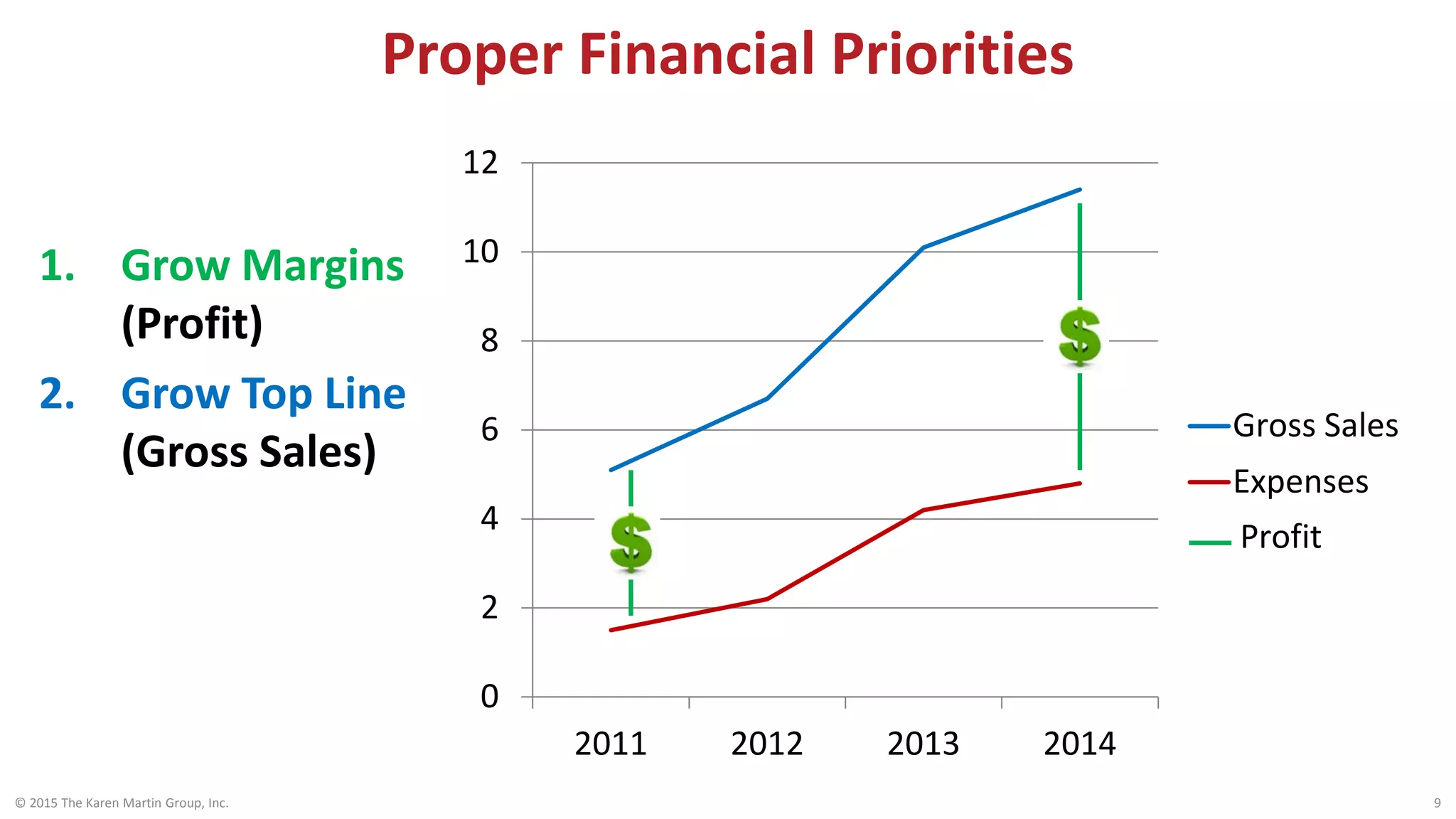

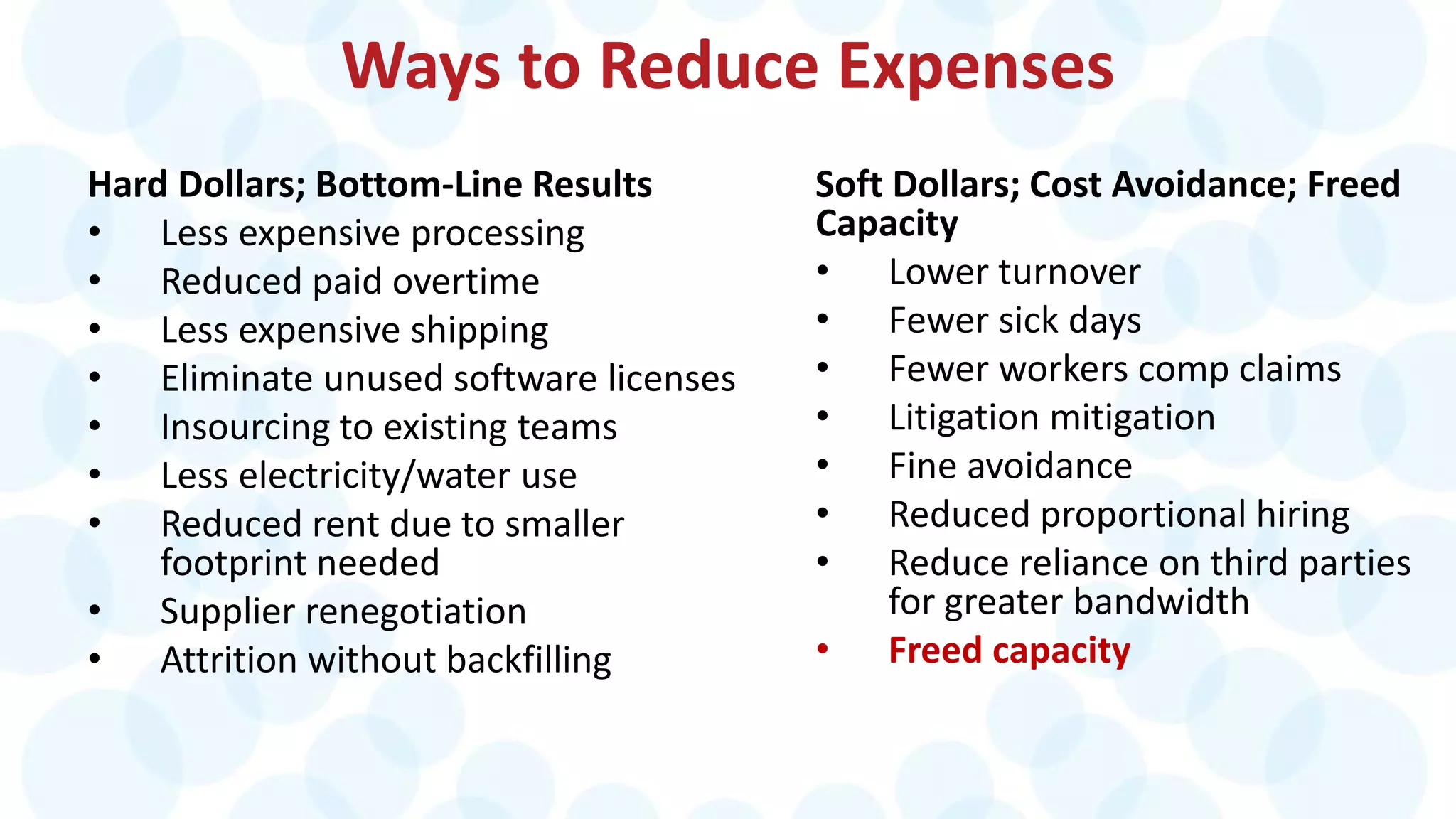

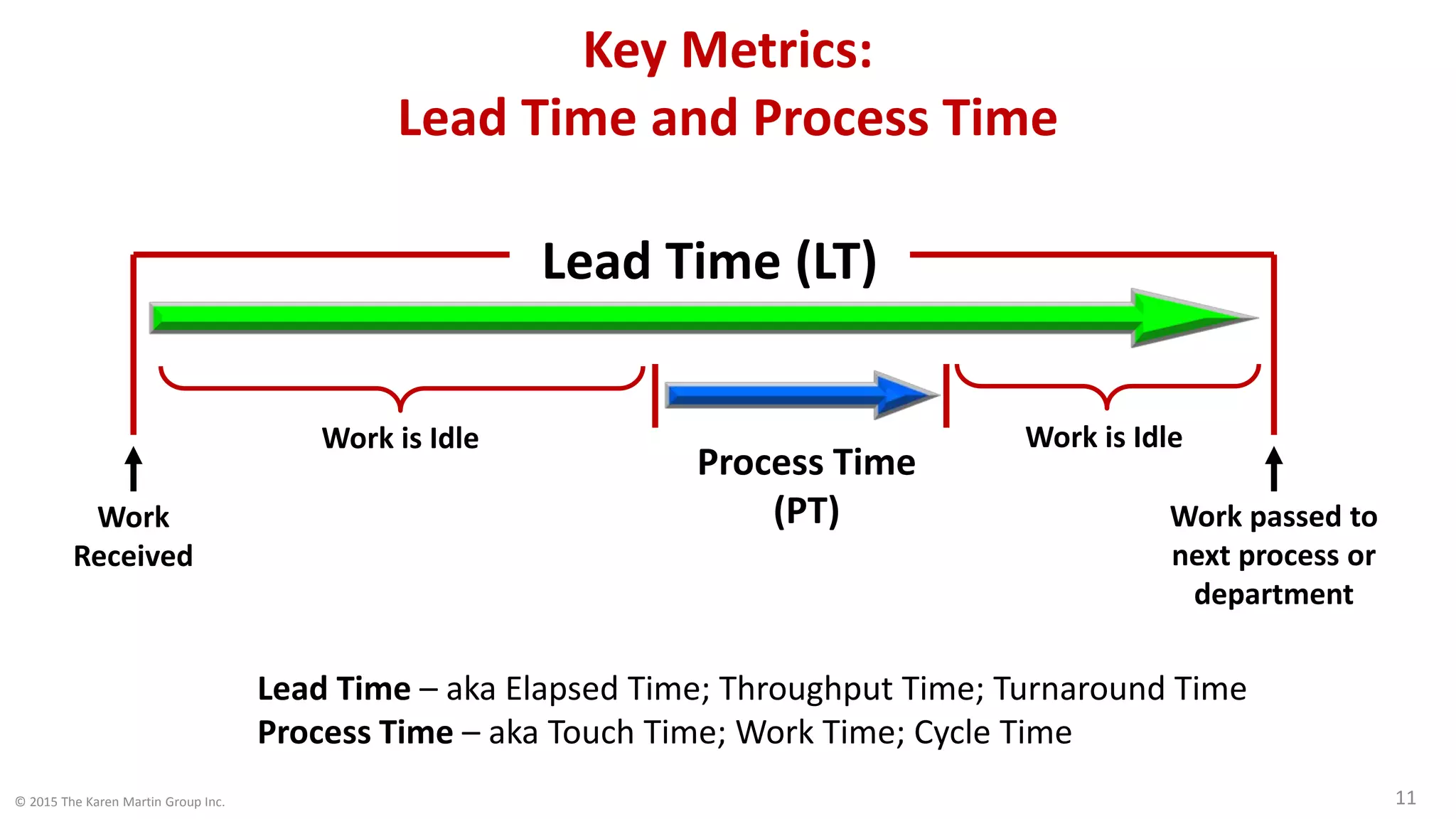

