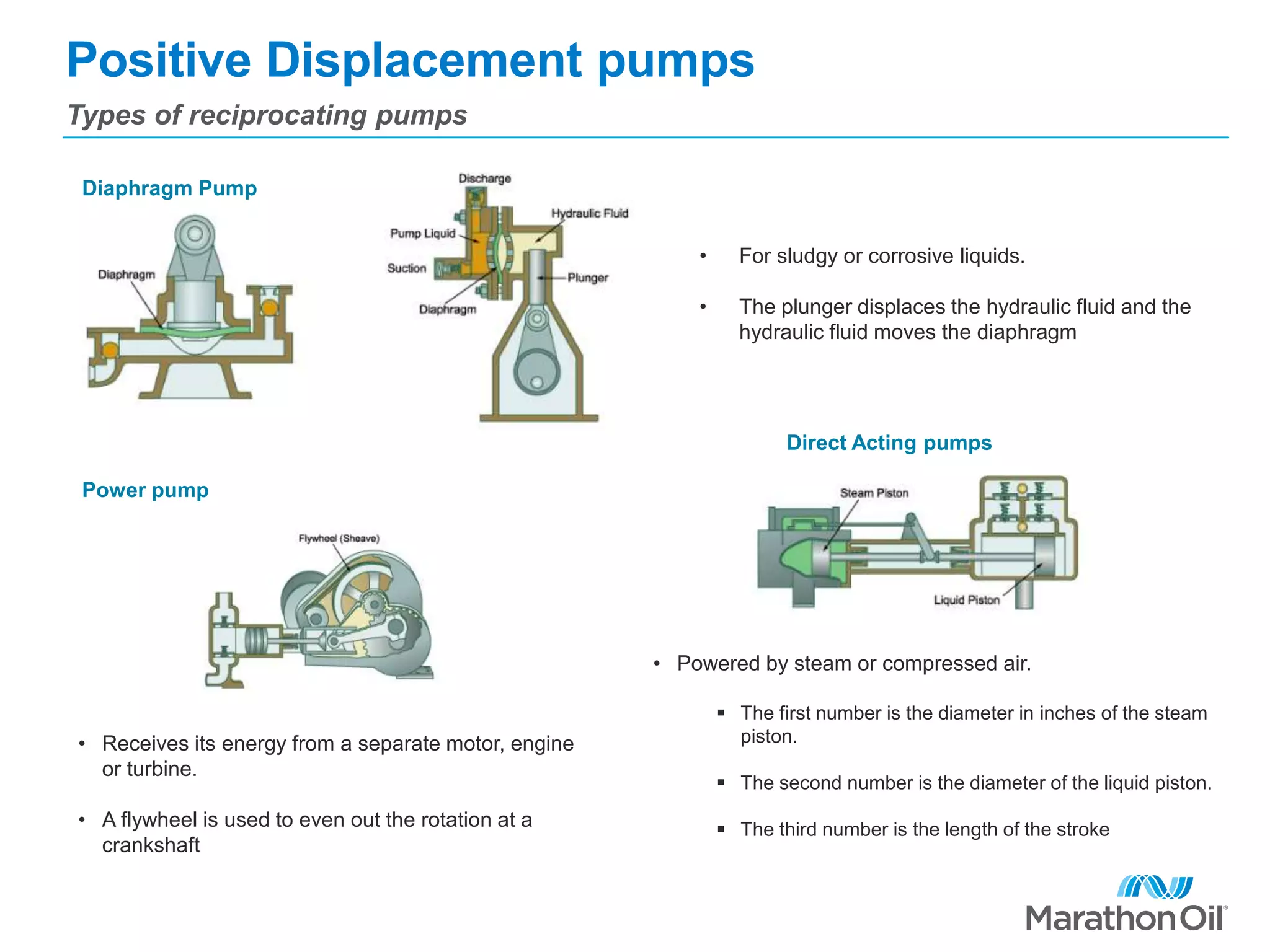

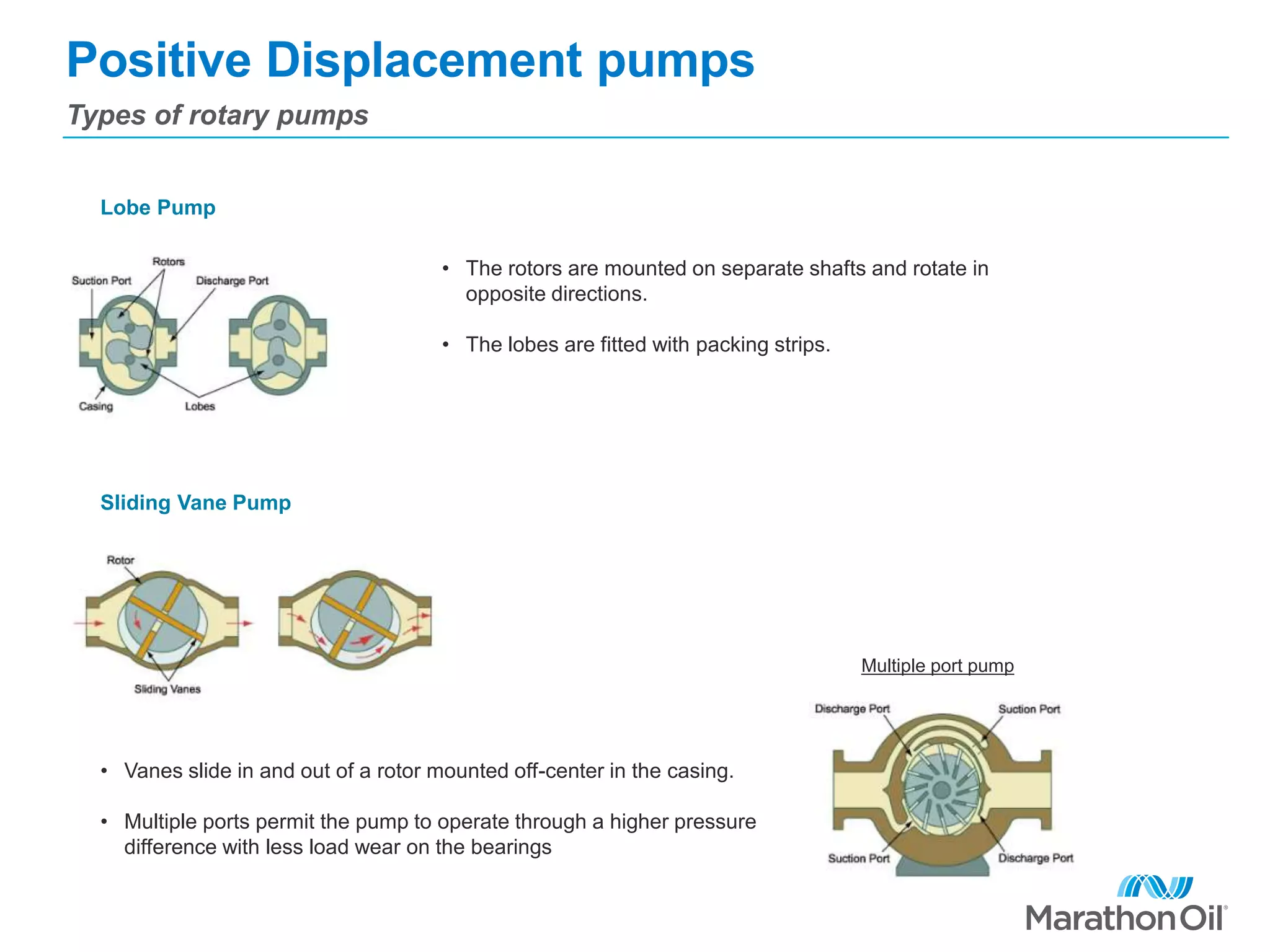

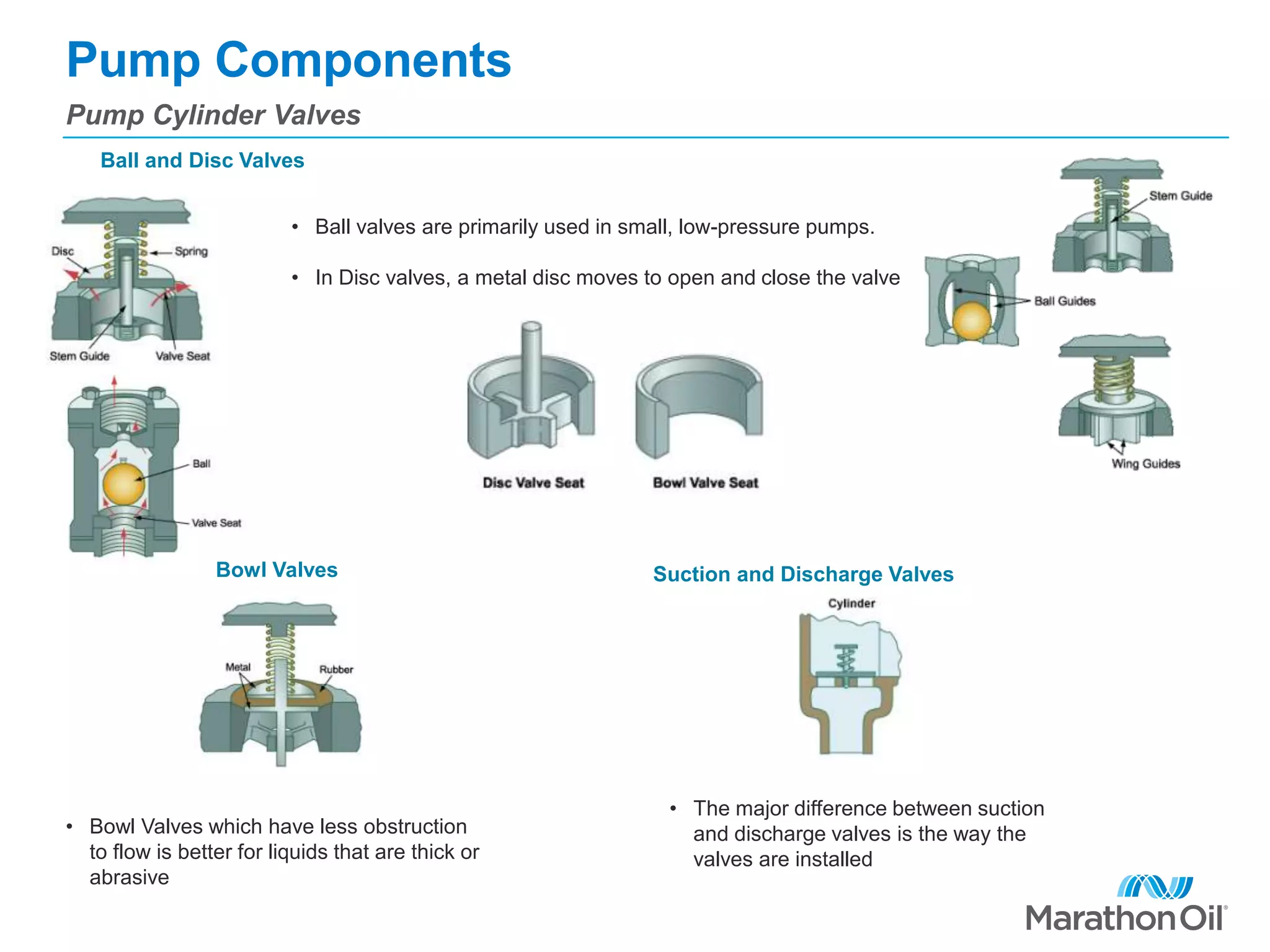

