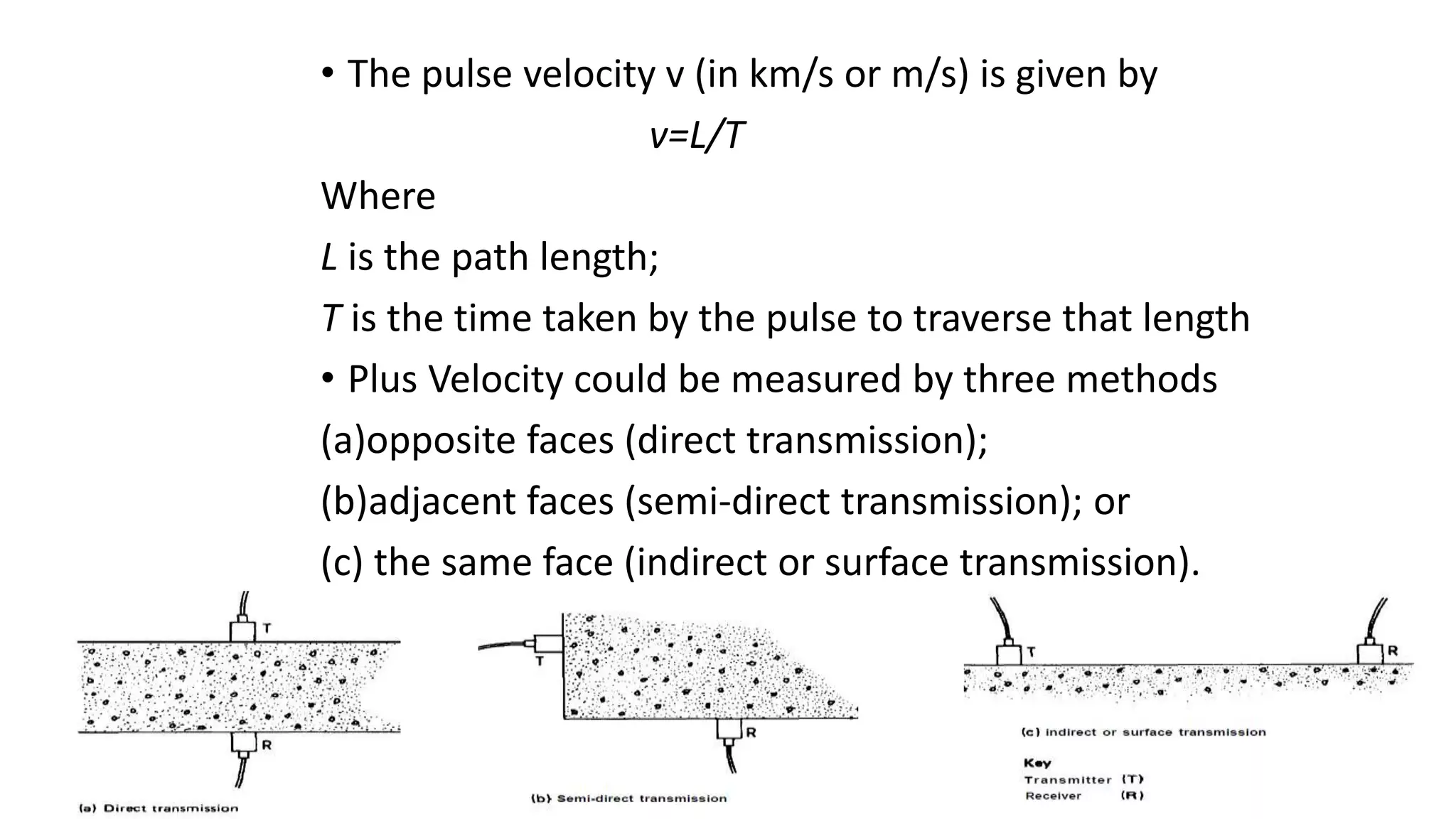

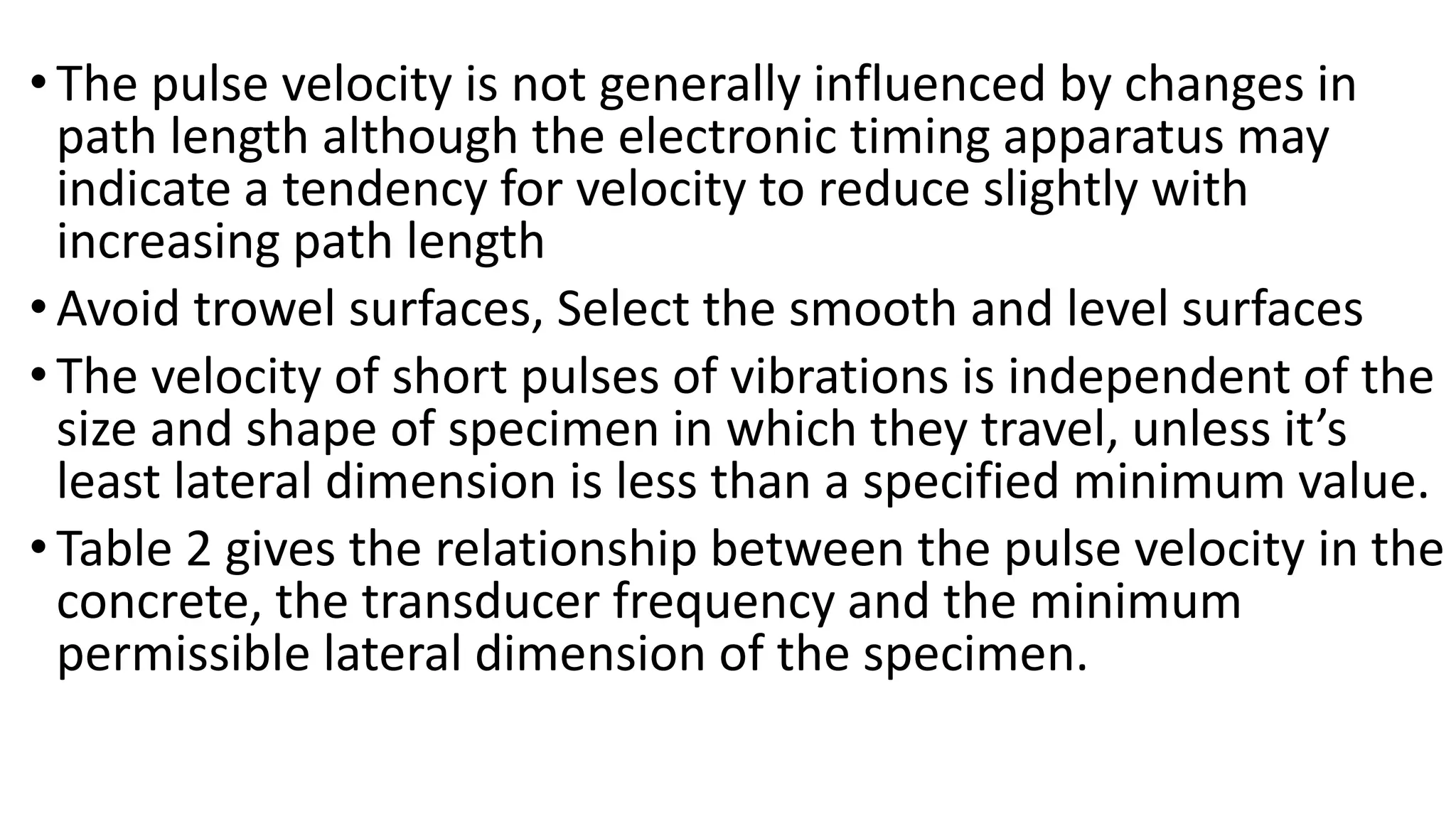

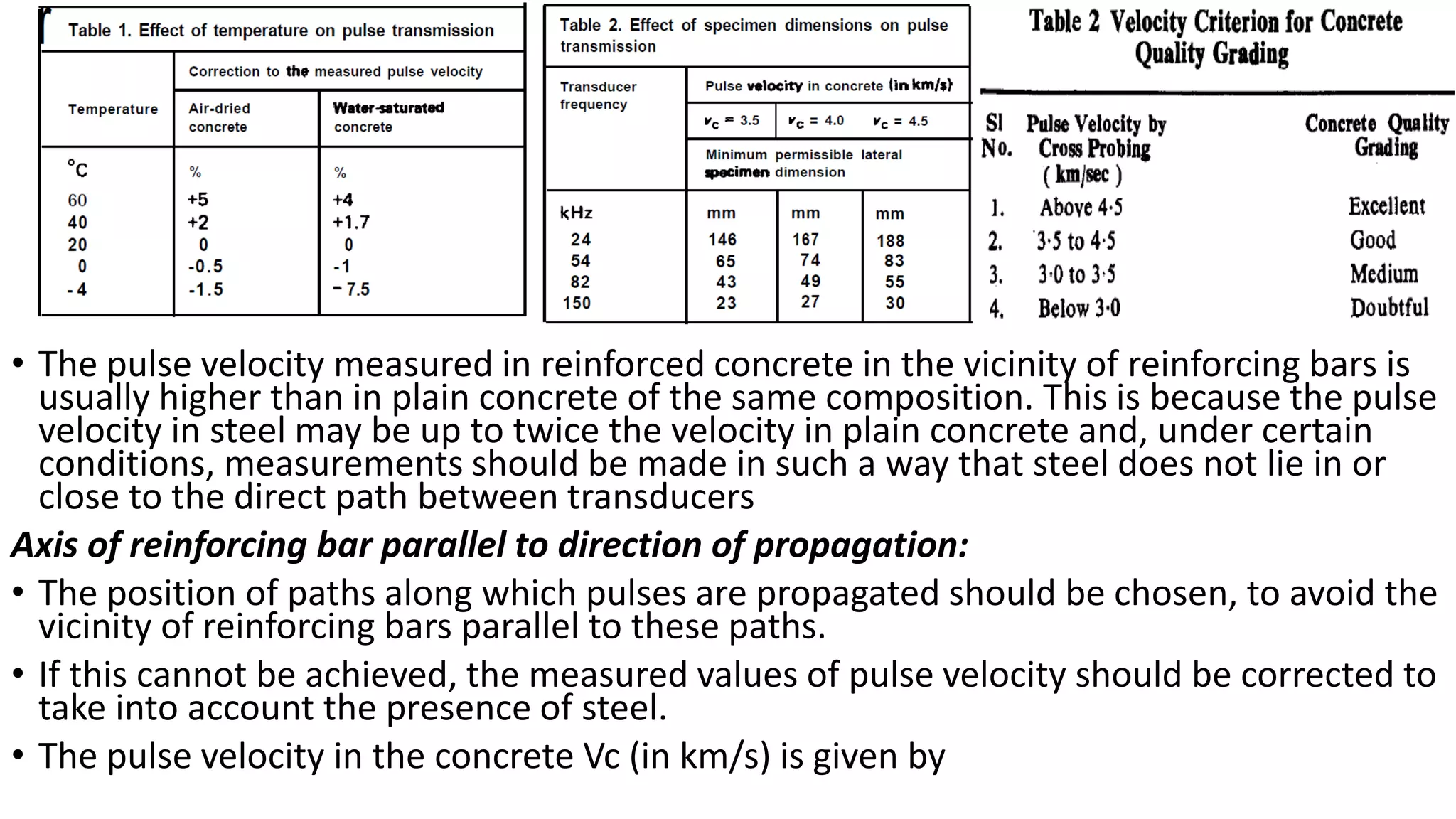

