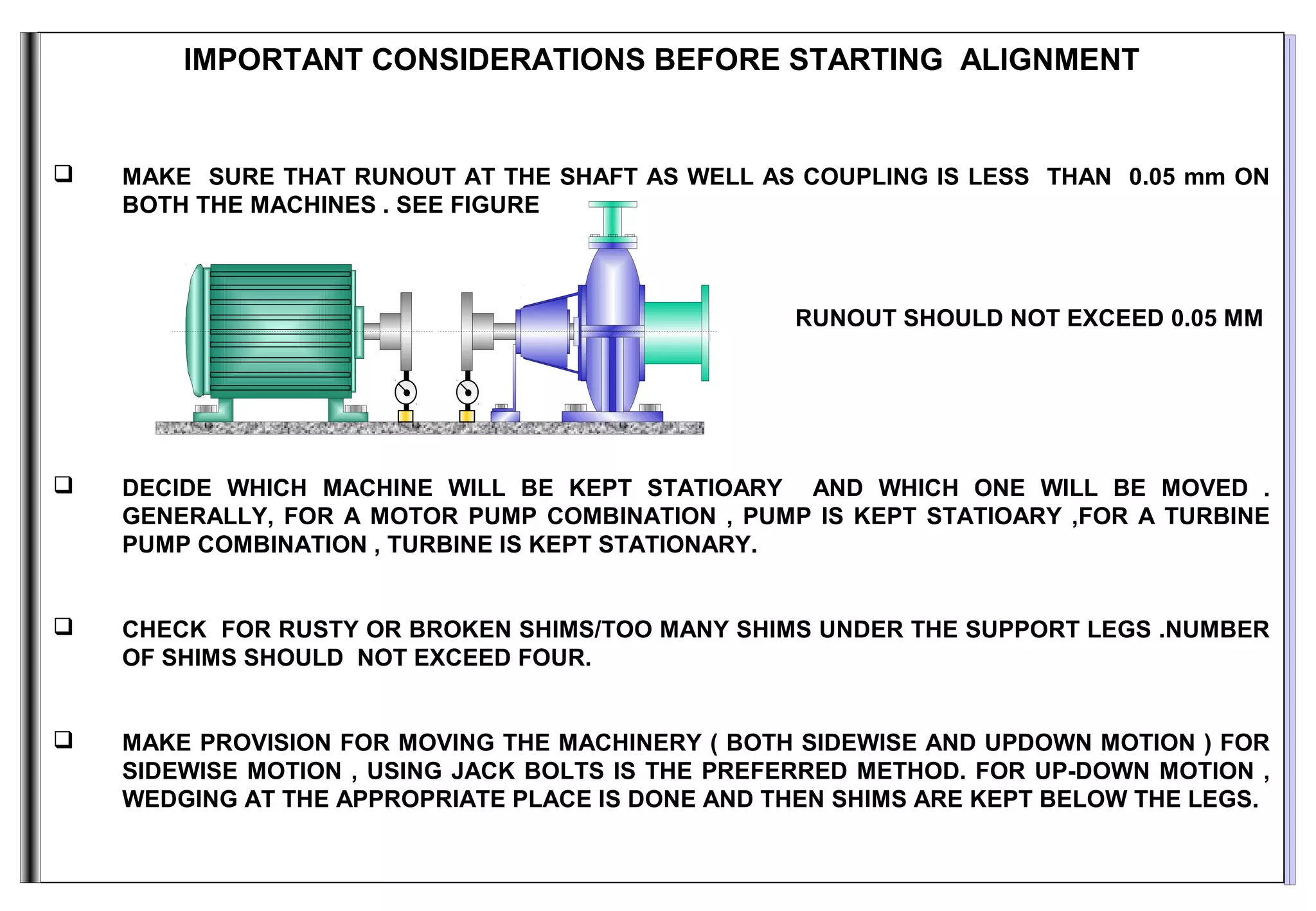

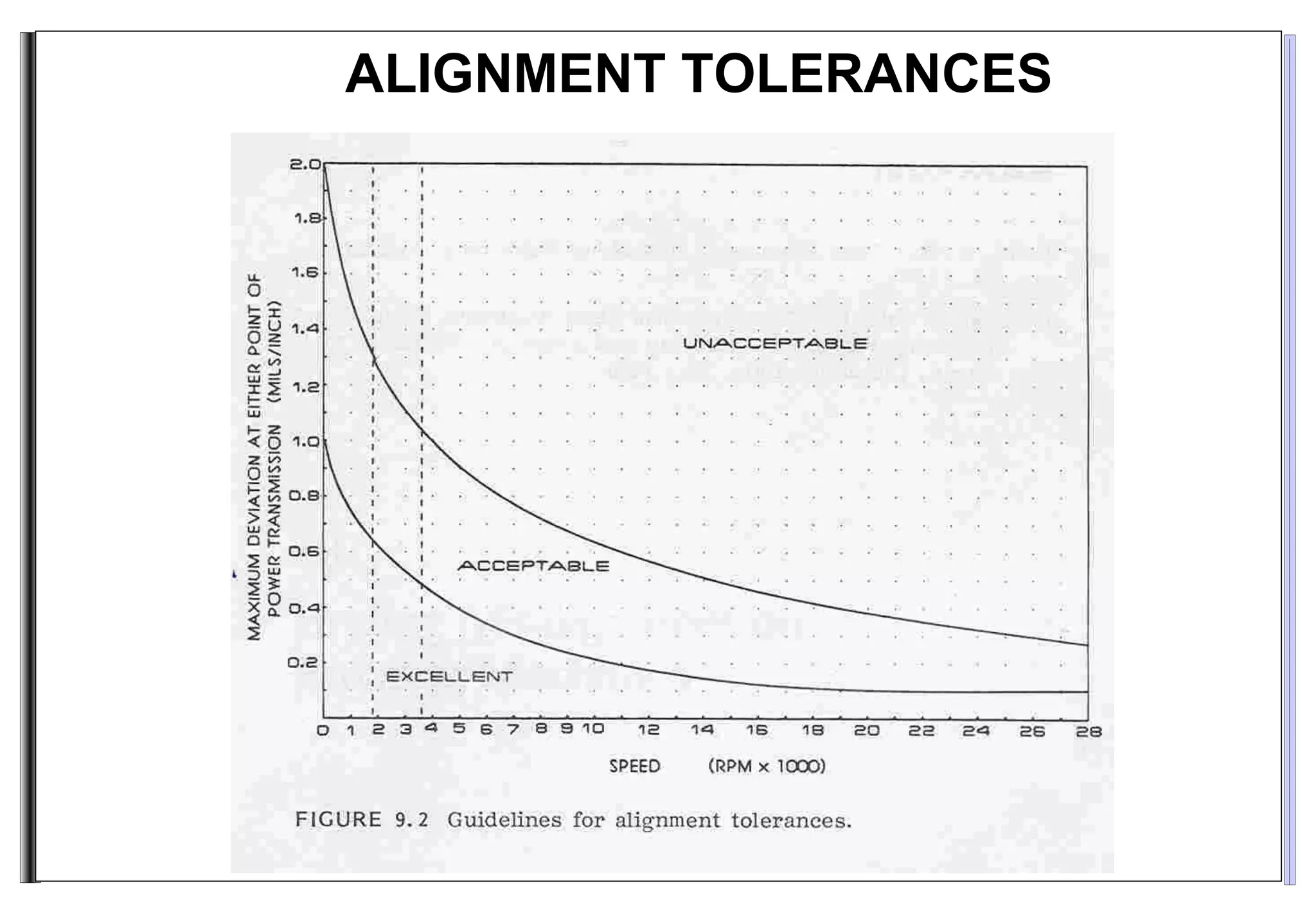

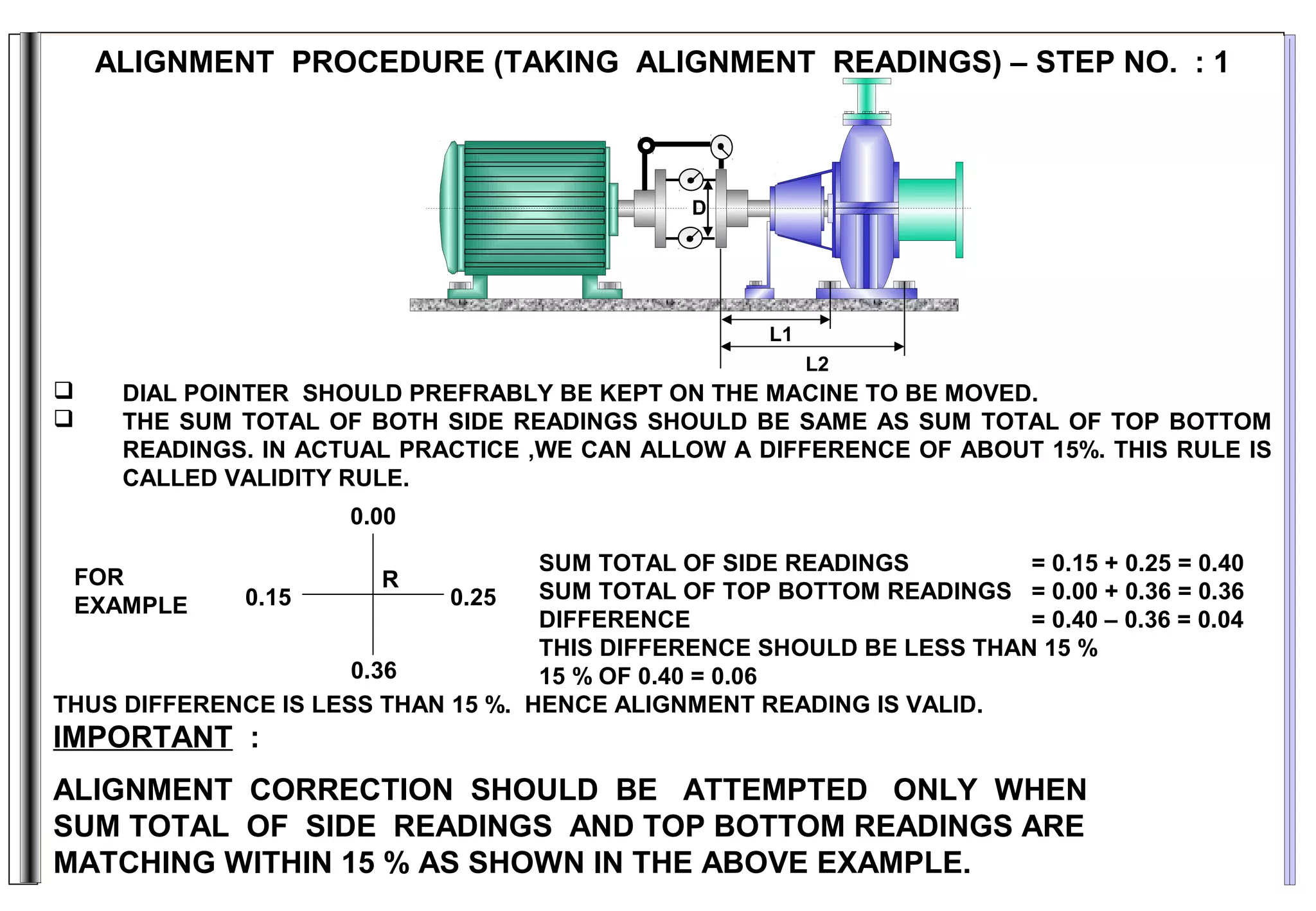

