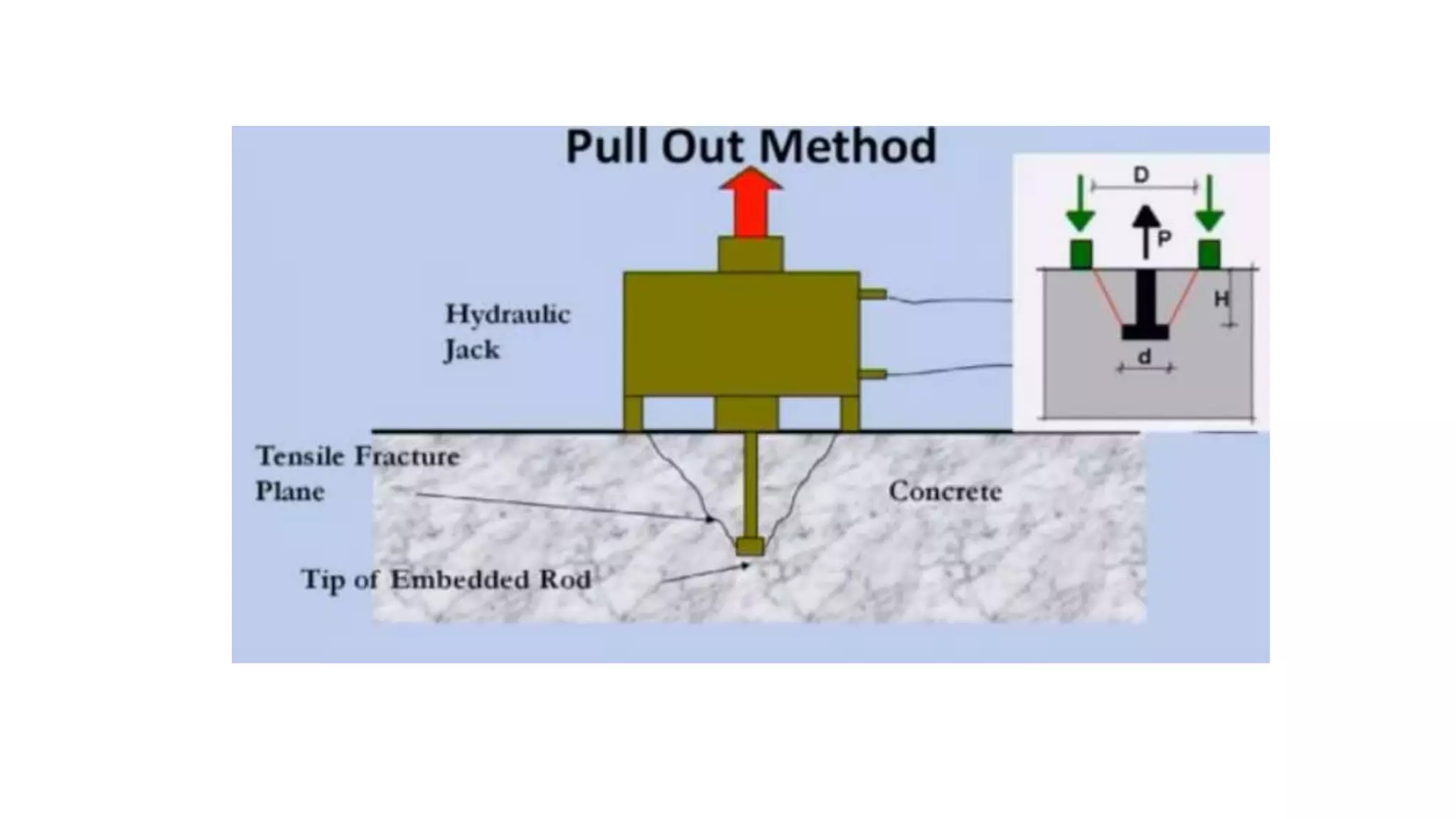

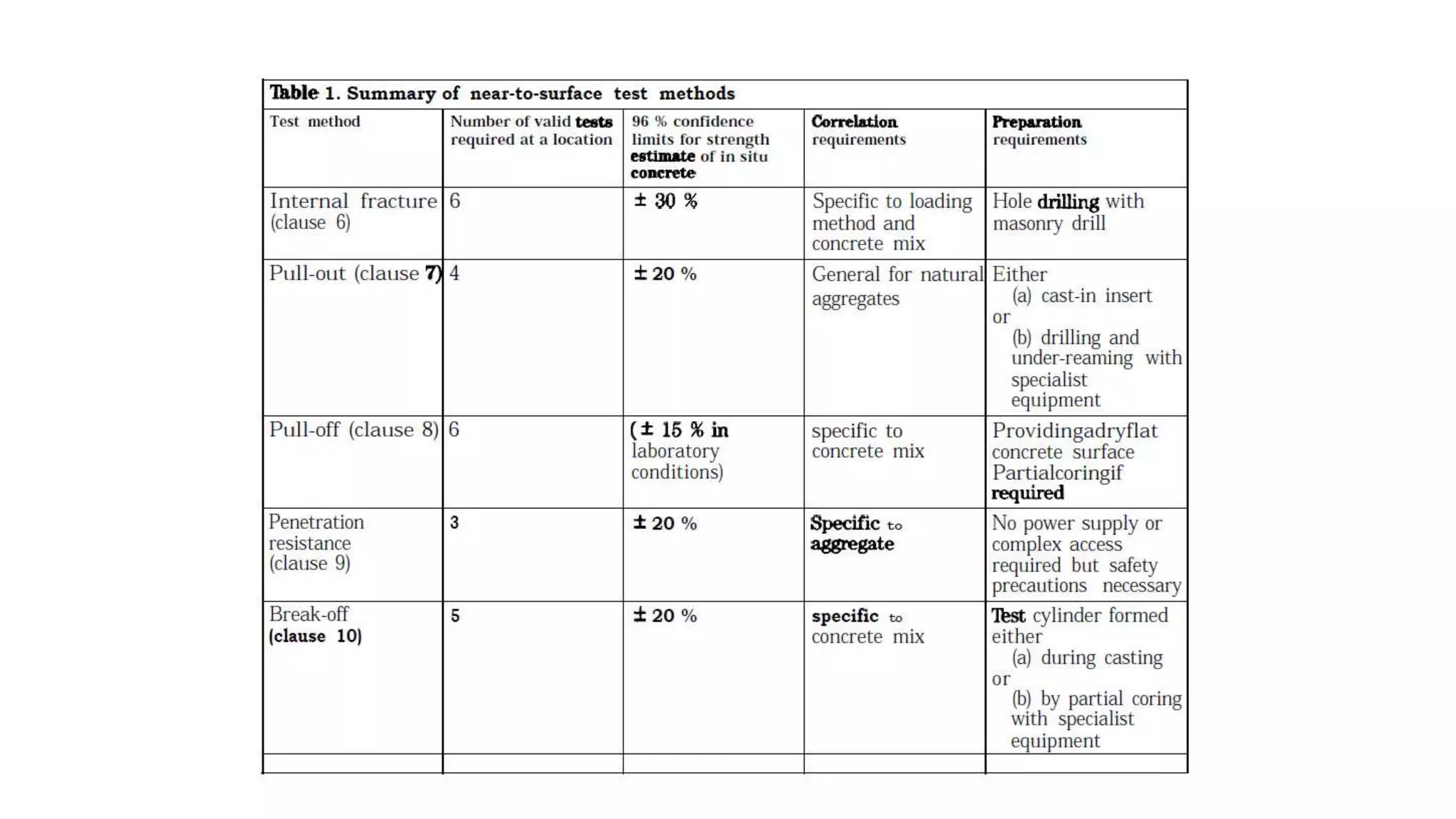

The document provides instructions for conducting pull-out tests to determine the compressive strength of concrete. It states that pull-out tests should be confirmed to BS 1881 Part 207 and give a direct tensile strength value. It describes how inserts can be cast into wet concrete or positioned in hardened concrete using an under-reamed groove. When testing, at least four pull-out tests should be performed at each location and a loading rate of 0.5 ± 0.2 kN/s should be used for 25mm diameter inserts. The compressive strength can then be calculated from the direct tensile strength value obtained during testing.