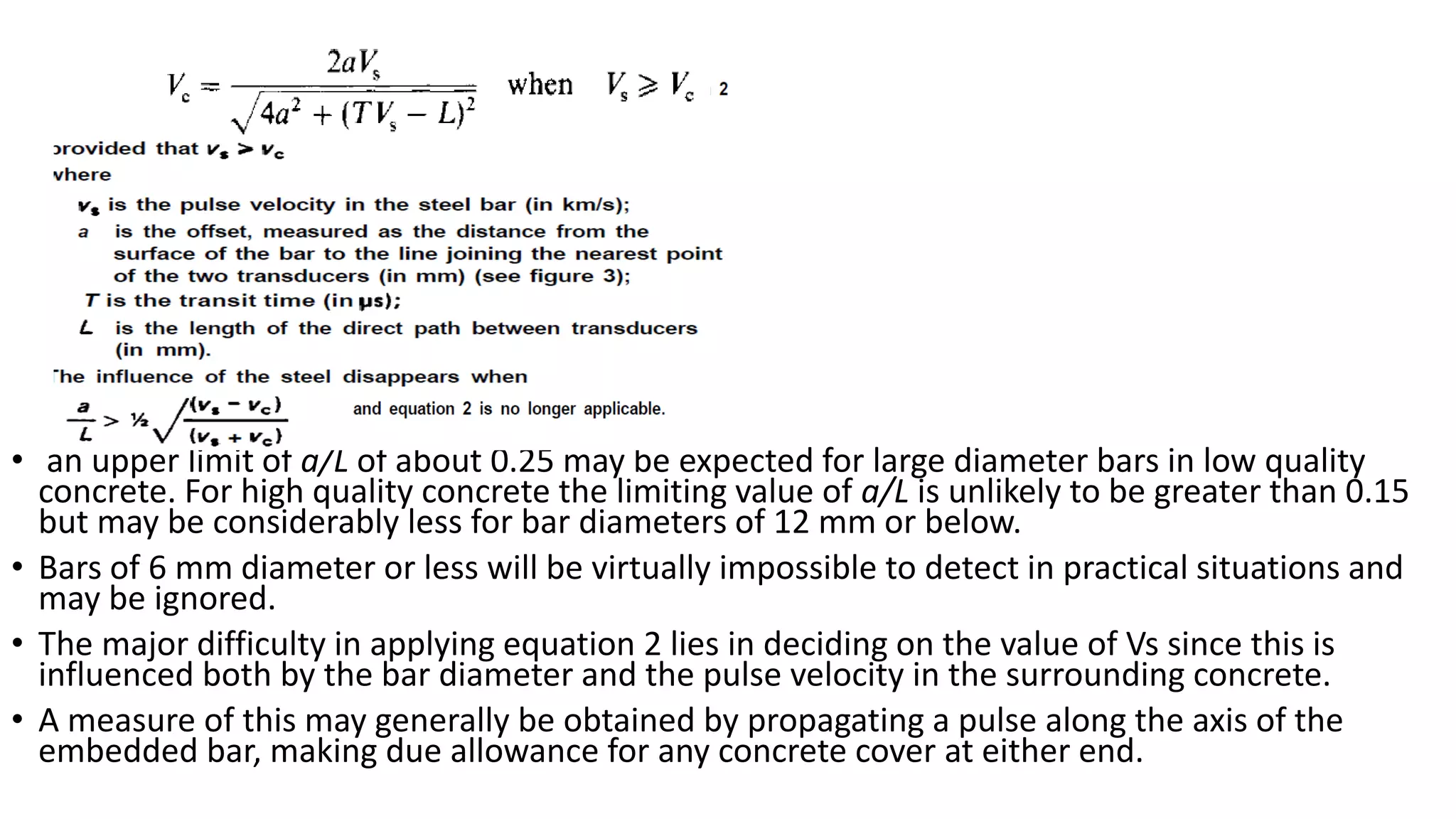

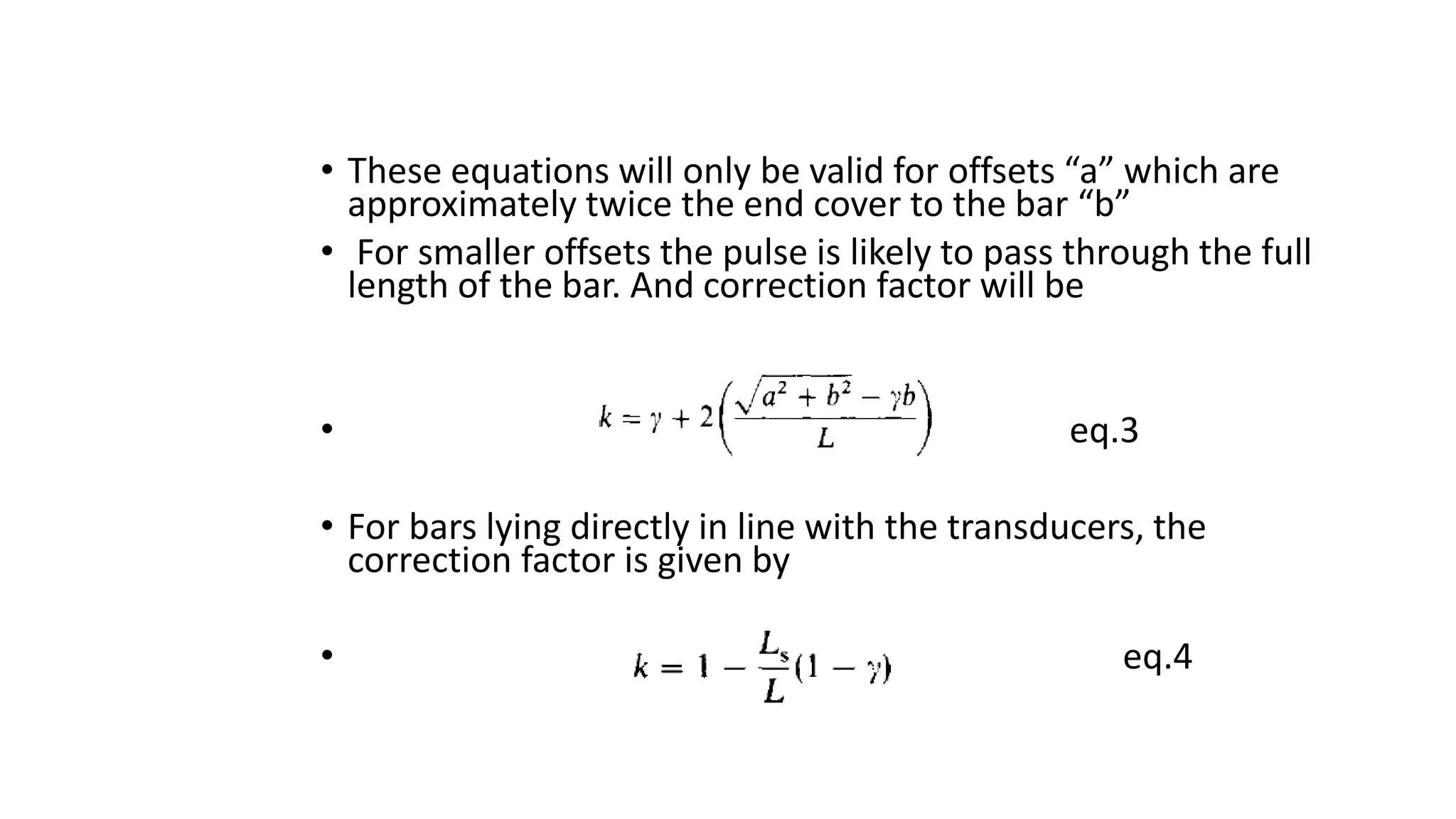

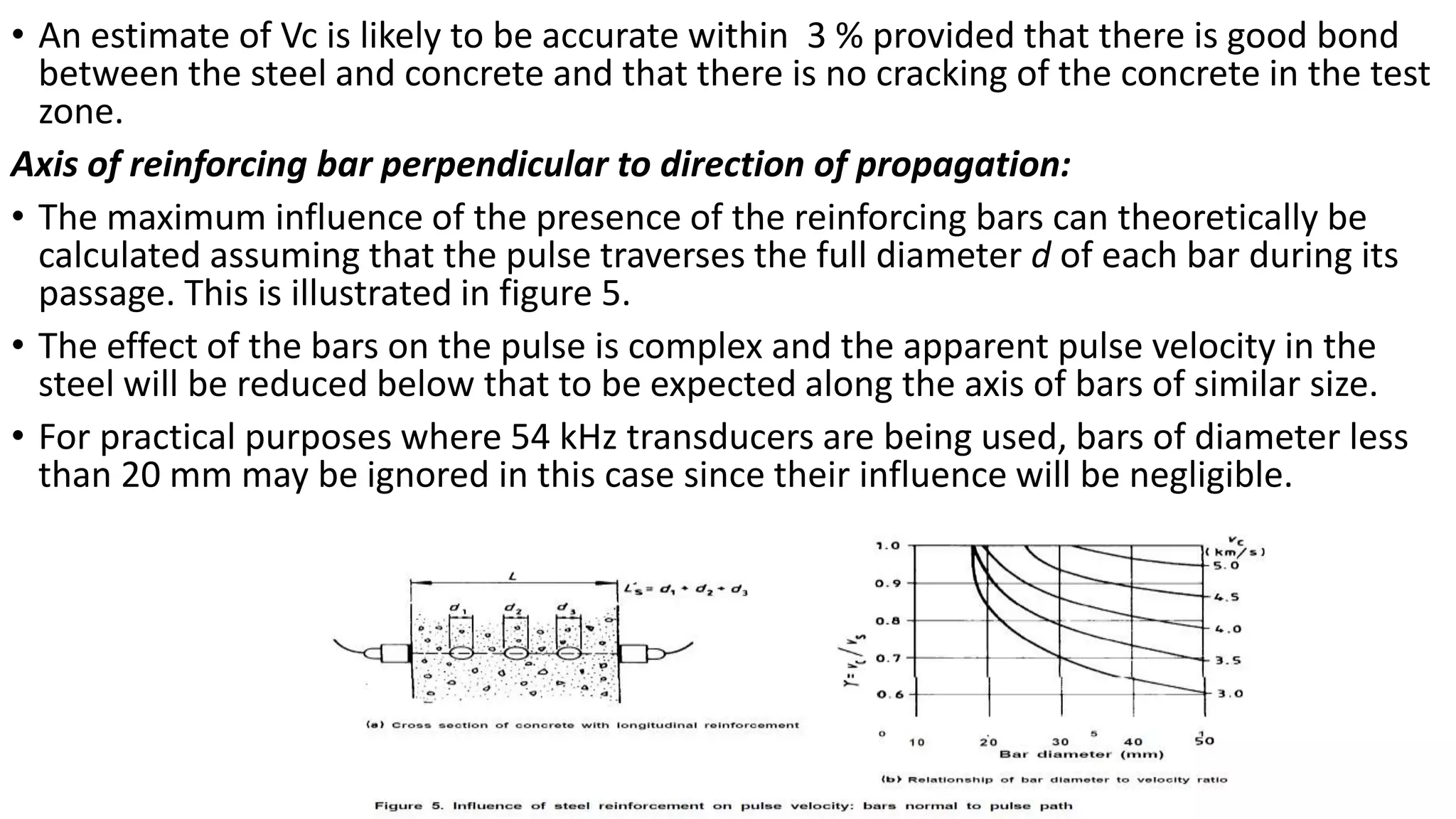