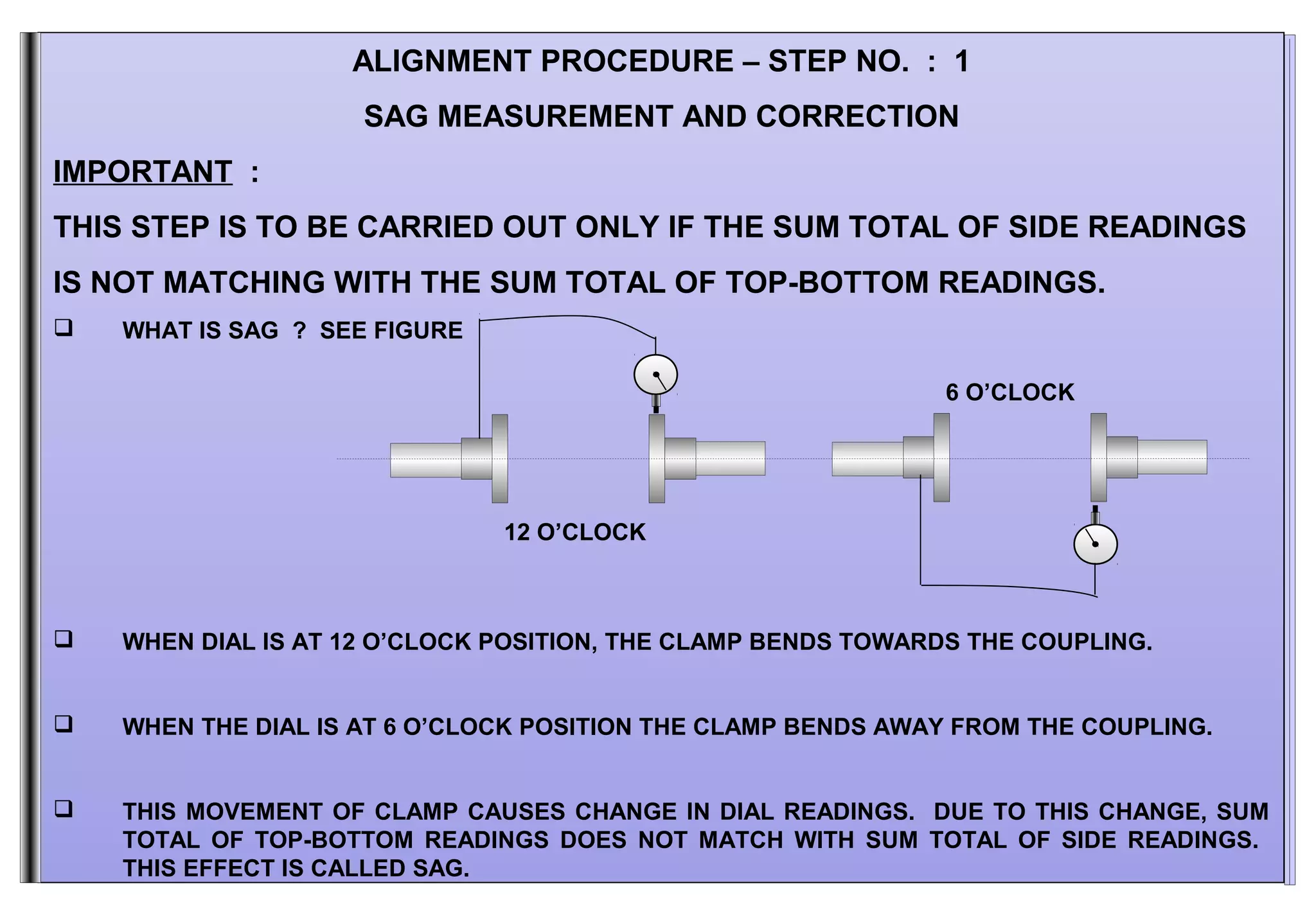

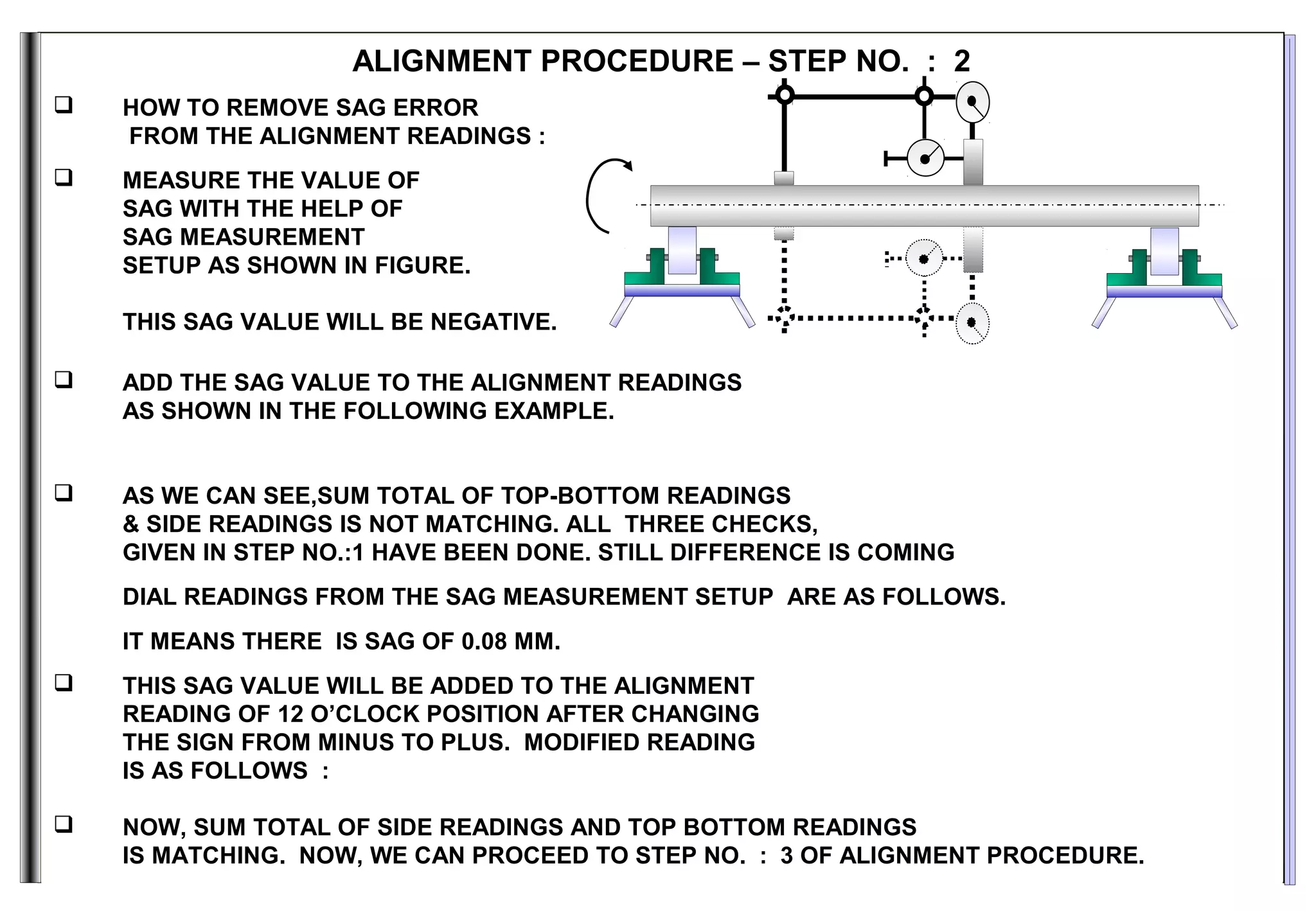

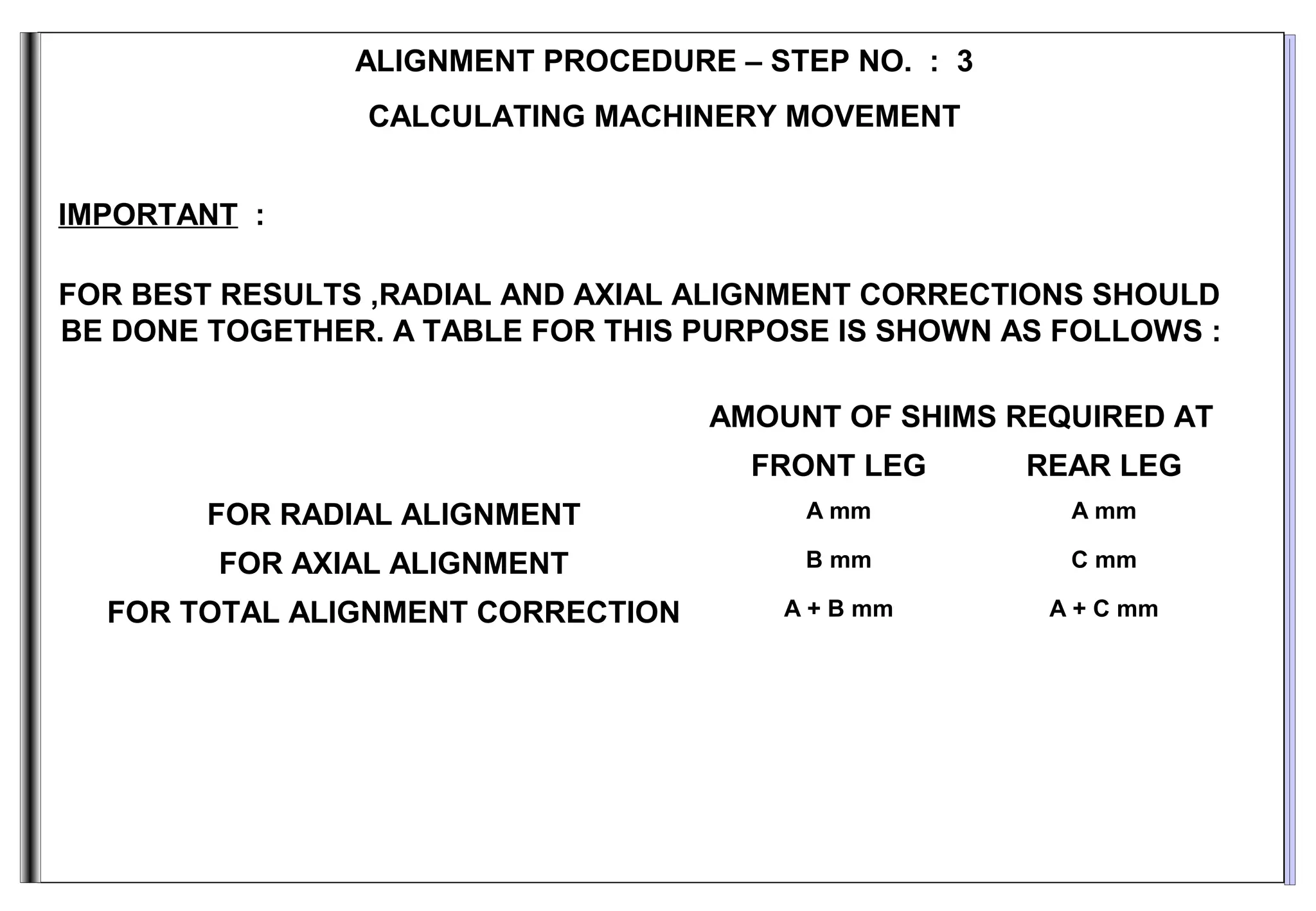

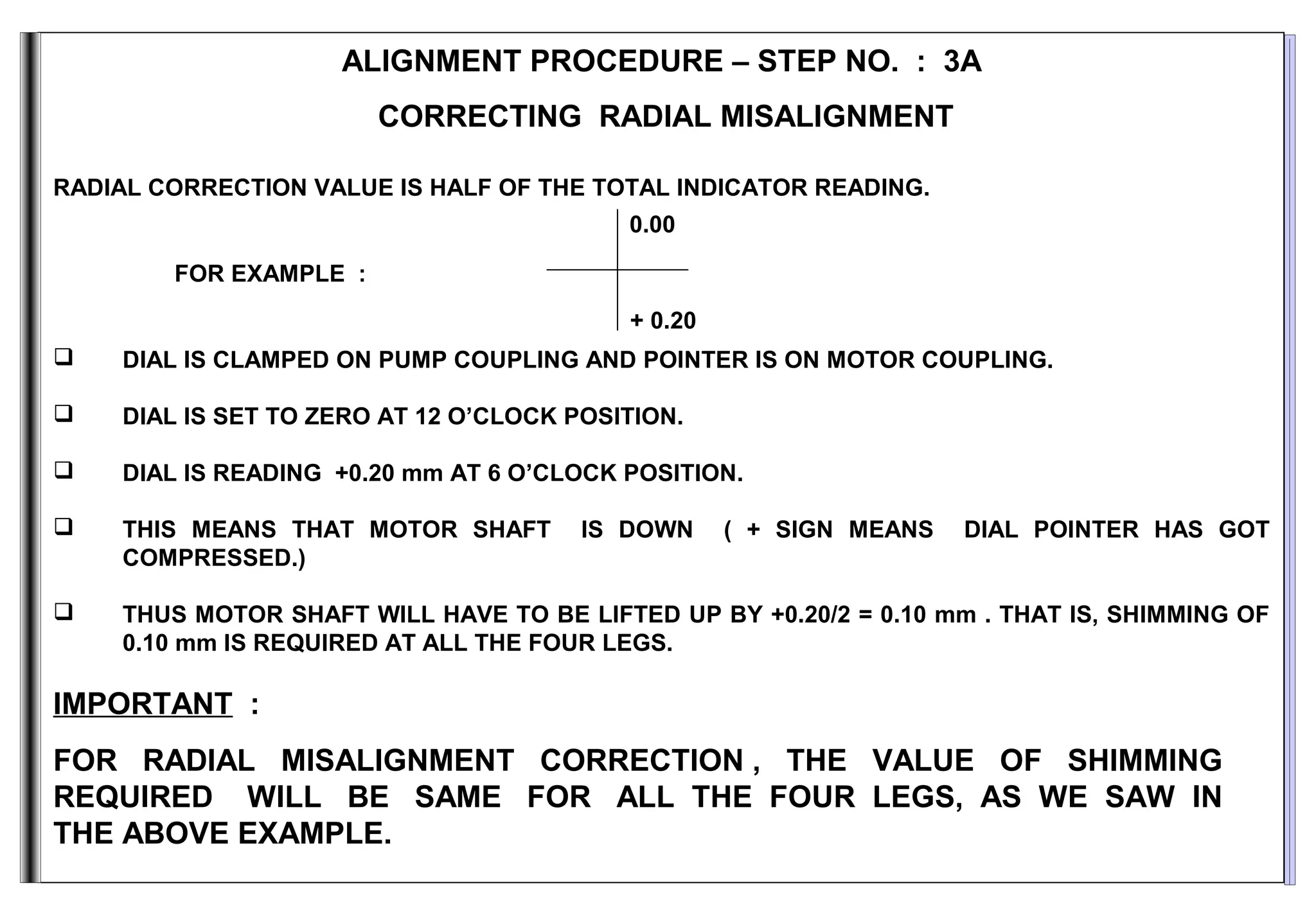