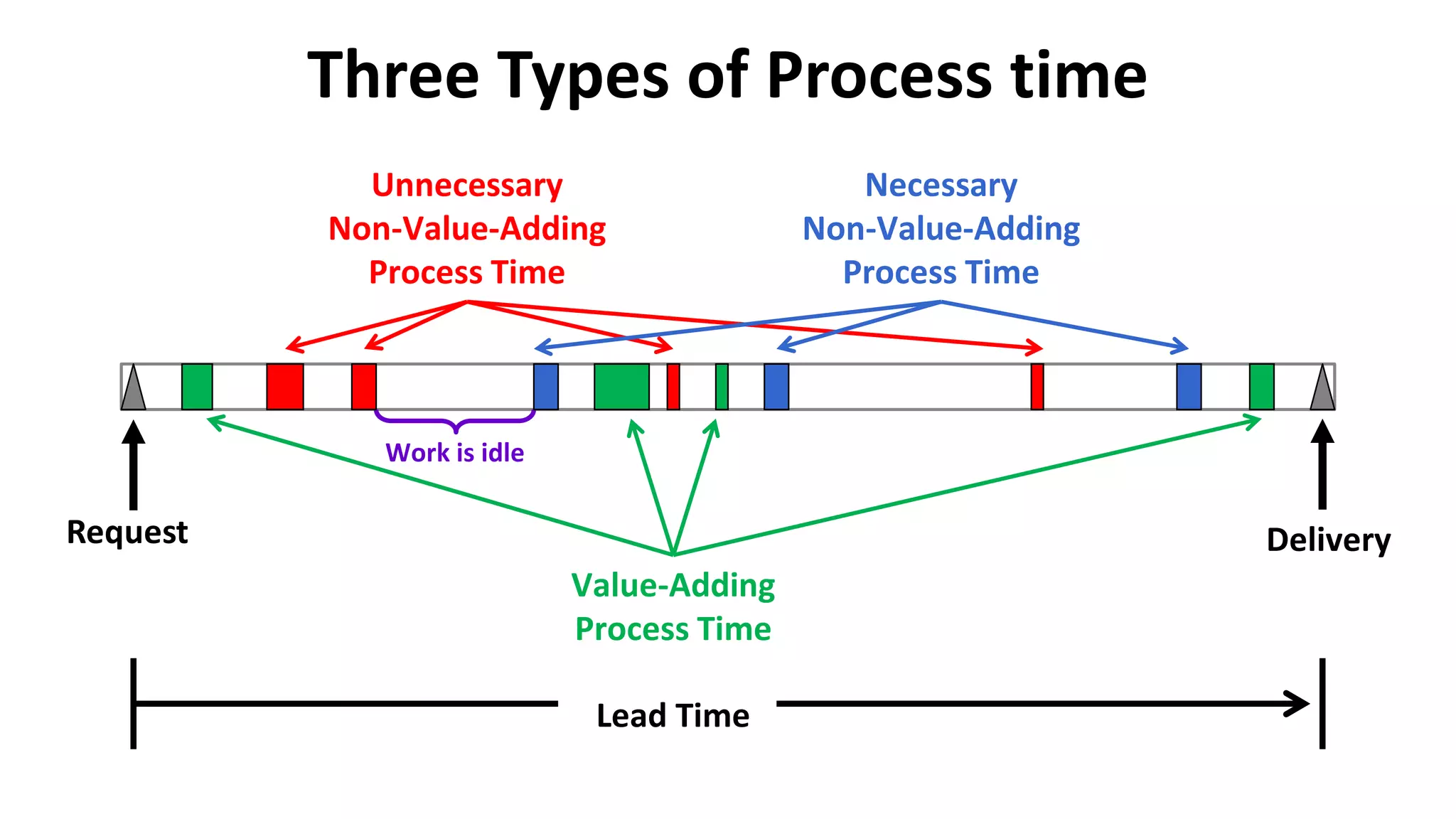

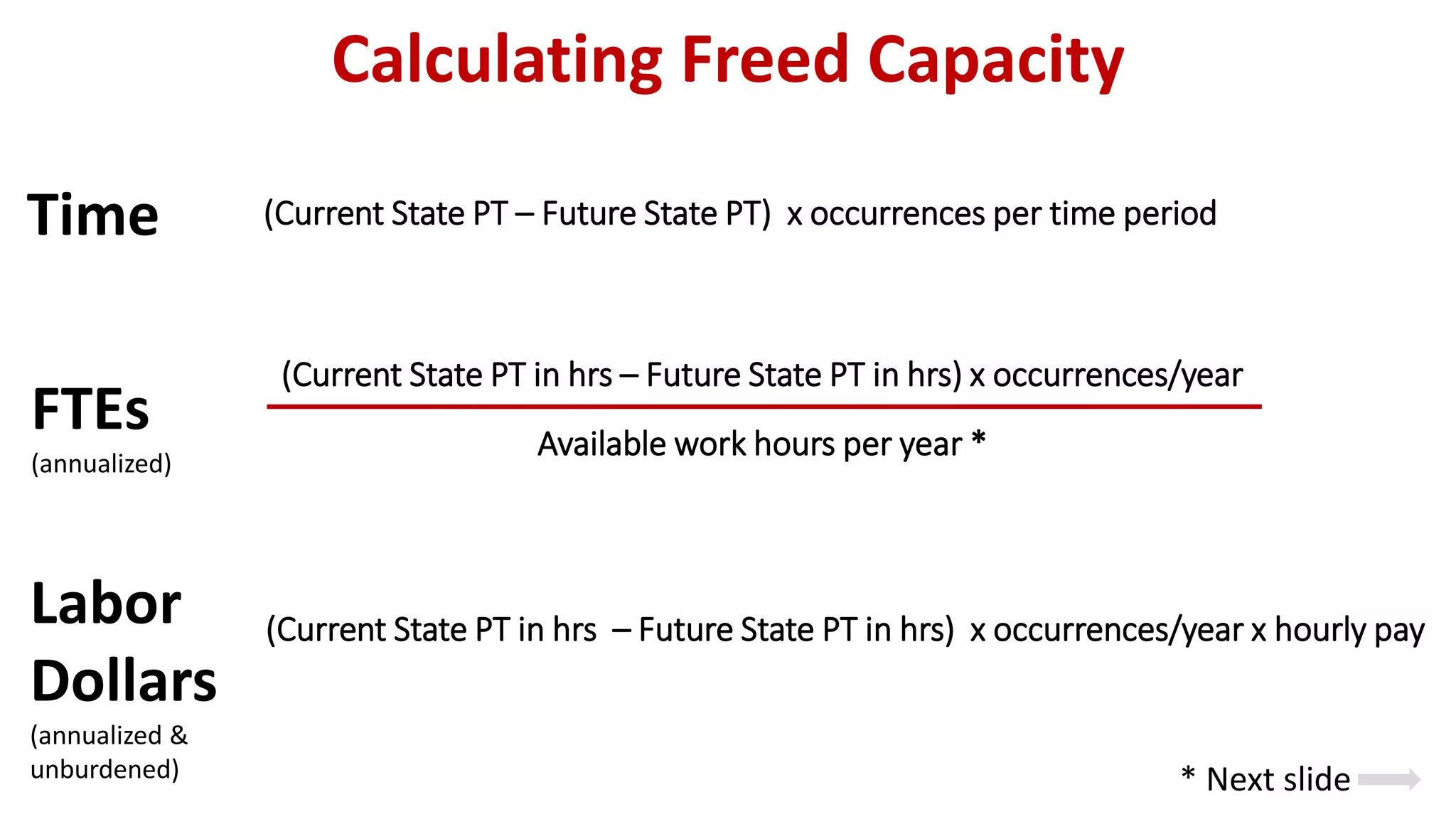

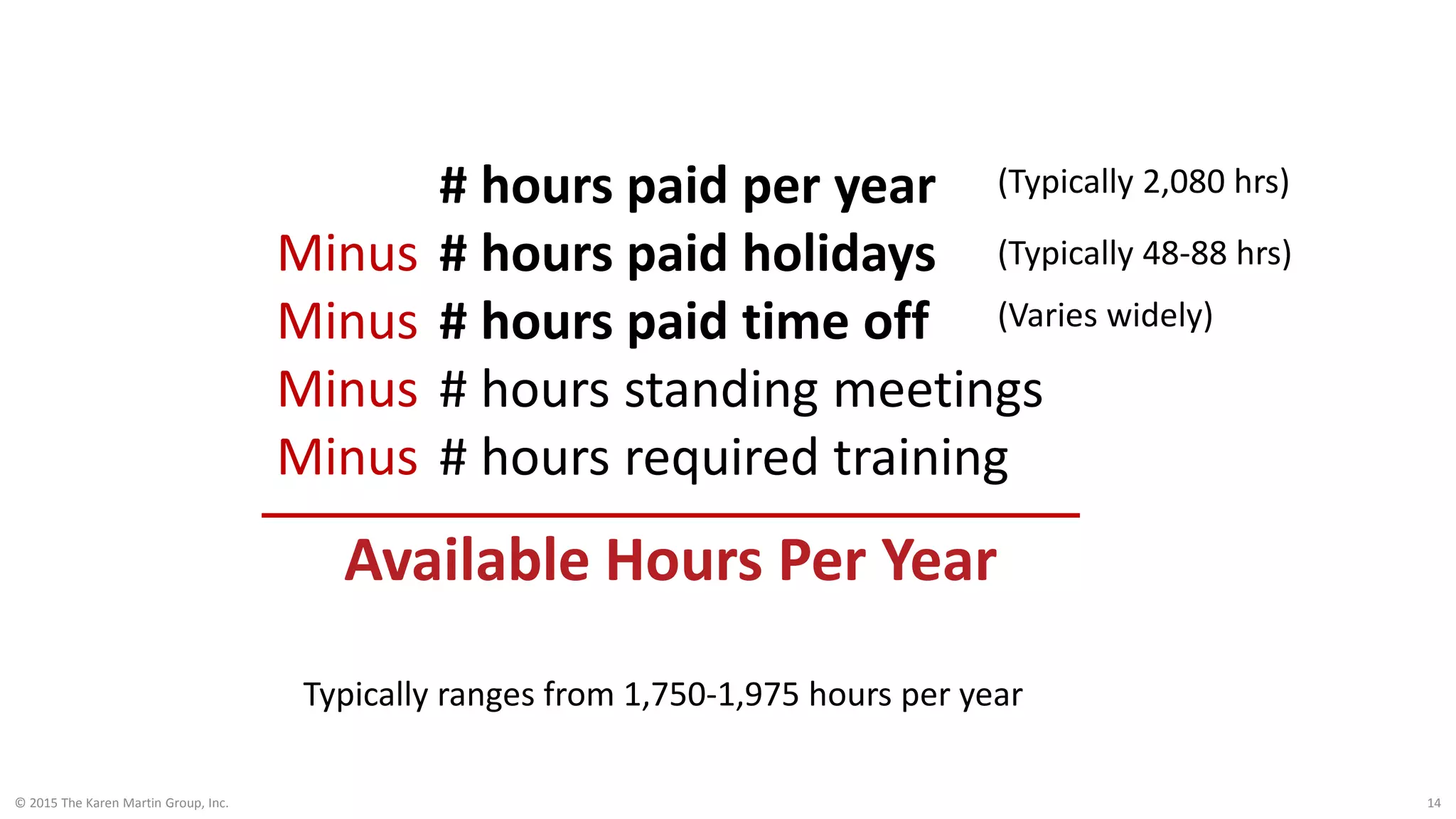

