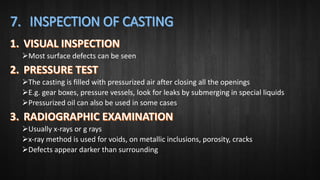

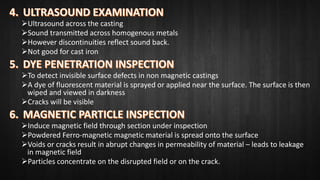

The document provides an overview of the casting process in manufacturing, detailing the necessary steps from pattern preparation to the inspection of final castings. It discusses various types of casting methods, materials used, and considerations for furnace operation and pouring techniques. Additionally, it touches on the importance of mold quality and outlines inspection methods for detecting defects in the cast products.