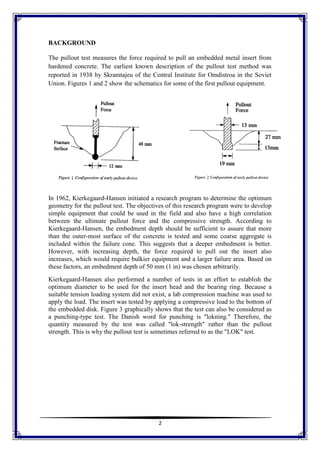

1. The pullout test measures the force required to pull an embedded metal insert from hardened concrete. It was first described in 1938 and research in the 1960s aimed to optimize the geometry and develop simple field equipment with high correlation to compressive strength.

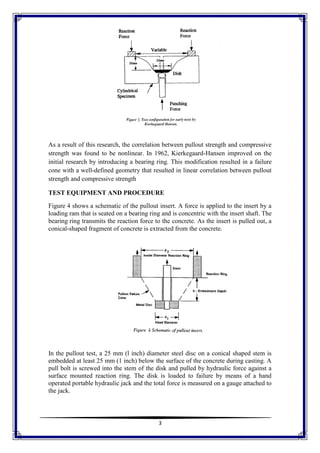

2. An embedment depth of 50mm was chosen as it tests beyond the surface while not requiring too much force. Tests established the optimal insert head and bearing ring diameters. Failure involves cracking around the insert and aggregate interlock up to the ultimate load.

3. For field use, a 25mm diameter steel disc on a conical stem is embedded and pulled against a reaction ring using a hydraulic jack, measuring the force. The test estimates concrete strength to determine