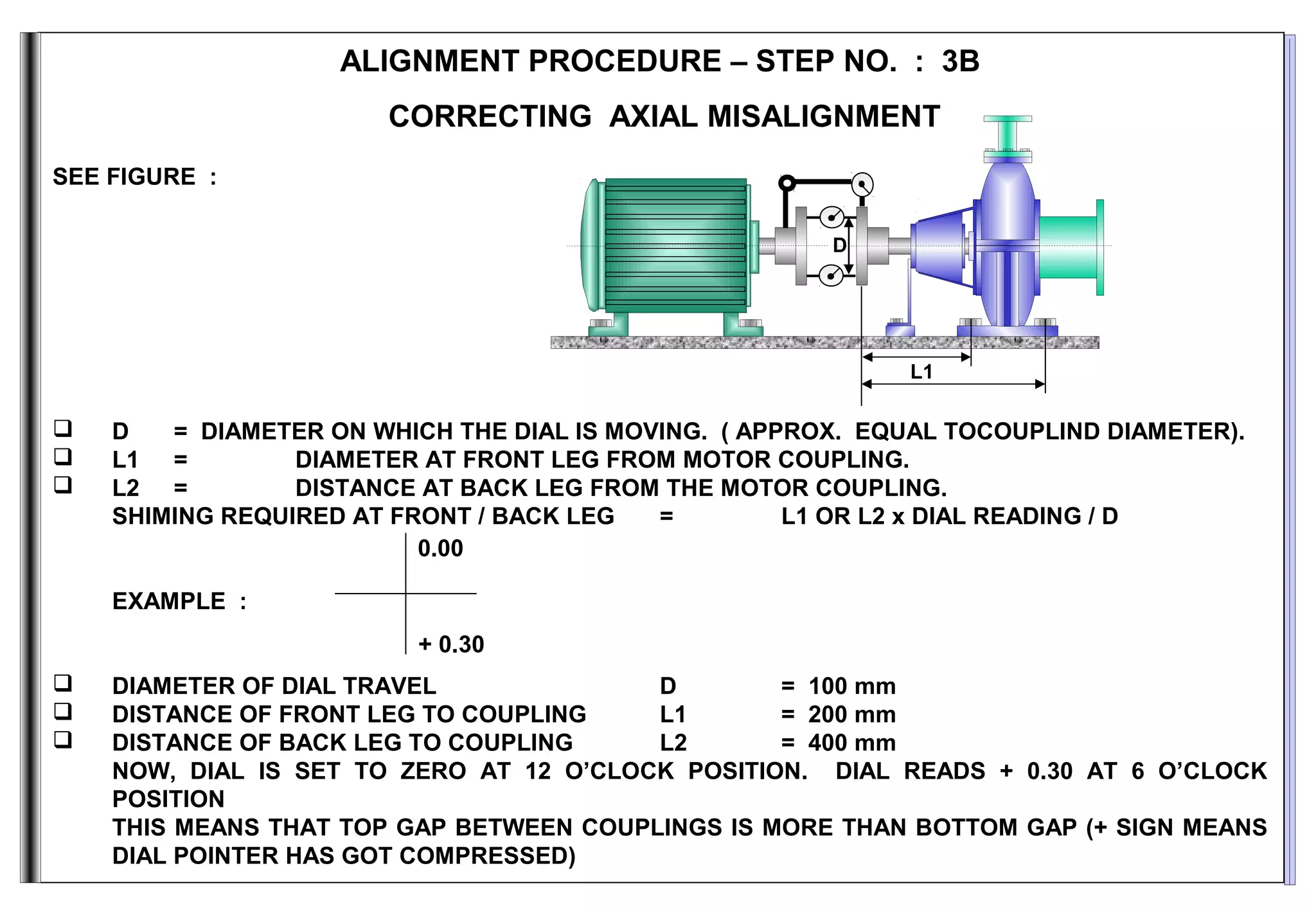

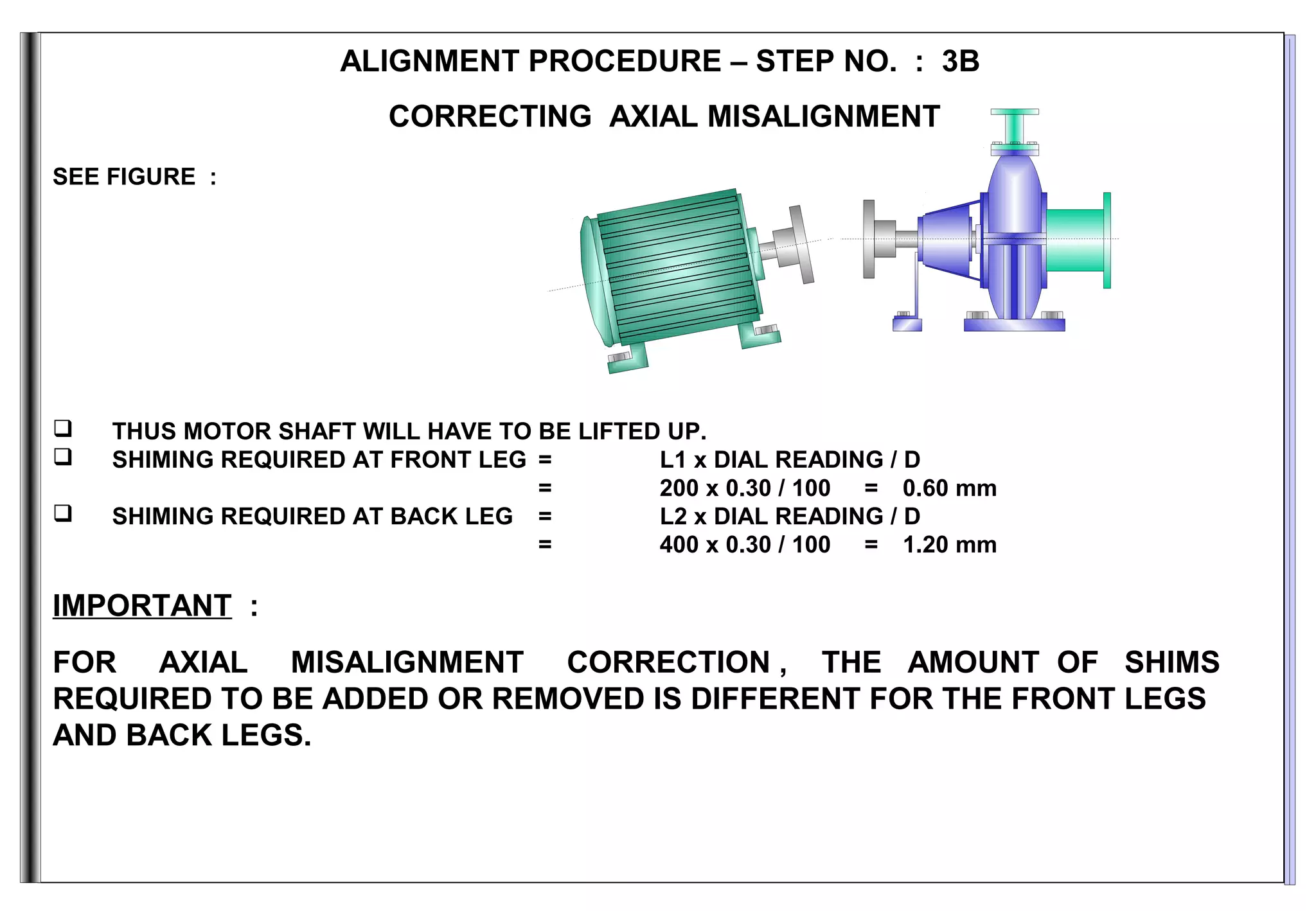

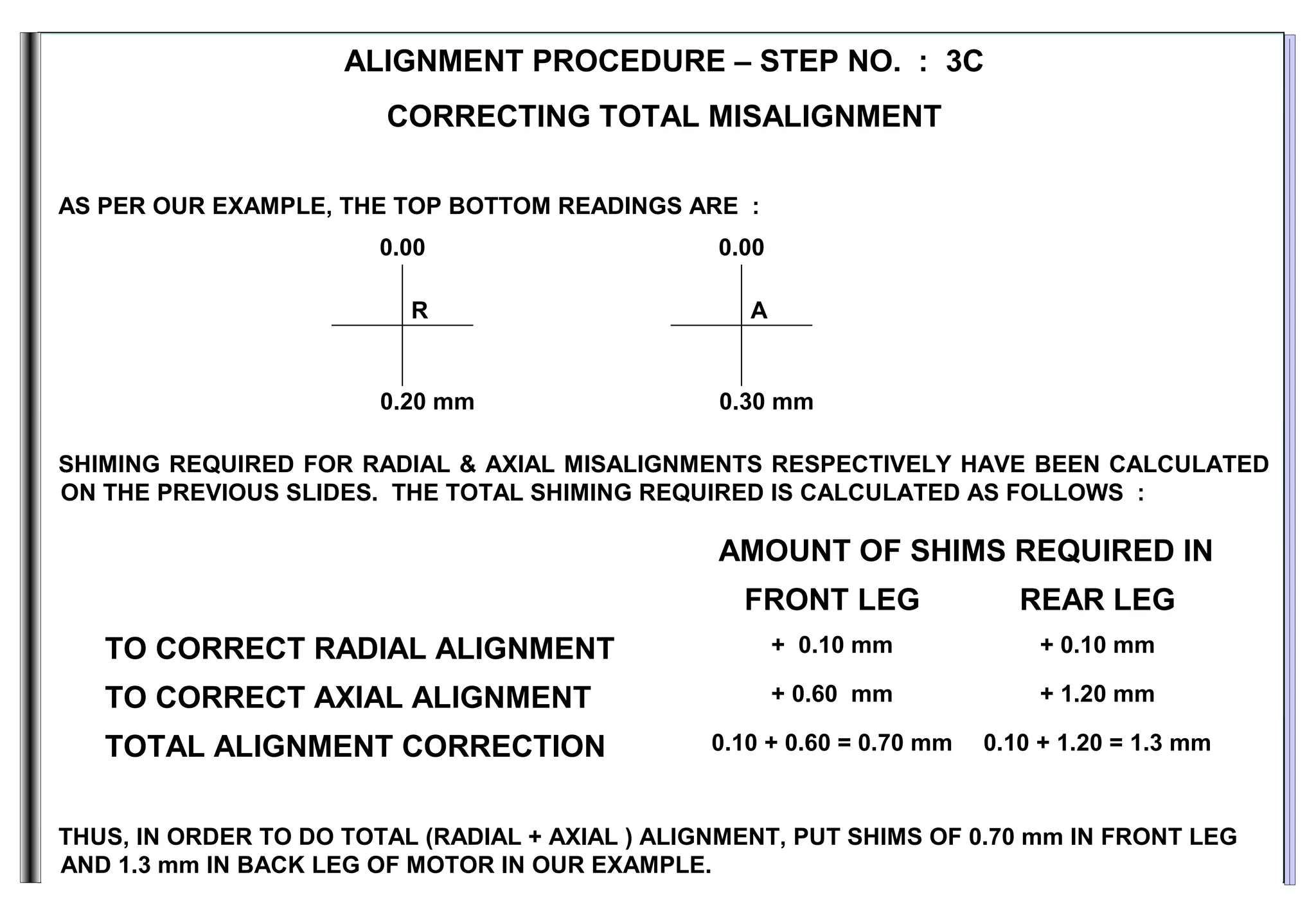

