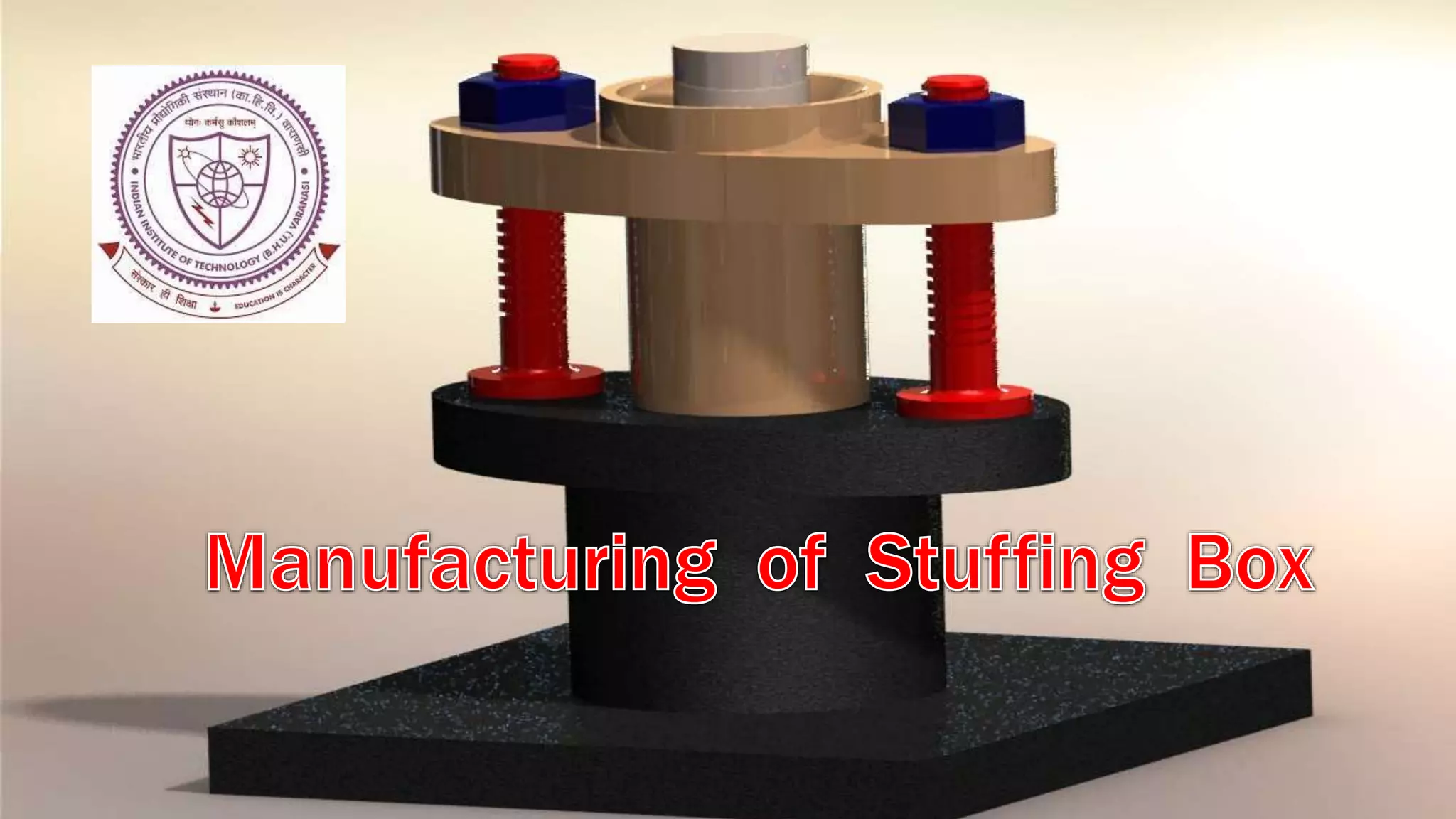

The document provides details about a team project to design and manufacture a stuffing box assembly. It includes:

1) A list of team members and sections to be covered including brief introduction, material selection, design and applications, manufacturing processes, and defects observed.

2) Descriptions of the purpose of a stuffing box to prevent leakage around a rotating shaft while allowing movement, and typical materials used like cast iron for the body and asbestos for packing.

3) An overview of the manufacturing processes used including green sand casting, machining operations like drilling and threading, and potential defects from casting like blowholes and porosity.