Elastomeric Fiber

- 2. Elastomer : An Elastomer is a polymer with the physical property of elasticity. Elastomer is a term derived from elastic polymer, which is often used interchangeably with the term rubber. Each of the monomers which link to from the polymer is usually made of carbon, hydrogen, oxygen and/or silicon. Elastomers are usually thermosets requiring a curing process of rubber involving heat and the addition of sulfur or other equivalent curatives. In addition elastomers might also be thermoplastic.

- 3. Elastomeric Fibers Elastomeric fibers are those fibers that possess extremely high elongations (400%-8001) at break and that recover fully and rapidly from high elongations up to their breaking point. Elastomeric fibers include the crosslinked natural and synthetic rubbers, spandex fibers (segmented polyurethanes), anidex fibers (crosslinked polyacrylates) and the side-by-side biconstituent fiber of nylon and spandex (Monvelle).

- 5. The spinning Process When the two types of pre-polymers are mixed together, they interact to form the spandex fibers. In this reaction, the hydroxyl groups (-OH) on the macro glycols react with the isocyanides. Each molecule gets added on to the end of another molecule, and a long chain polymer is formed. This is known as a step- growth or addition polymerization. To initiate this reaction, a catalyst such as diazobicyclo octane must be used. Other low molecular weight amines are added to control the molecular weight of the fibers.

- 6. Fig-2: Spinning process of elastomeric fiber

- 7. Physical properties of elastomeric fiber (spandex) Tenacity : 037gm/den Density : 1.21-1.35 Elongation at break : 400-700% Elasticity : Excellent Moisture regain : 0.6% Resiliency : Very good Ability to protest friction : Excellent Color : White or near white Luster : Less bright

- 8. Chemical properties of elastomeric fiber Acids : It has preventive power against all of the acidic action. Basic : Hot alkali damages the spandex filament. Effect of bleaching : Bleaching agent damages the fibre and it becomes weak. Protection ability organic solvent : Good. Protection ability light : Very good Protection ability against mildew : Good Protection ability against insects : It doesn’t affected by insect. Dyes : Disperse dyes , acid dye is suitable to dye spandex filament,

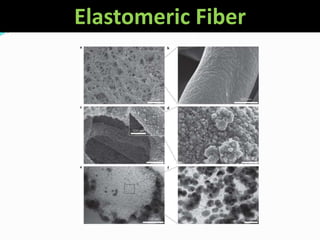

- 9. Preparation of the elastomeric fibers The preparation process of the elastomeric fibers is illustrated in Fig.3. Firstly, the prepared spinning dopes were stored in a container with piston and pressed very slowly into a artificial duct (about 500 μm in inner diameter, and about 12 cm in length). Secondly, the spinning dopes went through the duct and flowed into the pure tap- water in a glass water tank, immediately solidifying and spontaneously rising to form the initial fibers.

- 10. Fig-3: preparation of elastomeric fiber o

- 11. Thirdly, after the initial fibers freely rose from underwater to water surface and stayed for about 3 min in the tap-water, they were taken out of the water tank and received vertical stretching up to 5–6 times of the initial length in another water tank full of tap-water or air, and after the vertical stretching was kept for about 40 min, the stretched fibers were prepared. Fourthly, the stretched fibers were placed in a vacuum oven to be dried for about 12 h at 45 °C under vacuum, and the final fibers were produced. After the initial helical fibers were taken out of the tap-water, they were directly dried in the same conditions without vertical stretching, and the final helical fibers were also made.

- 12. Various other types of elastomers: Thermoplastic elastomers (TPE) The proteins resilin and elastin Polysulfide rubber Elastolefin, elastic fiber used in fabric productio

- 13. Application of elastomeric fiber 1.Apparel Athletic apparel , swimwear, underwear ,lingerie, foundation garment, hosiery ,normal clothing,belts,skipanty,slacks,socks,tubular knit fabrics for ladies, and, warp knit fabrics for ladies, warp knit fabrics for corsetry and sundry applications 2.Automotive Body fasteners, electrical boots, suspension system parts, seals and gaskets, belts, taillight assemblies, battery covers, hoses, covers for electronics, adhesives, bushings, bump stops, interlayer for laminates, air bag covers,transmission boots. 3.Adhesives and Sealants Shoes, laminated security glazing, aerospace, marine, magnetic media binders, construction.

