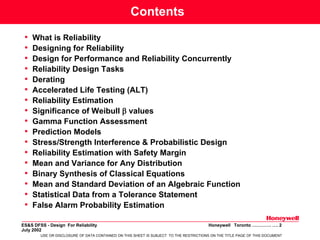

The document discusses various techniques for designing products for reliability, including derating components, accelerated life testing, and reliability estimation methods. It describes how reliability modeling should guide the design process from the beginning to design out potential failure mechanisms. The goal is to develop longer-lived products through an iterative approach of testing, analyzing failures, and redesigning to improve reliability. Key aspects of a reliability-focused design process include understanding failure mechanisms, developing reliability databases, and using super-accelerated life testing techniques.

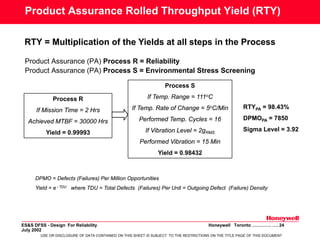

![Screening Strength Estimation

The Screening Strength of a given stress screen profile is defined as the

probability that the stress screen will precipitate a latent defect into a

detectable failure, given that a defect is present. Screening provide

assurance on the Outgoing Reliability

Screening Strength for Temperature Cycling (STn) is a function of Temperature Range =T;

Temp. Rate of Change =R; Number of Cycles =n

STn

= 1 − e[−[0.0017⋅(T + 0.6)

0.6

⋅ln(e + R ) ⋅n]]

3

Screening Strength for Random Vibration (SVt) is a function of G = gRMS; Vibration Duration = t

SVt

= 1 − e[−(0.0046⋅G

1.71

⋅t )]

Combined Screen Strength (SS) = 1 - (1-STn).(1-SVt)

When T = 111oC; R = 5oC/Min

n =16 Cyc; G = 2gRMS;

t = 15 Min

SS = 0.98432

The Screening Strength equations were developed by Hughes Aircraft Company, and modified by Rome Air

Development Centre (RADC) based on the data from McDonnel Aircraft Co. and Grumman Aerospace

Corporation

ES&S DFSS - Design For Reliability

July 2002

Honeywell Toronto …………. …. 21

USE OR DISCLOSURE OF DATA CONTAINED ON THIS SHEET IS SUBJECT TO THE RESTRICTIONS ON THE TITLE PAGE OF THIS DOCUMENT](https://image.slidesharecdn.com/designforreliability1-140208115704-phpapp01/85/Design-For-Reliability-21-320.jpg)