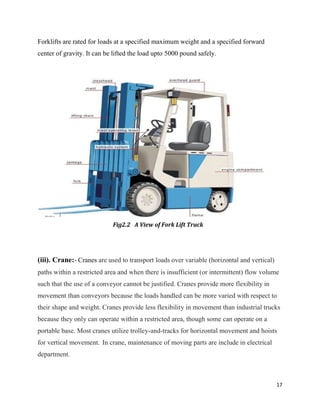

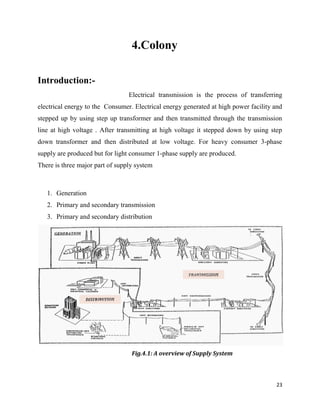

The document discusses a summer training report submitted by Akash Vishwakarma at the Diesel Locomotive Works in partial fulfillment of a Bachelor of Technology degree. It includes sections on the Maintenance Service Shop, Central Transport Shop, SCADA system, and the colony area. The Maintenance Service Shop section describes various sub-sections including the winding shop, electronics shop, meter shop, and battery shop which repair and maintain locomotive parts and systems.