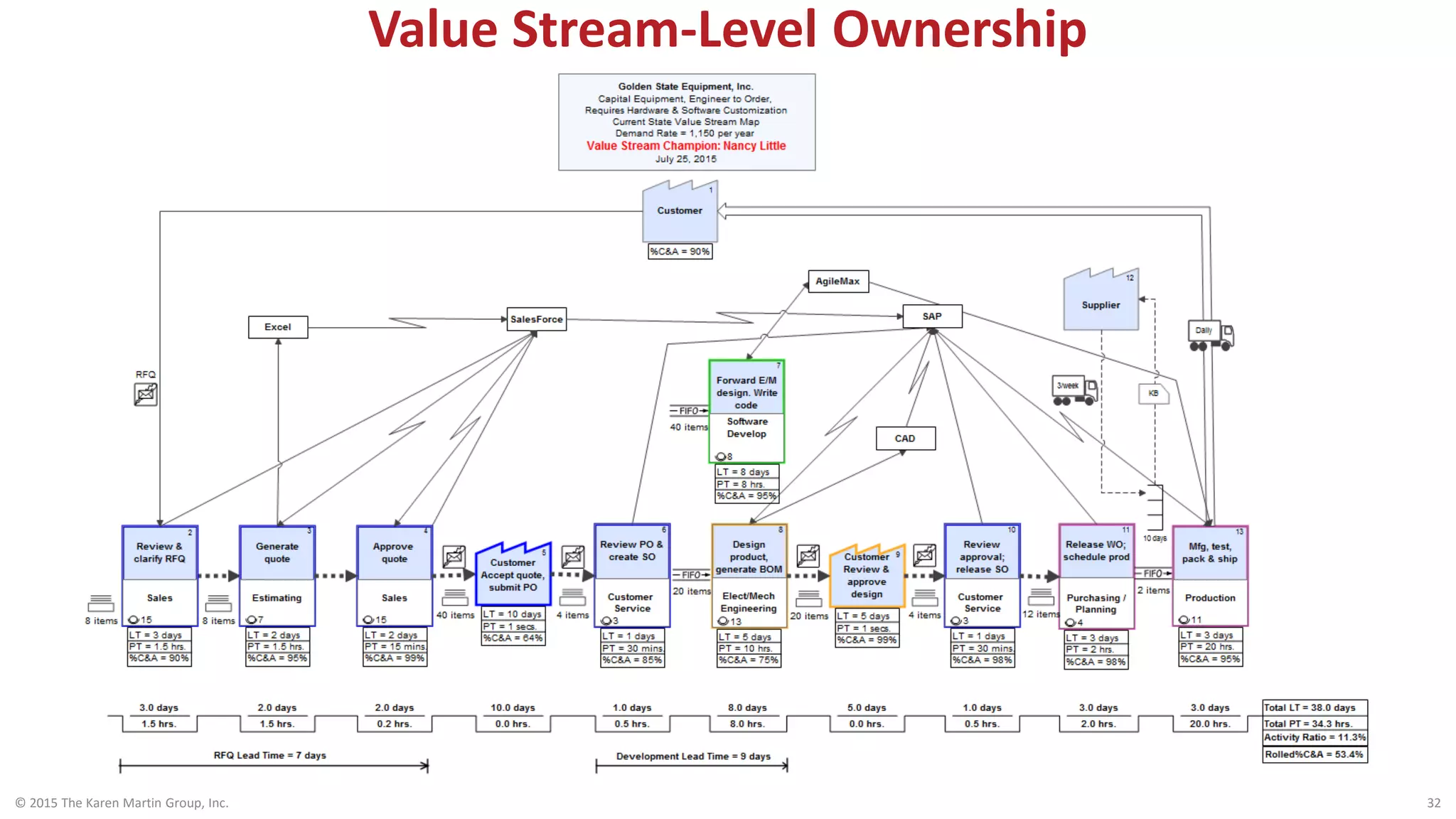

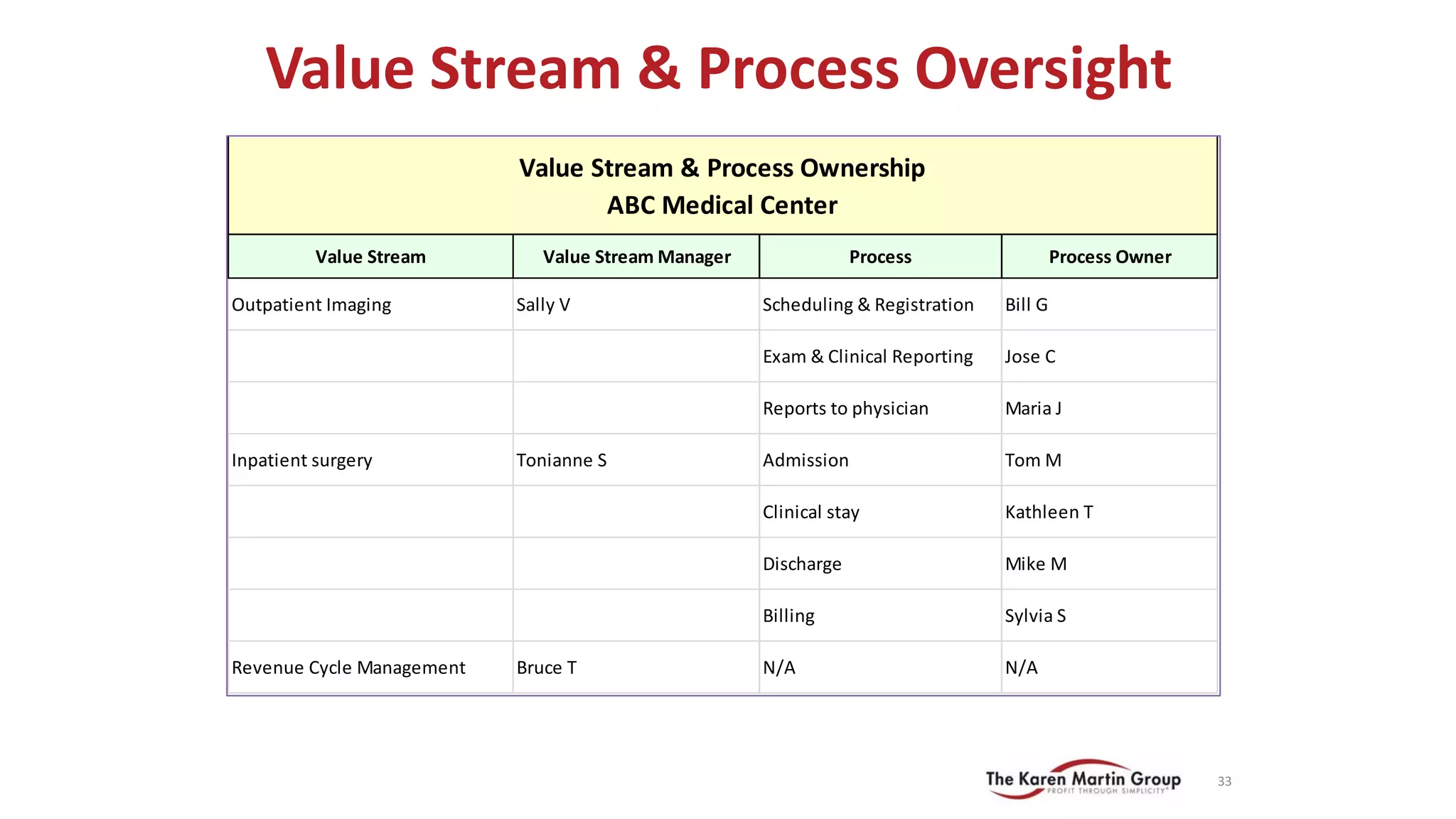

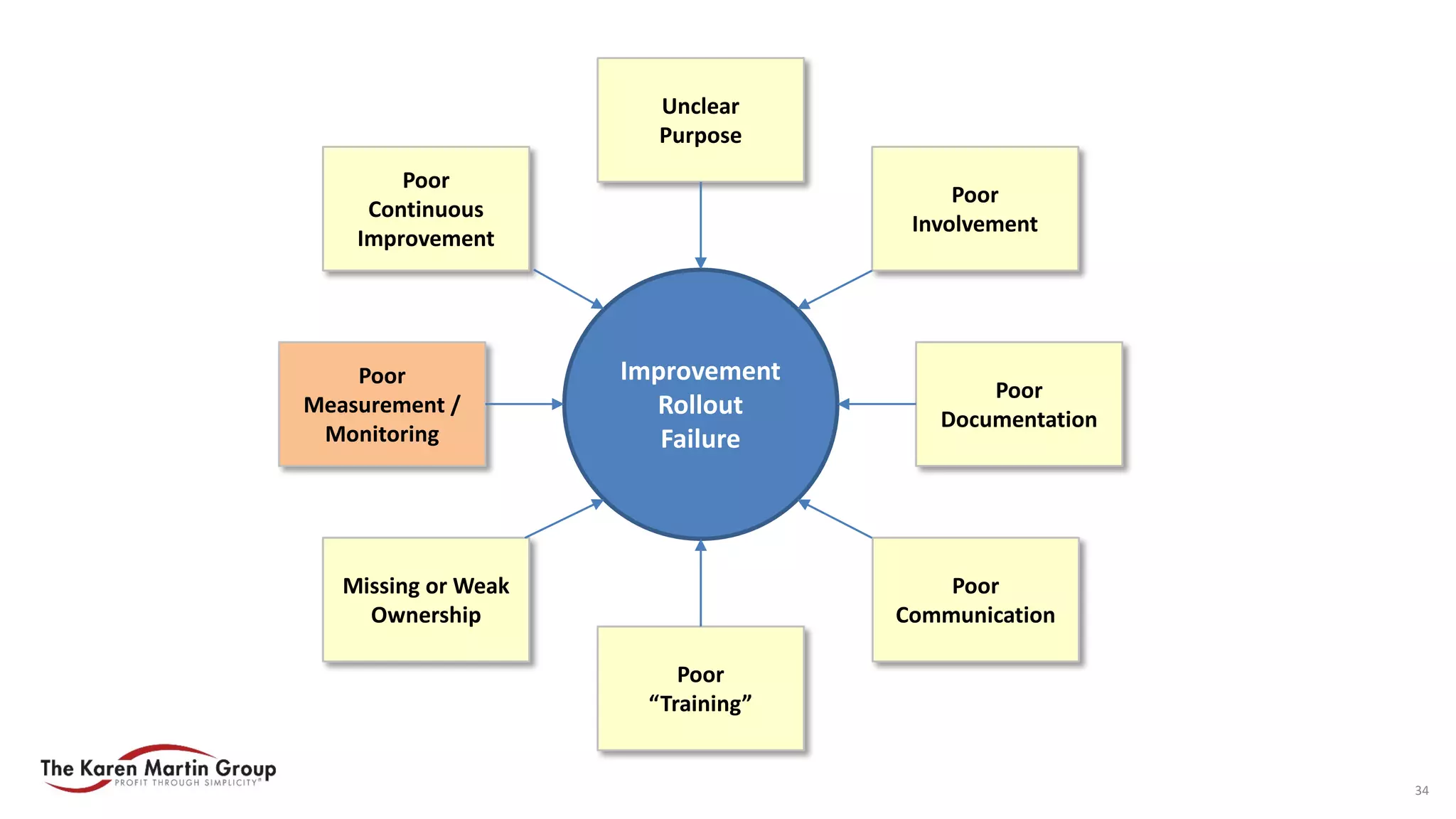

