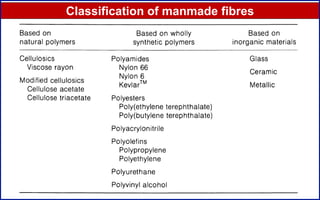

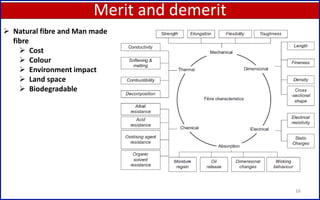

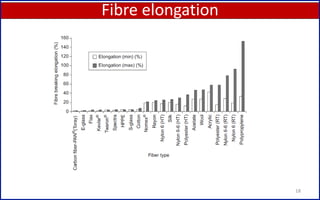

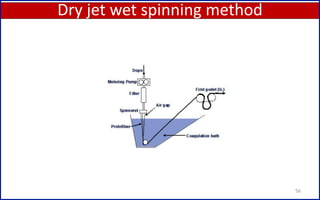

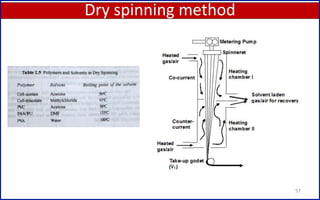

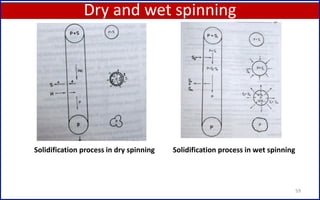

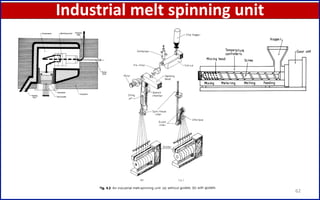

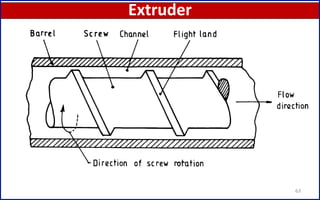

This document provides an overview of a course on man-made fibers taught by Dr. Mukesh Bajya. The course aims to develop an understanding of man-made fiber manufacturing processes and properties. Key topics covered include the history of man-made fibers, fiber formation methods like melt spinning and solution spinning, drawing and heat setting, common man-made fibers like polyester, nylon and acrylic, structure-property relationships, and new developments in the field. The course involves 40 total lectures across various fiber production topics.