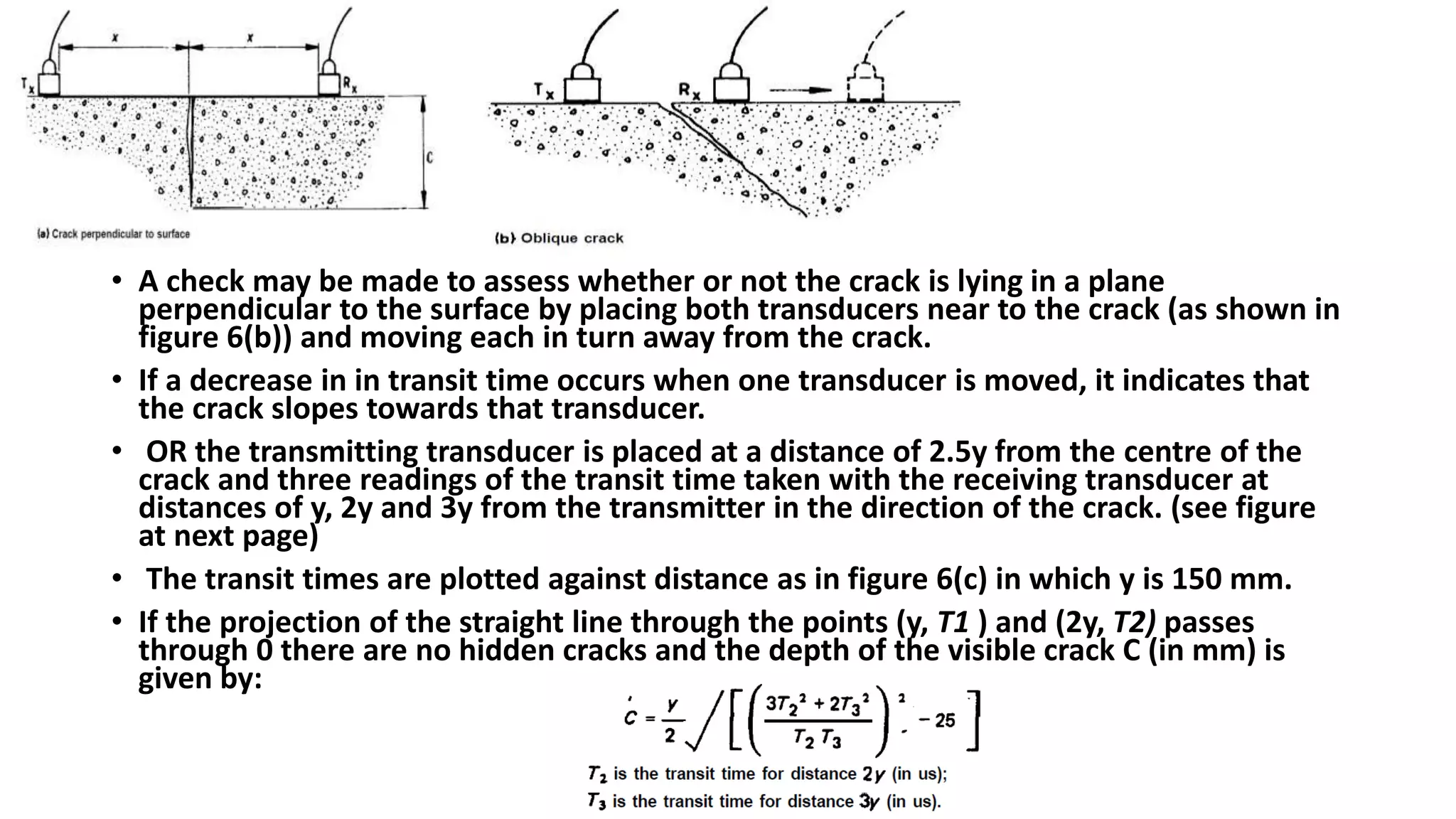

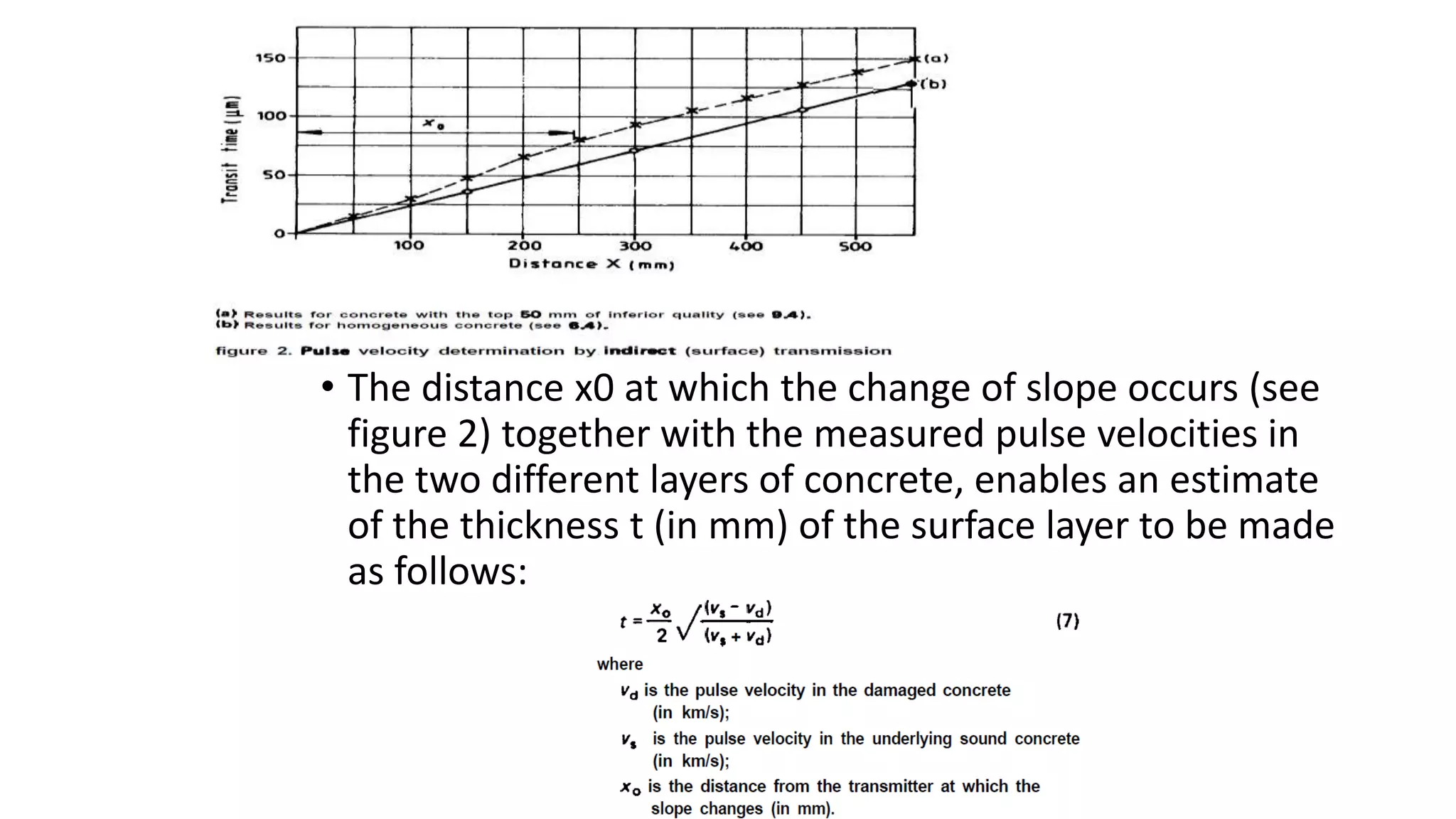

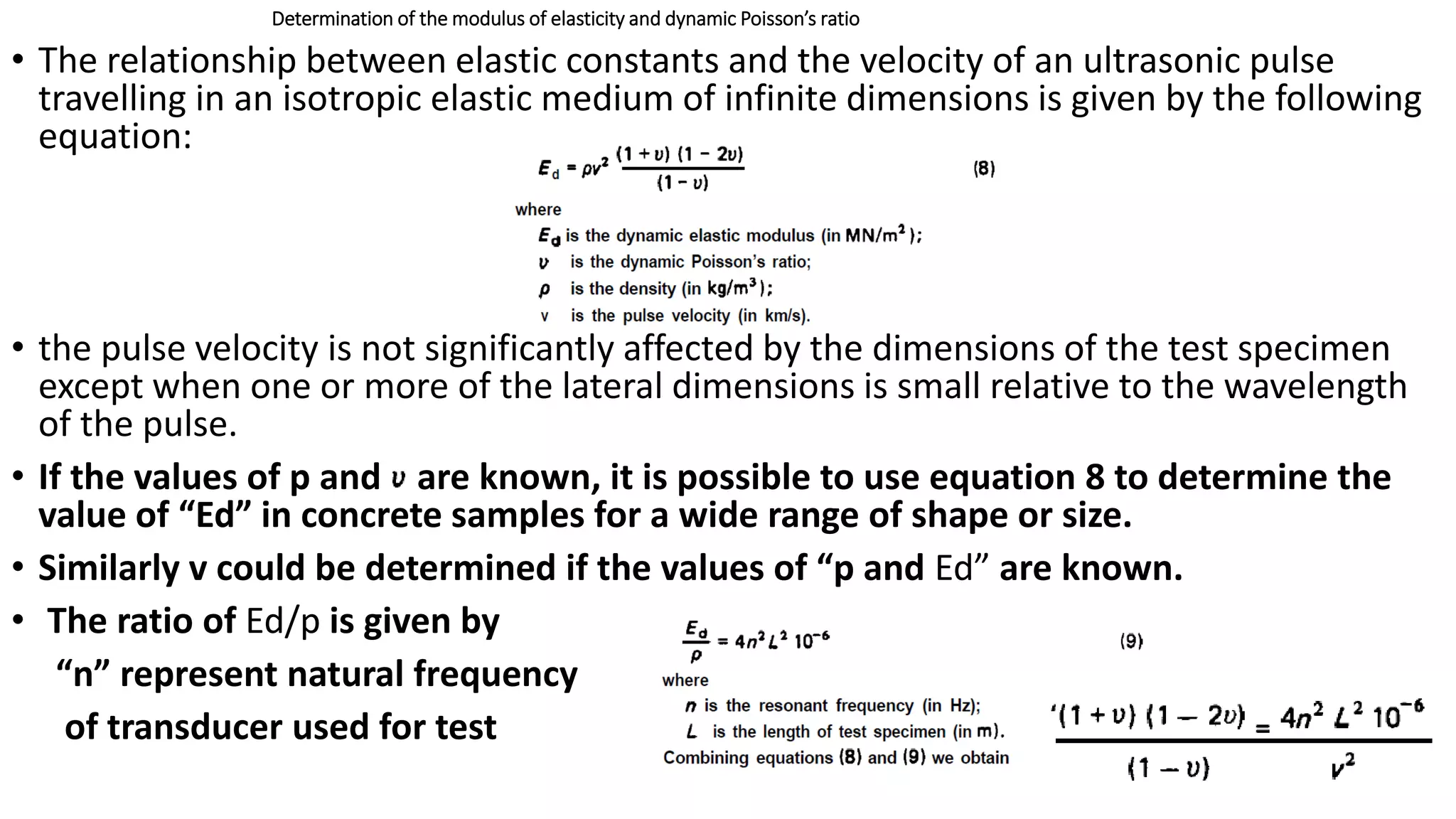

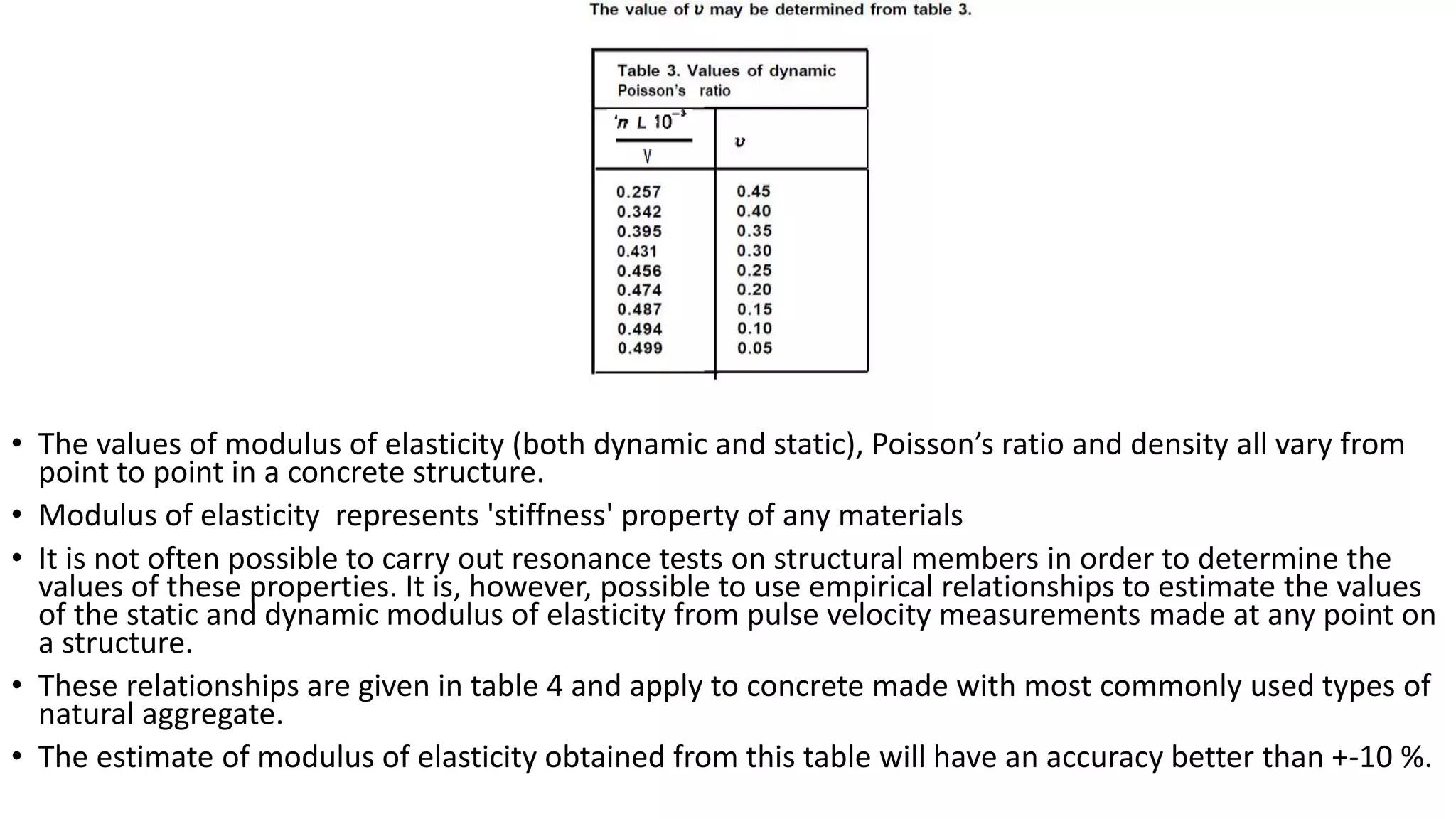

