Embed presentation

Downloaded 349 times

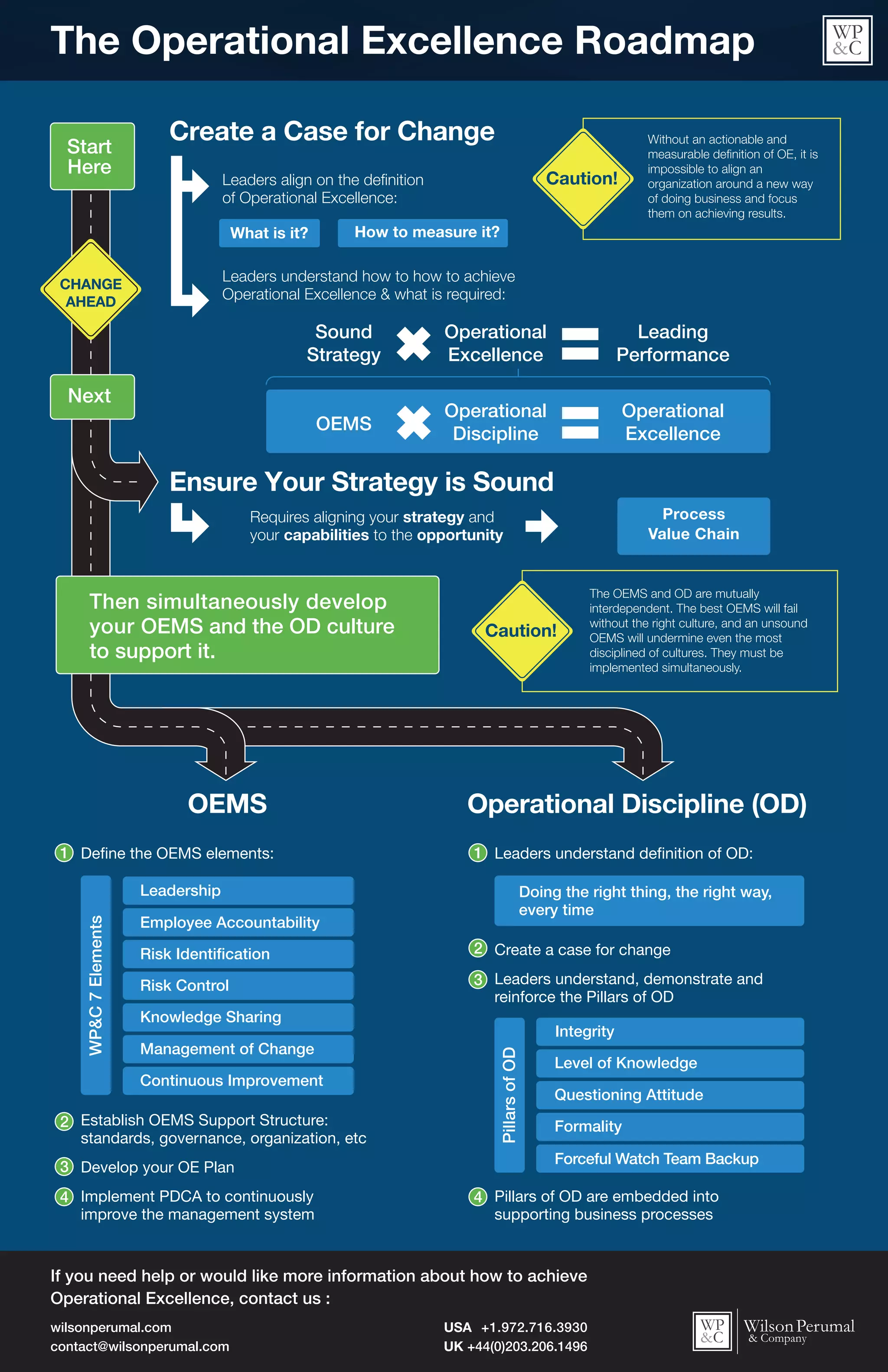

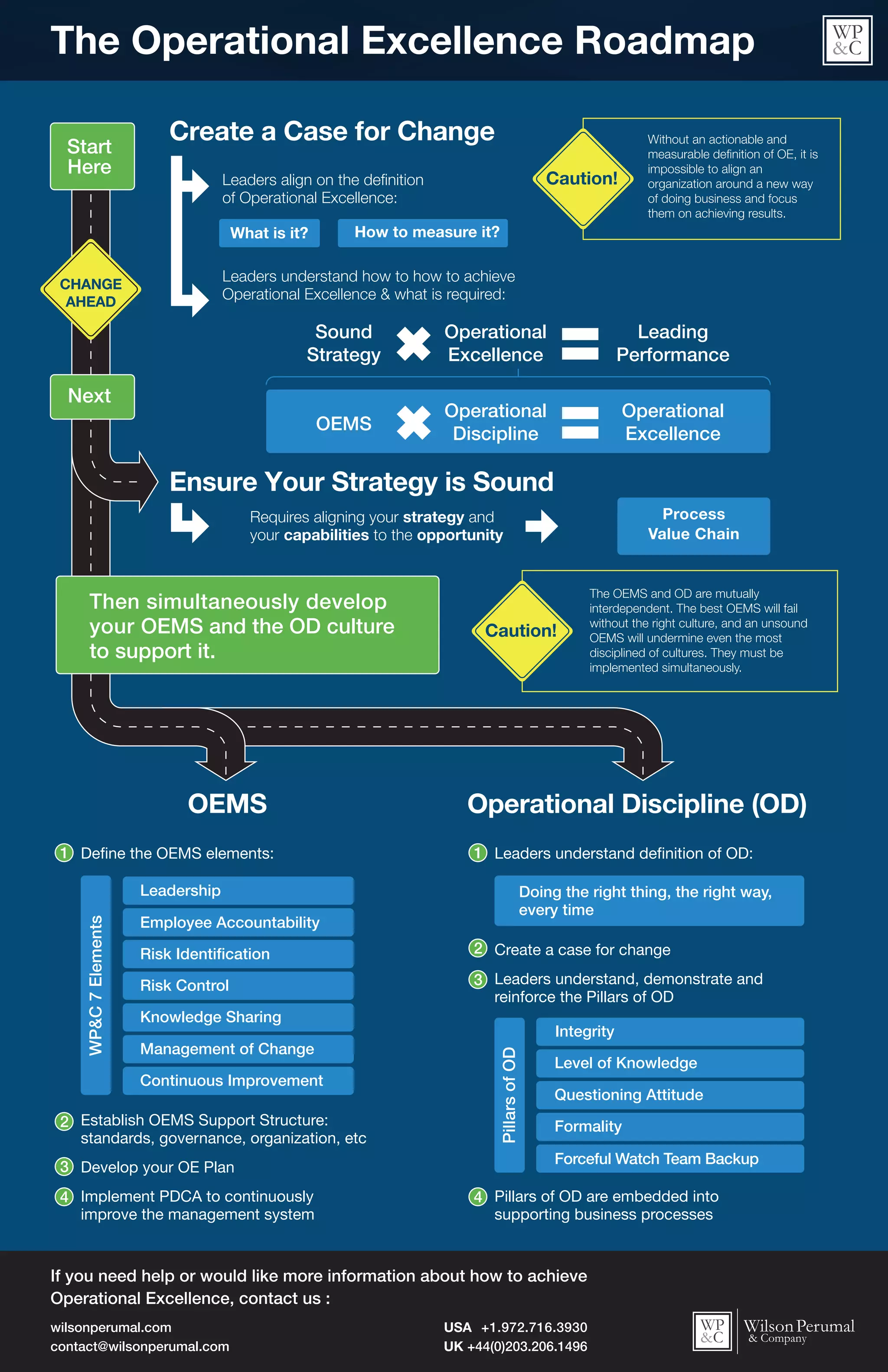

The document outlines a roadmap for achieving operational excellence (OE) by defining OE, aligning organizational leadership, and emphasizing the interdependence of operational excellence management systems (OEMS) and operational discipline (OD). It highlights the importance of implementing these frameworks simultaneously to foster a supportive culture and achieve measurable results across the organization. Furthermore, it provides guidance on developing an OE plan and continuous improvement through established processes.