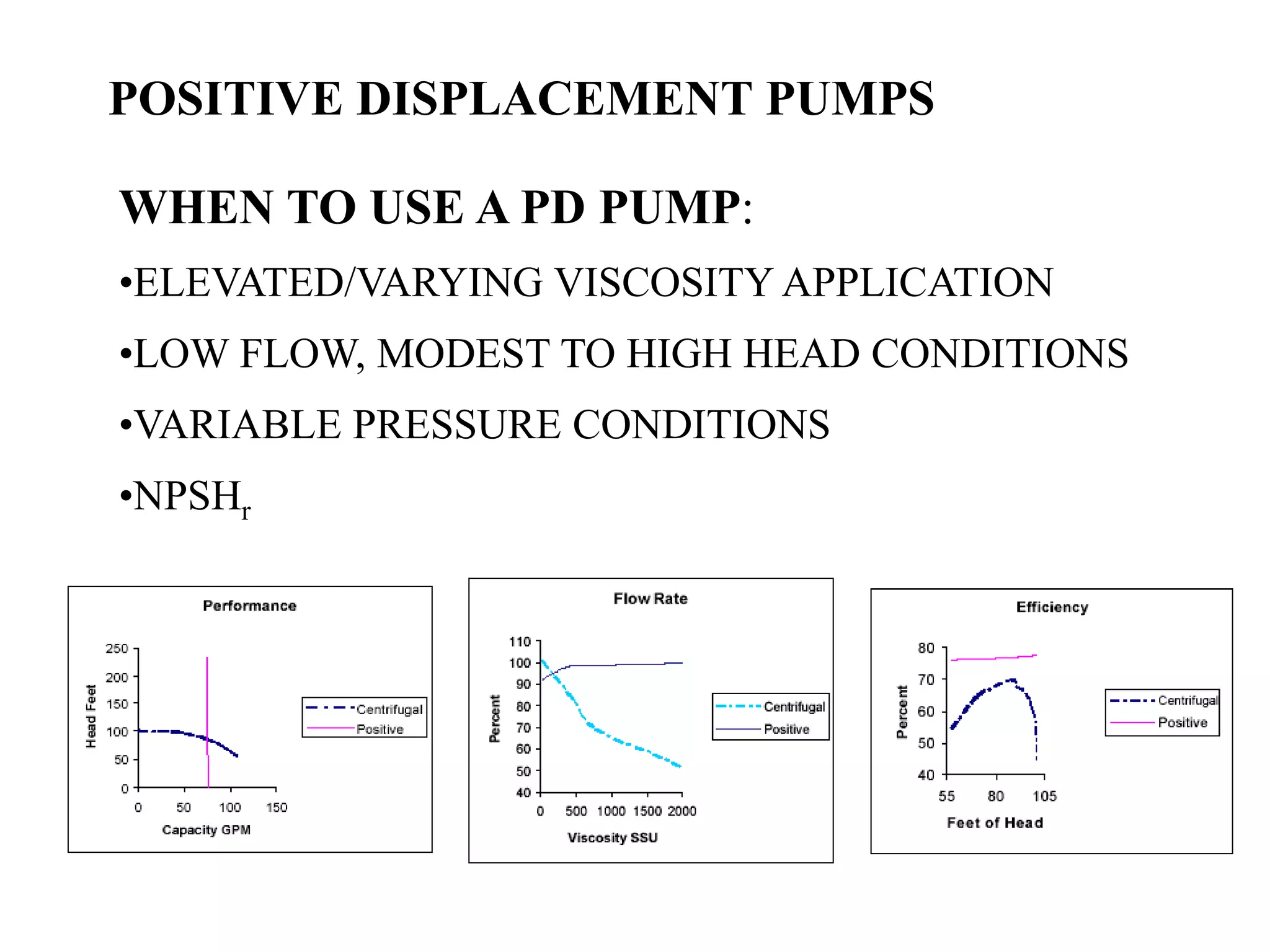

Positive displacement pumps are classified into three main types: centrifugal, reciprocating, and rotary, each designed for specific pressure and flow characteristics. They are preferred in applications involving varying viscosity and require careful control to prevent overpressurization, often using built-in relief valves. Unlike centrifugal pumps, which depend on head against the impeller, positive displacement pumps deliver a constant volume per cycle regardless of pressure conditions.