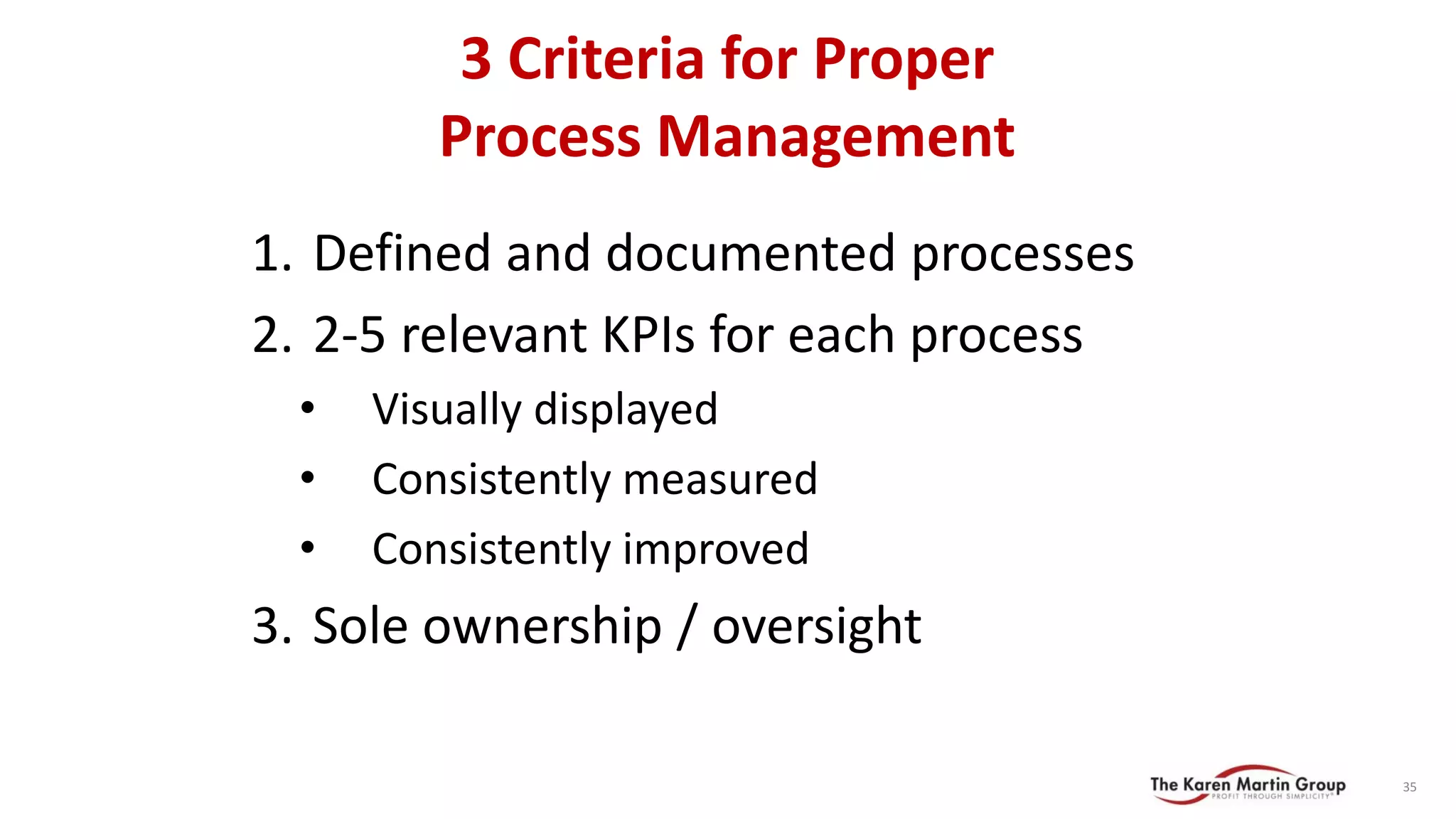

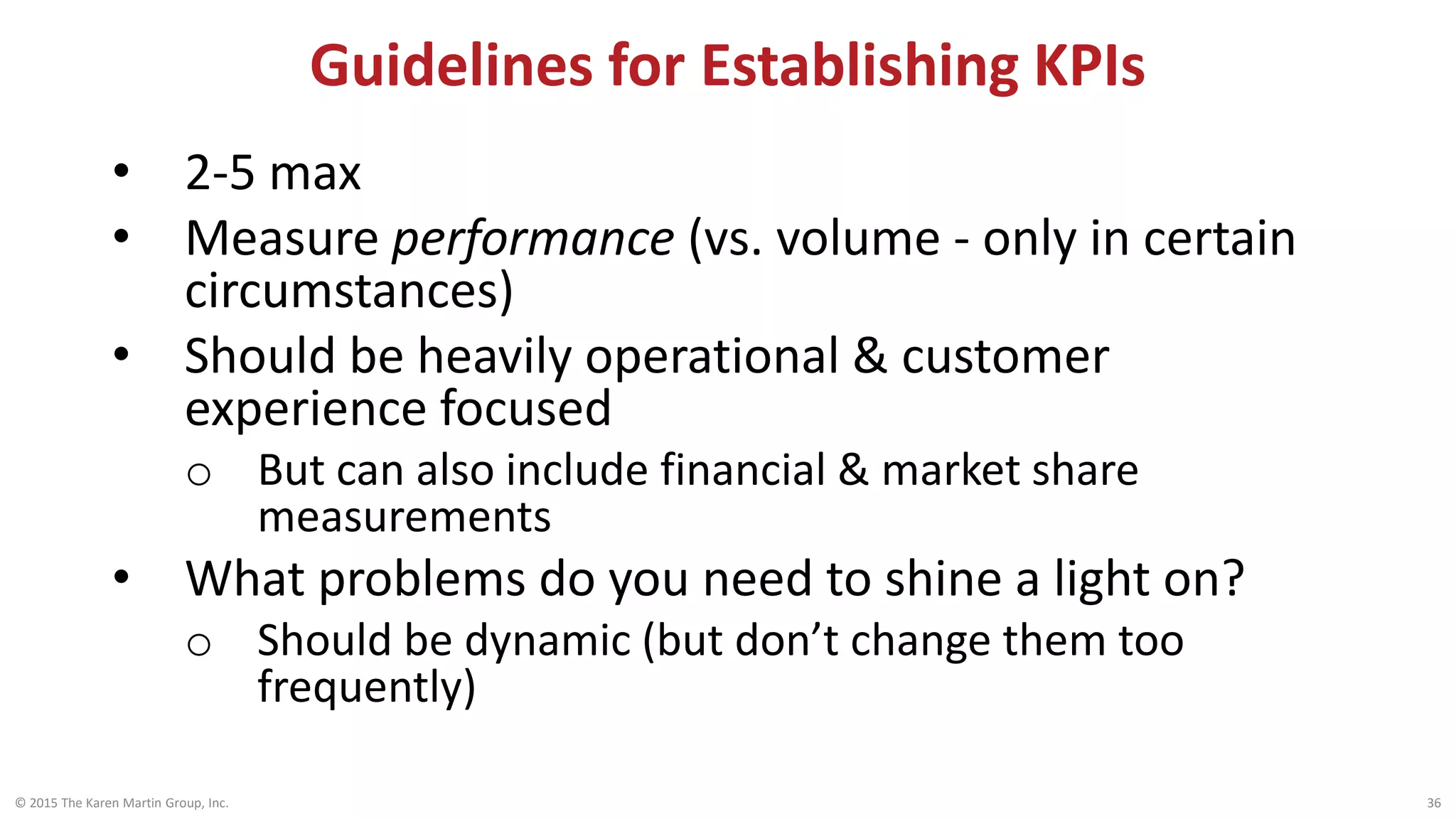

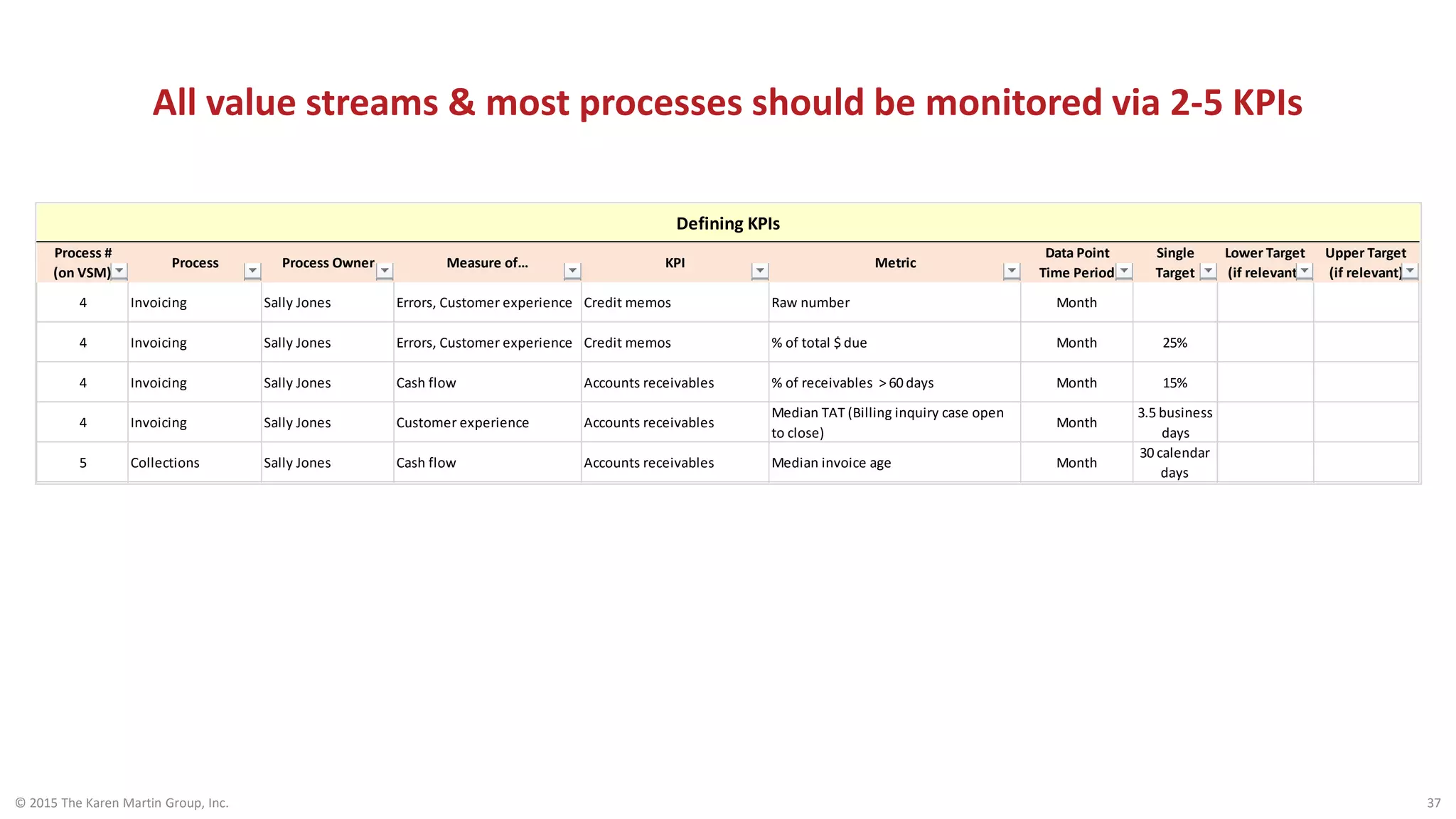

