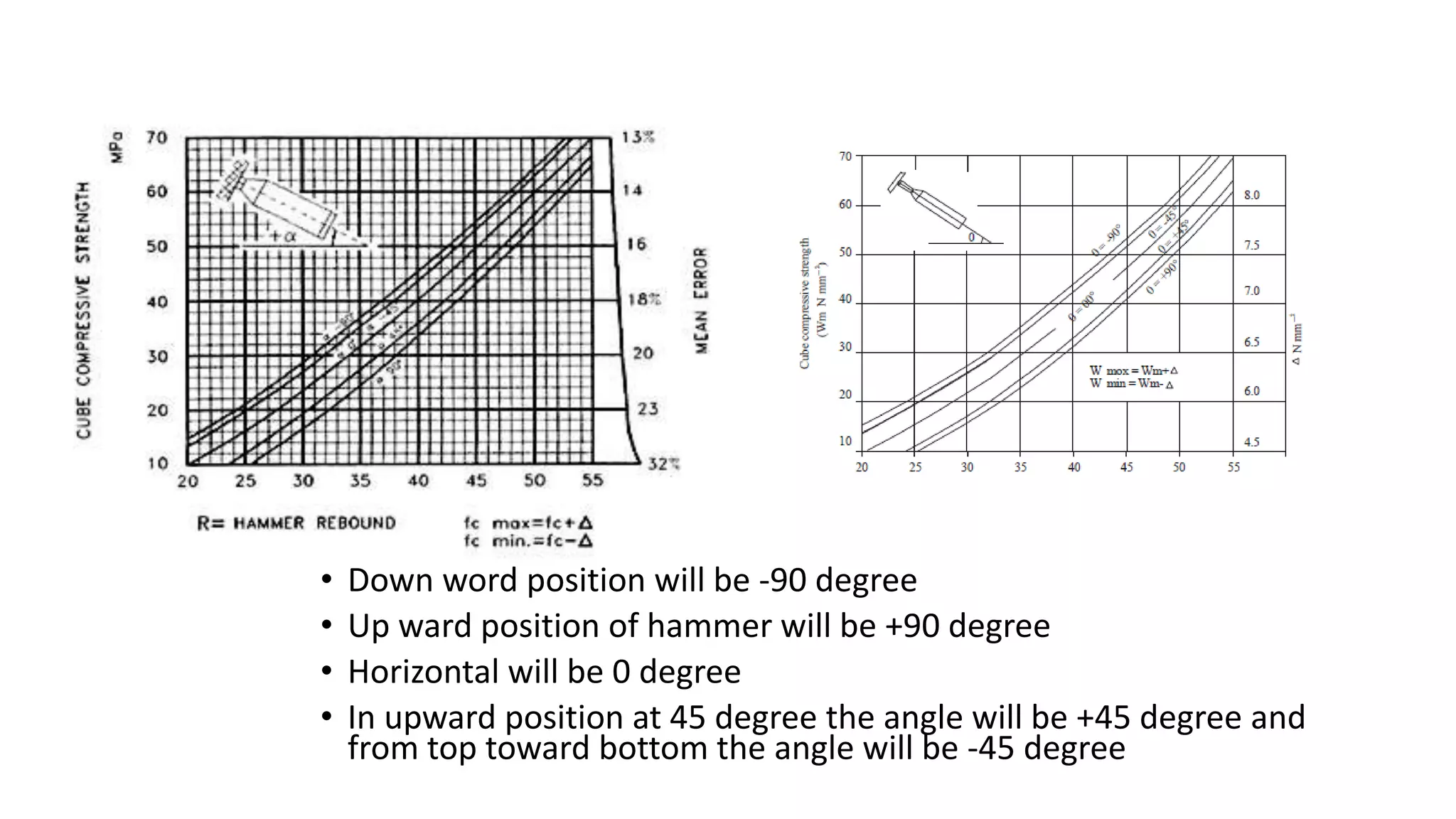

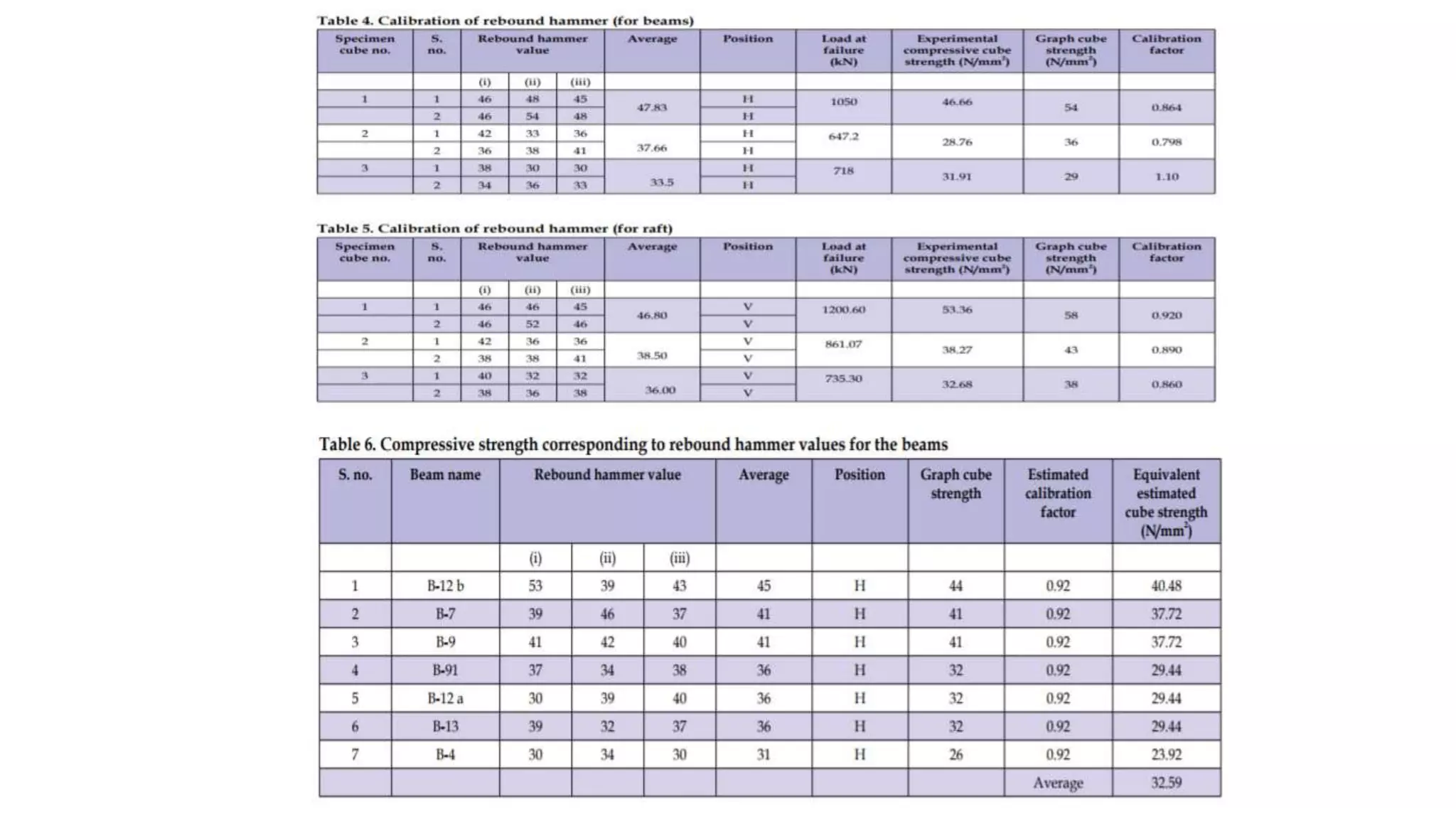

The rebound hammer test is a non-destructive test used to estimate the compressive strength of hardened concrete. Several factors must be controlled to obtain accurate results, including the concrete's surface condition and moisture level. To correlate rebound number readings to compressive strength, test specimens are measured with both the rebound hammer and compression testing machine. At least 9 readings should be taken on each face of specimens and averaged to estimate strength. The rebound hammer test provides an approximate strength measurement within 25% accuracy.