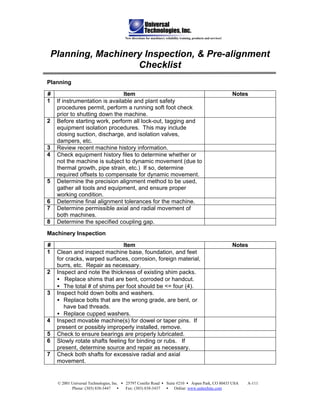

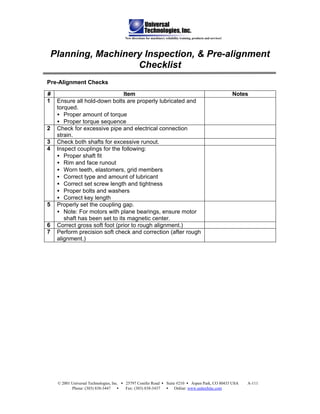

The document provides a checklist for planning, inspecting machinery, and performing pre-alignment checks before precision alignment of machinery. The planning section includes reviewing machine history, determining alignment methods and tolerances. The machinery inspection section lists items to check on the machine base, feet, shims, bolts and shafts. The pre-alignment section outlines checks for hold down bolts, strains, runout, couplings and correcting any soft foot issues.