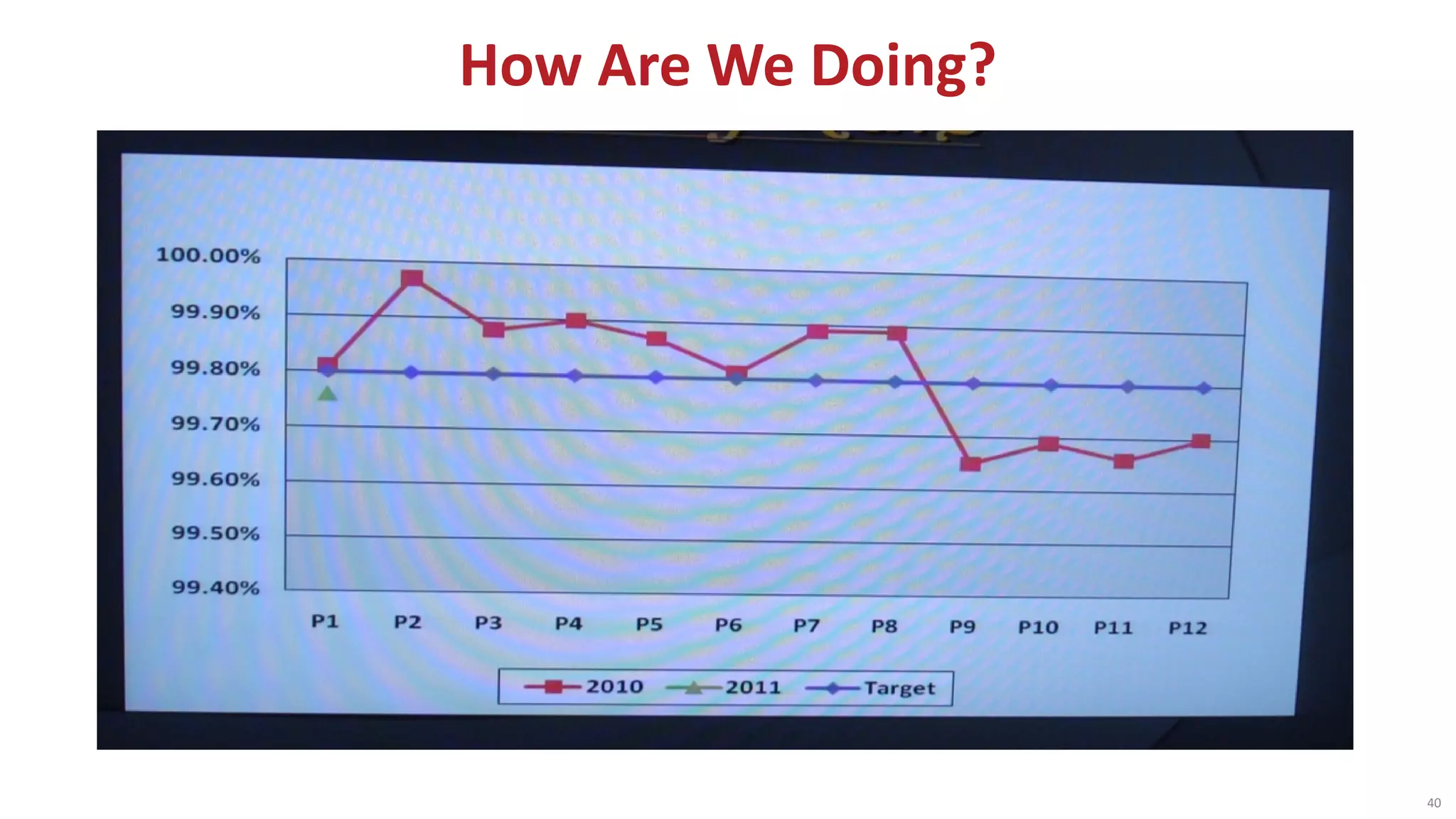

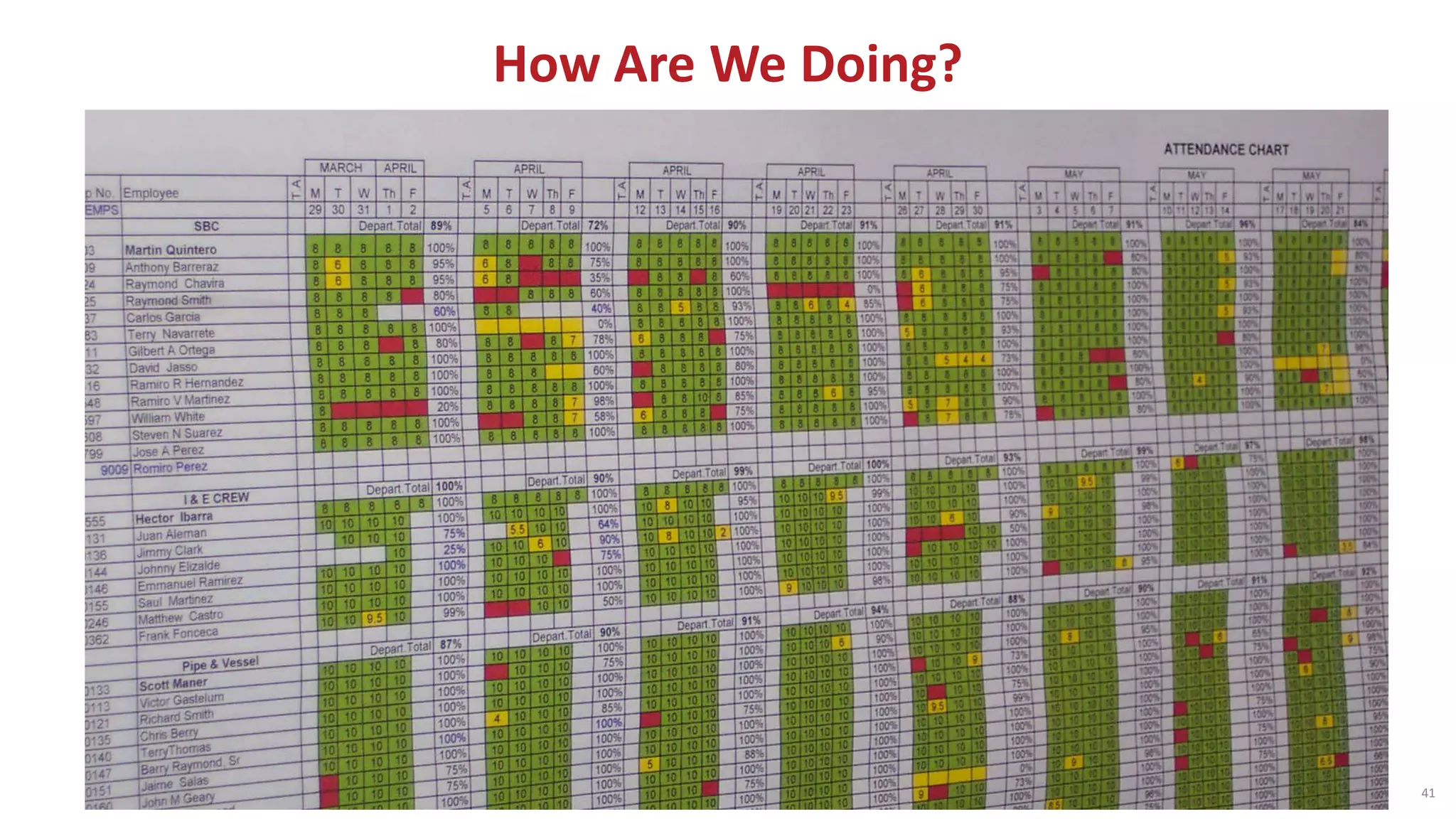

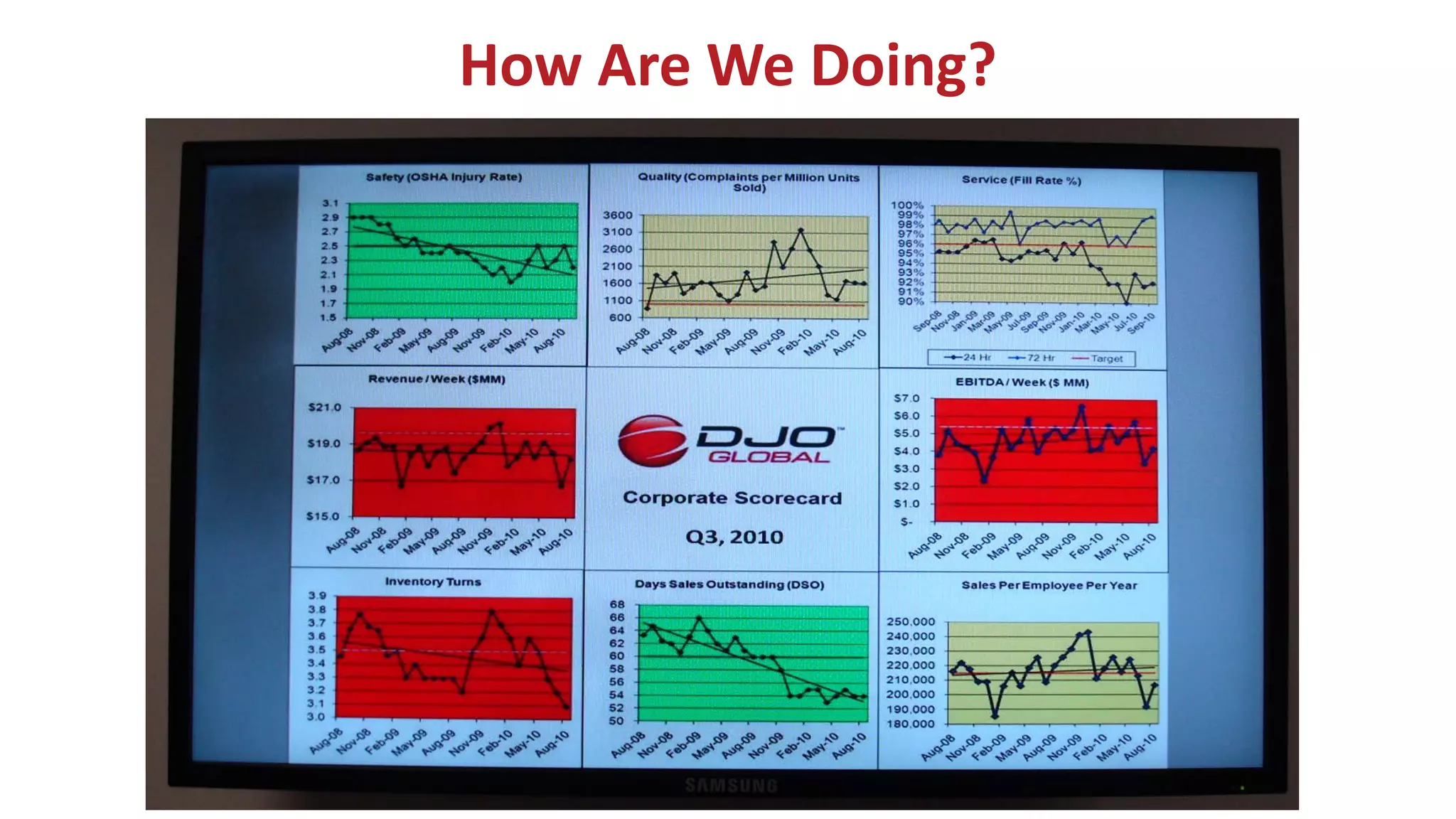

