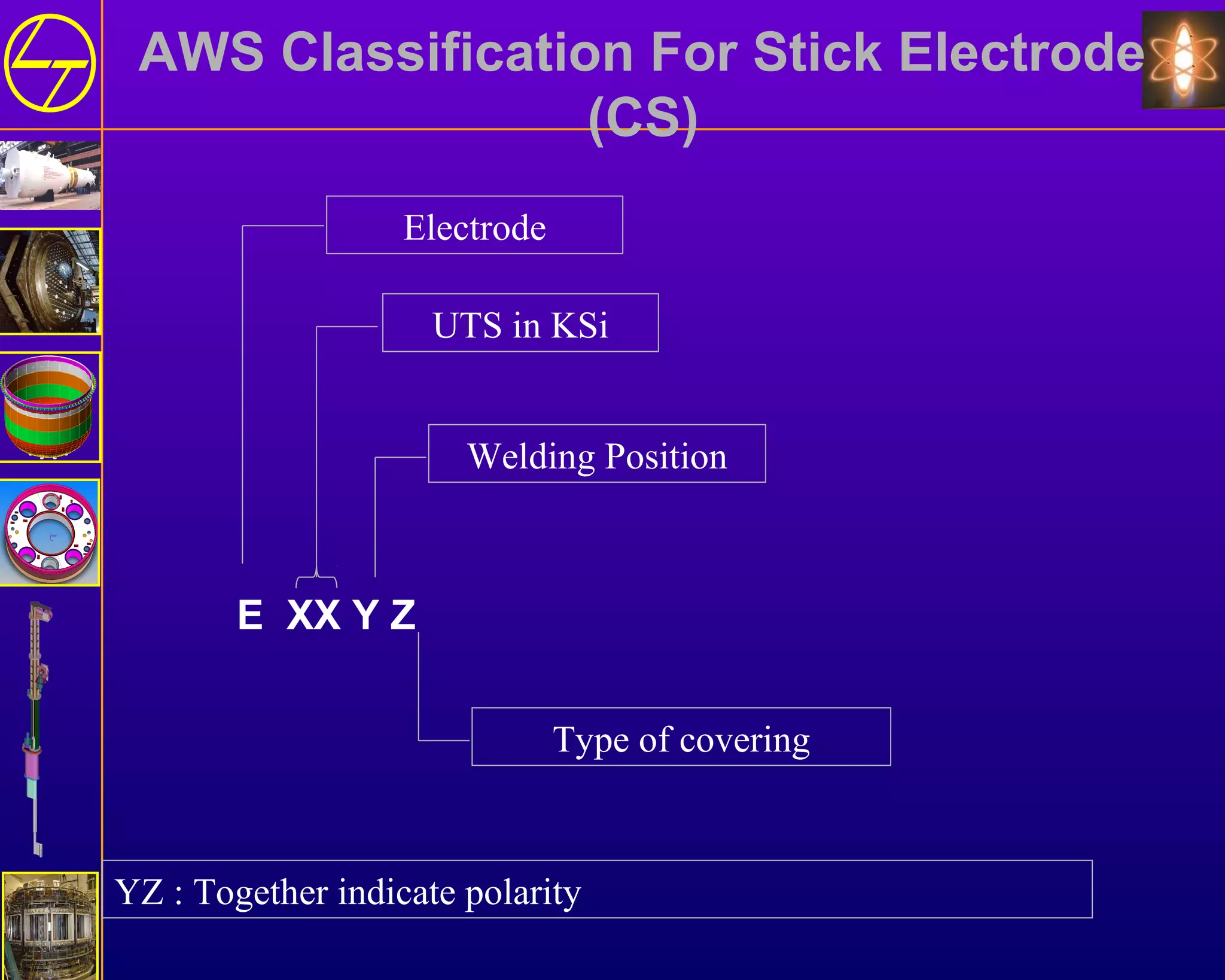

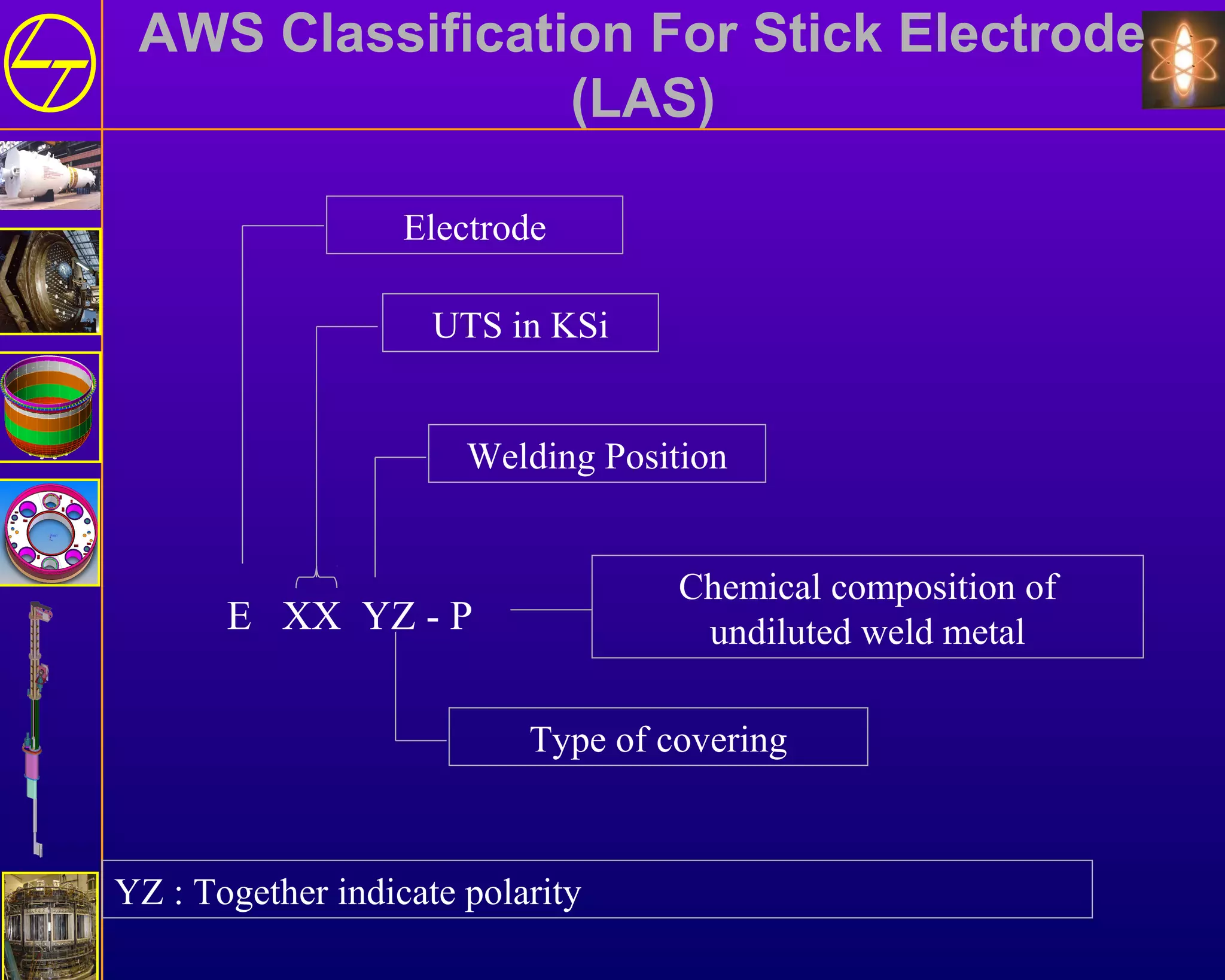

The document outlines the sections and subsections contained in the ASME Boiler and Pressure Vessel Code. It includes rules for construction of various types of boilers, pressure vessels, and containment systems. The sections cover materials specifications, welding requirements, nondestructive testing, in-service inspection, and rules for ongoing care and operation. The code also provides alternative rules for special construction applications.