The document provides information about Diesel Locomotive Works (DLW) in Varanasi, India. Some key points:

- DLW is a production unit owned by Indian Railways that manufactures diesel-electric locomotives. It was established in 1961 in collaboration with an American company.

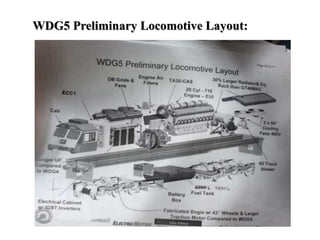

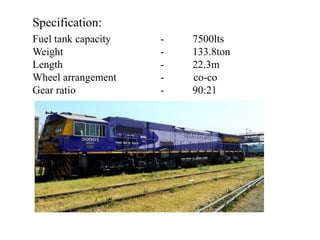

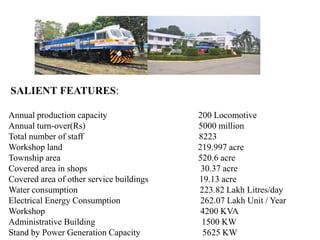

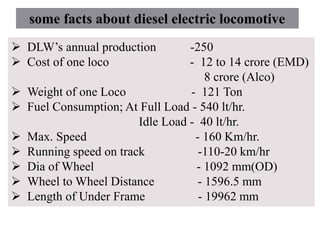

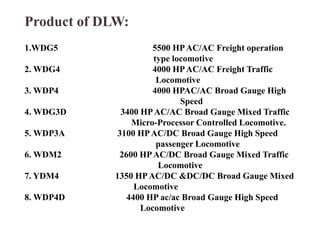

- DLW's annual production capacity is 200 locomotives. It produces various locomotive models for freight, passenger and mixed-use applications with power ratings ranging from 1300-5500 horsepower.

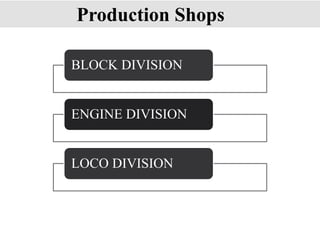

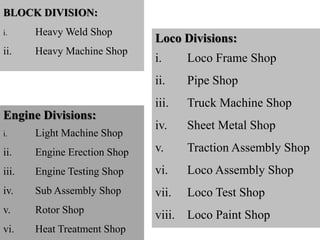

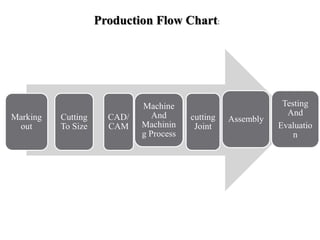

- The factory has different production shops for activities like welding, machining, engine assembly, and locomotive assembly. Locomotives pass through various stages from raw material to the final testing and painting processes.

-

![In India, locomotives are classified according to their track gauge, motive power, the

work they are suited for and their power or model number. The class name includes

this information about the locomotive.it comprises 4 and 5 letters.

Classification of locos on the basis of code form

WDG5A “ [ gauge ][ power ][load ][ series ][ sub type ]”

In the first letter [Gauge]:

W-Indian Broad Gauge (5.6ft)

Y-Meter Gauge or Yard Gauge (the "Y" stands 3ft or 1000mm)

Z-Narrow Gauge (2.5ft)

N-Narrow Gauge or Toy Gauge (2ft)](https://image.slidesharecdn.com/instituteofengineering-160412053033/85/INDUSTRIAL-TRAINING-PPT-DLW-Varanasi-12-320.jpg)

![In the second letter [Power]:

D-Diesel

C-DC Traction (can run under DC traction only)

A-AC Traction (can run under AC traction only)

CA-Both DC and AC (can run under both AC and DC tractions)

B-Battery Electric Motive (rare)

In the third letter [Load]:

G-goods

P-passenger

M-mixed Traffic (both goods and passenger)

S-Used for Shunting

U-Electric multiple units (EMU)

R-Railcars](https://image.slidesharecdn.com/instituteofengineering-160412053033/85/INDUSTRIAL-TRAINING-PPT-DLW-Varanasi-13-320.jpg)

![In the fourth letter [series]:

The series digit identifies the horsepower range of the locomotive.

Example for the series letter ‘3’ means that the locomotive has power

over 3000hp but less than 4000hp.

In the fifth letter [subtype]:

An optional letter or number that indicates some smaller variations in

the basic model.

For ex: ‘A’ for 100hp,

‘B’ for 200hp and so on……..

Example: Designation of ‘WDM-3A’ mean

"W" means broad gauge

"D" means diesel motive power

"M" means suitable for both goods and passenger service

"3A" means the locomotive's power is 3,100 hp('3'stands for 3000hp

’’A' denotes 100hp more)](https://image.slidesharecdn.com/instituteofengineering-160412053033/85/INDUSTRIAL-TRAINING-PPT-DLW-Varanasi-14-320.jpg)