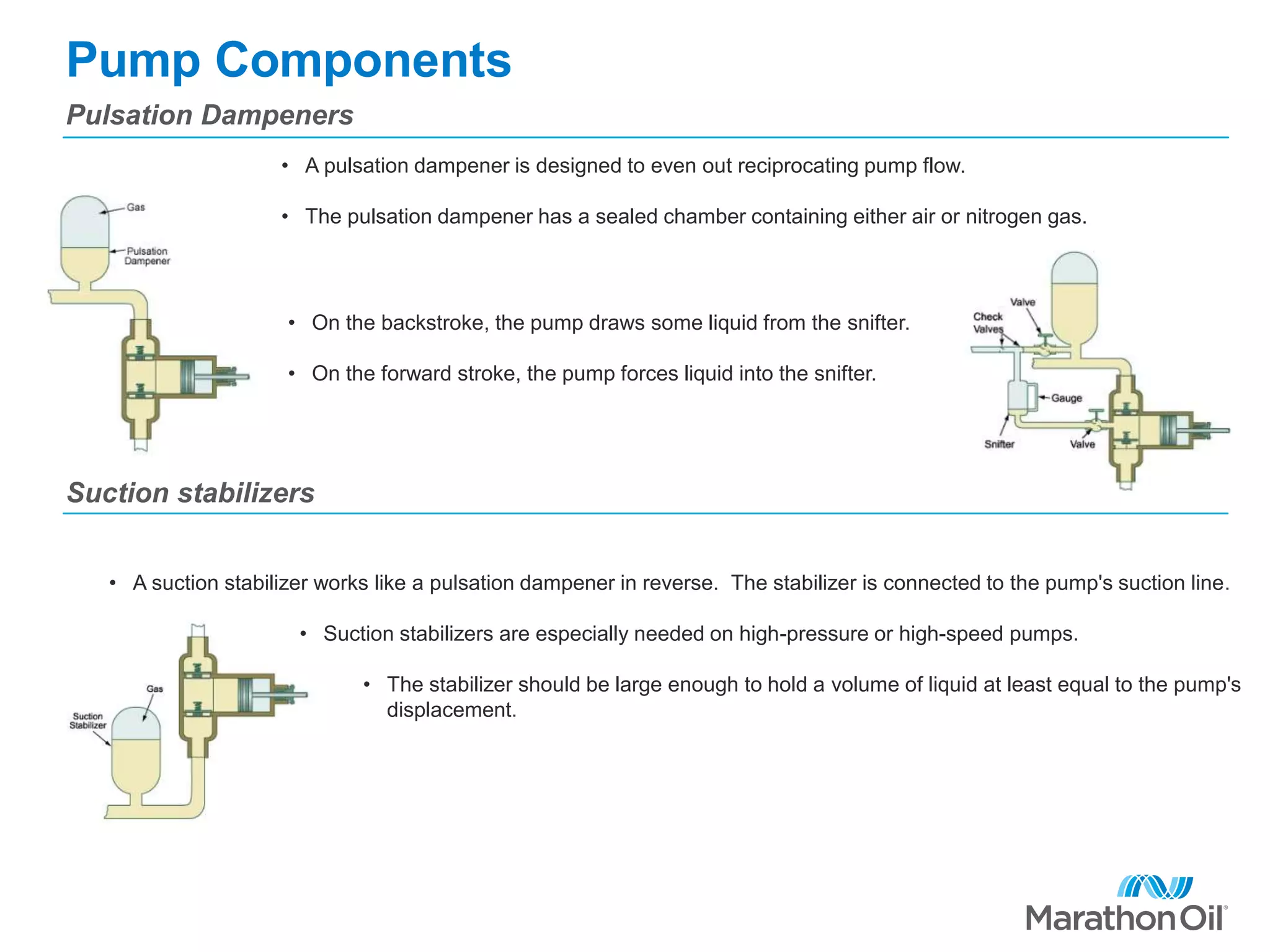

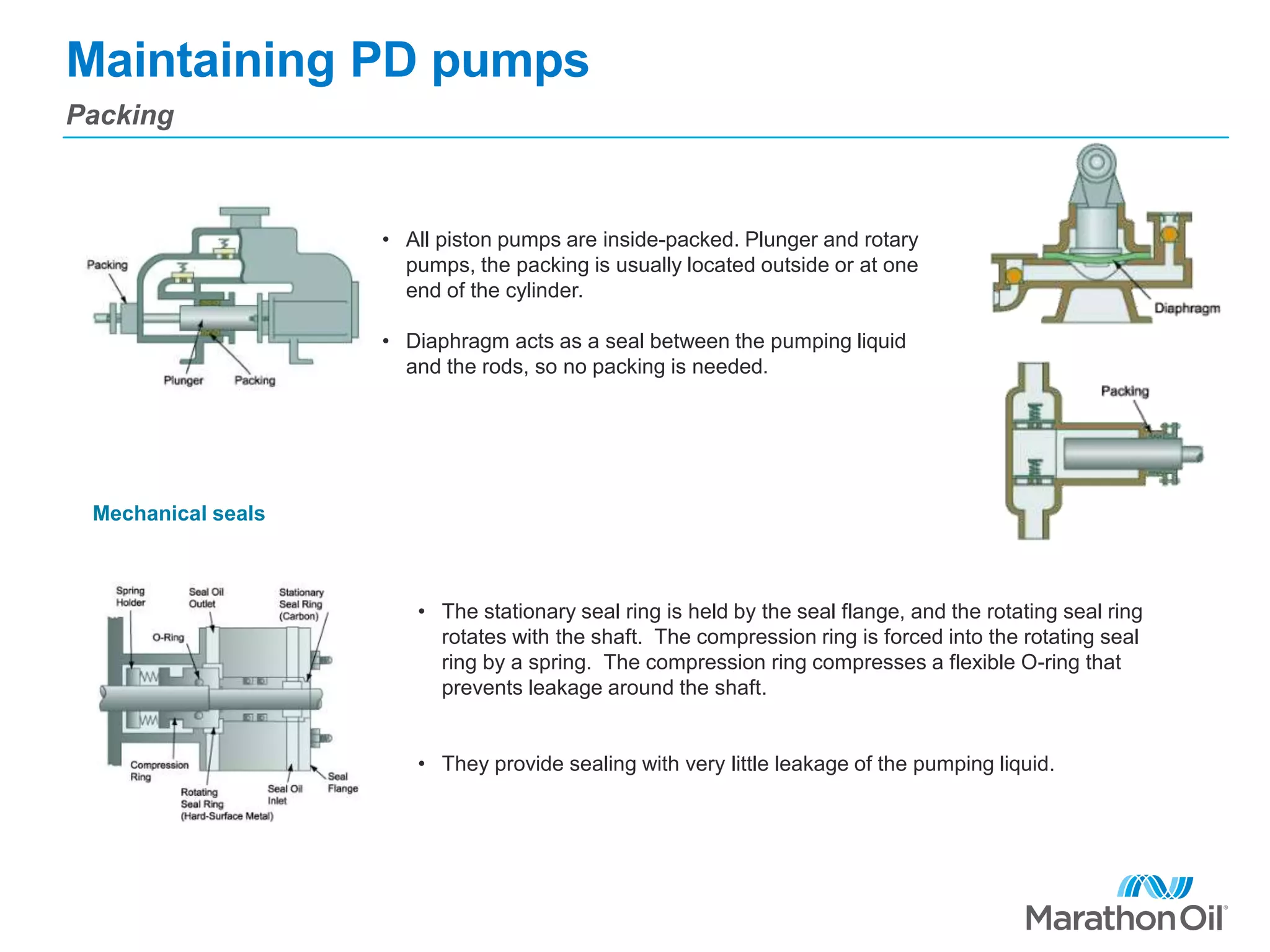

The document provides an extensive overview of positive displacement (PD) pumps, detailing various types including reciprocating and rotary pumps, as well as their components and operational principles. It discusses maintenance practices, common problems such as loss of capacity and vapor locking, and contrasts PD pumps with centrifugal pumps. Essential information on pump lubrication, alignment, and cooling systems is also highlighted to ensure effective operation.