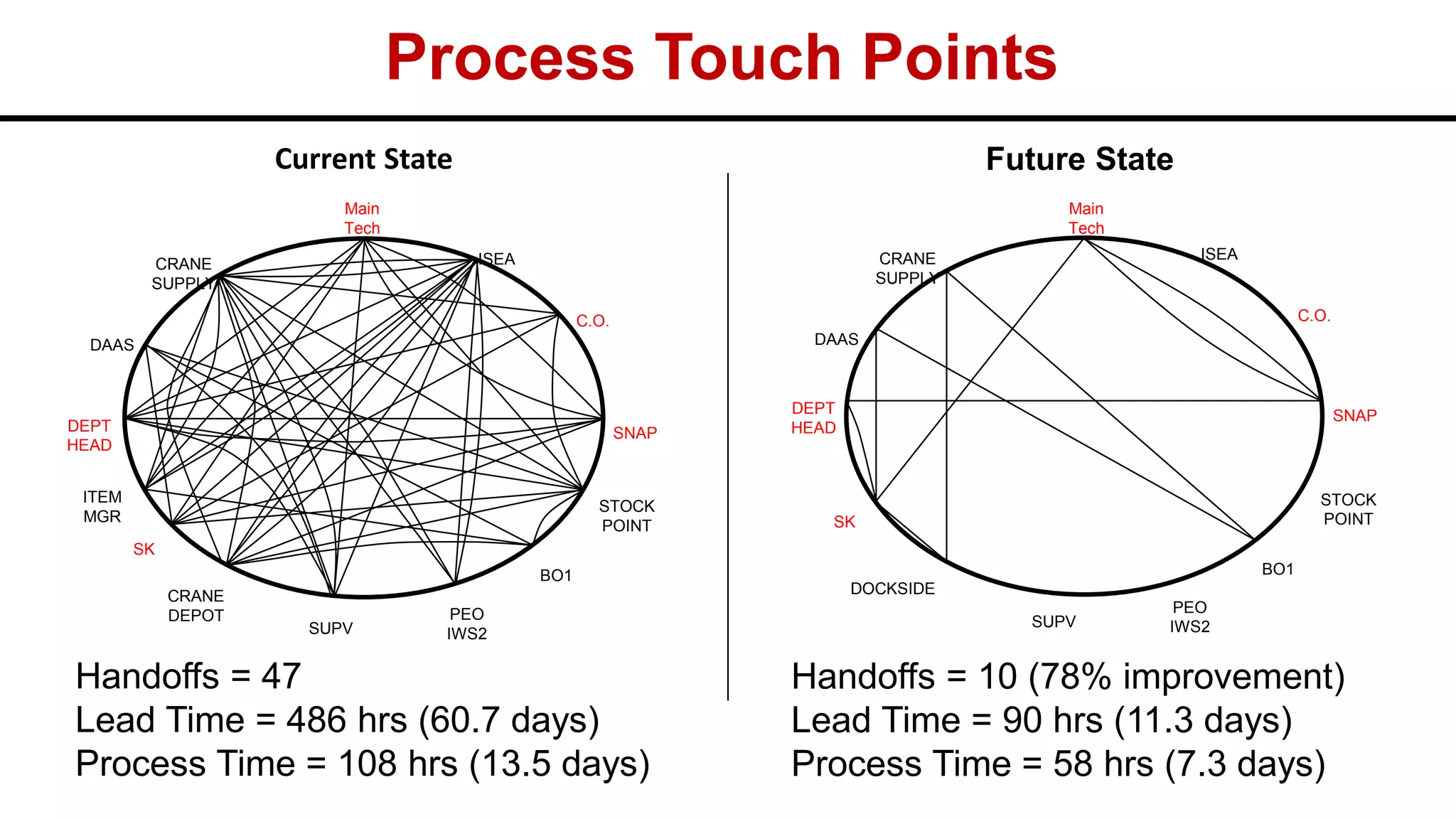

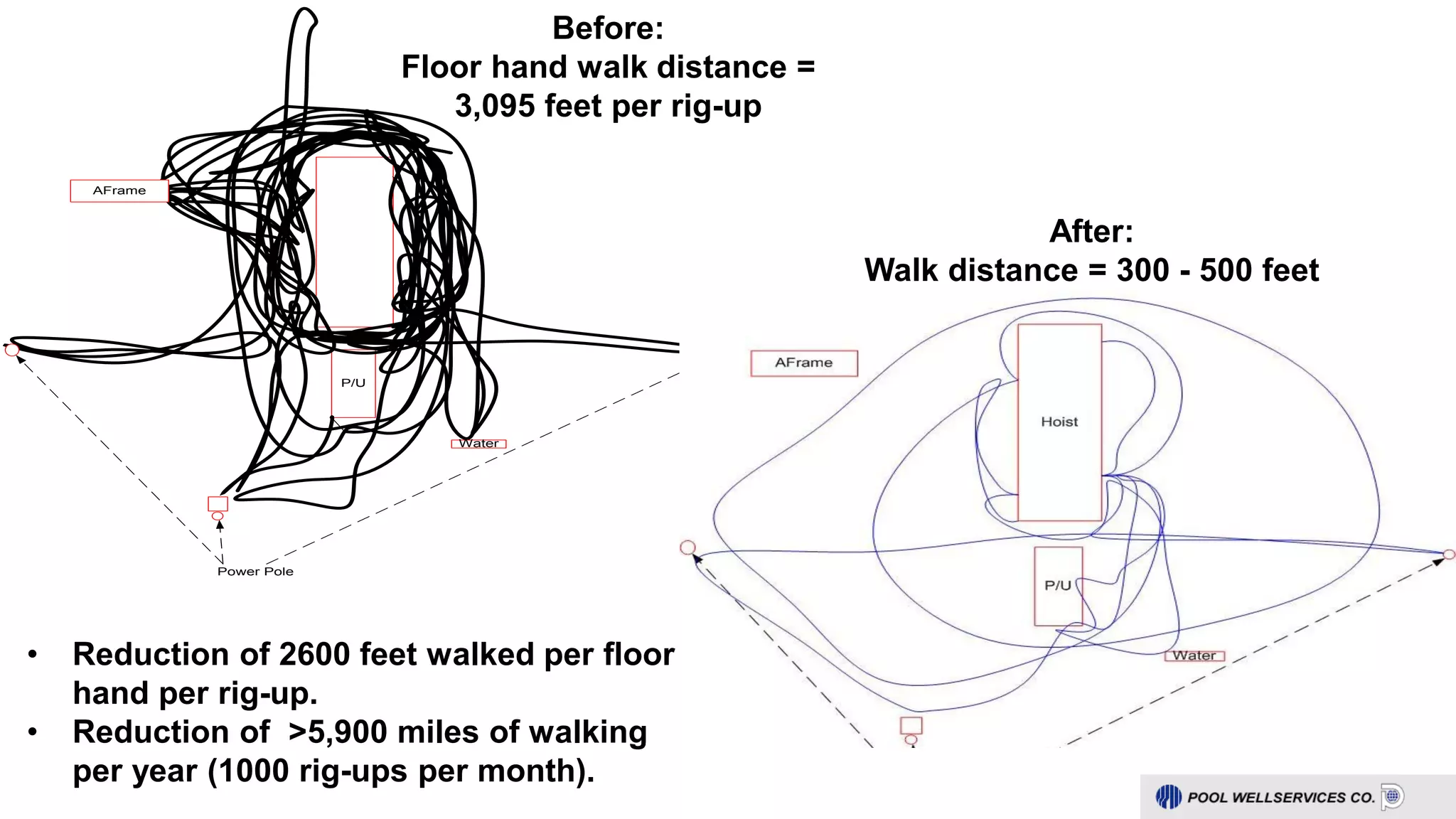

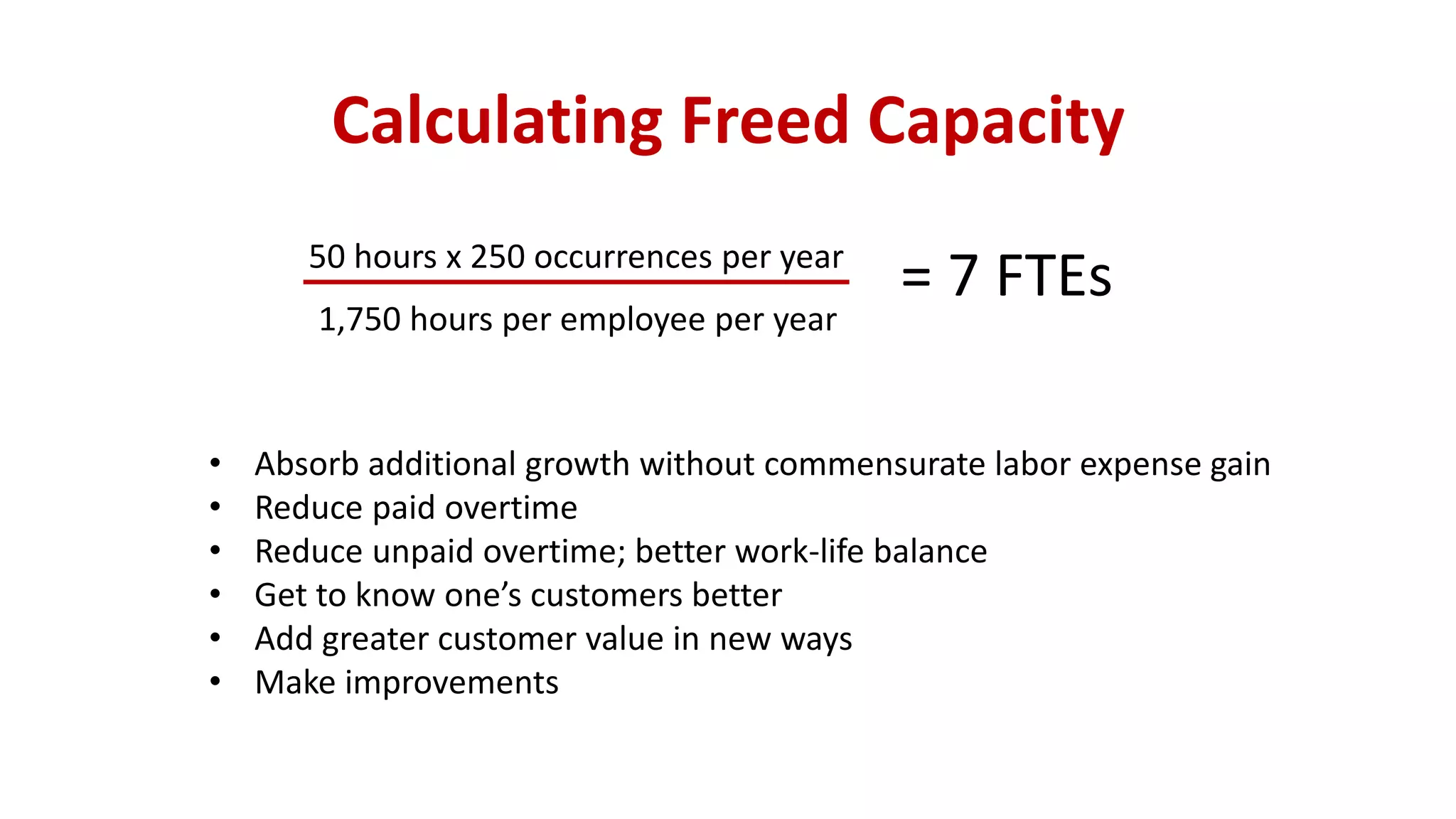

