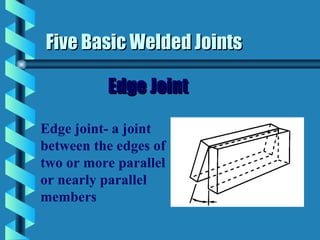

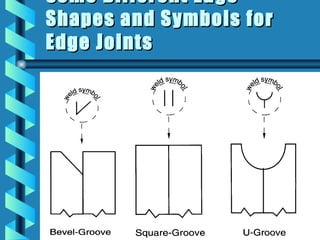

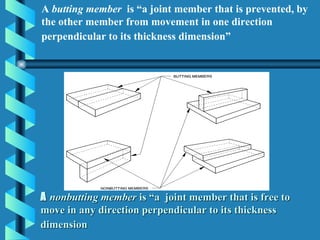

The document discusses various welded joint geometries including butt, corner, T, lap, and edge joints as well as their advantages and disadvantages. It provides examples of different edge shapes and symbols used for each type of joint. Key terms are defined, such as butting member, nonbutting member, and splice member, and load reactions in welded joints are illustrated.