- 14. 4.Coatings Floor, roof, wire and cable, fiber optics, waterborne, radiation curable, fabric, aircraft, pipe, concrete, vinyl. 5.Engineered Components Gears, sprockets, printer rolls, belts, wheels, fork lift tires, escalator wheels, heavy-duty casters. 6.Industrial Lined pipe, water valves, pump impellers, hopper car liners, conveyor belts, grain buckets, grain chute liners,marine bumpers, buoys, marine hoses, mining screens, cyclone liners, cattle tags. 7.Sports Roller wheels, ski boots, bicycle tires, horseshoes, athletic shoes. 8.Home furnishing Micro-bend pillows

- 15. Polyethylene Fiber A manufactured fiber made of polymerized polyethylene units. It is often a monofilament, but is also available as continuous filament yarns and as staple fiber. Polyethylene is a polymer. Many no. of ethylene monomers join with each in the synthesis of polyethylene polymer. Polyethylene yarn cannot be dyed. It is colored by the addition of pigments and dyes to the melt at extrusion. Polyethylene can be created in several different forms.

- 16. Polyethylene

- 17. Chemical composition and molecular structure: Ethylene (C2H4) is a gaseous hydrocarbon commonly produced by the cracking of ethane, which in turn is a major constituent of natural gas or can be distilled from petroleum. Ethylene molecules are essentially composed of two methylene units (CH2) linked together by a double bond between the carbon atoms—a structure represented by the formula CH2=CH2. Under the influence of polymerization catalysts, the double bond can be broken and the resultant extra single bond used to link to a carbon atom in another ethylene molecule. Thus, made into the repeating unit of a large, polymeric (multiple-unit) molecule, ethylene has the following chemical structure: .

- 18. Ethylene Polyethelyn polymer Molecular structure of polyethelyne fibre

- 19. Spinning process of polyethylene fiber Spinning of polyethylene is carried out by melt spinning. The polymer with a molecular weight of about 15,000 is spun from the melt at about 205 deg C and extended through a spinnerets of 0.1 mm diameter into a current of cooling gas. The filaments are cooled to 15 -60 deg C and stretched 4 to 10 times their original length. The drawn monofilaments are wound on spools

- 20. Fig-2: Spinning process of polyethylene fiber

- 21. Properties of Polyethylene Fiber 1. Polyethylene fibre has a round cross section and has a smooth surface. Fibres made from low molecular weight polyethylene have a grease like handle. 2. The moisture regain of polyethylene is practically nil and hence moisture does not affect the mechanical properties of the fibres. 3. Higher energy is needed to break because of specific modulus and high specific strength 4. Polyethylene is insoluble in most of the common organic solvents at room temperature. 5. Polyethylene fibres have a high degree of resistance to acids and alkalies at all concentrations even at high temperature.

- 22. 6. Very good ultra violet resistance 7. The fibre is generally inert and is resistant to wide range of chemicals at ordinary temperatures. They are attacked by oxidising agents. 8. Excellent electrical and chemical resistance 9. Very good abrasion resistance 10. Other Properties •Specific Gravity- 0.92 •Tenacity - 1.0-1.5 gpd •Elongation at Break %- 45-50 •Tensile Strength psi - 15000 •Softening Range: deg C- 85-90

- 23. Application of Polyethylene Medical implants Cable and marine ropes Sail cloth Composites like Pressure vessel boat hulls, sports equipment, impact shields Fish netting Concrete reinforcement Protective clothing Can be used in radar protective cover because of its low dielectric constant Can be used as a lining material of a pond which collects evaporation of water and containment from industrial plants Useful in geotextile applications

- 24. Conclusion The preparation of a nanofiber membrane of an elastomer was successful using the electrospinning process. The diameter of the fiber is dependent significantly on solution concentration, voltage, distance and the viscosity of the polymer. Beadless nanofiber membrane that consisted of polybutadiene was obtained under the condition of 5.25wt%, 25KV, and 5cm. The mean diameter of the fiber was 0.46 µm. In addition, it was found that fibers without beads were obtained by growing the multi-cone in the needle tip. It was possible to co-electrospin VGCF or VGNF with the elasotomer. The viscosity and electrical conductivity of the polymer increased with the addition of VGCF/VGNF. The tensile strength of the elastomeric nanofiber membrane was similar to that of the film. However, the initial elastic modulus was very low. A soft feeling elastomer nonwoven membrane was obtained

- 25. The End

- 26. ©right