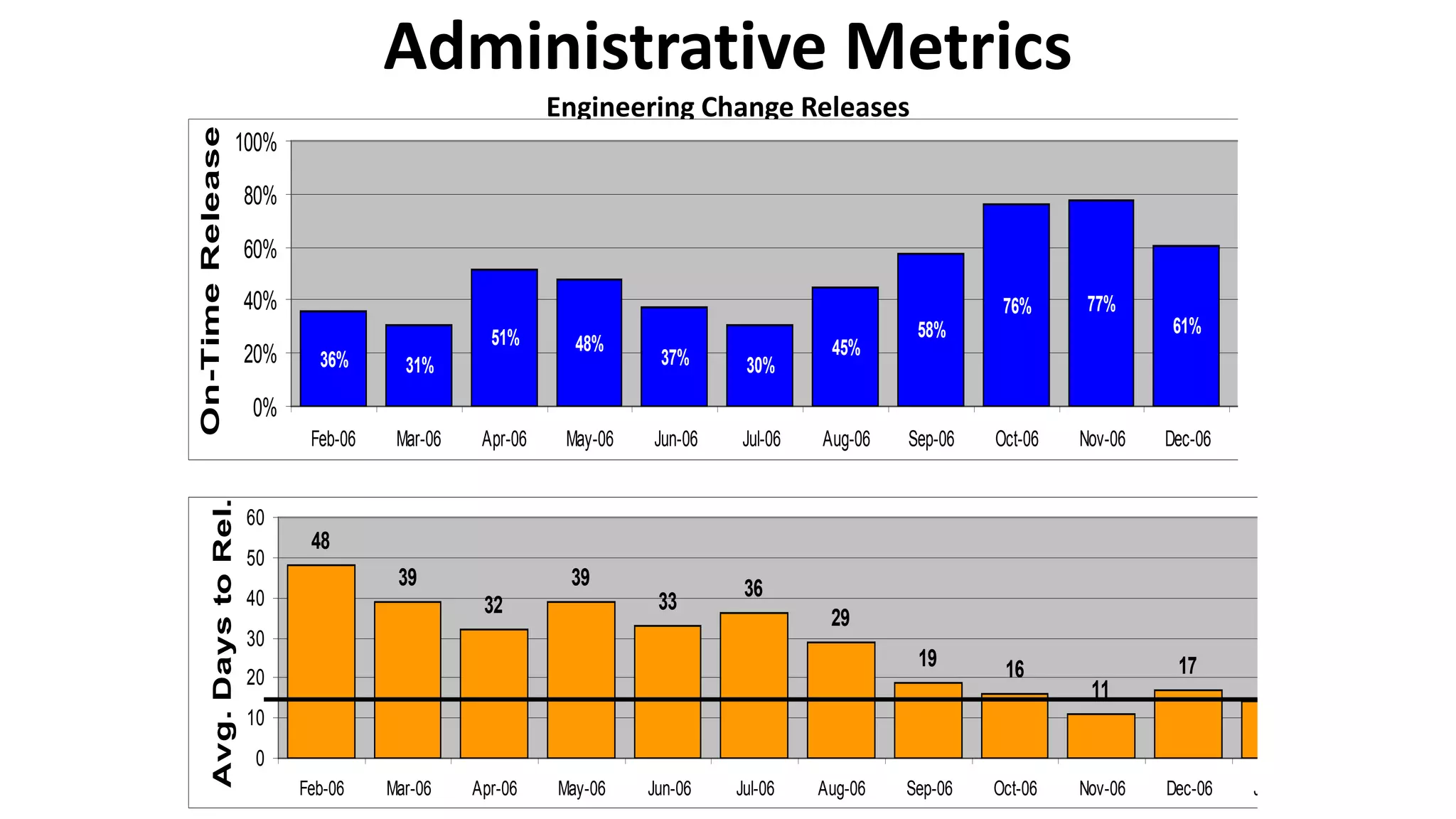

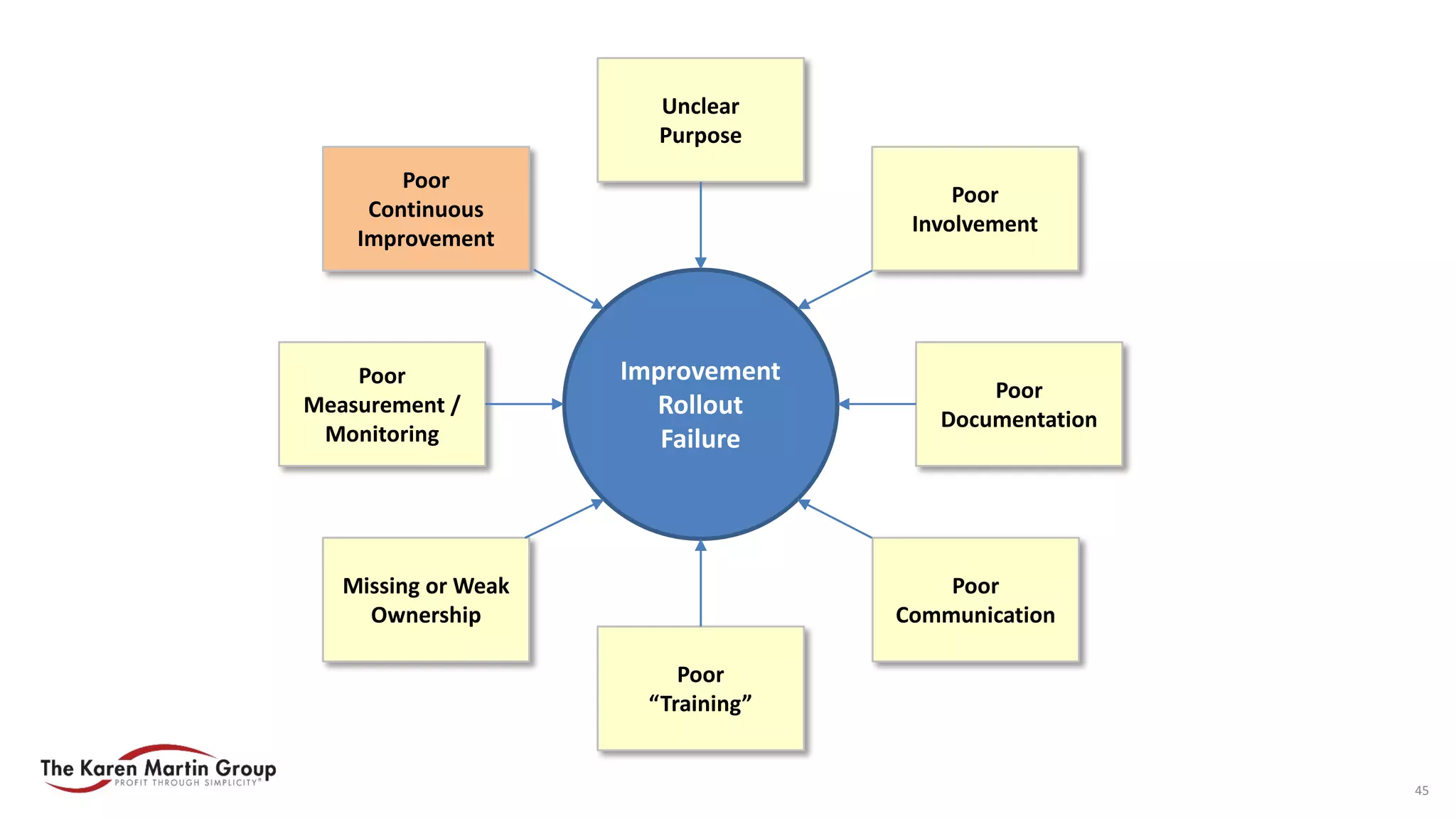

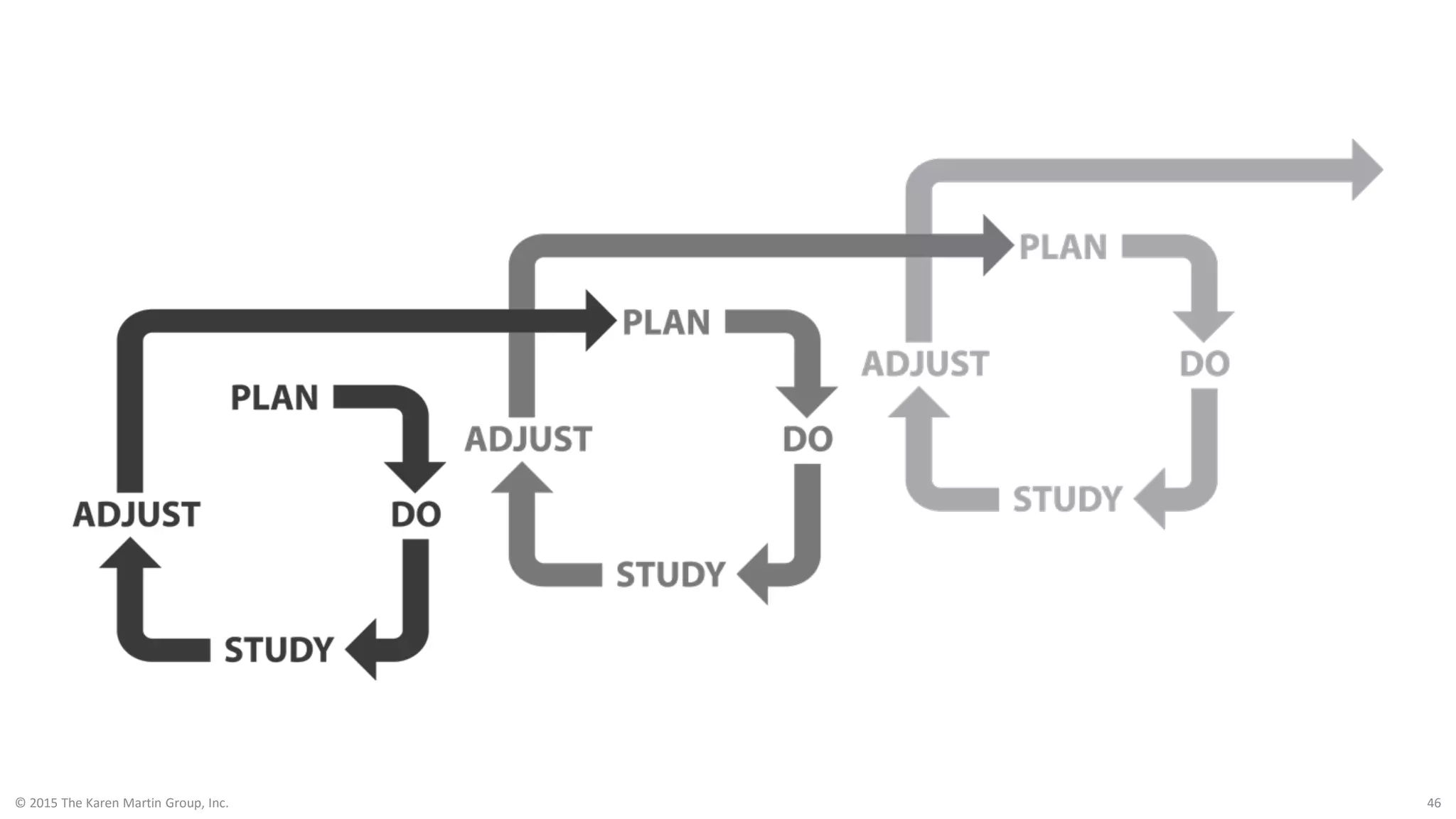

The document outlines strategies for effectively rolling out lean management processes within organizations, highlighting common points of failure such as poor communication and inadequate training. It emphasizes the importance of clear objectives, identifying target audiences, and assessing learning effectiveness in fostering successful process implementation. Additionally, it introduces frameworks for managing value streams and establishing key performance indicators to ensure continuous improvement and accountability.