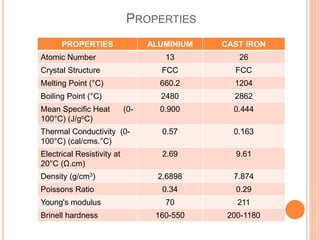

This document discusses materials used for pistons in engines. It describes that pistons are cylindrical components that slide back and forth in the engine cylinder. The most common piston materials are cast iron and aluminum alloys. Cast iron pistons are used for lower speed engines while aluminum alloy pistons are used for higher speed engines due to their lighter weight. Aluminum alloys have advantages over cast iron like higher thermal conductivity and lower density, making them a suitable material for pistons.