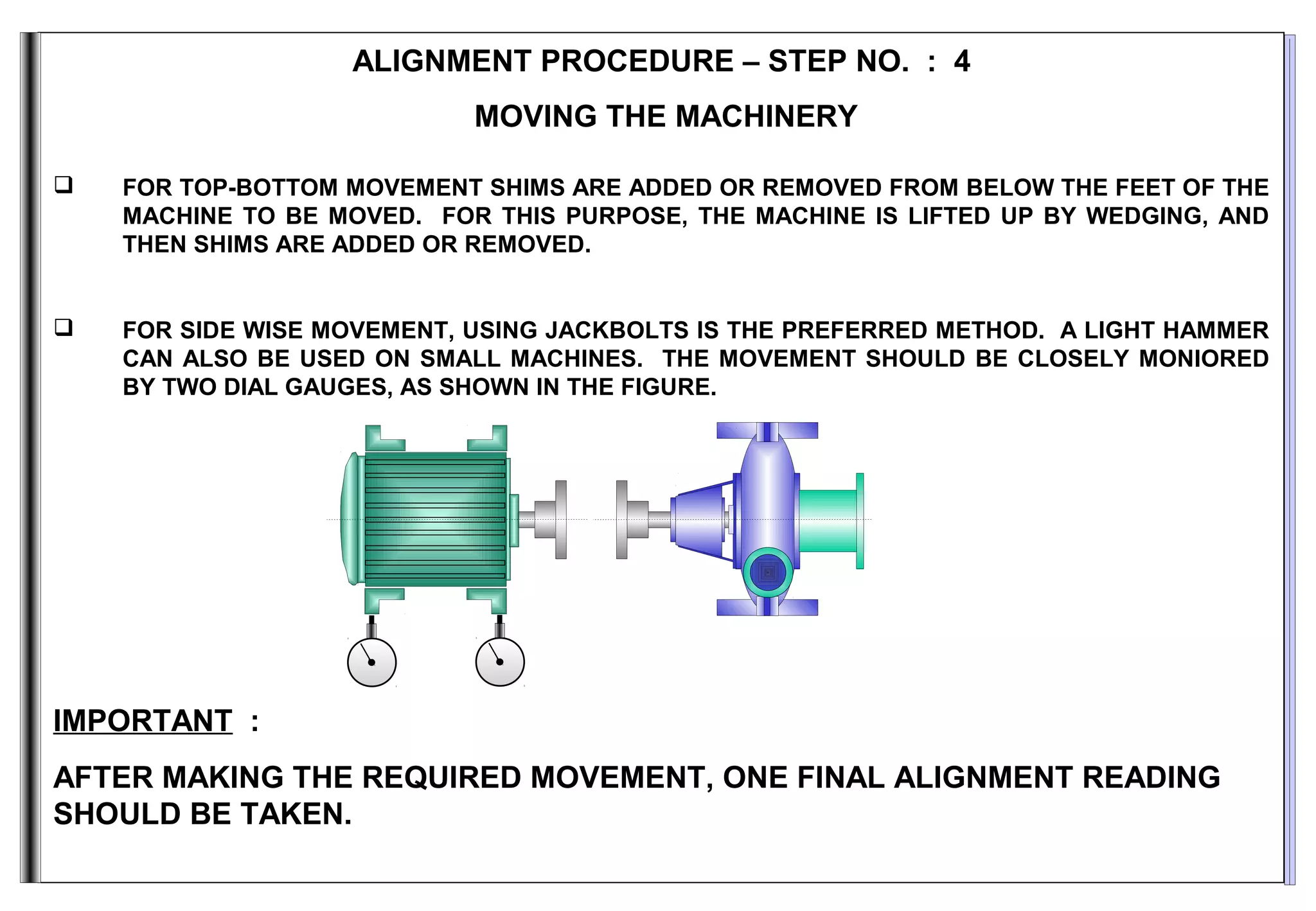

This document provides instructions for properly aligning coupled machinery. It outlines important checks to perform before starting alignment like ensuring low shaft and coupling runout. It describes taking initial alignment readings and calculating required movement if misalignment is found. The key steps are correcting for radial and axial misalignment separately, then total alignment by adding or removing shims at the machine legs as needed. The final step confirms alignment is within tolerance by taking a last reading. Overall the document stresses performing top-bottom alignment before side-to-side for best results.