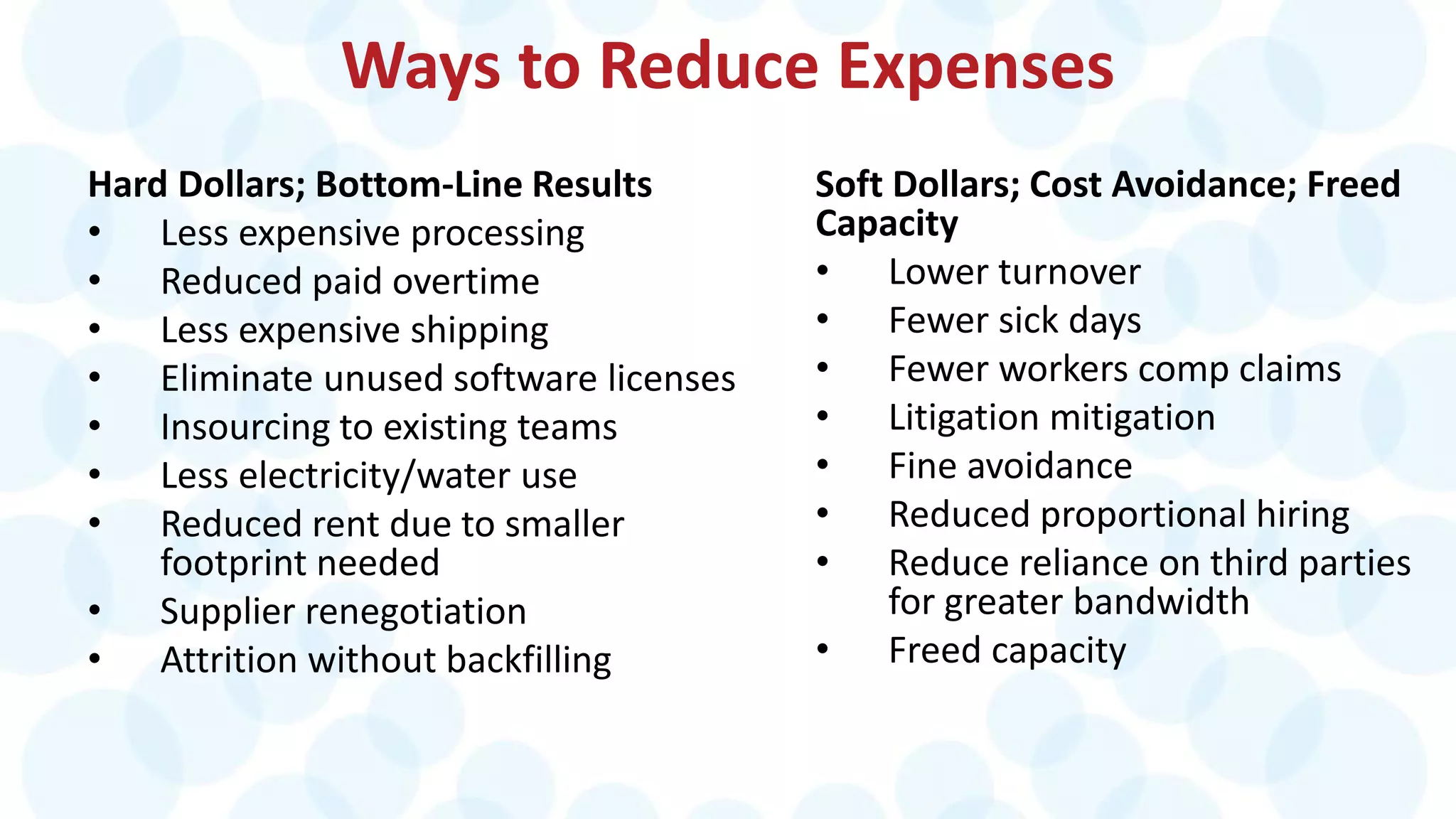

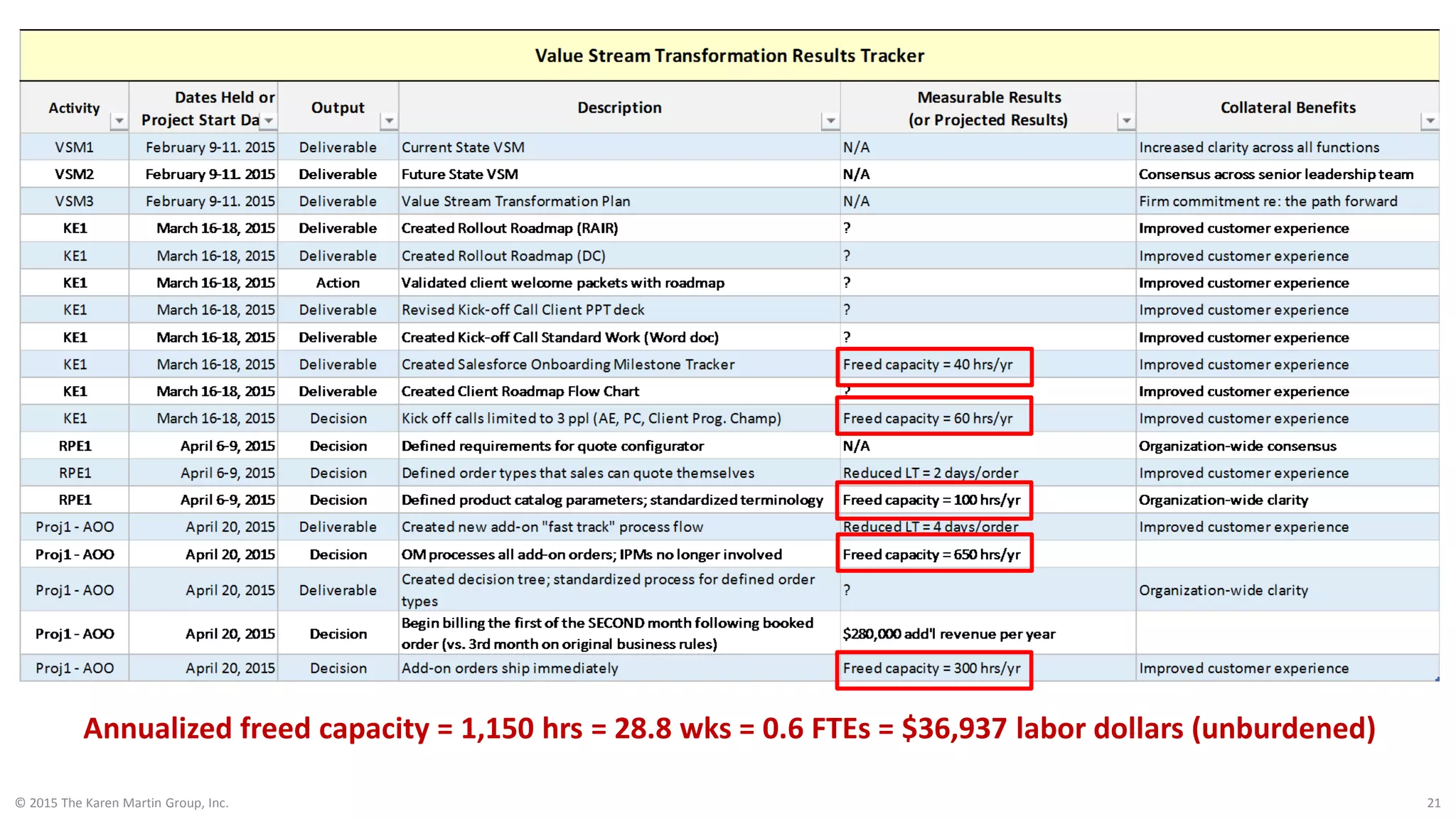

Karen Martin's presentation discusses the importance of lean management and its financial implications for businesses, highlighting strategies to improve margins and engage executives. It emphasizes the need for measurable improvements in processes and outlines various methods to reduce expenses while increasing capacity and revenue. The document also stresses the significance of calculating financial results in daily kaizen efforts to ensure the legitimacy and impact of improvement initiatives.