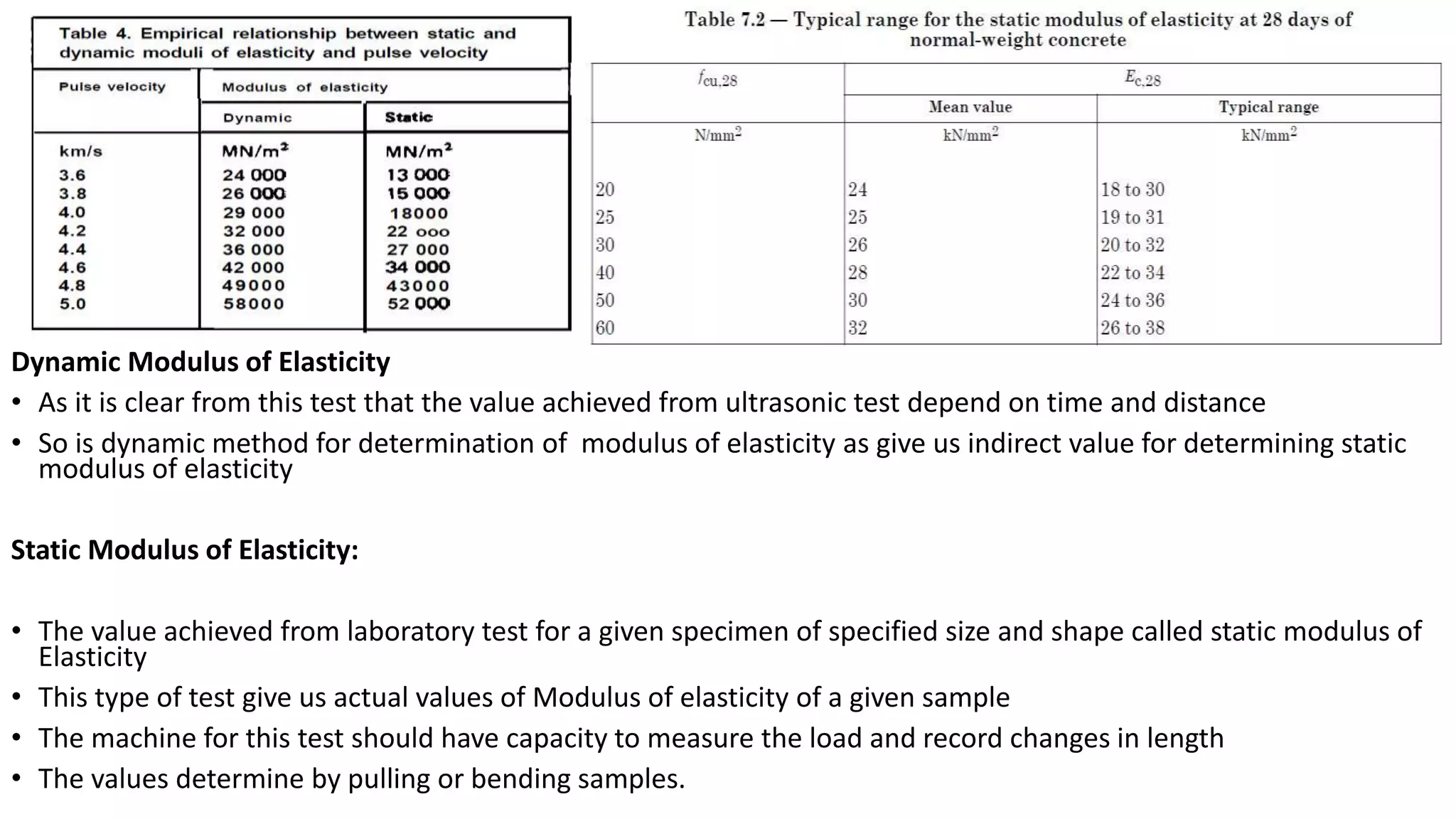

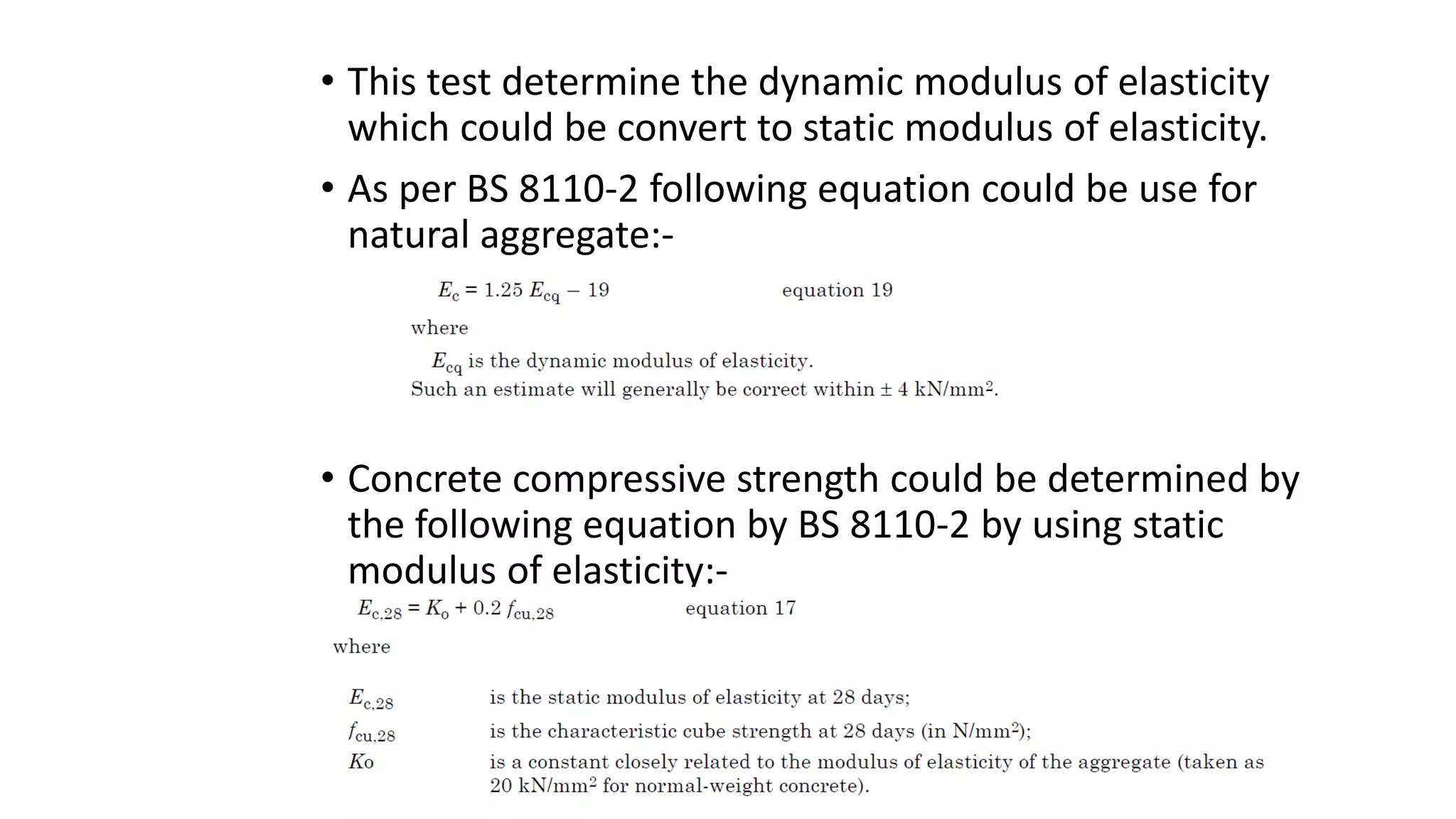

This document summarizes the ultrasonic test method for determining properties of concrete. It discusses using PUNDIT machines to transmit ultrasonic pulses through concrete and measure the transit time. Factors that affect pulse velocity like frequency, path length, and aggregate size are covered. The document outlines how ultrasonic testing can be used to determine uniformity, detect defects, measure changes over time, and estimate modulus of elasticity and Poisson's ratio of concrete. Corrections for the presence of reinforcing steel are also provided.