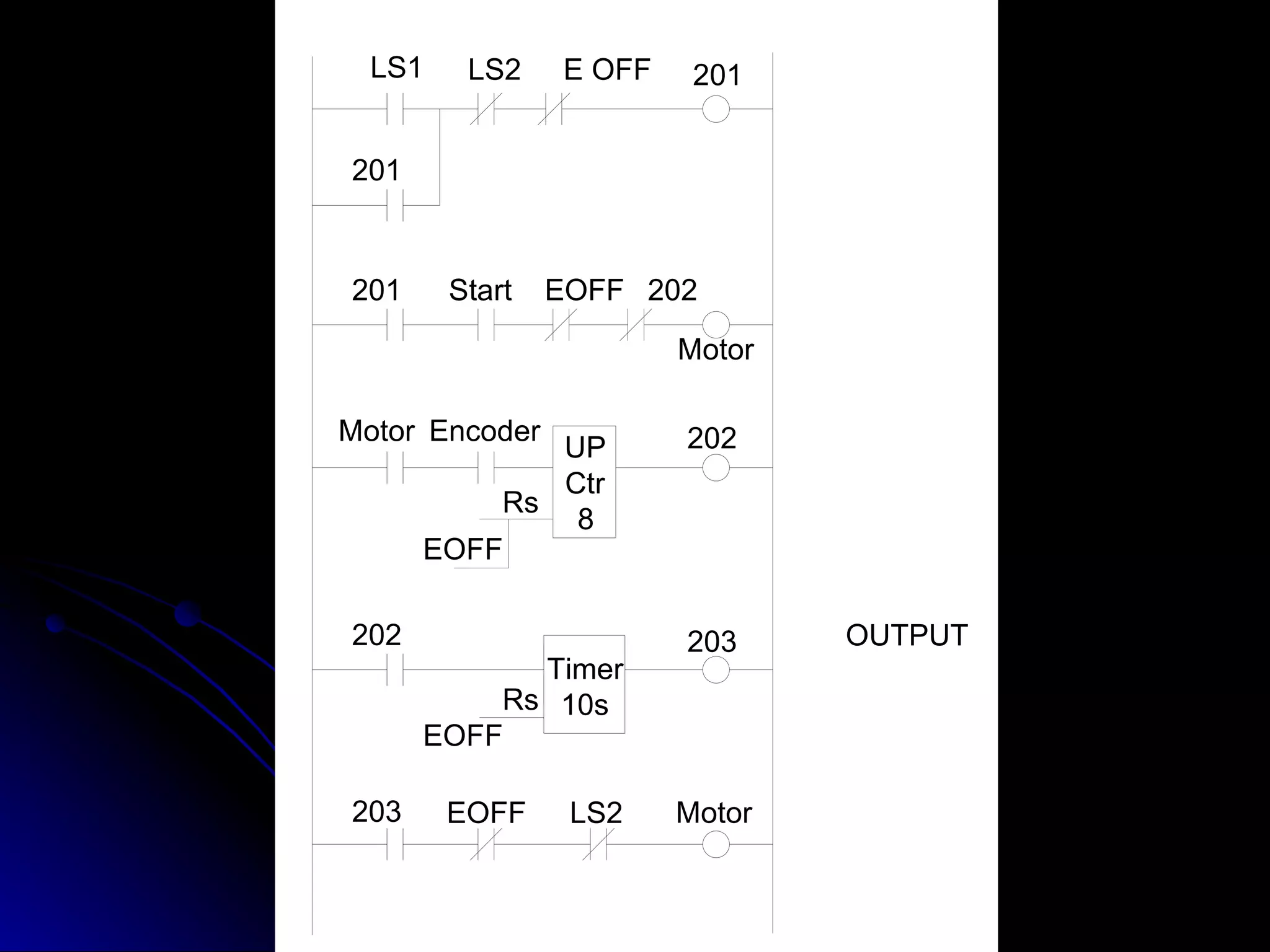

Programmable logic controllers (PLCs) are digital electronic devices used to automate industrial processes. A PLC consists of a central processing unit, input/output modules, and a programming device. PLCs scan their program continuously and cyclically to monitor inputs and control outputs. They are programmed using ladder logic to perform functions like timing, counting, and controlling relays. PLCs are used widely in applications like process control, machinery control, and some CNC machine functions. Factors like the number of I/O points, memory, and scan time are considered when selecting a suitable PLC for an application.